Main oil seal demounting tool provided with handle sleeve and used for remanufacturing of automatic transmission

A technology for automatic transmissions and removal tools, applied in the manufacture of tools, hand-held tools, etc., can solve the problem that the main oil seal cannot be reused, and achieve the effect of reducing remanufacturing costs and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

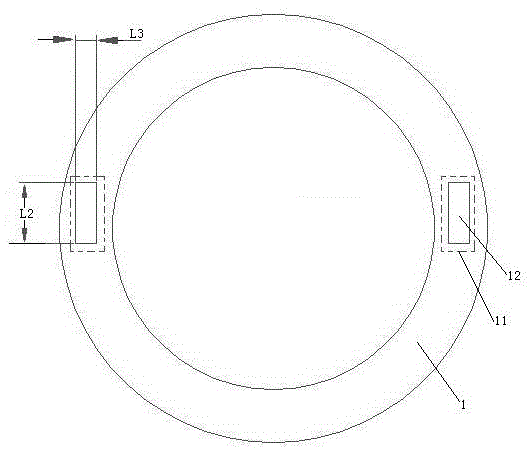

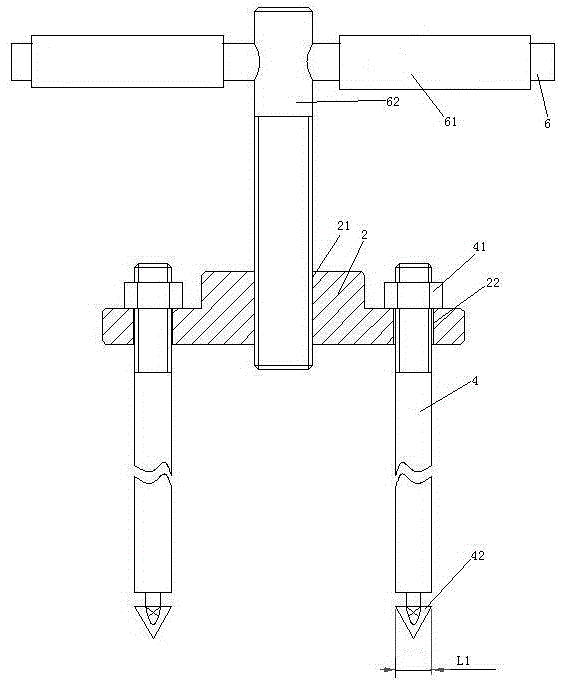

[0028] Embodiment one, see figure 2 , a main oil seal removal tool provided with a handle for automatic transmission remanufacturing, including a base 2, a gripping rod 6 and a pull rod 4.

[0029] A threaded hole 21 is provided in the middle of the base 2 . The threaded hole 21 runs through the base 2 . The base 2 is also provided with two optical holes 22 symmetrically distributed on both sides of the threaded hole.

[0030]Grip bar 6 has two. The two holding rods 6 are located on the same straight line and have an integral structure. 6 sets of grip bars are provided with handle gloves 61 . The handle glove 61 is a rubber sheath. One end of a connecting rod 62 is provided at the junction of the two holding rods 6 . The two holding rods 6 and the connecting rod 62 are connected together in a T-shape. The other end of the connecting rod 62 is provided with a threaded section and is threaded into the threaded hole 21 .

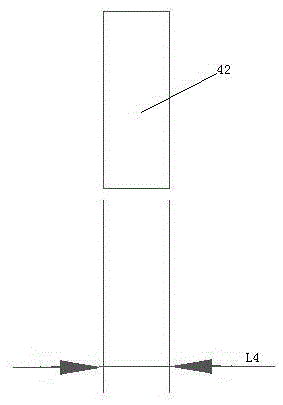

[0031] Pull bar 4 has two. The extension direct...

Embodiment 2

[0034] Embodiment two, the difference with embodiment one is;

[0035] see Figure 4 , also includes motor 5. The motor 5 includes a motor housing 51 and a motor shaft 52 . The motor housing 51 is fixedly connected with the base 2 through the support rod 53 . The motor casing 51 is provided with the connection terminal 3 . One end of the motor shaft 52 is connected to the connecting rod 62 through the reducer 54 . The grip bar 6 is connected to the other end of the motor shaft 52 .

[0036] see Figure 5 , An elastic adjustment mechanism 8 is provided between the grip bar 6 and the handle cover 61 . The elastic force adjustment mechanism 8 includes a base pipe 81 , a clamping layer 82 and a preload adjustment structure 83 . The base pipe 81 is sheathed outside the handle bar 6 . The base pipe 81 is passed through the handle glove 61 . The clamping layer 82 is composed of several friction strips 821 . The friction strips 821 are distributed along the circumferential d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com