Portable Left Half Shaft Flange Bearing Installation Tool for Automatic Transmission Remanufacturing

A technology for automatic transmissions and installation tools, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of inconvenient support flanges, etc., and achieve the effects of not easy to damage, fast installation speed, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

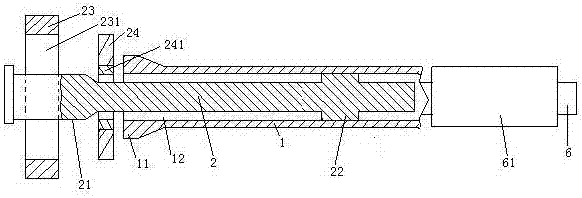

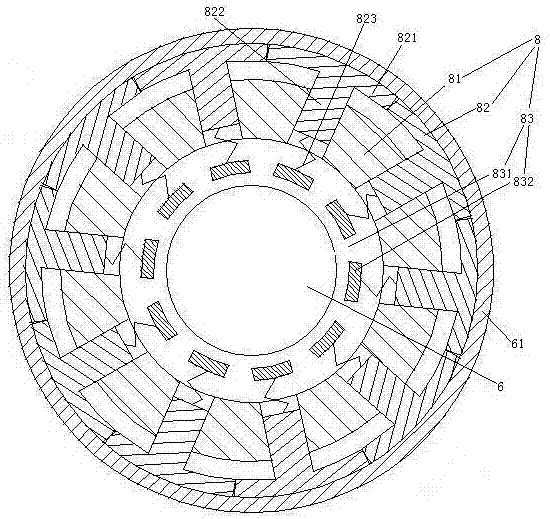

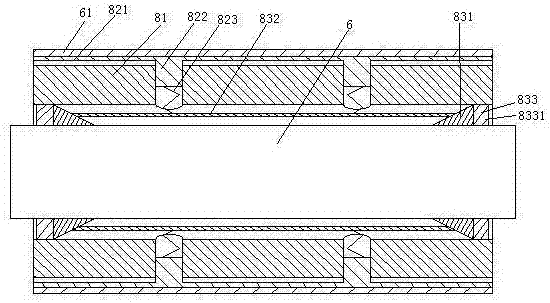

[0029] Embodiment one, see figure 1 , a portable left half-shaft flange bearing installation tool for automatic transmission remanufacturing, comprising a push rod 1. The right end of the push rod 1 is provided with a grip bar 6 . 6 sets of grip bars are provided with handle gloves 61 . The handle glove 61 is a rubber sheath. The left end of the push rod 1 is provided with a striking section 11 . An avoidance hole 12 is provided in the push rod 1 . The escape hole 12 runs through the end surface of the striking section 11 . The escape hole 12 extends along the length direction of the push rod 1 . The left end of the left half shaft 2 is provided with a bearing support section 21 , and the right end is provided with a large diameter section 22 . The diameter of the large-diameter section 22 is smaller than that of the bearing support section 21 . The flange 23 is provided with a shaft hole 231 for installing the bearing 24 . The bearing 24 is provided with an inner ring...

Embodiment 2

[0034] Embodiment two, the difference with embodiment one is;

[0035] see Figure 4 , The push rod 1 is also provided with a bearing dismounting booster mechanism 9. The bearing disassembly and assembly booster mechanism 9 includes a blower fan 91 , an air duct 92 and a wind direction conversion mechanism 93 . The fan 91 is provided with an air inlet 911 and an air outlet 912 . The fan 91 includes fan blades 913 and a motor 914 for driving the fan blades. The air duct 92 is an annular structure. The air duct 92 communicates with the air inlet 911 and the air outlet 912 . The air duct 92 is provided with an entrance and exit passage 921 , an entrance passage 922 and an exit passage 923 . The access road 921 runs through to the push ring 14 . The entrance and exit passage 921 is provided with an annular cylinder 924 extending circumferentially along the knocking section 11 . The annular cylinder body 924 is sealed and slidably connected with an annular thimble driving pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com