Patents

Literature

52 results about "Body burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

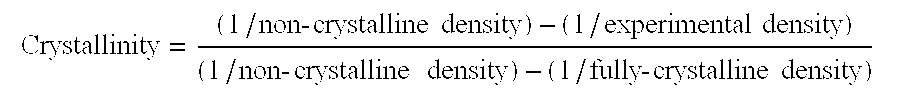

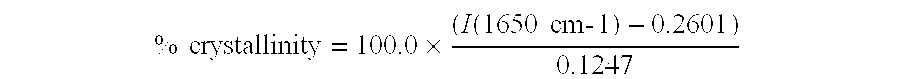

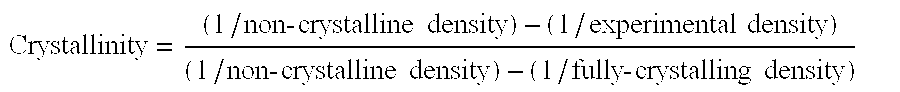

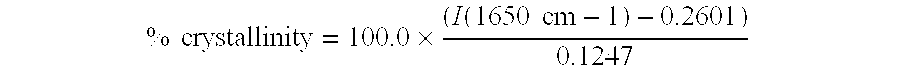

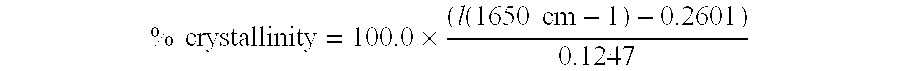

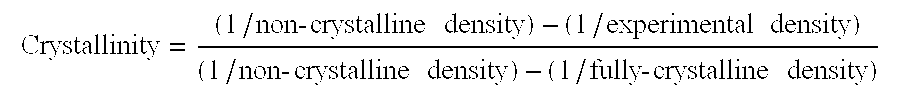

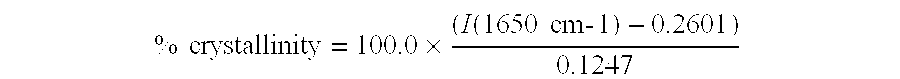

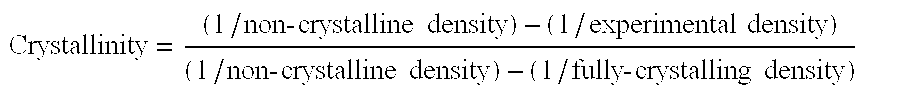

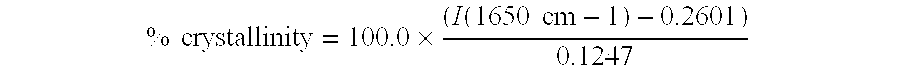

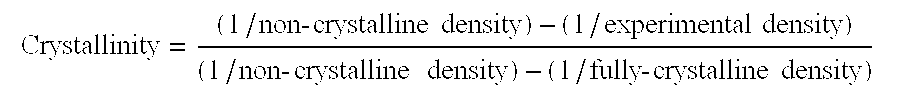

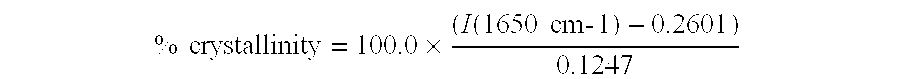

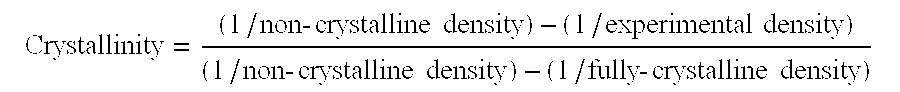

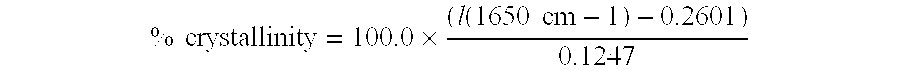

Crystallized meta-aramid blends for improved flash fire and arc protection

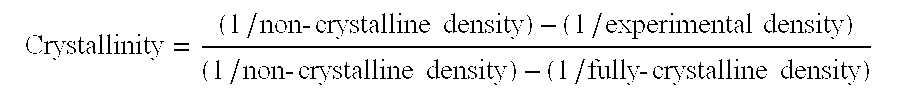

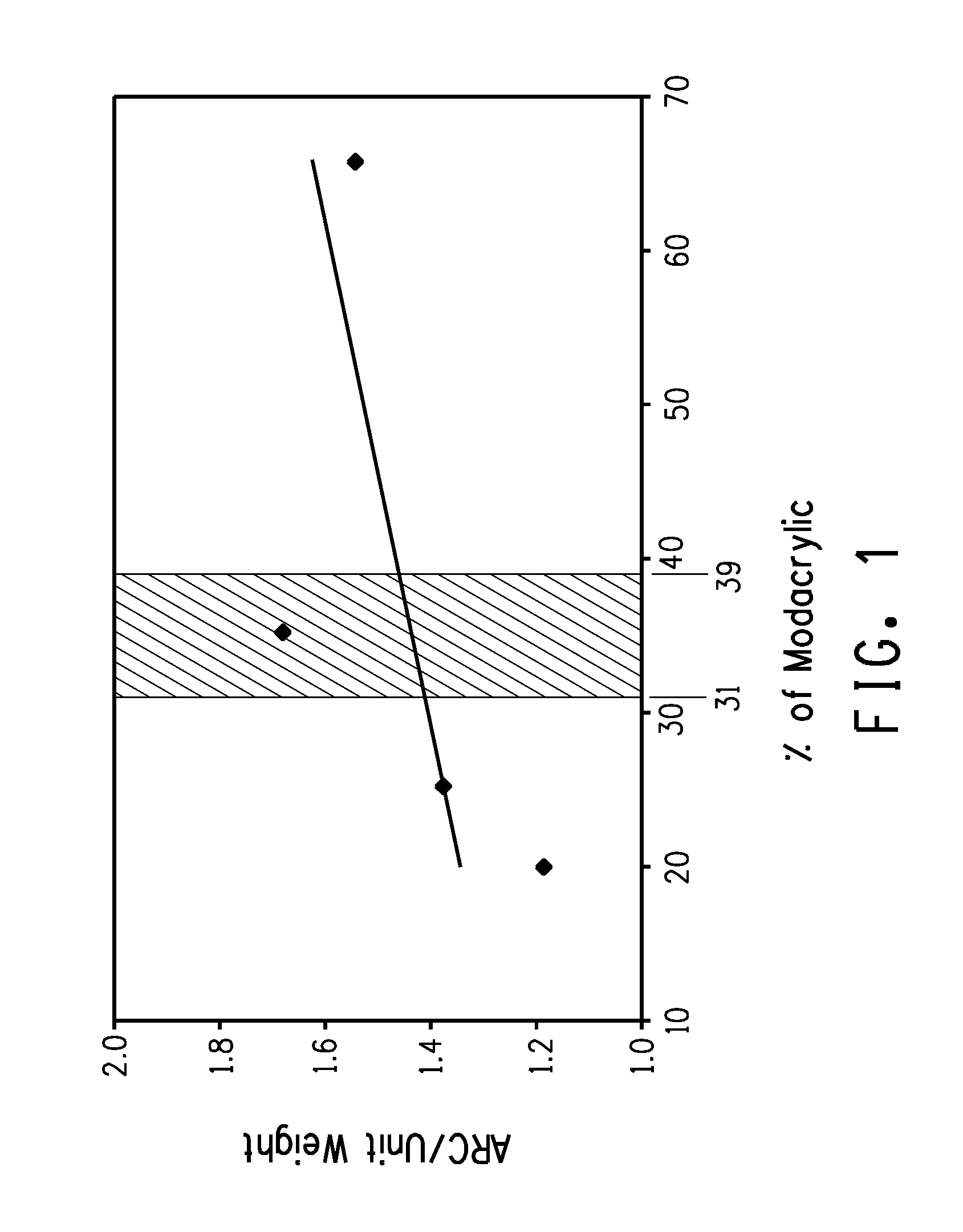

A yarn, fabric, and garment suitable for use in arc and flame protection and having improved flash fire protection contains a majority, by weight, of meta-aramid fibers having a degree of crystallinity of at least 20%, and a minority of modacrylic fibers, para-aramid fibers, and antistatic fibers. Garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

Crystallized meta-aramid blends for flash fire and arc protection having improved comfort

A yarn, fabric, and garment suitable for use in arc and flame protection and having improved flash fire protection consisting essentially of from (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 30 weight percent flame-retardant rayon fiber, (c) 10 to 20 weight percent modacrylic fiber, (d) 0 to 5 weight percent para-aramid fiber, and (e) 0 to 3 weight percent antistatic fiber based on the total weight of components (a), (b), (c), (d), and (e). In one embodiment, garments made from the yarn provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating.

Owner:DUPONT SAFETY & CONSTR INC

Limited-antimony-content and antimony-free modacrylic / aramid blends for improved flash fire and arc protection

A yarn, fabric, and garment suitable for use in arc and flame protection comprising aramid fiber and modacrylic fiber wherein the modacrylic fiber has less than 1.5 percent antimony and is preferably antimony-free. In one embodiment, the yarn, fabric, and / or garments consist essentially of (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 40 weight percent modacrylic fiber that is antimony-free, (c) 5 to 20 weight percent para-aramid fiber, and (d) 1 to 3 weight percent antistatic fiber, based on the total weight of components (a), (b), (c) and (d). In some embodiments, garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

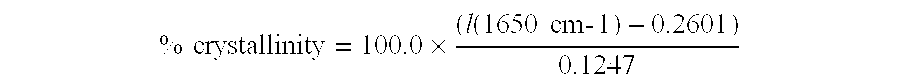

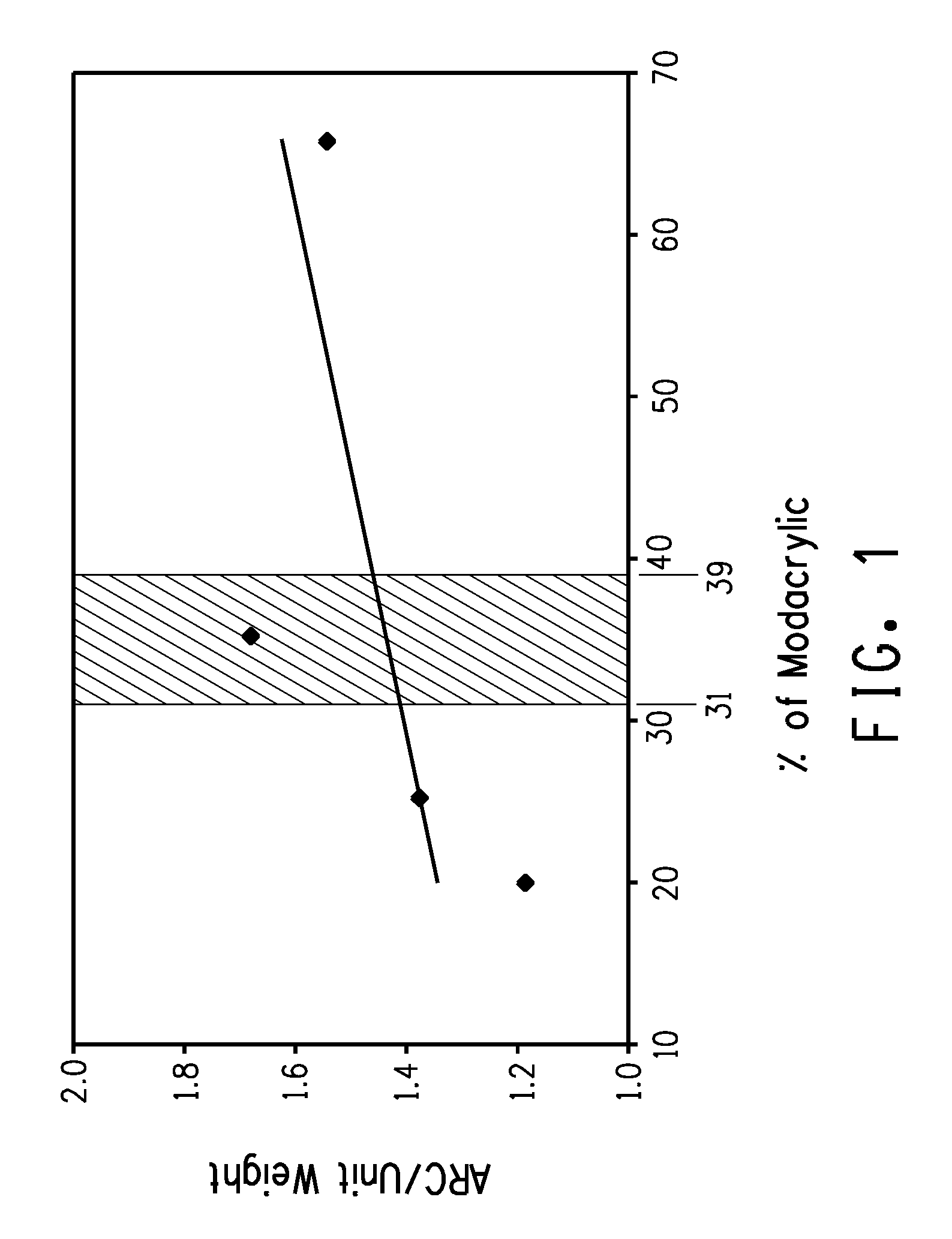

Crystallized meta-aramid blends for improved flash fire and superior arc protection

A yarn, fabric, and garment suitable for use in arc and flame protection and having improved flash fire protection, consisting essentially of (a) 50 to 60 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%; (b) 31 to 39 weight percent modacrylic fiber; and (c) 5 to 15 weight percent para-aramid fiber; said percentages on the basis of components (a), (b), and (c). In some embodiments, 1 to 3 weight percent of the meta-aramid fiber is replaced with an antistatic fiber comprising carbon or metal with the proviso that at least 50 weight percent meta-aramid fiber is maintained. Garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

