Re-manufacturing method for direct laser cladding of failed carburized quenching piece

A technology of carburizing and quenching and laser cladding, which is applied in the direction of coating and metal material coating technology, etc., can solve the problems that carburizing and quenching parts cannot be preheated, damage the overall performance of the workpiece, and crack the substrate and repair layer. Achieve the effects of shortening the remanufacturing process, improving remanufacturing efficiency, and saving resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

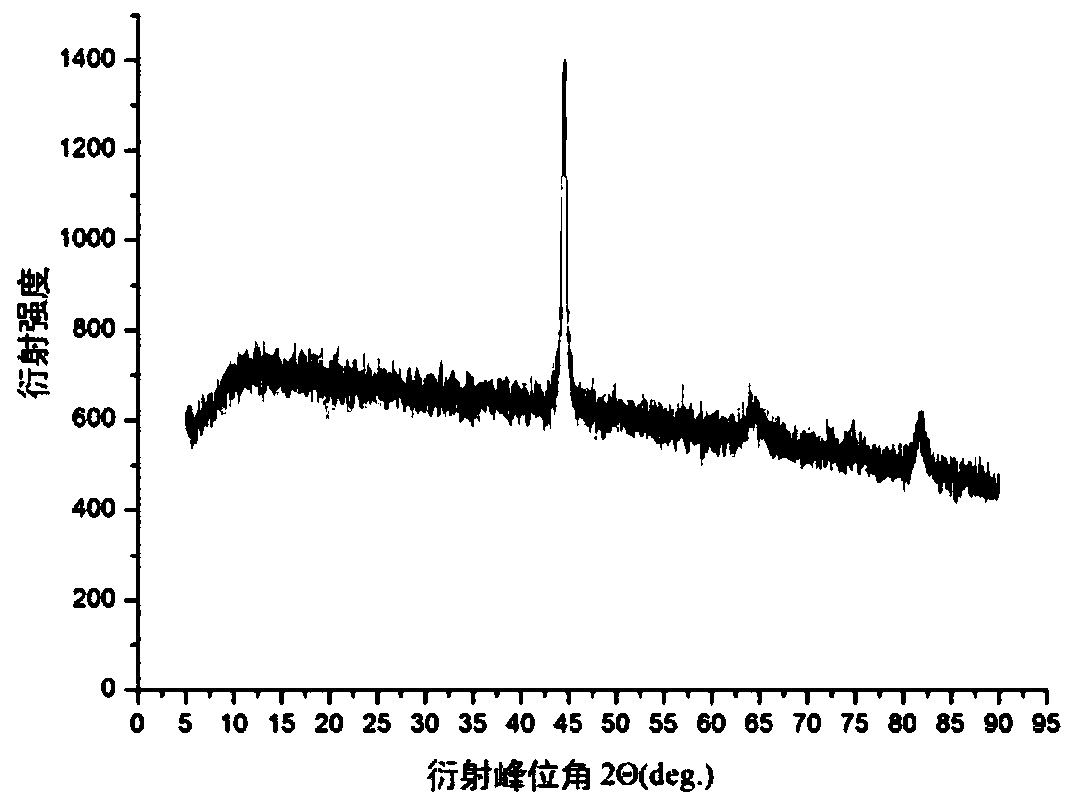

[0022] The matrix body material of the cross shaft is 18Cr2Ni4W alloy, and the mass fraction percentage of the matrix components is as follows: Cr 4.80~5.50wt.%, Mn 0.20~0.50wt.%, Si 0.80~1.20wt.%, Mo 1.00~1.50wt.%. %, V0.30~0.60wt.%, W 1.00~1.50wt.%, P≤0.025wt.%, S≤0.015wt.%, C 0.48~0.55wt.%, and the balance is Fe. After carburizing and quenching treatment: the thickness of the surface carburized layer is ≥3.0mm, the C content on the surface of the carburized layer is 0.85-1.05wt.%, and the surface hardness is 58-62HRC.

[0023] When the cross shaft fails, direct laser cladding is performed on it. The specific steps of the remanufacturing method are:

[0024] ①Cross shaft surface treatment (cleaning + machining):

[0025] Use cleaning techniques such as ultrasonic or pickling to remove oil stains on the surface of the cross shaft, and use grinding wheel grinding and other processing methods to remove the oxide layer on the surface of the workpiece;

[0026] ②Cross axis lase...

Embodiment 2

[0035] The base material of the bearing seat is 20CrNi4, and its surface hardness is 58-62HRC after carburizing and quenching treatment.

[0036] When the bearing seat fails, it is directly laser clad, and the specific steps of the remanufacturing method are:

[0037] ① Bearing surface treatment (cleaning + machining):

[0038] Use ultrasonic or pickling cleaning methods to remove oil stains on the surface of the bearing seat, and use grinding wheel grinding to remove the oxide layer on the surface of the workpiece;

[0039] ②Bearing seat laser cladding:

[0040] According to the base material of the bearing seat, select the cladding material, select the cladding equipment, set the process parameters during cladding, and remanufacture and repair the treated bearing seat surface by laser cladding;

[0041] The remanufactured repair material used in cladding is a powder material with a particle size of 150 mesh to 270 mesh; the mass fraction percentage of the components is as ...

Embodiment 3

[0046] The base material of the flat headgear is 18Cr2Ni4W, after carburizing and quenching: the surface hardness is 58-62HRC.

[0047] When the flat headgear fails, it is directly laser clad, and the specific steps of the remanufacturing method are:

[0048] ①Surface treatment of flat hood (cleaning + machining):

[0049] Ultrasonic or pickling and other cleaning methods are used to remove oil stains on the surface of the flat headgear, and processing methods such as grinding wheel grinding are used to remove the oxide layer on the surface of the workpiece.

[0050] ④Laser cladding of flat headgear:

[0051] According to the base material of the flat hood, select the cladding material, select the cladding equipment, set the process parameters during cladding, and remanufacture and repair the treated flat hood surface by laser cladding;

[0052] The remanufactured repair material used in cladding is a powder material with a particle size of 150 mesh to 270 mesh; the mass fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com