Remanufacturing method for inefficient three-phase asynchronous motor

A three-phase asynchronous motor technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low-efficiency three-phase asynchronous motors and low efficiency of three-phase asynchronous motors, achieve short payback period, low manufacturing cost, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific Embodiment 1: A remanufacturing method of a low-efficiency three-phase asynchronous motor described in this embodiment, the process of the method is: replacing the asynchronous squirrel-cage rotor of the original low-efficiency three-phase asynchronous motor with a built-in permanent magnet rotor.

[0020] In this embodiment, without changing the original low-efficiency three-phase asynchronous motor stator, shaft and end cover, only the original asynchronous squirrel cage rotor is replaced with a built-in permanent magnet rotor, while improving the energy efficiency of the motor , to achieve frequency control and position sensorless operation.

[0021] According to the IEC60034-30 (2008) standard, the energy efficiency level of the motor remanufactured by the present invention reaches IE4 level, which is equivalent to the first level energy efficiency of the national standard GB18613-2012, and the system efficiency can be further improved by frequency conversi...

specific Embodiment approach 2

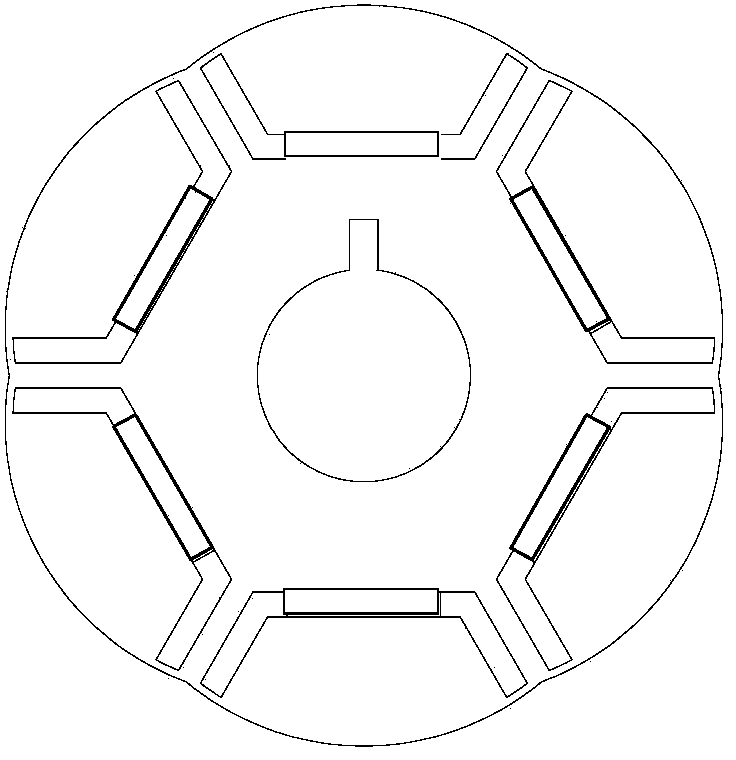

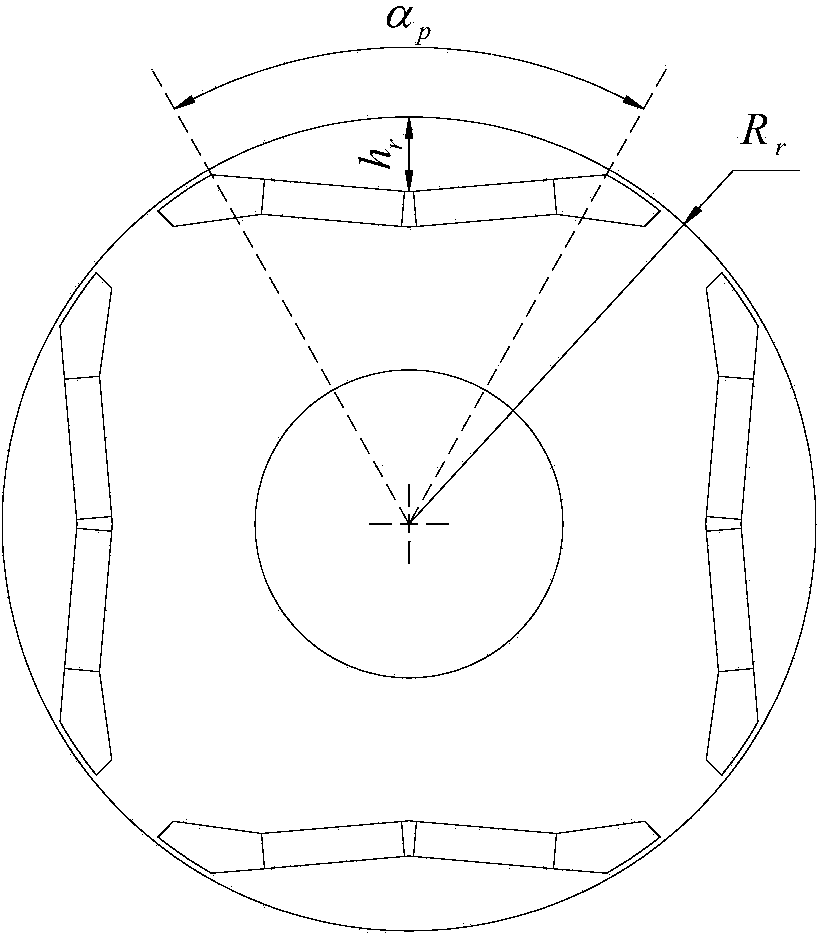

[0022] Specific implementation mode two: refer to figure 1 Describe this embodiment in detail. This embodiment is a further description of the remanufacturing method of a low-efficiency three-phase asynchronous motor described in the first specific embodiment. In this embodiment, the original low-efficiency three-phase