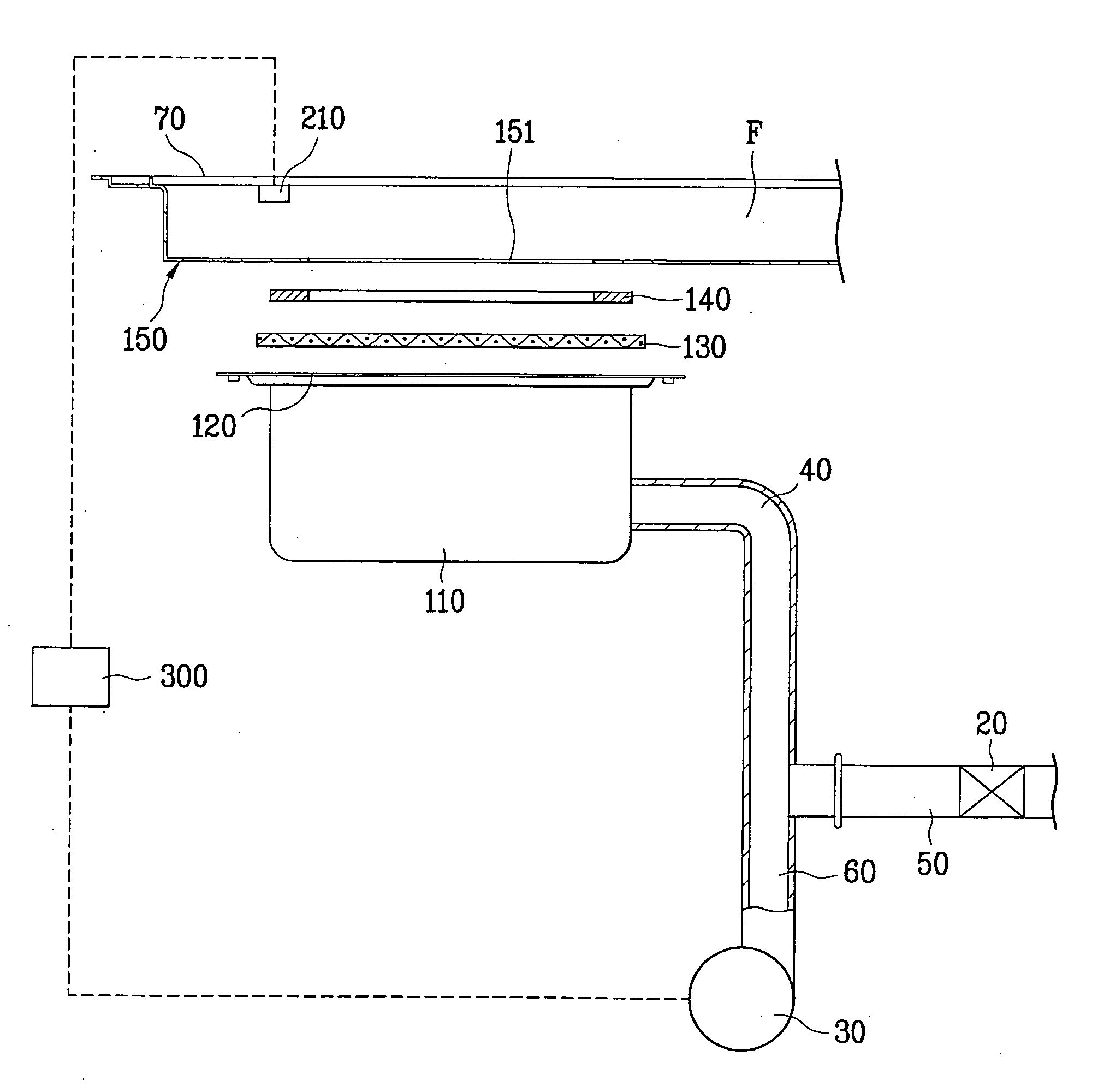

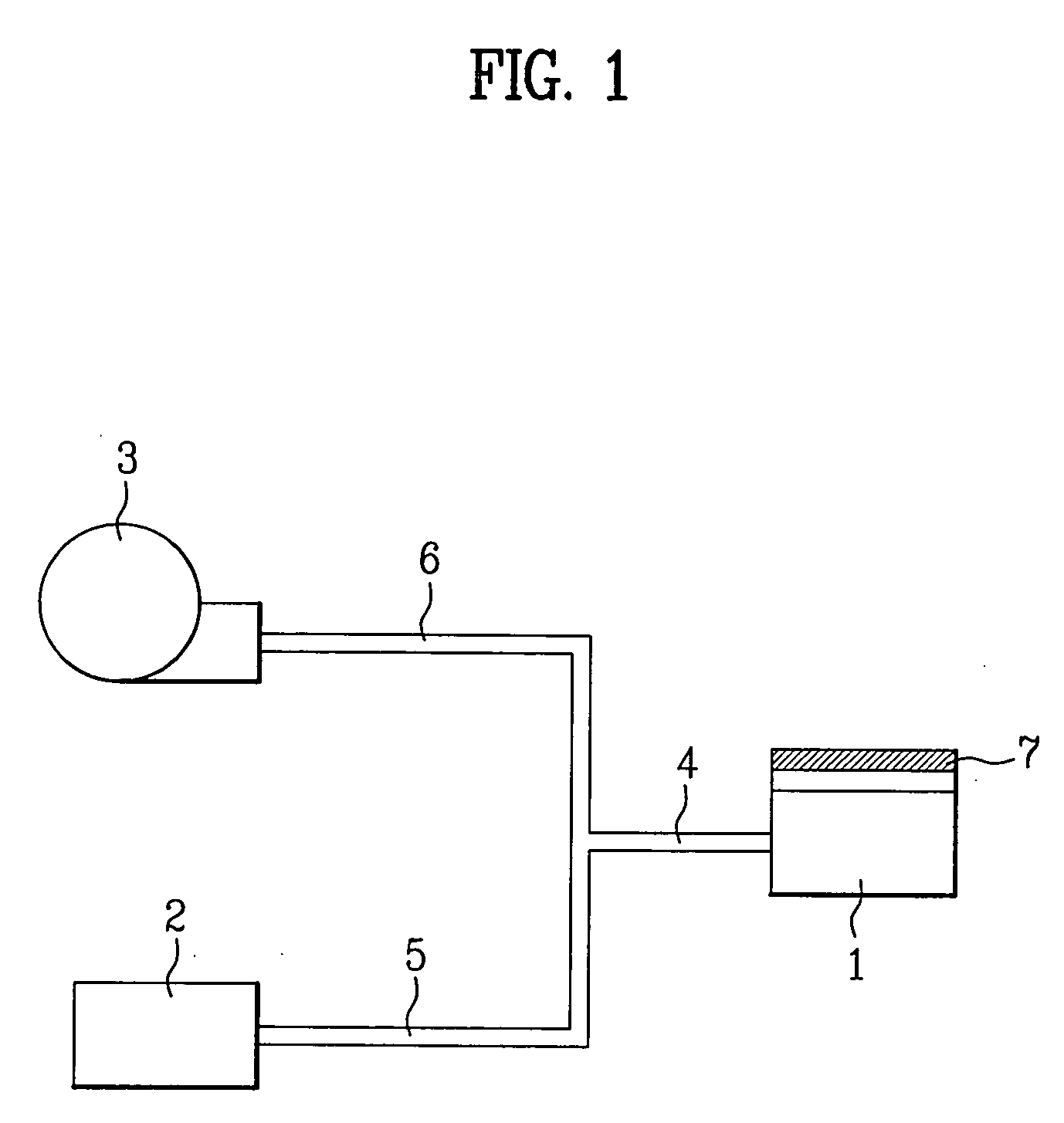

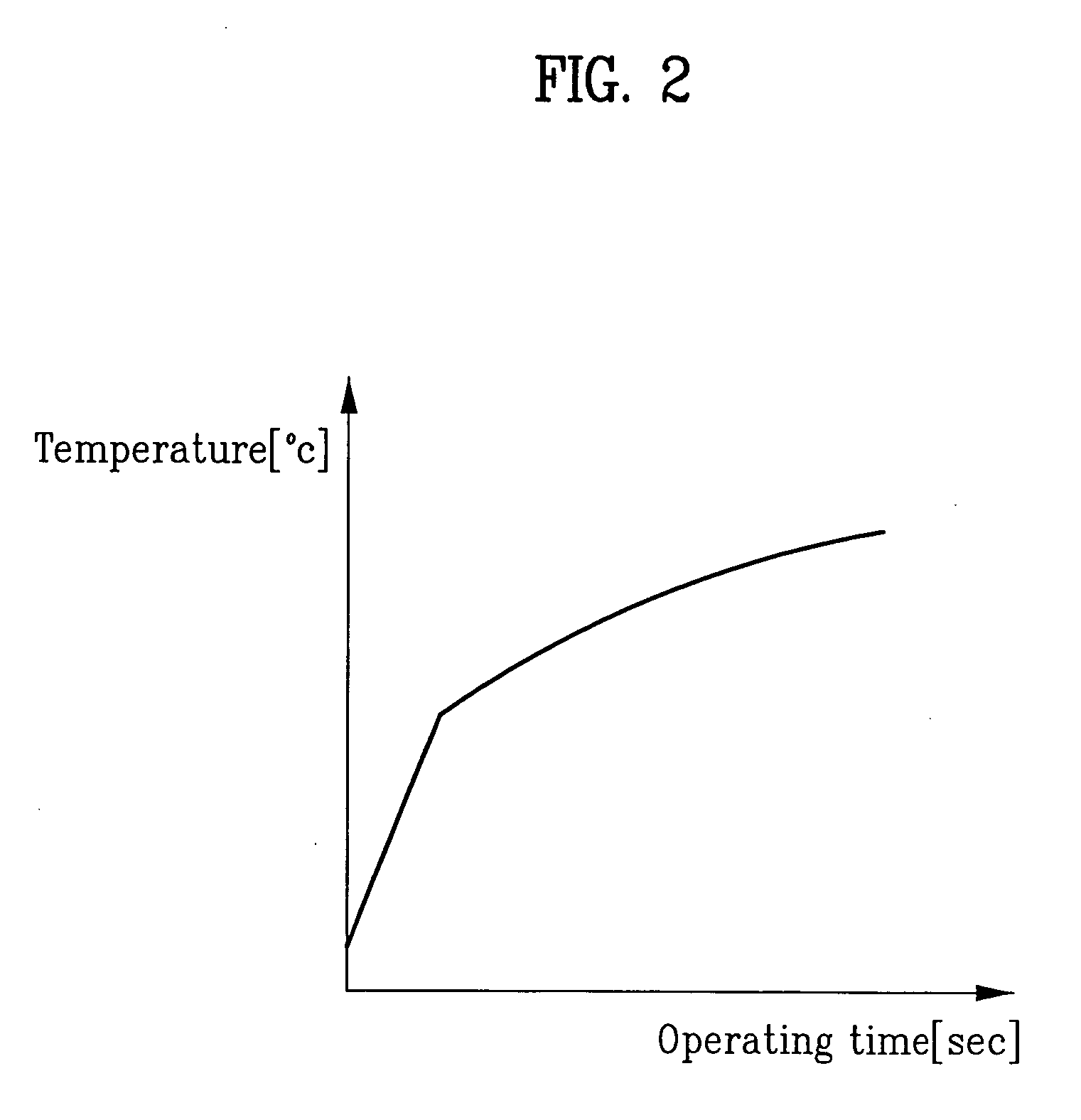

Gas burner and method for controlling the same

InactiveUS20060078836A1Improve combustion efficiencyFuel supply regulationAir supply regulationBody burningProcess engineering

Disclosed are a gas burner and a method for controlling the same in which stable use is possible and combustion efficiency is improved. The gas burner includes a burner body burned by a mixture gas of gas fuel and air, a gas supplying valve supplying the gas fuel to the burner body through a gas supplying tube connected with the burner body, an air supplying fan supplying the air to the burner body through an air supplying tube connected with the burner body, and a control part controlling air flow supplied to the burner body by controlling revolution per minute (RPM) of the air supplying fan. Since an optimal air-fuel ratio can be maintained by controlling the RPM of the air supplying fan, combustion efficiency can be increased. Since a temperature of a glass can be maintained properly, life span of the gas burner can be increased and its stable use is possible.

Owner:LG ELECTRONICS INC

Crystallized meta-aramid blends for flash fire and arc protection having improved comfort

A yarn, fabric, and garment suitable for use in arc and flame protection and having improved flash fire protection consisting essentially of from (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 30 weight percent flame-retardant rayon fiber, (c) 10 to 20 weight percent modacrylic fiber, (d) 0 to 5 weight percent para-aramid fiber, and (e) 0 to 3 weight percent antistatic fiber based on the total weight of components (a), (b), (c), (d), and (e). In one embodiment, garments made from the yarn provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating.

Owner:EI DU PONT DE NEMOURS & CO

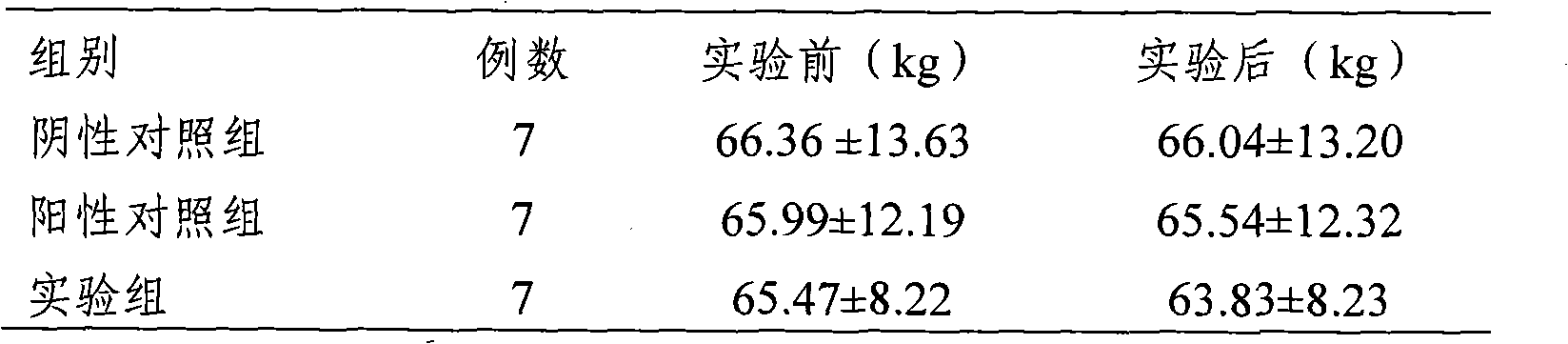

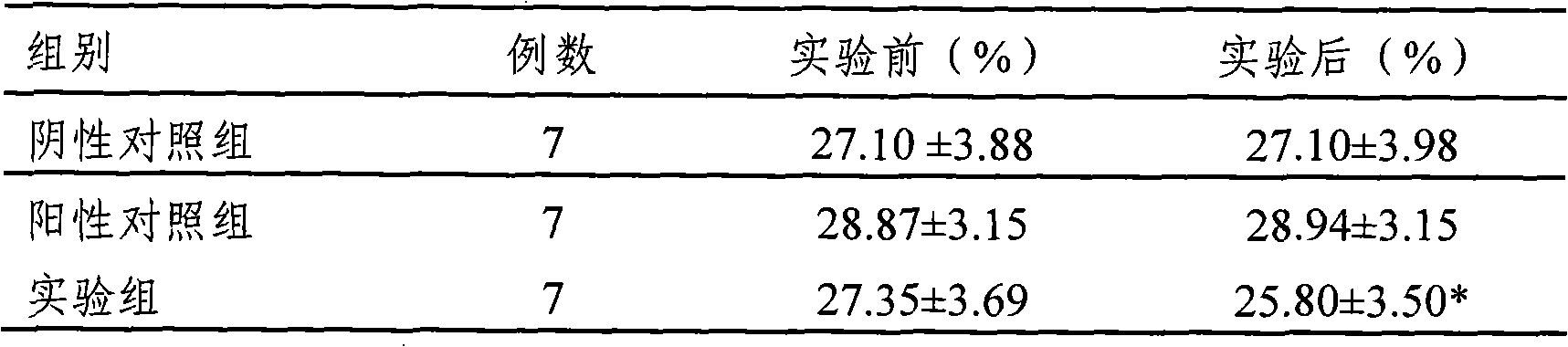

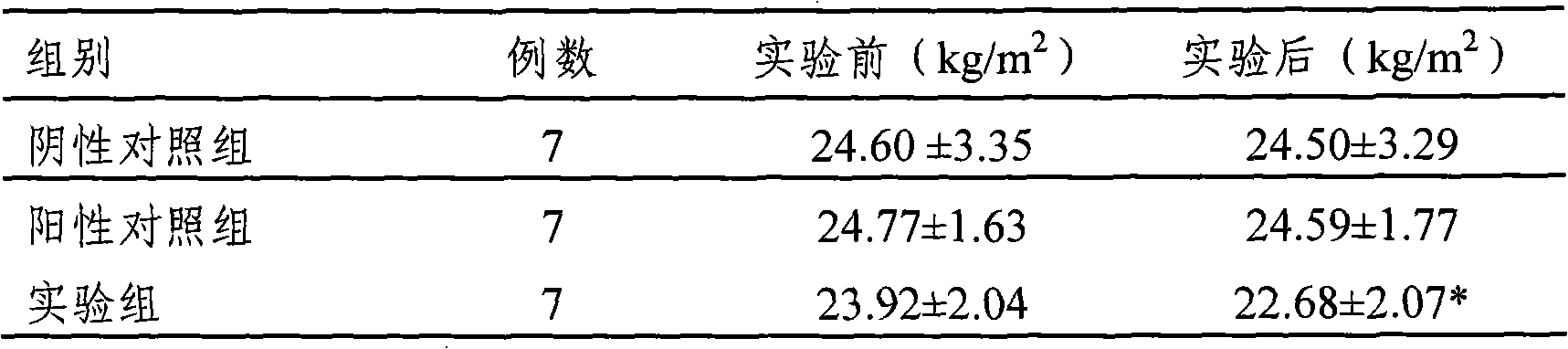

Composition for losing weight

ActiveCN101926891ATo promote metabolismAvoid absorptionOrganic active ingredientsMetabolism disorderCapsaicinBody burning

