A dismantling process for deformed pin shaft of remanufactured concrete pump truck

A concrete pump truck and remanufacturing technology, applied in the direction of manufacturing tools, vehicle parts, metal processing, etc., can solve the problems of increasing processing cost, prolonging production cycle, increasing remanufacturing cost, etc., improving production efficiency, solving production bottlenecks, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

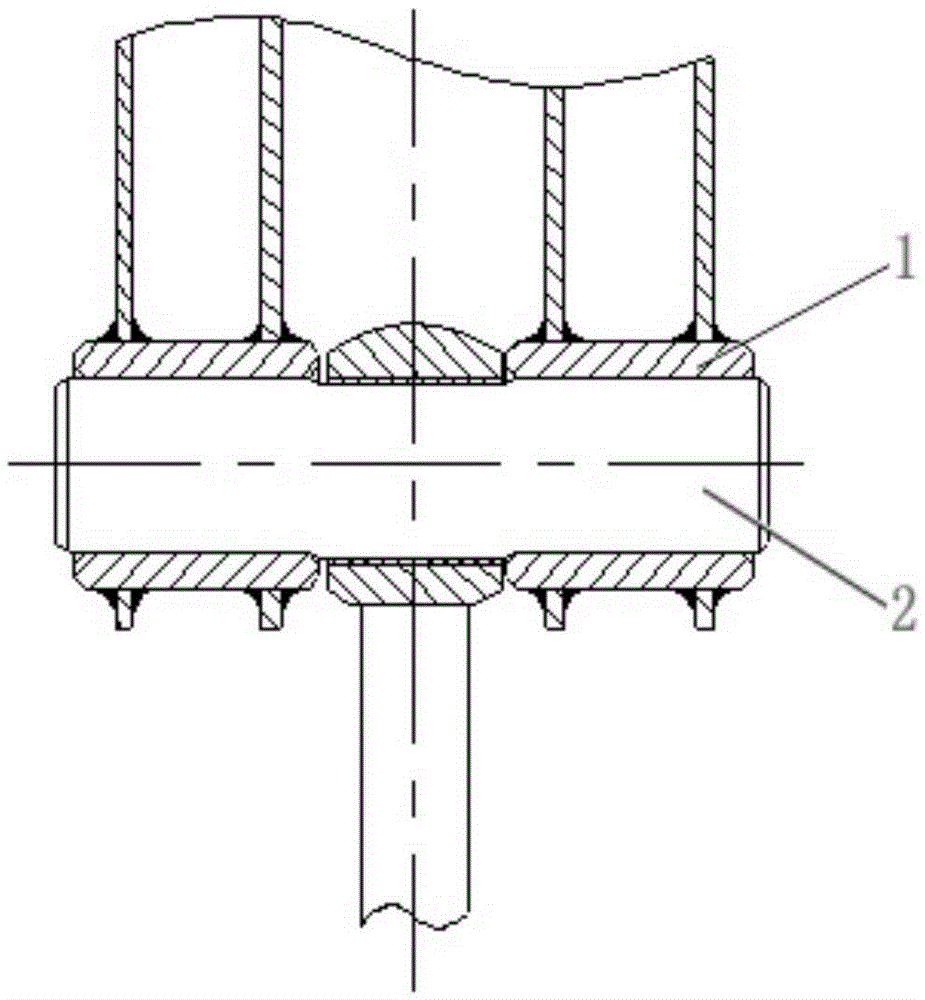

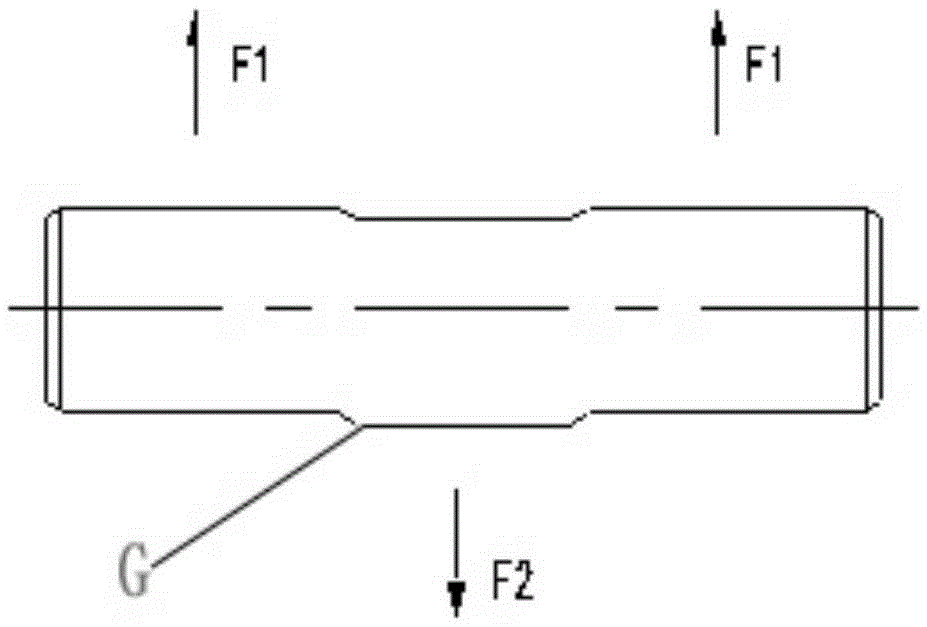

[0024] Such as figure 2 , image 3 , Figure 4 As shown, before dismantling, drill a blind hole 3 at the axial center of the pin shaft 2. The diameter of the drill hole is 3mm smaller than the diameter of the pin shaft 2, so that the wall thickness of the pin shaft after drilling is 1.5mm, and the hole depth of the blind hole 3 is smaller than that of the pin shaft. 2 The length is 10mm. When the pin shaft 2 has a large diameter, it can be drilled and then bored, so that the processed pin shaft wall has a softer elastic structure; then the deformed pin is removed by knocking the pin shaft wall through the auxiliary support 4 and hammer 5 Axis 2.

