Torque converter turbine oil seal mounting tool with holding rod for remanufacturing of automatic gearbox

An automatic transmission and installation tool technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problem of inconvenient installation of the hydraulic torque converter turbine oil seal, and achieve the effect of reducing remanufacturing costs and fast and accurate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

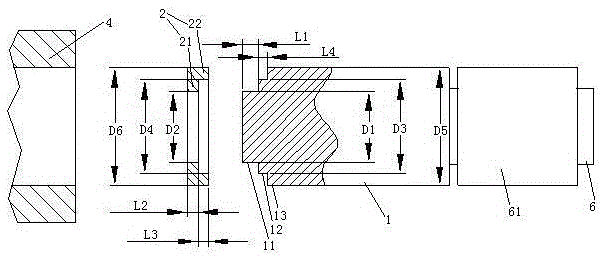

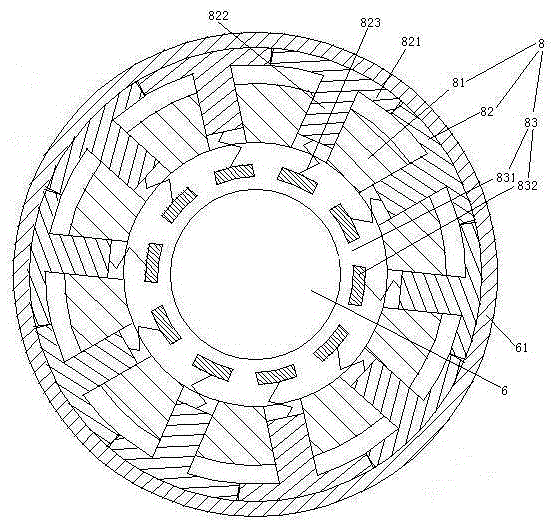

[0029] Embodiment one, see figure 1 , a torque converter turbine oil seal installation tool with a holding rod for automatic transmission remanufacturing, comprising a push rod 1. The right end of the push rod 1 is provided with a grip bar 6 . 6 sets of grip bars are provided with handle gloves 61 . The handle glove 61 is a rubber sheath. The left end of the push rod 1 is provided with a column head 11 , a first protruding ring 12 and a second protruding ring 13 in sequence. The oil seal 2 includes an oil seal main body 21 and an annular sealing lip 22 . The sealing lip 22 is arranged on the radially outer side of the end surface of the oil seal main body 21 .

[0030] The diameter D1 of the column head is smaller than the inner diameter D2 of the main body of the oil seal. The length L1 of the column head is greater than or equal to the axial length L2 of the main body of the oil seal. The outer diameter D3 of the first collar is smaller than the inner diameter D4 of th...

Embodiment 2

[0035] Embodiment two, the difference with embodiment one is;

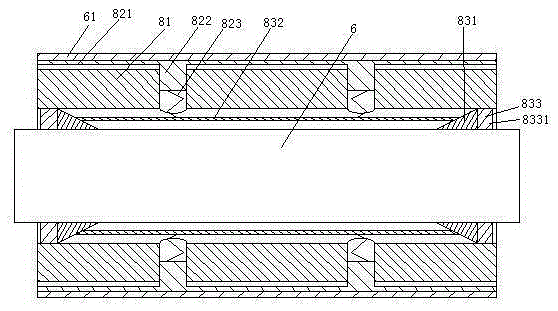

[0036] see Figure 4 , The push rod 1 is also provided with an oil seal dismounting booster mechanism 9. The oil seal detachment assisting mechanism 9 includes a fan 91 , an air duct 92 and an air direction conversion mechanism 93 . The fan 91 is provided with an air inlet 911 and an air outlet 912 . The fan 91 includes fan blades 913 and a motor 914 for driving the fan blades. The air duct 92 is an annular structure. The air duct 92 communicates with the air inlet 911 and the air outlet 912 . The air duct 92 is provided with an entrance and exit passage 921 , an entrance passage 922 and an exit passage 923 . The entrance and exit passage 921 passes through the annular groove 14 on the first protrusion ring 12 . The entrance and exit passage 921 is provided with an annular cylinder 924 extending along the circumference of the column head 11 . The annular cylinder body 924 is sealed and slidably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com