The invention provides a composition for losing weight. The composition consists of a formula A and a formula B, wherein the formula A comprises the following raw materials in part by weight: 5 to 50 parts of capsaicin, 10 to 100 parts of guarana extract, 10 to 100 parts of green tea extract and 100 to 1,000 parts of lotus leaf extract; and the formula B comprises the following raw materials in part by weight: 100 to 1,000 parts of chitin and 100 to 1,000 parts of white kidney bean extract. The formula A of the composition for losing weight can accelerate the metabolism of a body and improve the burnt calories of the body; and the formula B can inhibit a human body from absorbing starch and fatty foods, and can effectively reduce the intake of energy under the condition of not controlling diet.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

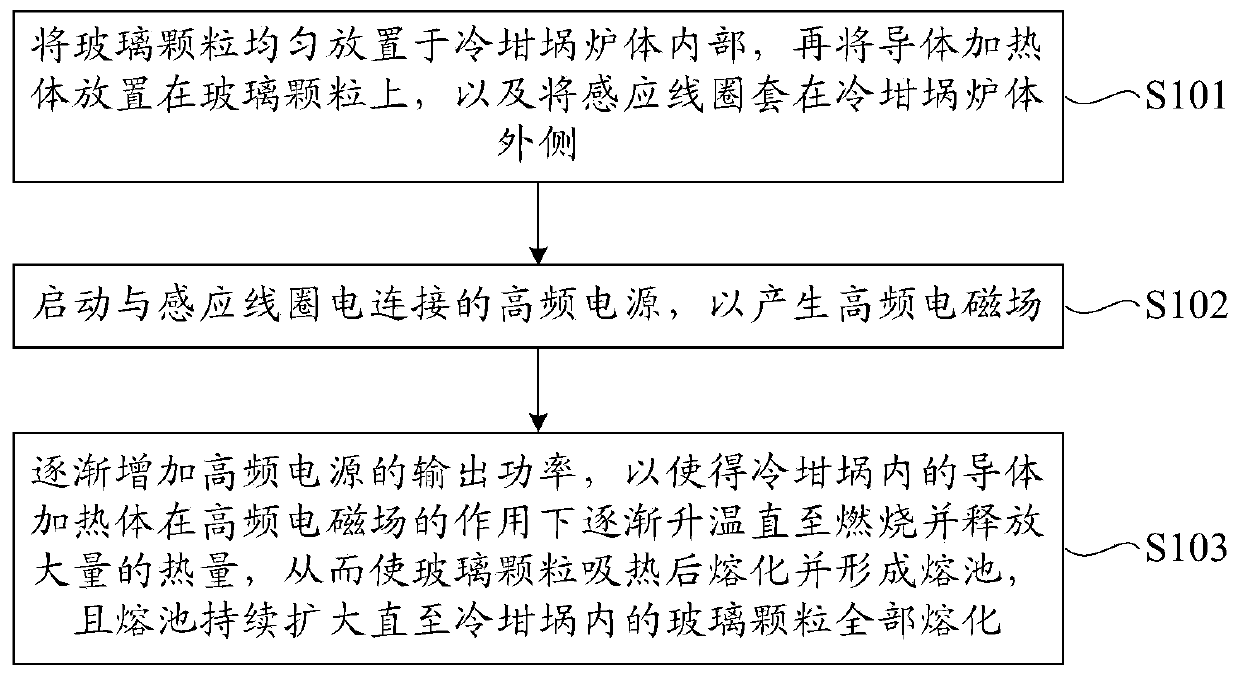

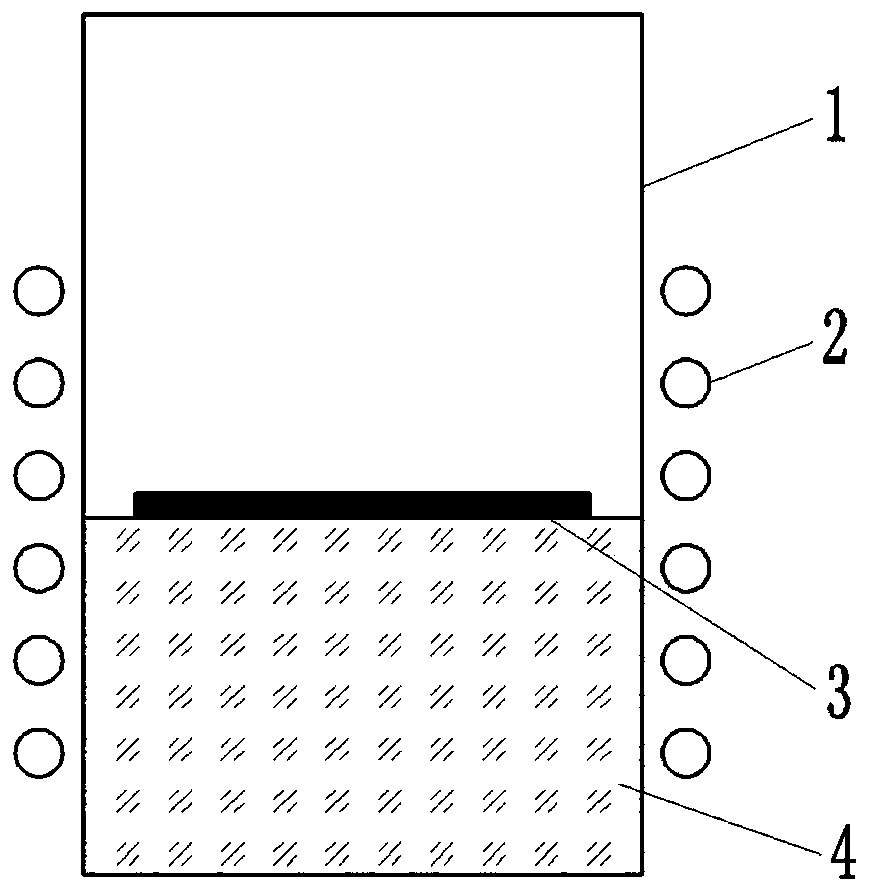

Method and device for preheating and initially melting glass raw materials

InactiveCN109734286ALarge heat releaseReduce smokeGlass furnace apparatusElectric furnaceMelting tankElectrical conductor

The invention provides a method and device for preheating and melting glass raw materials. The preheating and initially melting method comprises the following steps: placing glass particles inside a cold crucible furnace body, placing a conductor heating body on the glass particles, and sleeving the cold crucible furnace body with an induction coil; starting a high-frequency power supply electrically connected with the induction coil to generate a high-frequency electromagnetic field; gradually increasing the output power of the high-frequency power supply, so that the conductor heating body in a cold crucible is gradually heated up under the action of the high-frequency electromagnetic field until the conductor heating body burns and releases a large amount of heat, thereby melting glassparticles after absorbing the heat and forming a molten pool, wherein the molten pool is continuously expanded until all glass particles in the cold crucible are completely molten. According to the invention, the conductor heating body is arranged on the glass particles in the cold crucible as a starting material, and the conductor heating body is rapidly heated up and burned under the action of ahigh-frequency electromagnetic field, so that the released heat not only forms the glass molten pool, but also accelerates the whole starting process, and no additional heating equipment is needed for the cold crucible.

Owner:CHINA NUCLEAR POWER ENG CO LTD

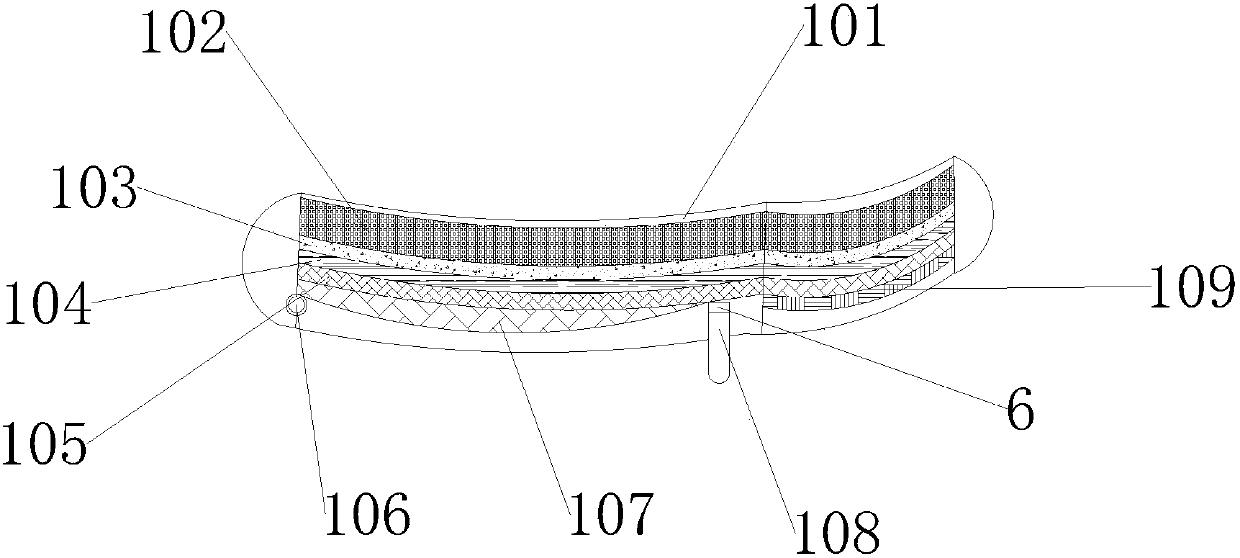

Hot compress sticker for improving microcirculation and preparation method thereof

InactiveCN105943238APromote local blood circulationAvoid hypoxiaElectrotherapyNervous disorderDiseaseEye burning sensation

The invention discloses a hot compress sticker for improving microcirculation. The heating material of the hot compress sticker is prepared from far infrared ceramic powder, magnet powder, negative ion powder, pepper, mint, camphor, borneol and heat sensitizer. According to the hot compress sticker for improving microcirculation, heat produced can be stabilized at 40-50 DEG C, the lasting time is 16-20 h, and the hot compress sticker can be continuously and repeatedly used for 2-6 months, will not cause body burning heat sensation if being used for a long time, and can promote body local blood circulation, prevent histanoxia, relieve local organ and tissue pain, and effectively treat various kinds of muscular soreness, cervical spondylosis, shoulder joint and scapulohumeral periarthritis and the like. In addition, due to the fact that the far infrared ceramic powder, the magnet powder and other traditional Chinese medicine raw materials are adopted in the hot compress sticker, the additional magnet therapy effect and medicine treatment effect are obtained, and the hot compress sticker has the good treatment effect on female breast diseases, endocrine disorder, cold in uterus, insomnia and the like.

Owner:马南行

Crystallized meta-aramid blends for flash fire and arc protection having improved comfort

A yarn, fabric, and garment suitable for use in arc and flame protection and having improved flash fire protection consisting essentially of from (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 30 weight percent flame-retardant rayon fiber, (c) 10 to 20 weight percent modacrylic fiber, (d) 0 to 5 weight percent para-aramid fiber, and (e) 0 to 3 weight percent antistatic fiber based on the total weight of components (a), (b), (c), (d), and (e). In one embodiment, garments made from the yarn provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating.

