A method for predicting the timing of mechanical equipment remanufacturing

A technology of mechanical equipment and prediction method, applied in the field of remanufacturing, can solve problems such as increasing the complexity of optimization control of remanufacturing systems, and achieve the effects of maximizing benefits, saving remanufacturing costs, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

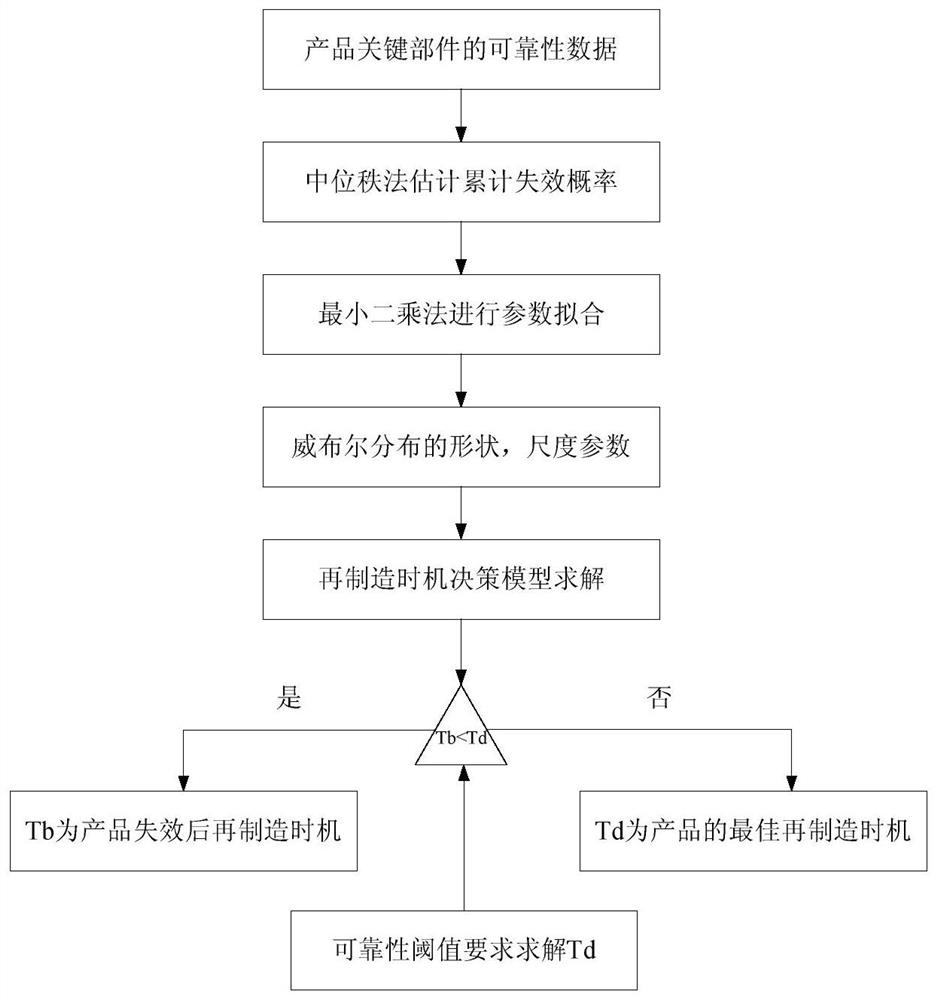

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

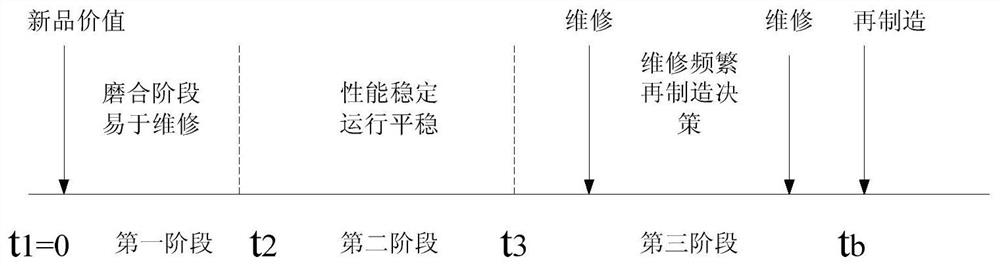

[0043] Waste equipment will inevitably fail during service. In the later period of product service, due to the coupling effect of fatigue, wear, corrosion and other failure forms, the frequency of product failure increases, and the number of maintenance and maintenance costs also gradually increase. Choosing the right timing is very critical to repairing and improving the remanufacturing performance of the product. The present invention uses the remanufacturing timing prediction of the two-parameter Weibull distribution to recycle and remanufacture the waste equipment at an appropriate timing.

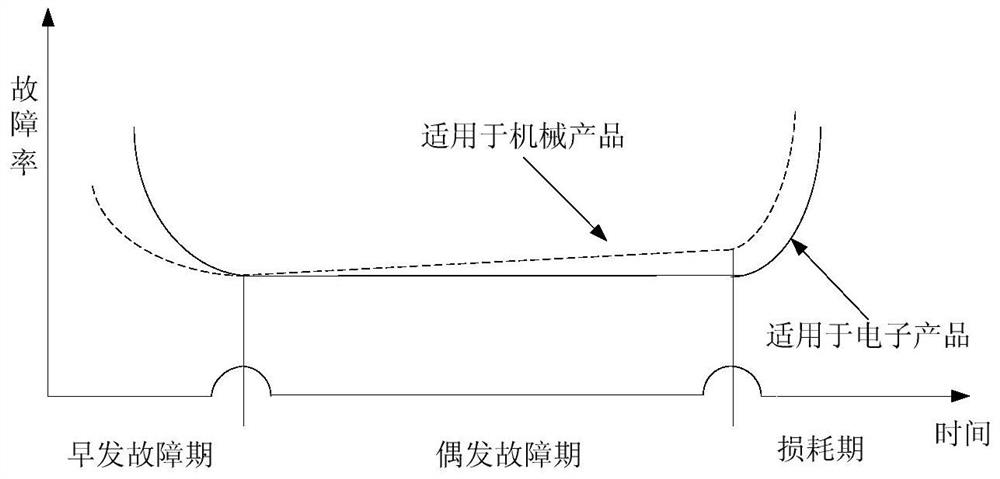

[0044] see figure 1 According to the bathtub curve, the study found that the performance curve of the product roughly obeys the "bathtub curve" during the service process. From the service time of the product into the third stage of the bathtub curve, the product perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com