asynchronous motor The winding is star-connected, and each pole of the built-in permanent magnet rotor includes a layer of permanent magnet layer. There is a U-shaped permanent magnet slot on the permanent magnet layer. The permanent magnet is located at the bottom of the permanent magnet slot. The opening of each U-shaped permanent magnet slot corresponds to an eccentric arc; the ratio of the radius of the eccentric arc to the radius of the rotor is between 0.7 and 0.8, and P is the number of poles of the rotor.

[0023] In this embodiment, for low-efficiency three-phase asynchronous motors whose windings are star-connected, a U-shaped rotor structure is adopte...

specific Embodiment approach 3

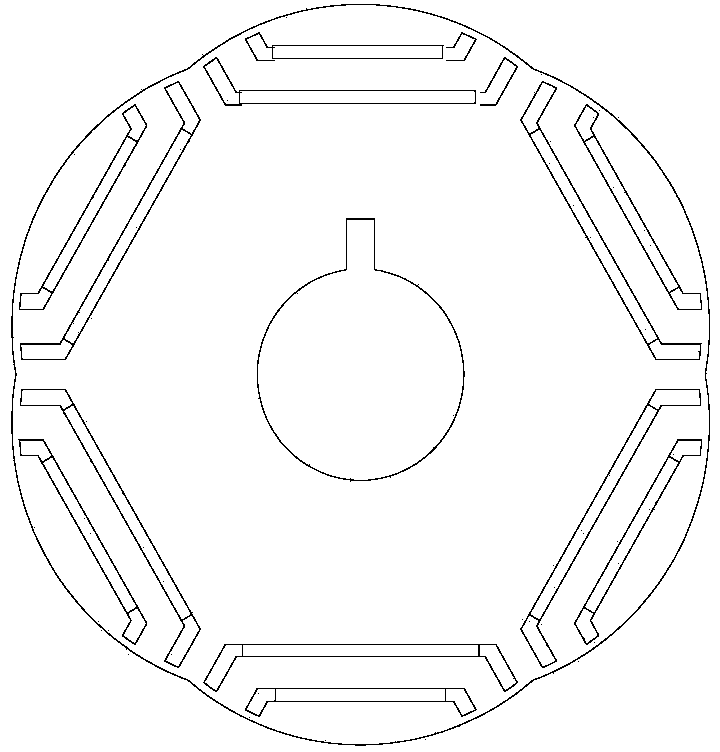

[0024] Specific implementation mode three: refer to figure 2 Describe this embodiment in detail. This embodiment is a further description of the remanufacturing method of a low-efficiency three-phase asynchronous motor described in the first specific embodiment. In this embodiment, the original low-efficiency three-phase asynchronous motor The winding is star-connected, and each pole of the built-in permanent magnet rotor includes two layers of permanent magnet layers. There are U-shaped permanent magnet slots on the two layers of permanent magnet layers. The permanent magnets are located at the bottom of the permanent magnet slots, and the two layers of permanent magnets are parallel to each other. , the outer wall of the rotor core is composed of P-section eccentric arcs, and the opening of each U-shaped permanent magnet slot in the outer layer corresponds to an eccentric arc; the ratio of the eccentric arc radius to the rotor radius is between 0.7 and 0.8 , P is the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com