Owner:DUPONT SAFETY & CONSTR INC

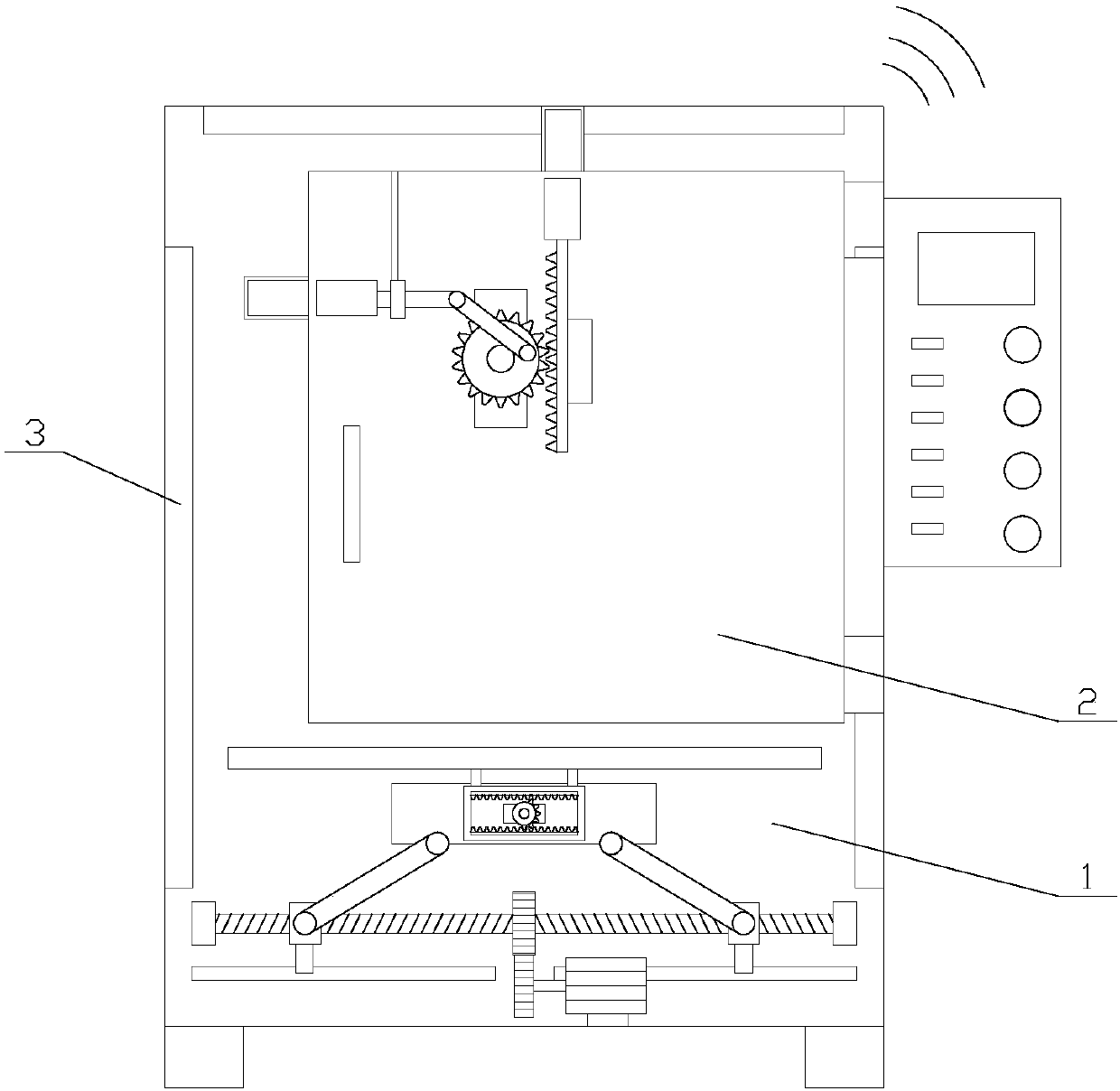

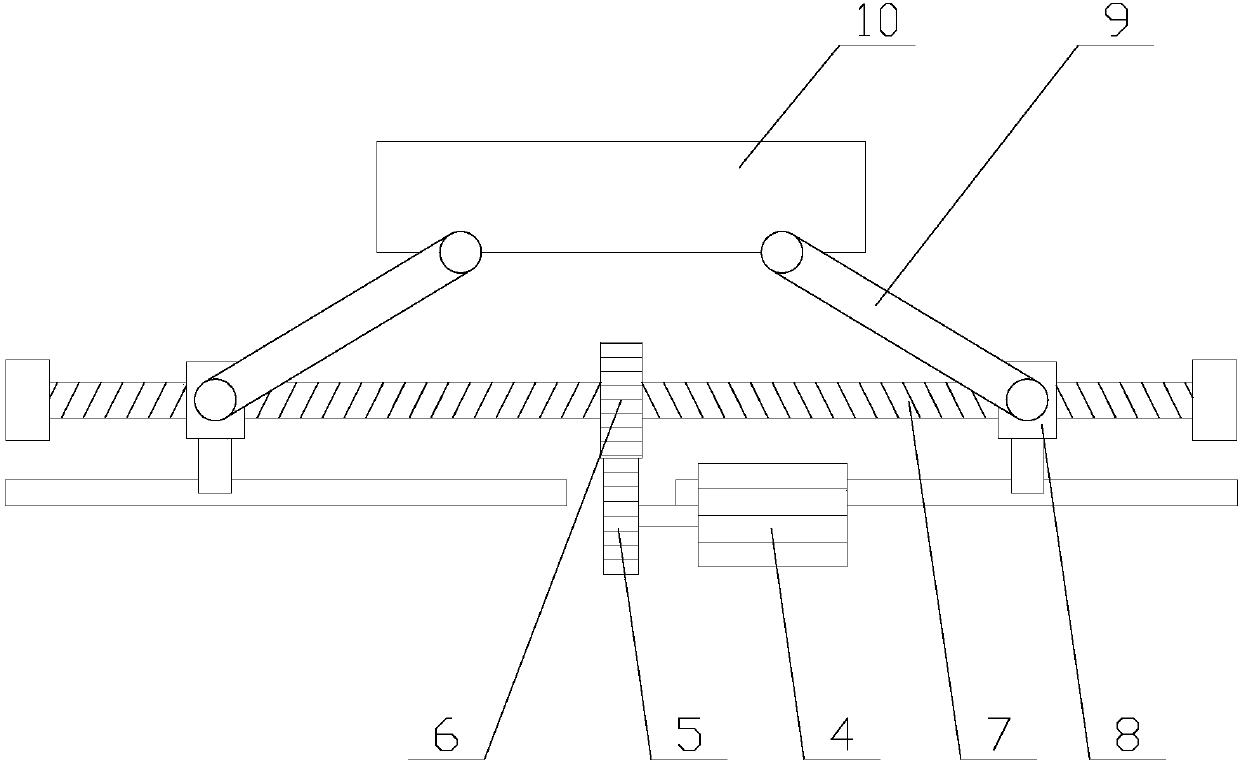

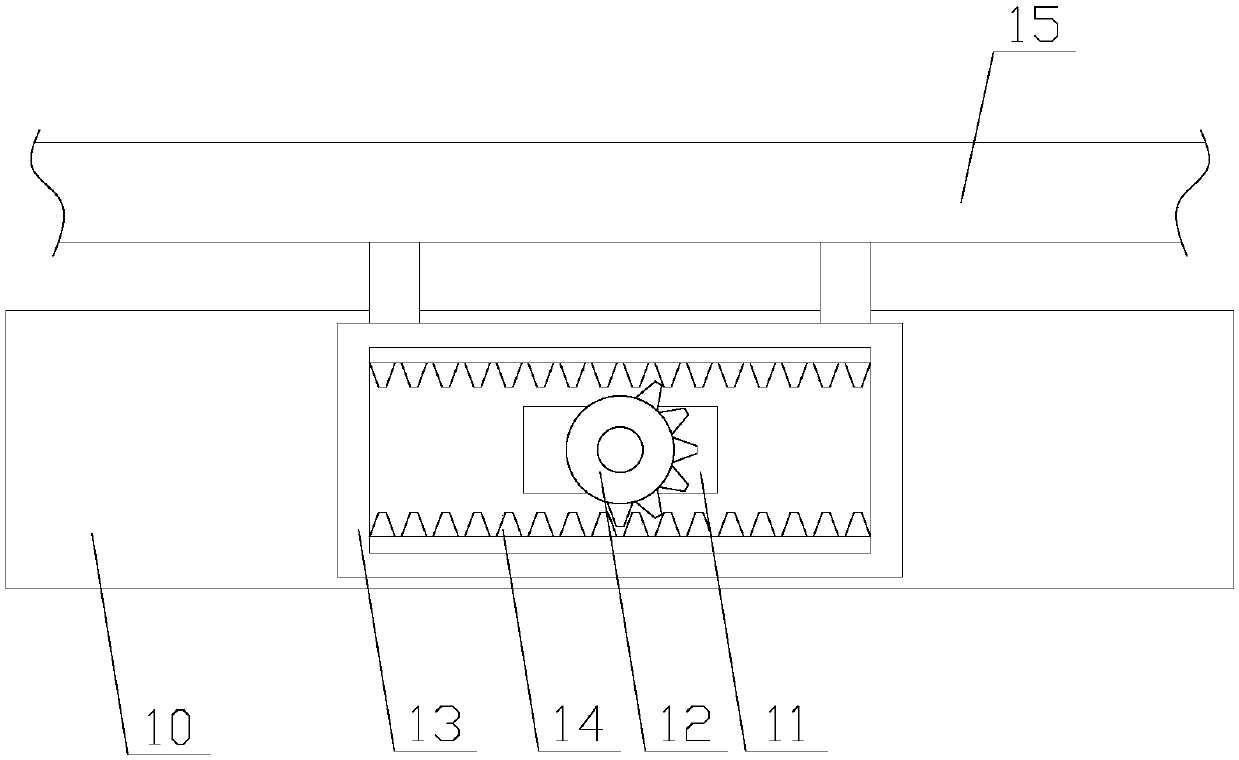

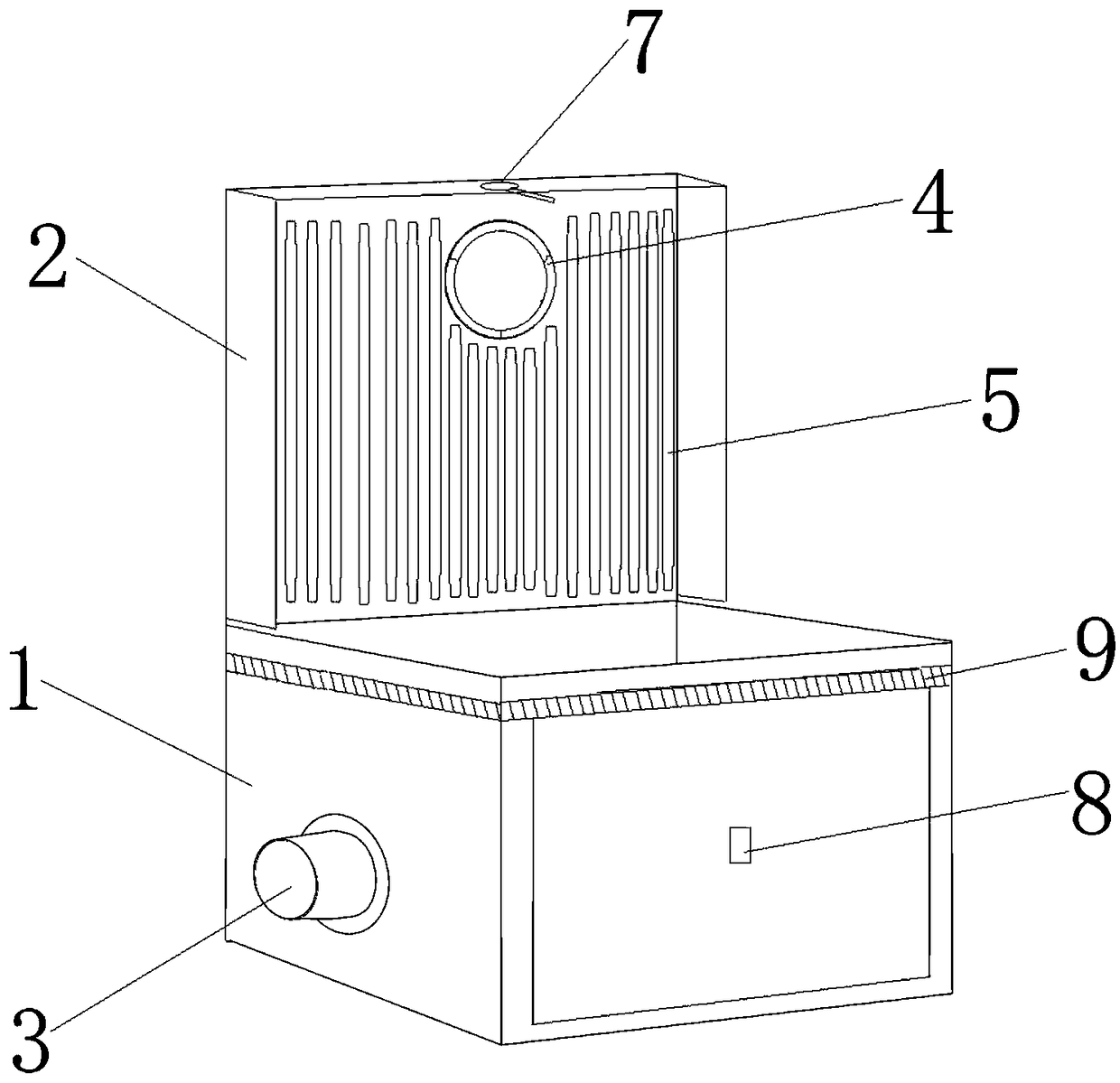

Internet-of-things-based braking box for automobile spare and accessory part production

InactiveCN107763984AEasy to adjust for bakingSpeed up the flowDrying chambers/containersDrying solid materialsLocking mechanismHeat losses

The invention relates to a baking oven for the production of auto parts based on the Internet of Things, which includes a main body, a sealed door, a heating plate and a center console, and also includes an adjustment mechanism and a locking mechanism. The adjustment mechanism includes a lifting assembly and a reciprocating assembly. The locking mechanism includes a drive assembly, a first fixed assembly and a second fixed assembly. In the baking oven for the production of auto parts based on the Internet of Things, through the adjustment mechanism, the pallet can be lifted up and down and moved left and right, so as to control the pallet close to or away from the heating plate, adjust the heating temperature, and accelerate the heating process. The flow of air improves the baking effect, and it is convenient to adjust the baking of spare parts of different sizes. Through the locking mechanism, it prevents the heat loss caused by the looseness of the sealing door, improves the sealing performance, and prevents the heat inside the main body from overflowing and scalding the staff, causing Safety accidents, improve the safety and practicability of equipment.

Owner:泉州德化宇胜技术咨询有限公司

Crystallized meta-aramid blends for improved flash fire and arc protection

A yarn, fabric, and garment suitable for use in arc and flame protection and having improved flash fire protection contains a majority, by weight, of meta-aramid fibers having a degree of crystallinity of at least 20%, and a minority of modacrylic fibers, para-aramid fibers, and antistatic fibers. Garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

Limited-antimony-content and antimony-free modacrylic / aramid blends for improved flash fire and arc protection

ActiveUS8069643B2Electroconductive/antistatic filament manufactureFlame-proof filament manufactureYarnBody burning

A yarn, fabric, and garment suitable for use in arc and flame protection comprising aramid fiber and modacrylic fiber wherein the modacrylic fiber has less than 1.5 percent antimony and is preferably antimony-free. In one embodiment, the yarn, fabric, and / or garments consist essentially of (a) 50 to 80 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%, (b) 10 to 40 weight percent modacrylic fiber that is antimony-free, (c) 5 to 20 weight percent para-aramid fiber, and (d) 1 to 3 weight percent antistatic fiber, based on the total weight of components (a), (b), (c) and (d). In some embodiments, garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

