Oil-tanker-transformed fish-farming work ship and transformation method

A technology for oil tankers and industrial ships, which is applied in the field of deep-sea aquaculture equipment, and can solve problems such as difficult disassembly and recycling, and large environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

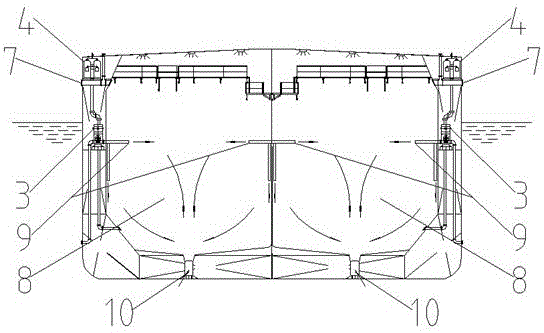

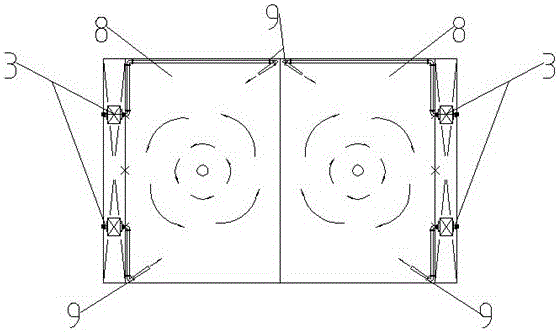

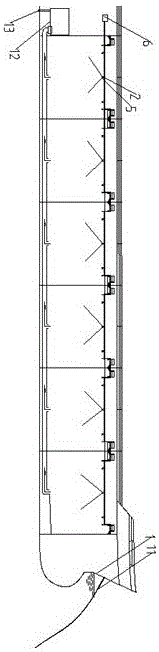

[0021] Such as Figure 1-Figure 3 As shown in the present embodiment, a fish farming workboat transformed from an oil tanker includes an oil tanker main body 1 and a 360° rotatable feeding device 2 arranged in the oil tanker main body 1, a water exchange pump 3, an aeration device 4, and a feed hole 5. Fish feed cabin 6, overflow hole 7, cultured fish pond 8, water injection port 9, drainage pipe 10, mooring rope 11, sewage treatment center 12, sewage discharge port 13, the bulkhead of the tanker main body 1 is provided with Anti-corrosion materials form the cultured fish pond, which can not only maximize the use of the cultured space but also reduce the time and materials for transformation. The water exchange pump 3 and the oxygenation equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com