[0025] Drill the blind hole 3 to disassemble the deformed pin shaft, so that the pin shaft 2 can be processed into a thin-walled structure, and the rigidity of the pin shaft 2 can be reduced. The dislocation part is easy to sag, so as to achieve the purpose of disassembly.

Embodiment 2

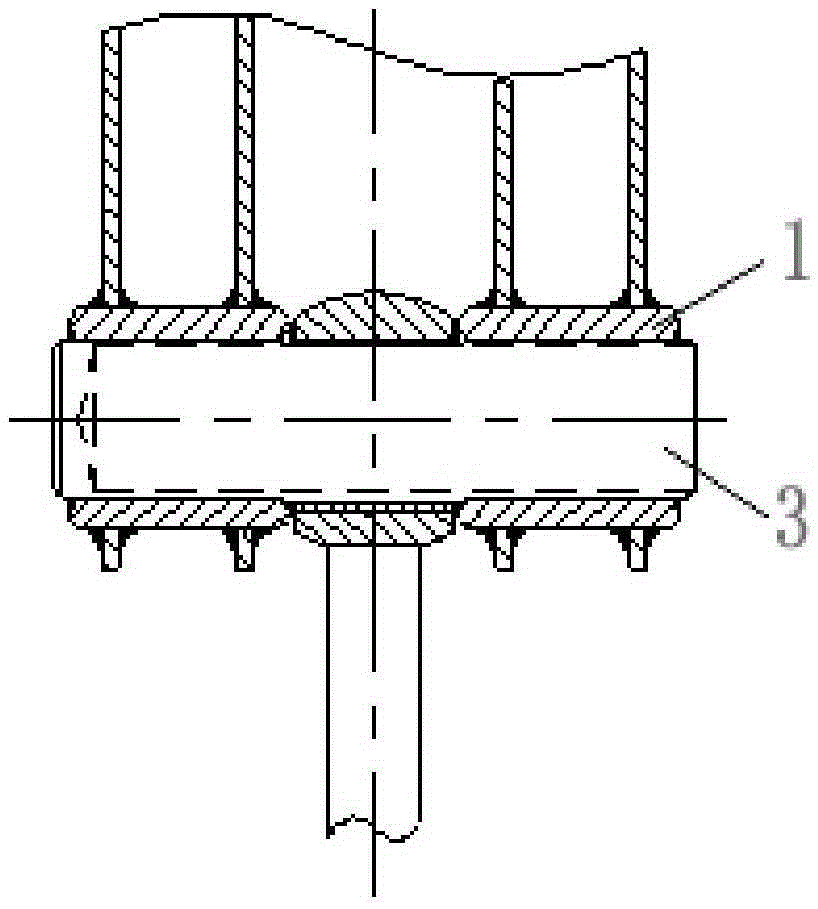

[0027] Such as Figure 6 , Figure 7 , Figure 8 As shown, a through hole 6 is drilled at the axial center of the deformed pin shaft 2. The diameter of the drilled hole is smaller than the diameter of the pin shaft 2 by 4 mm, so that the wall thickness of the pin shaft after drilling is 2 mm. Disassemble pin shaft 2.

[0028] The invention realizes the reuse value of the shaft sleeve without damaging the shaft sleeve and the main body of the component, effectively reduces the remanufacturing cost, and does not need to reassemble the shaft sleeve, mark the line, process the shaft sleeve hole and other processes, and solves the problem of Production bottlenecks have increased production efficiency by more than 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com