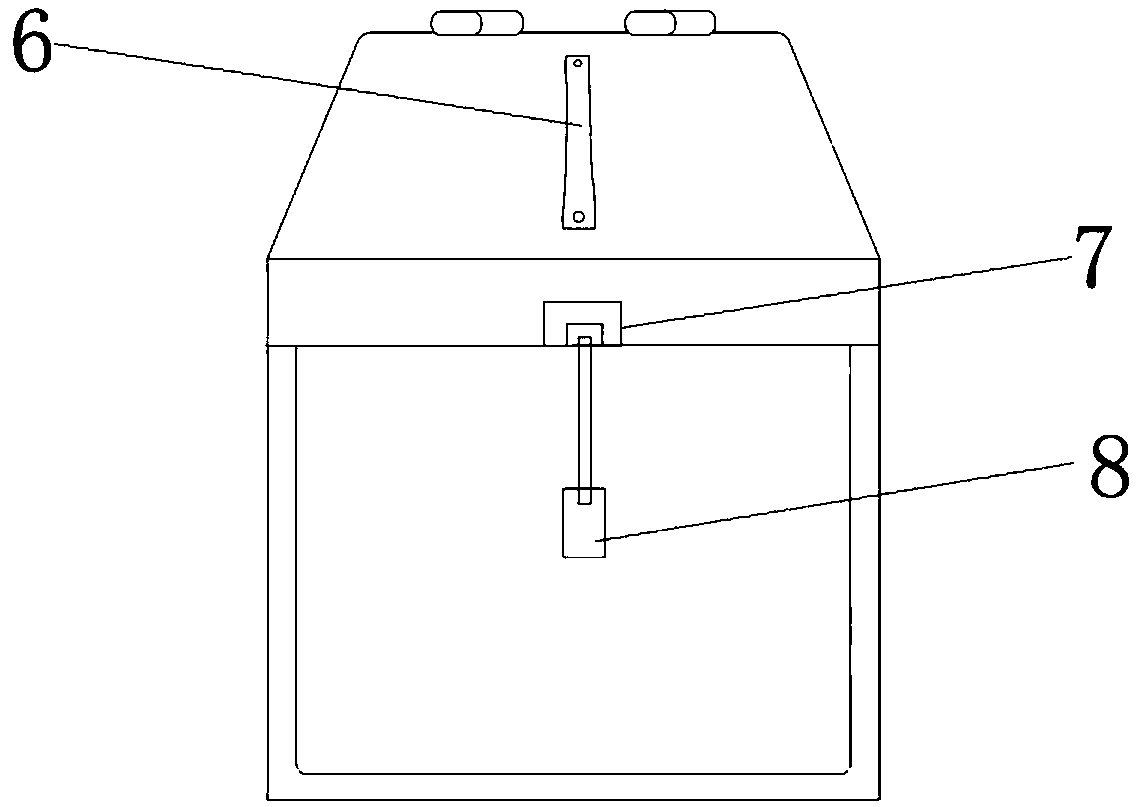

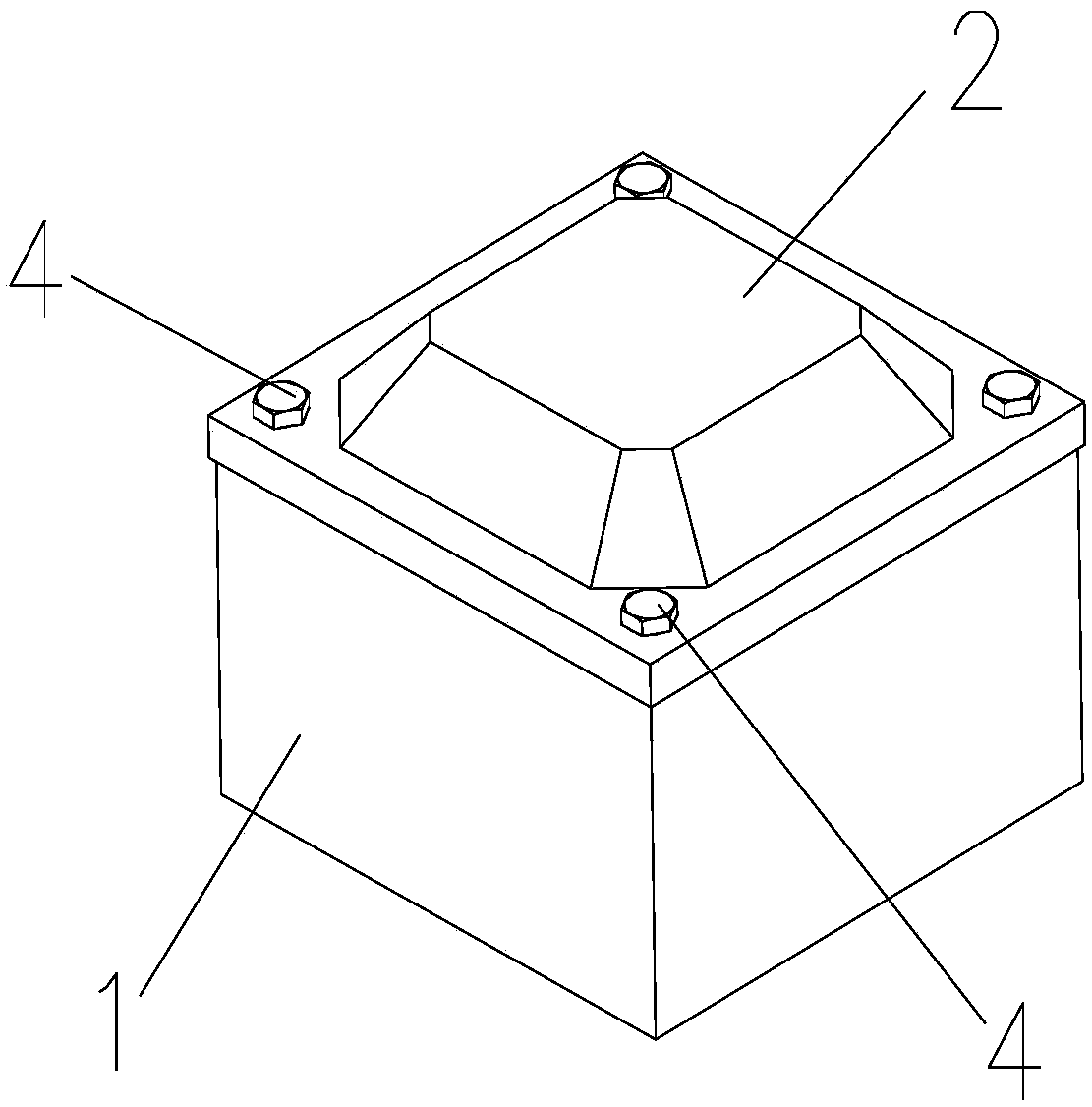

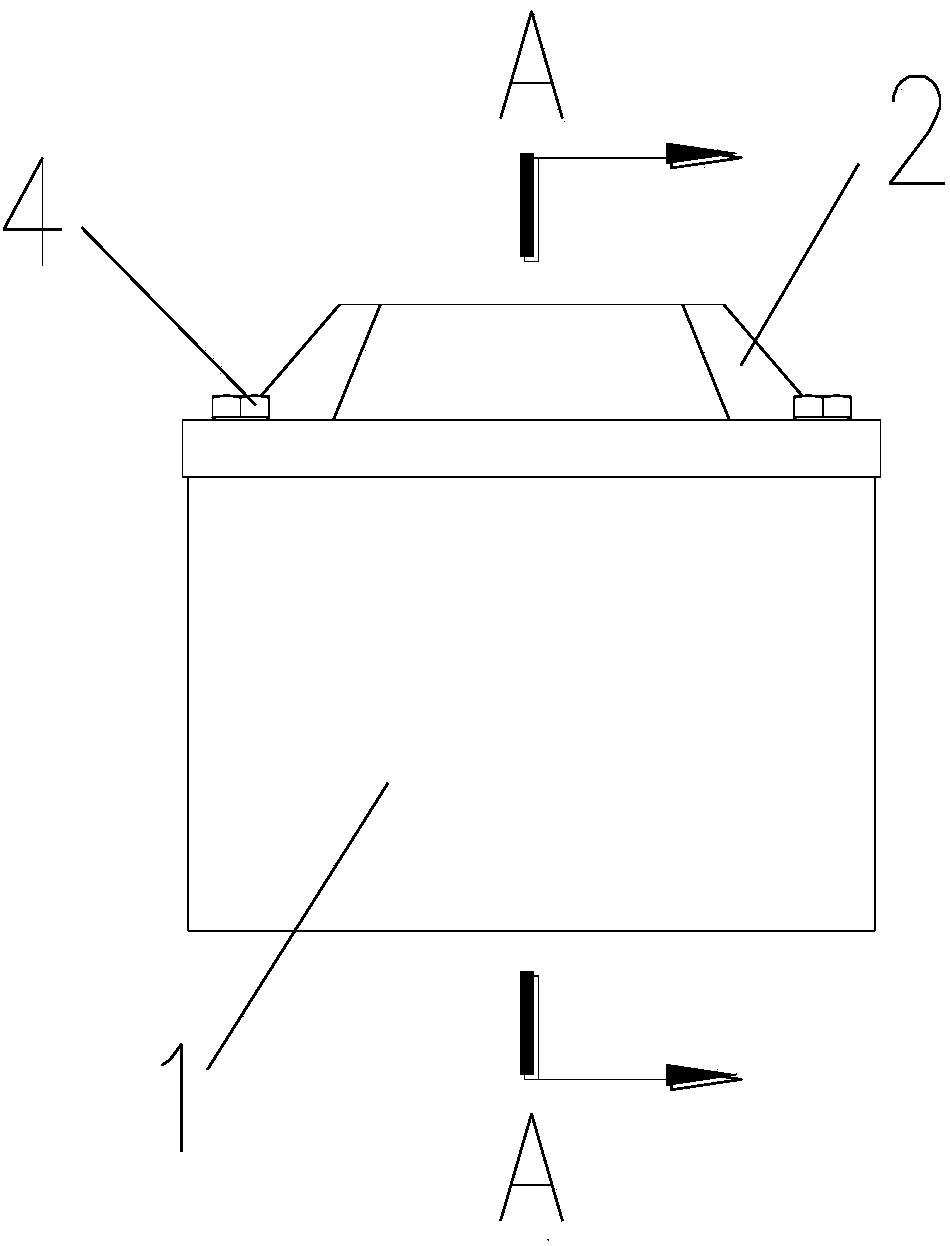

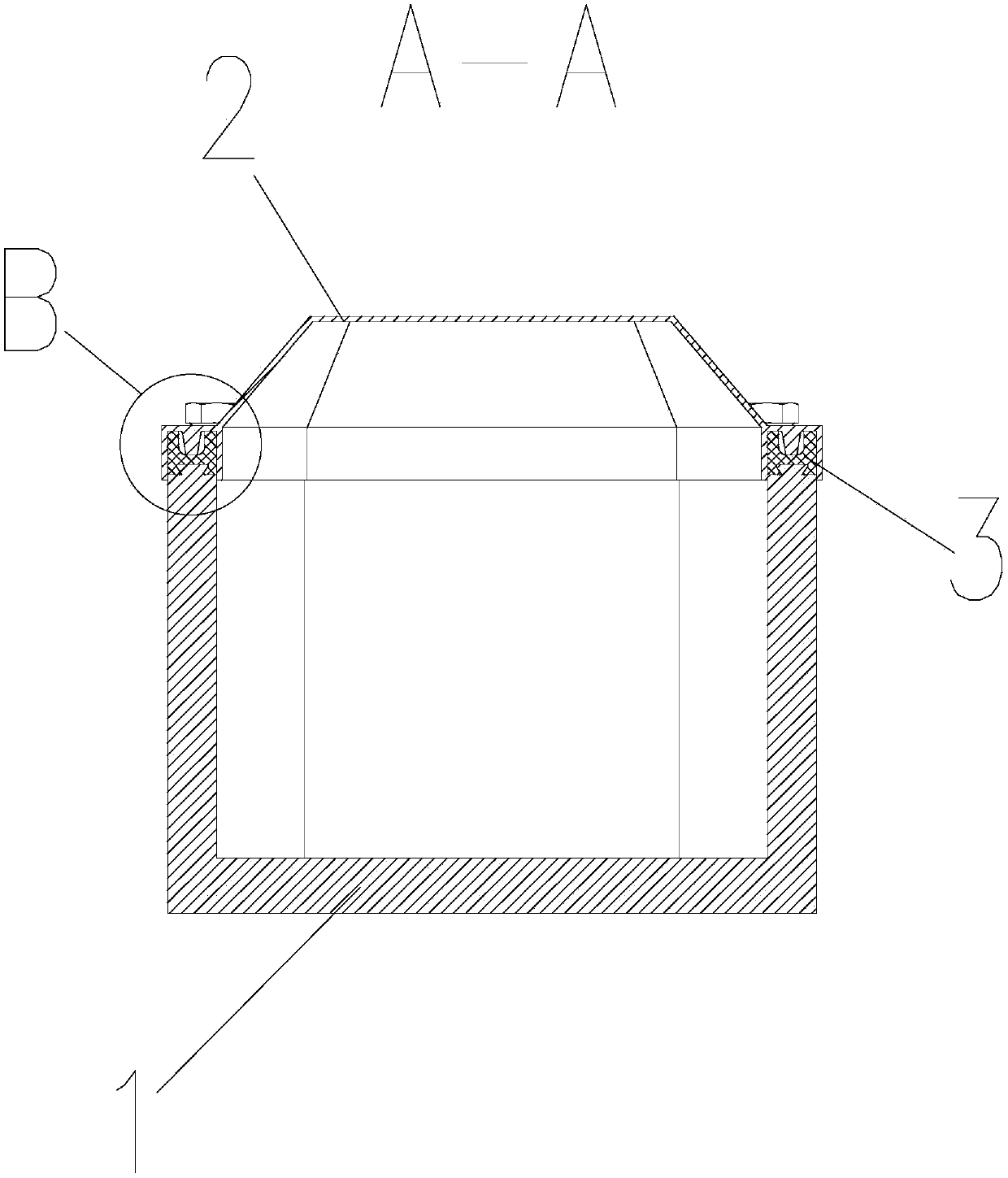

Specialized lithium battery charging explosion-proof box

PendingCN108649160AAvoid harmRealize the charging functionBattery isolationSecondary cellsFire - disastersEngineering

The invention discloses a specialized lithium battery charging explosion-proof box, and the box comprises a box body, a box cover, a charging connector, a smoke sensing alarm and a fire extinguishingtube. A lithium battery is placed in the box body and the box body is covered with the box cover, thus, the lithium battery is isolated from the outside, and harm to the lithium battery caused by an outside environment, particularly an outside fire source, is avoided. Meanwhile, a function of charging and protecting the lithium battery is realized, the lithium battery is prevented from generatingaccidents of burning and explosion in a charging process. With the smoke sensing alarm, when smoke concentration in the box body is relatively high, the smoke sending alarm can give an alarm for reminding, fire disaster can be avoided, and usage can be safe. With the fire extinguishing tube, and fire extinguishing agent set in the fire extinguishing tube, when the lithium battery in the box body burns, the fire extinguishing tube fractures in case of fire flame, the fire extinguishing agent overflows, a fire extinguishing effect is realized, generation of the explosion accident is prevented effectively, and safety is high.

Owner:北京电小二网络科技有限公司

Pug of firewood-fired Nixing pottery and process for manufacturing Nixing pottery from pug

InactiveCN106116511AExpanded firing temperature rangeAvoid burnsCeramic materials productionClaywaresFirewoodWoody plant

The invention provides pug of firewood-fired Nixing pottery and a process for manufacturing the Nixing pottery from the pug. The pug is prepared from, by weight, 5.5-6.8 parts of eastern mud, 1.3-2.0 parts of western mud, 1-1.5 parts of wood ash and 2-2.5 parts of kaolin. The process of for manufacturing the Nixing pottery from the pug comprises the steps of blank preparation, blank body forming, blank body drying and blank body firing; according to blank preparation, the eastern mud, the western mud, the wood ash and the kaolin with the formula amount are prepared into a blank through a conventional process; according to blank body burning, the blank body is fed into a wood-fired kiln, woody plants are adopted as fuel, the firing temperature ranges from 1,160 DEG C tot 1,180 DEG C, and after firing is completed, cooling and drawing are carried out. The kaolin and the wood ash are added into conventional Nixing pottery pug, so that the firing temperature range of the Nixing pottery is greatly widened; the melting temperature of ash of fuel wood can be reduced, the melting time of the ash can be shortened, and the fuel wood cost is greatly reduced.

Owner:钦州市壮冠坭兴陶材料开发有限公司

Crystallized meta-aramid blends for improved flash fire and superior arc protection

A yarn, fabric, and garment suitable for use in arc and flame protection and having improved flash fire protection, consisting essentially of (a) 50 to 60 weight percent meta-aramid fiber having a degree of crystallinity of at least 20%; (b) 31 to 39 weight percent modacrylic fiber; and (c) 5 to 15 weight percent para-aramid fiber; said percentages on the basis of components (a), (b), and (c). In some embodiments, 1 to 3 weight percent of the meta-aramid fiber is replaced with an antistatic fiber comprising carbon or metal with the proviso that at least 50 weight percent meta-aramid fiber is maintained. Garments made from the yarns provide thermal protection such that a wearer would experience less than a 65 percent predicted body burn when exposed to a flash fire exposure of 4 seconds per ASTM F1930, while maintaining a Category 2 arc rating per ASTM F1959 and NFPA 70E.

Owner:DUPONT SAFETY & CONSTR INC

Air compressor junction box of good sealing performance

PendingCN107910833AWill not short circuit burnWill not cause short circuit burnPositive displacement pump componentsElectrical apparatusEngineeringBody burning

The present invention belongs to the air compressor structure technology field, in particular to an air compressor junction box of good sealing performance. The air compressor junction box comprises abox body and a box cover, a groove is arranged in the circumferential direction of the outer edge of the box cover, and a flange of the box body is arranged in the groove cooperatively. A gasket is clamped between the flange of the box body and the groove, the box cover, the gasket and the box body are assembled as one via the bolts, and a dovetail groove is arranged in the annular direction of the gasket. A dovetail protrusion is arranged on the flange of the box body, the dovetail groove and the dovetail protrusion cooperate with each other, and a Y-shaped lip is arranged on one end face ofthe gasket far away from the dovetail groove annularly. The two lip edges of the Y-shaped lip are attached to the groove walls of the groove, and a protruding tooth is fixed at the bottom of the groove and is pressed in the Y-shaped lip. The beneficial effects of the present invention are that by adopting the bolts to connect, the overhauling is convenient; a sealing surface of the flange of thebox body and the walls of the groove of the box cover are together attached to the gasket separately and always, so that a gap is not generated, the waterproof and dustproof performances are good, aninternal circuit in the box body is not in short circuit and is not burnt out, and the reliability is high.

Owner:江苏奥吉瑞斯新能源有限公司

Preparation method of green, environment-friendly and smoke-free incense

The invention discloses a preparation method of green, environment-friendly and smoke-free incense and relates to the field of incense for worship. The method comprises steps as follows: 1), plant starch, plant sticky powder and light calcium carbonate powder are mixed, and a solid mixture is prepared; 2), alkyl glycoside is added and taken as a solubilizer, alkyl glycoside, water, potassium nitrate and toner are mixed, and a liquid mixture is prepared; 3), an incense body is prepared from the solid mixture and the liquid mixture. Dispersity and solubleness of the materials are increased underthe solubilization action of alkyl glycoside, potassium nitrate is uniformly dispersed in the materials, besides, alkyl glycoside has quite high C content, so that gross calorific value of the incense in a burning process is increased, the incense prepared from the plant starch and other green and environment-friendly raw materials is burnt sufficiently, and the smoke-free effect in the incense body burning process is realized without addition of carbon powder.

