Manufacturing process of combined sprocket for scraper conveyor in coal mine

A technology of scraper conveyor and manufacturing process, which is applied in the field of forging and machining, and can solve problems such as complex procedures, waste of materials, and inapplicability to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

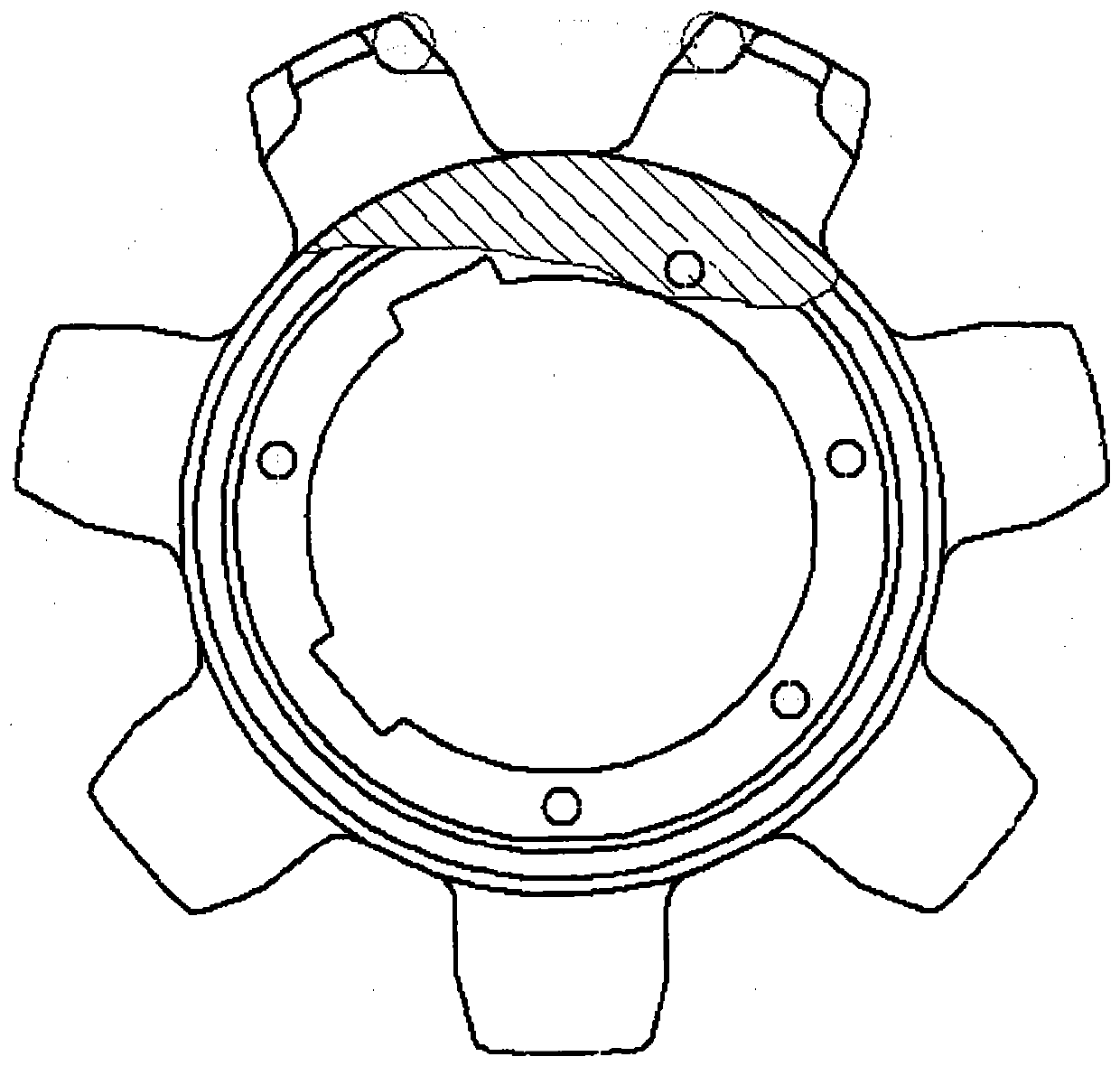

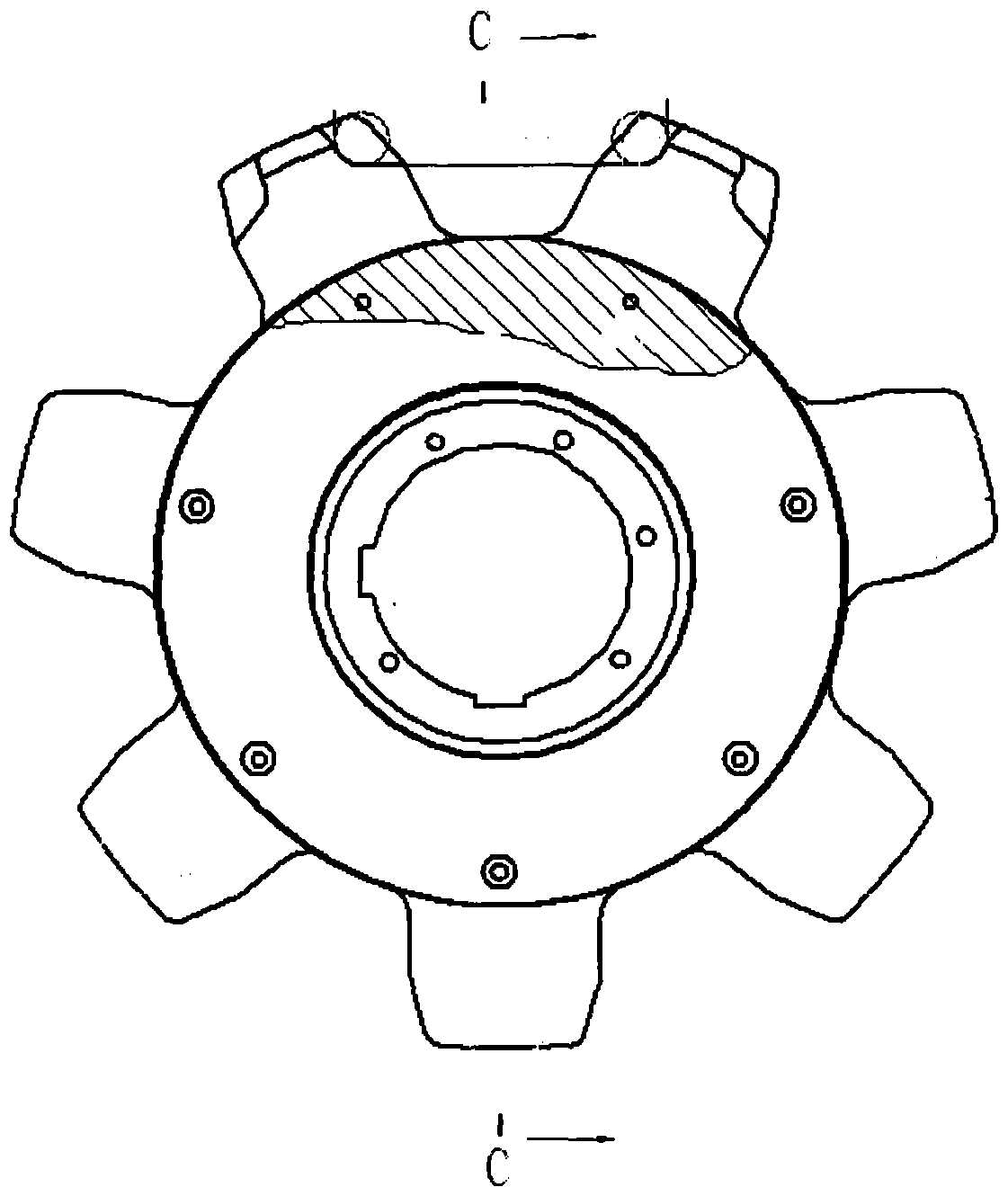

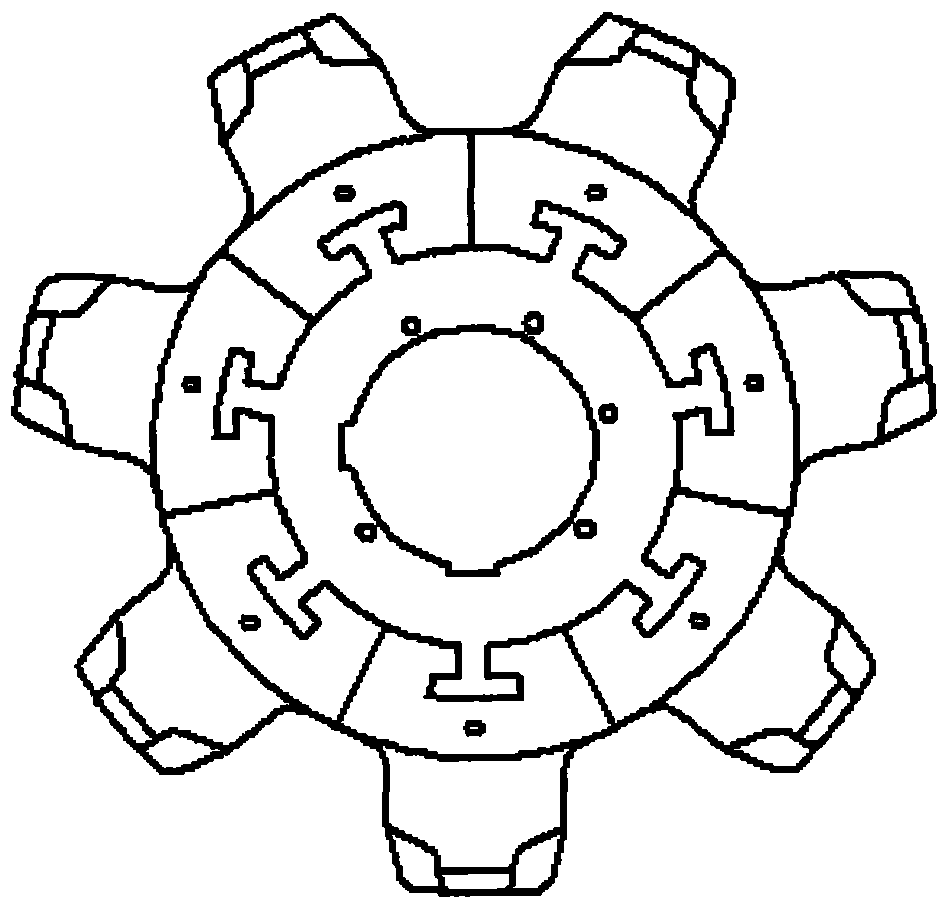

[0026] In the figure: 1 right end cover, 2 sprocket tooth block, 3 shaft sleeve, 4 positioning bolt, 5 left end cover, 6 nut;

[0027] Depend on Figure 2-10 As shown, it is composed of right end cover 1, sprocket tooth block 2, shaft sleeve 3, positioning bolt 4 and left end cover 5; right end cover 1 and left end cover 5 have the same structure, and 7 bolt holes are evenly distributed along the circumferential direction; There is a "T" shaped groove on the toothed block 2 corresponding to the "T" shaped boss on the sleeve 3, and there are positioning holes on the toothed block of the sprocket, and the apertures are consistent with those on the left and right end covers, and The distribution score circles have the same diameter. After the above-mentioned 1 piece of left end cover 5, 1 piece of right end cover 1, 1 piece of shaft sleeve 3, 14 pieces of sprocket toothed blocks 2, 7 pieces of positioning bolts 4, and 7 pieces of nut parts are completed, the combined sprocket wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com