Owner:刘丽华

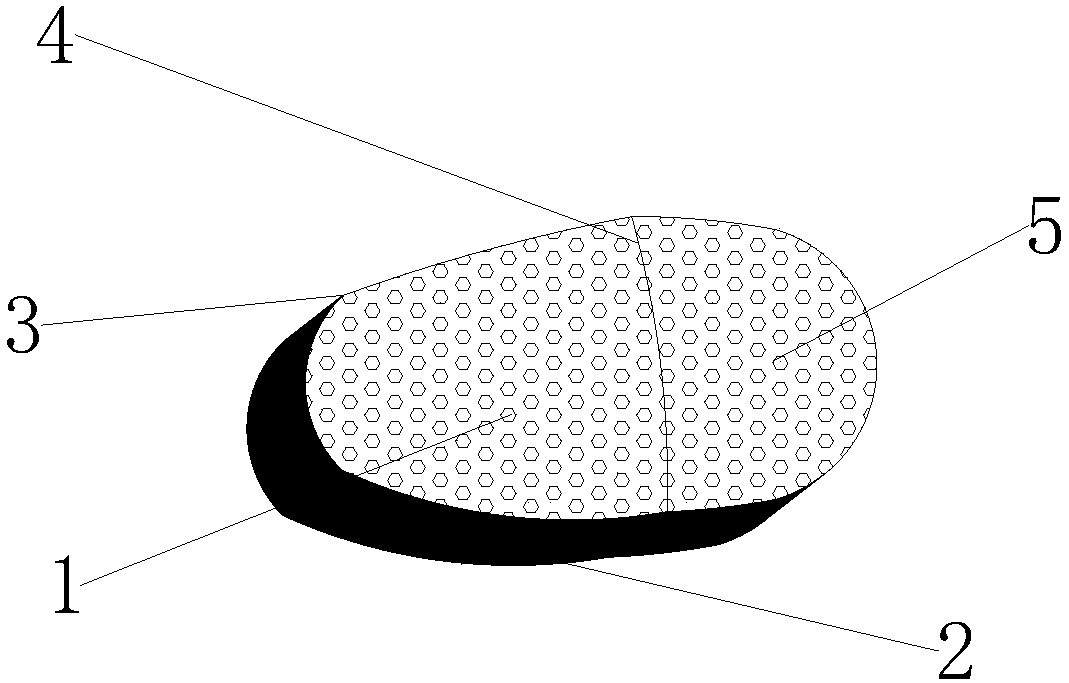

Ventilation seat cushion for electric bicycle

InactiveCN107776737AStrong memorySolve the problem of inconvenience caused by easy deformation and collapseCycle saddlesCooling effectBody burning

The invention discloses a ventilated seat cushion for an electric bicycle, which comprises a seat cushion and a back seat. The back seat is arranged on the right side of the seat cushion, and the back seat is fixedly connected in the seat cushion. The air-permeable layer makes the seat cushion air-permeable, increases the friction force of the seat cushion, and effectively prevents slipping. And in summer, it has a heat dissipation effect to prevent the temperature of the cushion from being too high and scalding the human body. The sponge layer increases the comfort of the cushion, and the softness makes driving more comfortable and relaxing. performance, preventing the cushion from collapsing and deforming, greatly prolonging the service life of the cushion, reducing the number of times people replace the cushion, and bringing convenience to people's lives. Its structure is clear and has a good heat insulation effect, preventing the cushion from being exposed to sunlight in summer Finally, the temperature of the cushion is too high, which reduces the service life of the cushion and brings inconvenience to people driving.

Owner:WUXI CHUANGGE TECH CO LTD

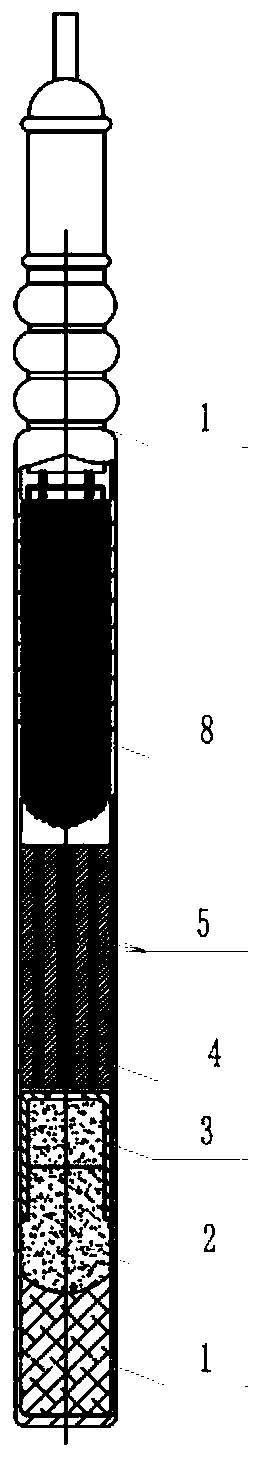

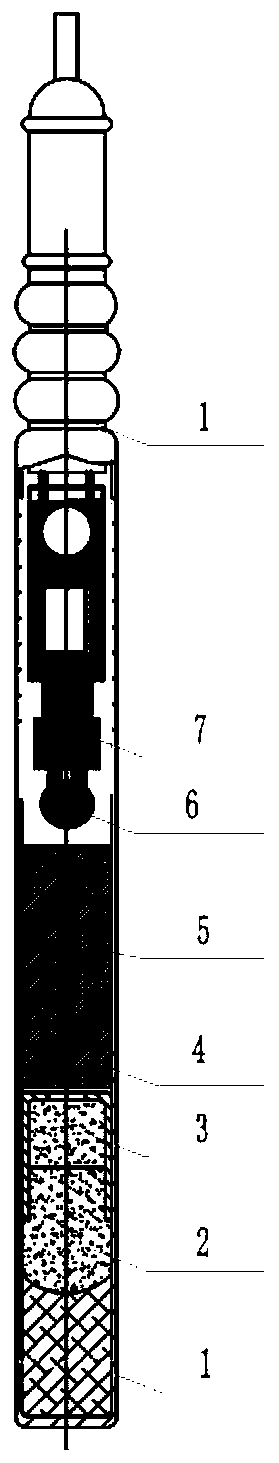

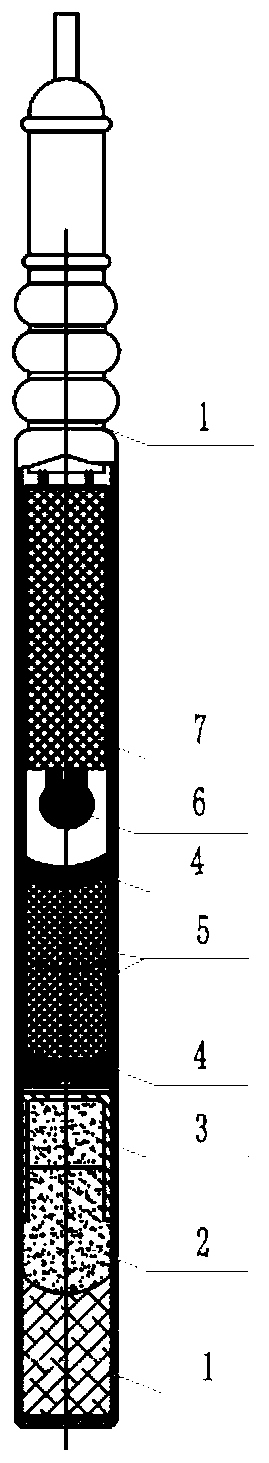

Electronic ignition delay detonator

PendingCN110186330ADelivery normalReliable deliveryBlasting cartridgesAmmunition fuzesElectricityDetonator

The invention provides an electronic ignition delay detonator. The electronic ignition delay detonator comprises an electronic control module, an electric ignition powder head, a pyrotechnic delay body and a base detonator, wherein the electric ignition powder head is fixedly and electrically connected with the electronic control module with an electronic password control function and an electronic timing function to form an electronic ignition piece; the electronic ignition piece and the pyrotechnic delay body are packaged in a base detonator shell; the electric ignition powder head is opposite to an open end of the pyrotechnic delay body; and the electronic ignition piece controls the electric ignition powder head to ignite the pyrotechnic delay body after delay, and the pyrotechnic delay body burns for a set time to detonate the base detonator. The electronic ignition delay detonator not only has the management and control functions of an industrial digital electronic detonator, being convenient to use, but also has the ignition reliability of a traditional delay detonator.

Owner:广西金建华民用爆破器材有限公司 +1

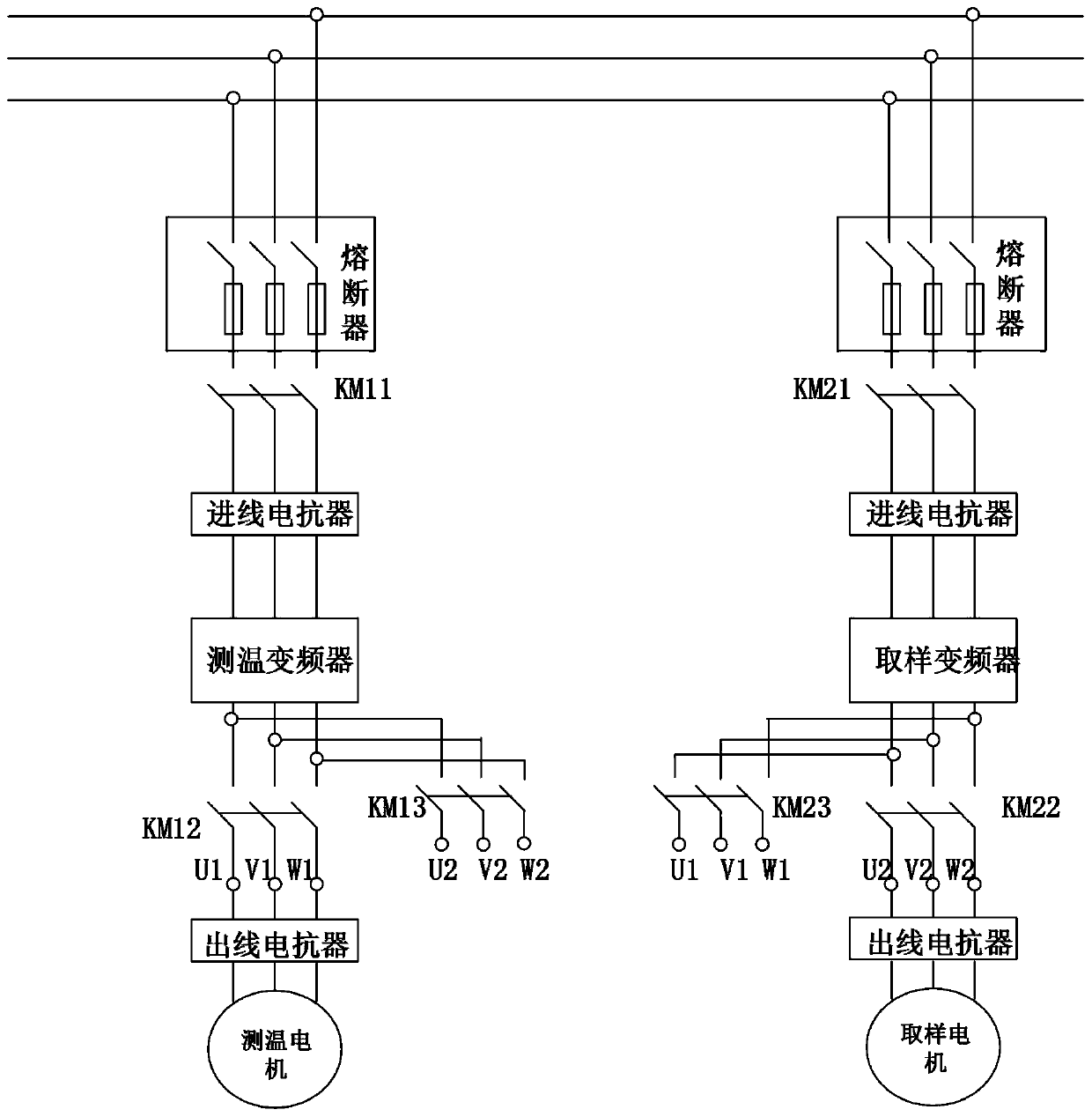

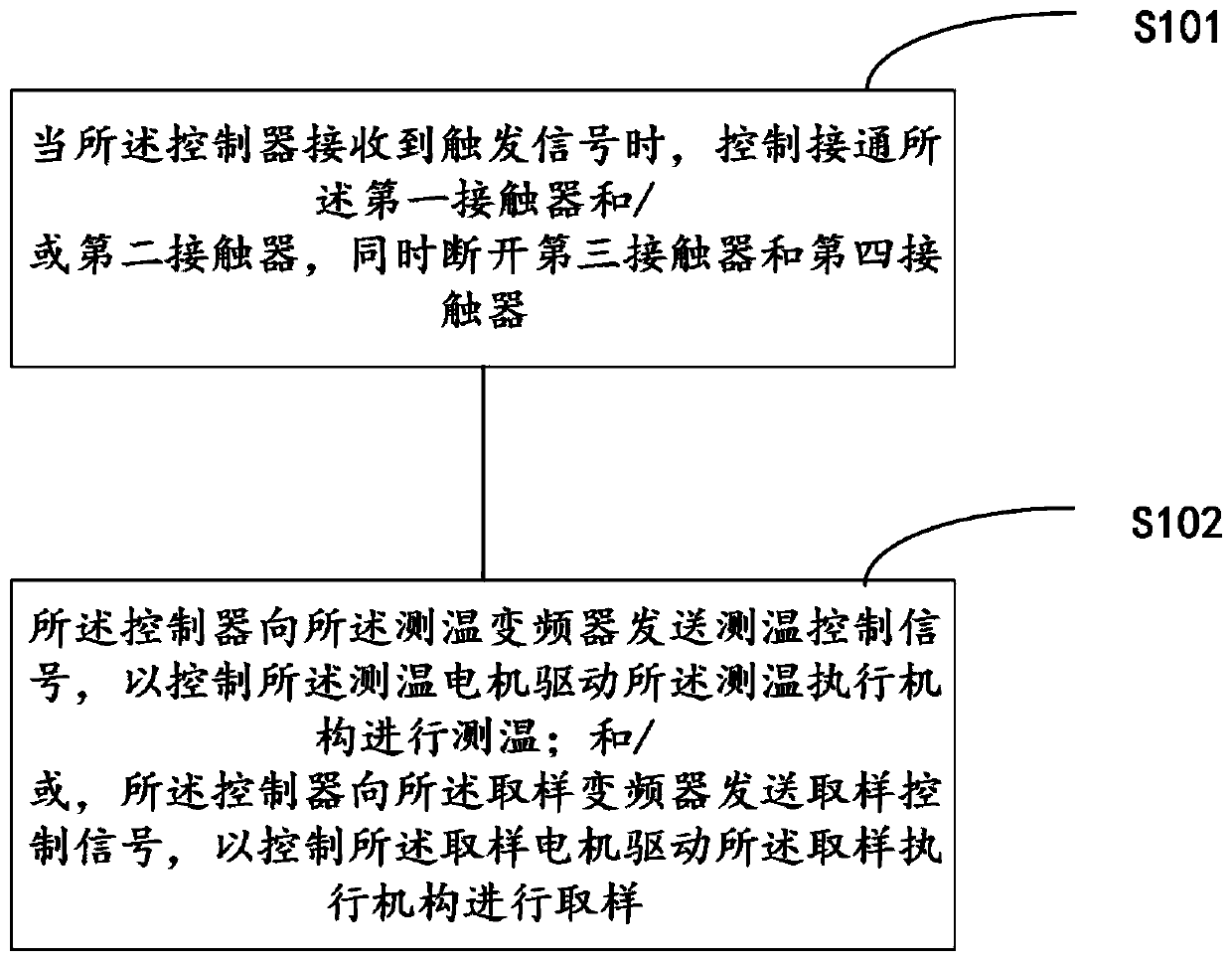

Temperature measurement and sampling control method

InactiveCN110586879AImpede operationReduce production efficiencyWithdrawing sample devicesCasting parameters measurement/indication devicesFrequency changerControl signal

The invention discloses a temperature measurement and sampling control method. The method is applied to a steel ladle temperature measurement and sampling system which comprises a controller, a steelladle temperature measurement system and a steel ladle sampling system; the method comprises the steps that when the controller receives a trigger signal, a first contactor and / or a second contactor are controlled to be switched on, and a third contactor and a fourth contactor are simultaneously switched off; the controller sends a temperature measurement control signal to a temperature measurement frequency converter to control a temperature measurement motor to drive a temperature measurement execution mechanism to measure the temperature; and / or the controller sends a sampling control signal to a sampling frequency converter to control a sampling motor to drive a sampling execution mechanism to sample. The method can avoid the situations that when the sampling frequency converter or thetemperature measurement frequency converter fails, the maintenance treatment is not timely, so that a temperature measurement or sampling gun body just stays in high-temperature molten steel, not only is the gun body burnt, but also a molten steel car is prevented from running, and the production efficiency is reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Surface treatment process of engine body in engine refabrication process

The invention discloses a surface treatment process of an engine body in an engine refabrication process and belongs to the technical field of engine refabrication. The surface treatment process comprises the steps of firing the engine body to make combustible in attachments on the surface of the engine body burnt thoroughly and noncombustible in the attachments hardened and sintered; carrying out shot blasting treatment on the fired engine body to smash the noncombustible on the engine body, and to simultaneously remove an oxide layer on the surface of the engine body; carting out shot cleaning on the engine body; flushing the engine body by using inflaming retarding kerosene; placing the engine body in a cleaning liquid, utilizing an ultrasonic vibrator to produce ultrasonic wave for agitating water molecules and removing the inflaming retarding kerosene and greasy dirt remaining in an internal cavity of the engine body. According to the surface treatment process, the production efficiency is high, each part of the engine body can be cleaned, the process is applicable to processing on the surface of the engine body in batches, and therefore the refabrication of the engine body is facilitated.

Owner:WEICHAI POWER CO LTD

Fabrication process of nixing pottery with chain

The invention discloses a fabrication process of nixing pottery with a chain. The fabrication process comprises the steps of: preparing a blank, molding a blank body, drying the blank body and burning the blank body, wherein the step of molding the blank body is performed for twice, the step of molding the blank body for the first time is as follows: twisting and kneading the prepared blank into circular rings with fractures, orderly sleeving a plurality of circular rings into a group of chain blank bodies, and cutting the circular rings at two ends of the chain blank bodies to finish fabrication of the chain blank bodies, the step of burning the blank body is performed for twice, the step of burning the blank body for the first time is as follows: putting the dried chain blank bodies into a kiln to burn, the step of burning the blank body for the second time is as follows: preparing into an apparatus blank body from the prepared blank, and sleeving the chain blank bodies burnt for the first time on the apparatus blank body to finish fabrication of the chain apparatus blank body, and the step of burning the blank body for the second time is as follows: putting the dried chain apparatus blank body into the kiln to burn. According to the invention, the chain blank body is burnt for twice, so that the rate of finished products is greatly improved.

Owner:钦州市奇点坭兴陶有限公司

Preparation method of abrasion-resistant ceramic glaze

The invention discloses a preparation method of an abrasion-resistant ceramic glaze. The abrasion-resistant ceramic glaze comprises a green body and a glaze adhered to the outer surface of the green body, wherein the glaze is prepared from the following raw materials in parts by weight: 95 to 100 parts of a base glaze, 3 to 5 parts of an abrasion-resistant agent and 0.3 to 0.8 part of a glaze conditioning agent; the glaze conditioning agent comprises sodium carboxymethylcellulose and sodium tripolyphosphate; and the mass ratio of the sodium carboxymethylcellulose to the sodium tripolyphosphateis 1: 3. According to the preparation method of the ceramic glaze prepared in the invention, the ceramic glaze is smooth and compact in surface, high in glaze hardness and high in abrasion resistance, and a ceramic piece product glaze body burnt at high temperature is good in combination and high in heat stability.

Owner:江西省正大陶瓷有限公司

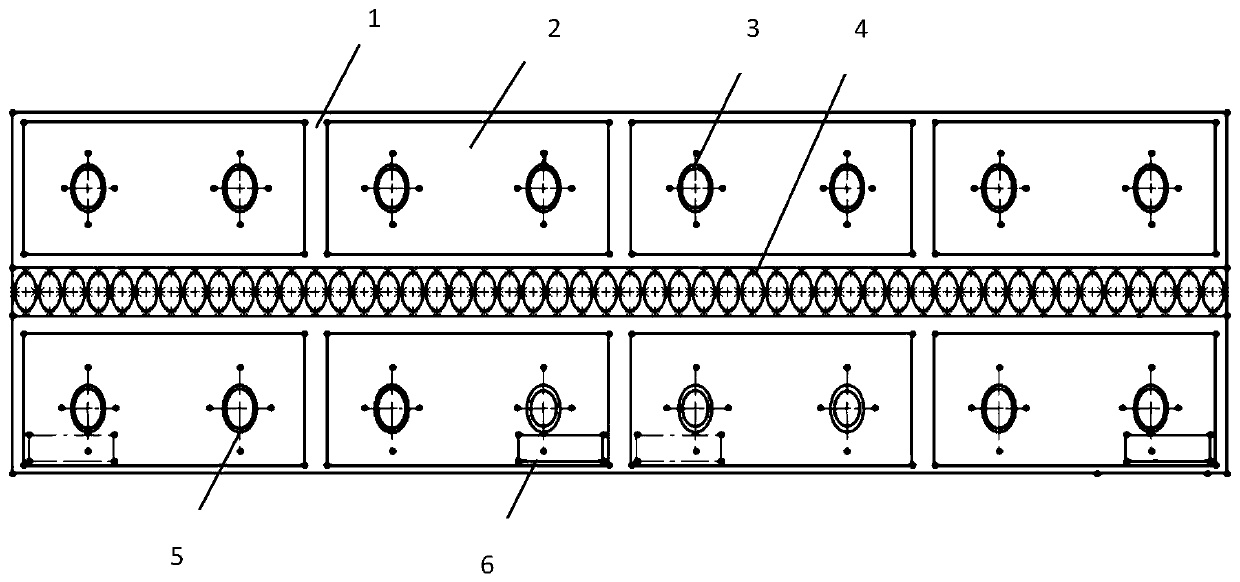

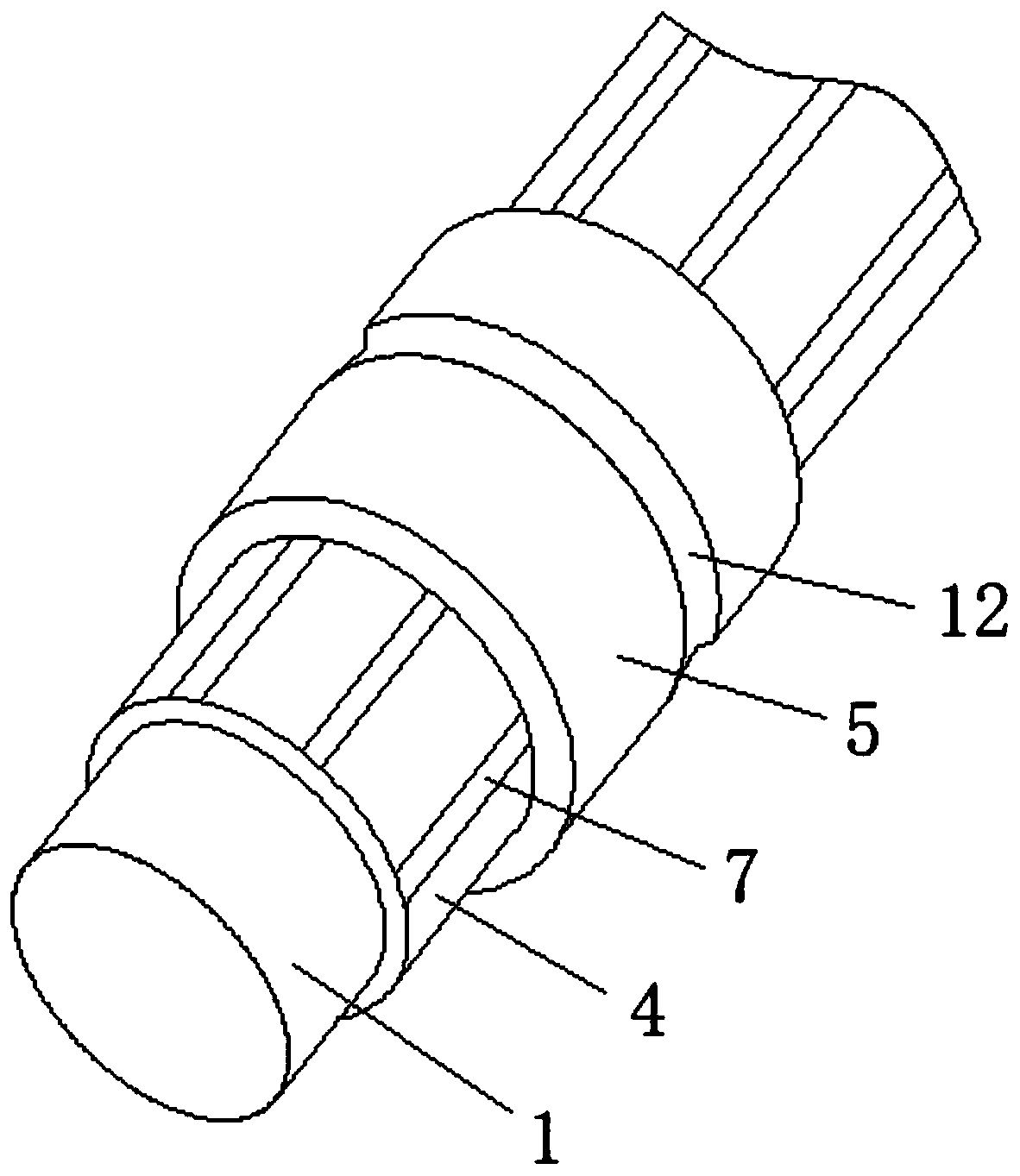

Adjustable ceramic roller kiln nozzle layout structure

InactiveCN111412746AChange the layoutSpeed up the flowFurnace typesStructural engineeringBody burning

The embodiment of the invention discloses an adjustable ceramic roller kiln nozzle layout structure. The adjustable ceramic roller kiln nozzle layout structure comprises a kiln body, a roller way arranged in the kiln body, upper nozzles and lower nozzles, wherein the upper nozzles and the lower nozzles are arranged in the kiln body and symmetrically arranged on the left side and the right side ofa kiln body burning zone; the upper nozzles are positioned above the roller way; the lower nozzles are positioned below the roller way; and the upper nozzles and the lower nozzles are in one-to-one correspondence and are arranged symmetrically up and down. According to the adjustable ceramic roller kiln nozzle layout structure, the layout mode of original nozzles is changed, so that gas turbulenceinside a kiln is enhanced, gas flowing is accelerated, the temperature difference is reduced, and therefore the uniformity of a temperature field is improved, the heat transfer rate is increased, andthe quality of a ceramic product is improved.

Owner:GUANGDONG UNIV OF TECH

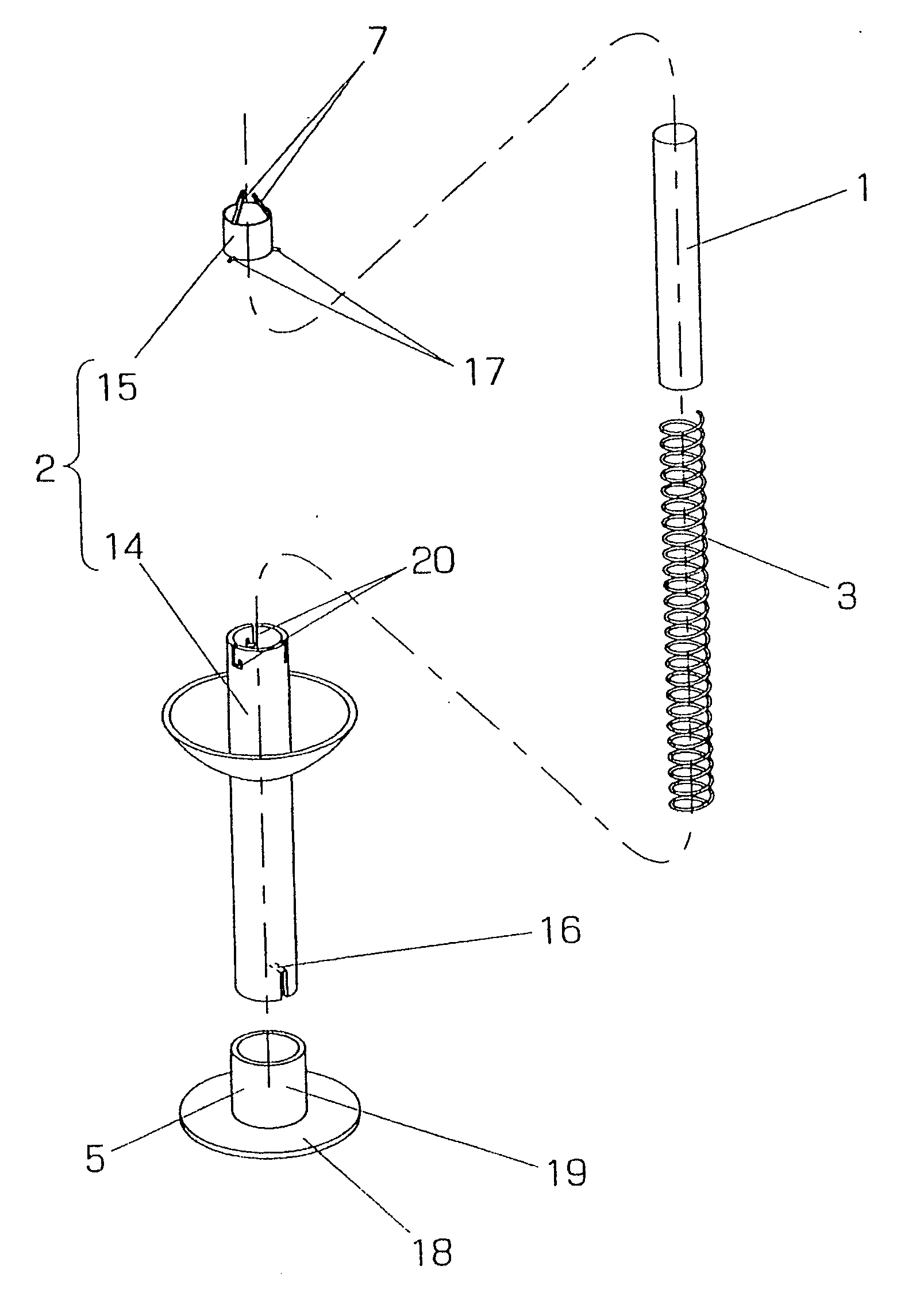

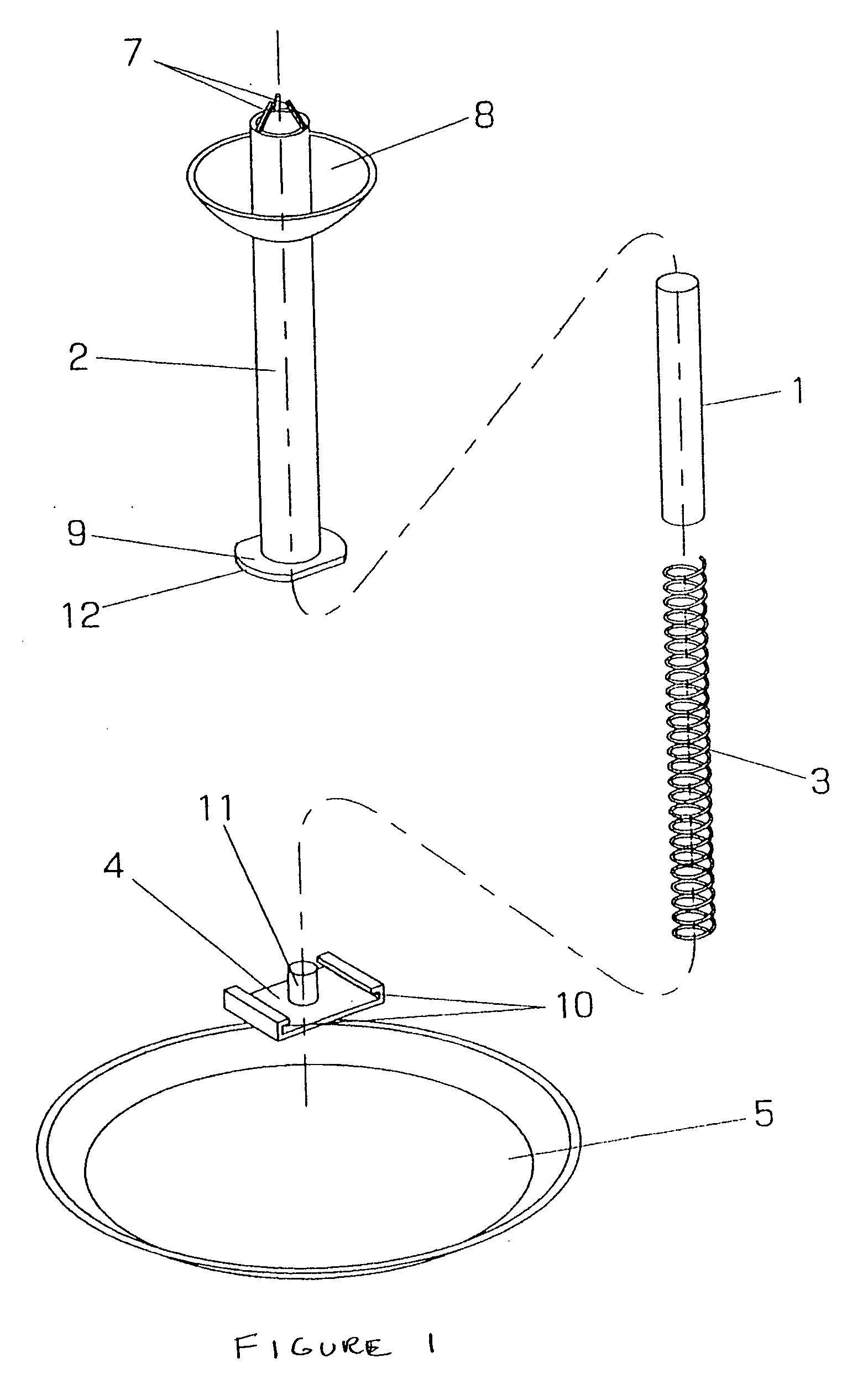

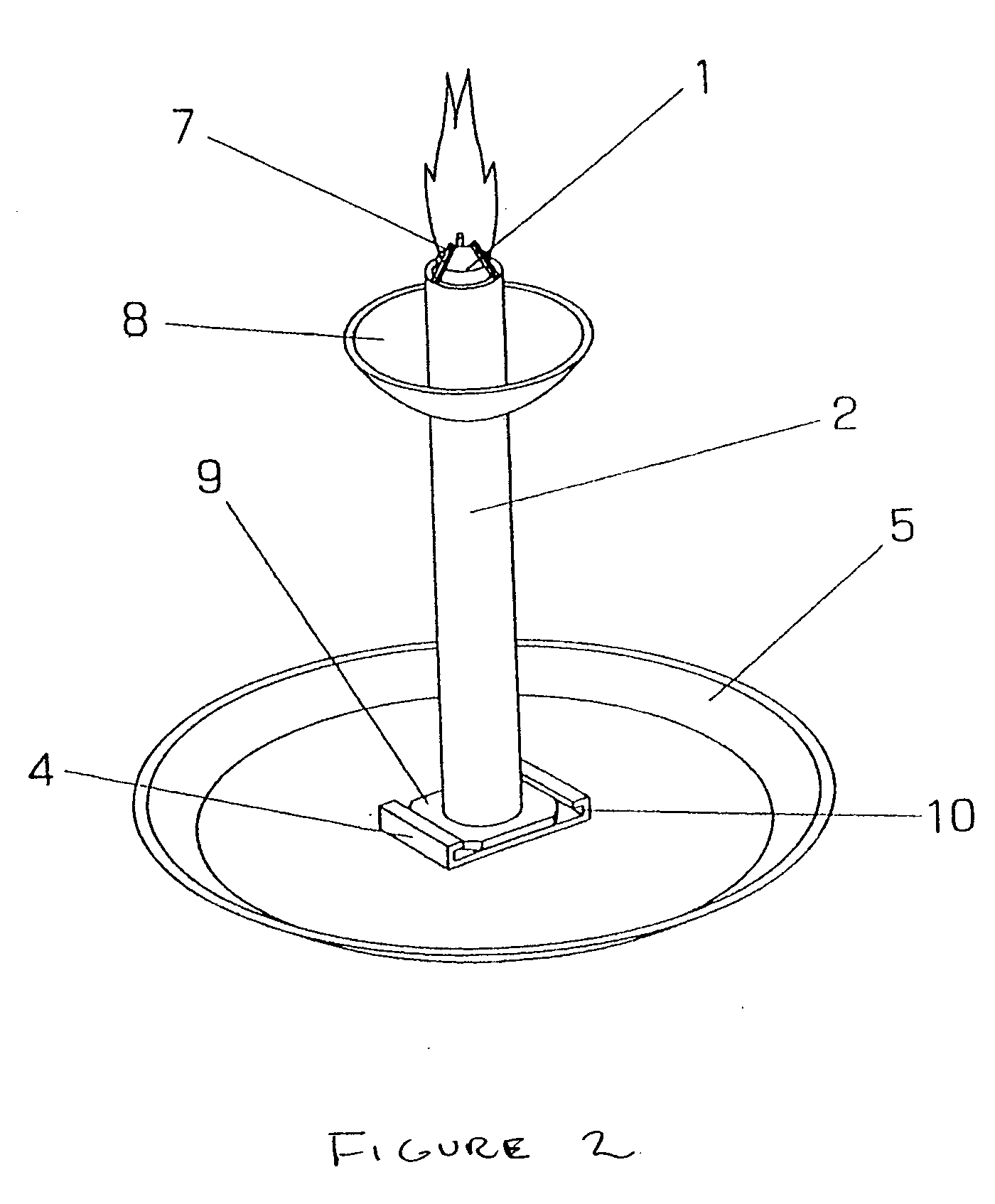

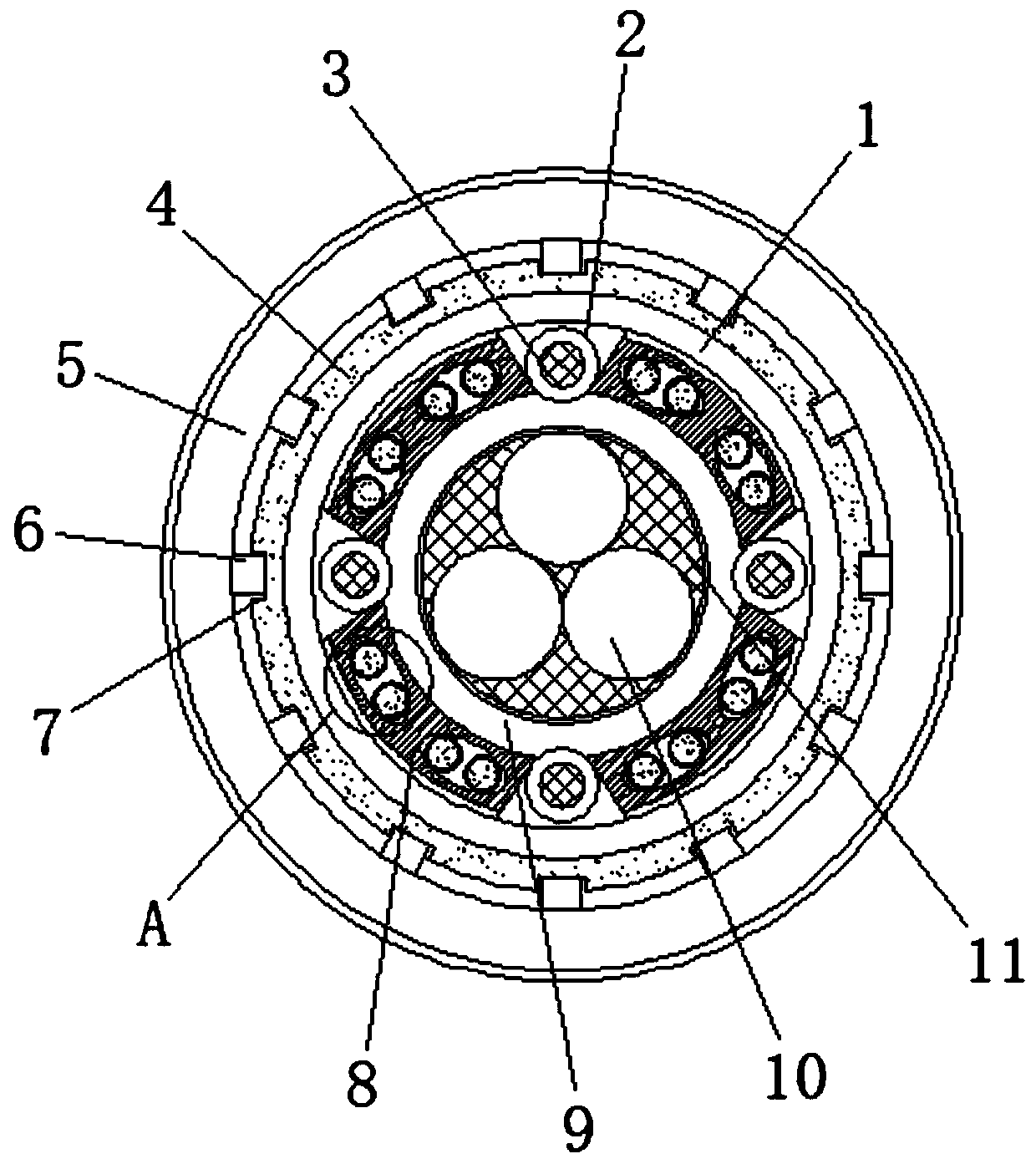

Combustion body which produces a multi-colored flame

InactiveUS20060110696A1Avoid spreadingAvoid distractionFuel lightersCapillary burnersCombustionBody burning

A cylindrically shaped combustion body of several metals or compounds like alkaline, metal or copper, which when burned produce multi-colored flames without a wick or liquid contents, and holds the flame in a stable position. As the cylindrically shape combustion body burns up, a spring mechanism pushes it upward through a tube, and a claw-like restraining device at the top of the tube keeps the combustion body from emerging out of the tube. Thus, the tip of the combustion body is held just above the rim of the tube, and the flame remains in a constant position, even as the combustion body burns shorter.

Owner:WILSON RAYMOND

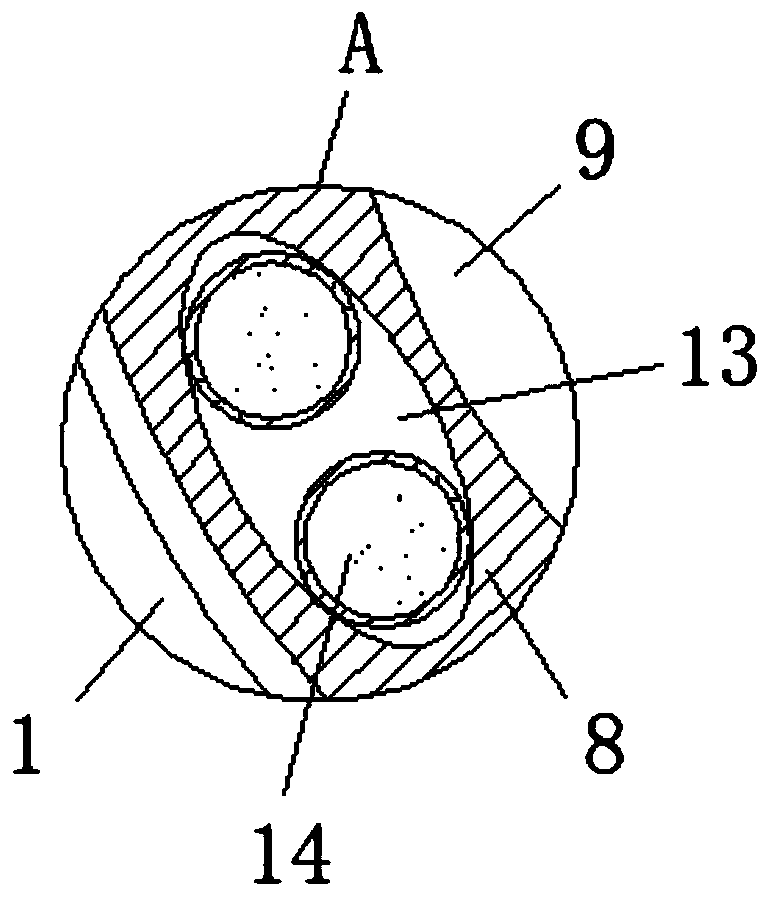

Vehicle-mounted data cable

PendingCN111564255AElasticImprove protectionInsulated cablesCommunication cablesIn vehicleStructural engineering

The invention discloses a vehicle-mounted data cable, and belongs to the technical field of data cables. The data cable comprises a cable main body, a first flame-retardant layer is arranged in the cable main body, a second flame-retardant layer is bonded to the inner wall of the first flame-retardant layer, four flexible adhesive tapes are fixedly connected in the first flame-retardant layer, anda plurality of cavities are arranged in the first flame-retardant layer. According to the vehicle-mounted data cable, the first flame-retardant layer, the second flame-retardant layer, the cavities,an inner wrapping body and a filling layer are arranged; the characteristic of different fire resistance of the first flame-retardant layer and the second flame-retardant layer is utilized; the cablemain body can be subjected to multi-stage flame retardance; the cavities are matched with the inner wrapping body, so that the cable body has certain elasticity, wires can be well protected, meanwhile, when the cable body burns, a fire extinguishing agent in the inner bag body can be diffused by the broken cavity through air, the burning range is effectively reduced, electronic equipment and a human body can be further protected, and potential safety hazards are reduced.

Owner:ANHUI TIANXING OPTICAL FIBER COMM EQUIP

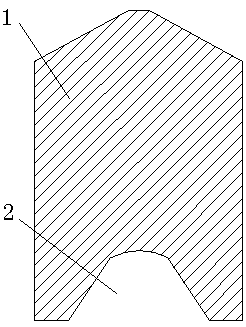

Bird-repellent bomb specially for airport

InactiveCN109169627AImprove the sparkle effectSimple structureAmmunition projectilesAnimal repellantsBody burningBody burnt

The invention discloses a bird-repellent bomb specially for an airport, which comprises a bomb body and a propellant, wherein the bomb body is a truncated cone-cylinder, the upper half part has a truncated cone structure and the lower half part has a cylinder structure; a layer of moisture-proof coating coats the outer surface of the bomb body; the center of the bottom surface of the cylinder structure is provided with an inner concave propellant cavity; the propellant cavity, on the whole, is a groove body in a truncated cone structure with a small upper part and a large lower part, and the propellant cavity is filled with the propellant; and the port of the propellant cavity is sealed by using non-woven fabric. According to the bird-repellent bomb disclosed in the invention, the overallstructure of the bomb body is improved, the resistance in the rising process of the bomb body is reduced, and the flying speed is improved; as the outer surface of the bomb body is coated with celluloid gum, moisture prevention is achieved, and the flammability is improved; the propellant is sealed in the propellant cavity by using the non-woven fabric dipped in the celluloid gum, the ignition rate of the propellant is increased, the explosion and scintillation effects of the bird-repellent bomb are effectively improved, visible light is generated, and as birds are afraid of the explosion andscintillation visible light, a bird-repellent role is played; and after the whole bomb body burns, no residual exists, the environment is protected, environmental pollution is reduced, the explosion and scintillation rate is high, and bird-repellent effects are improved.

Owner:唐山市安航电子科技有限公司

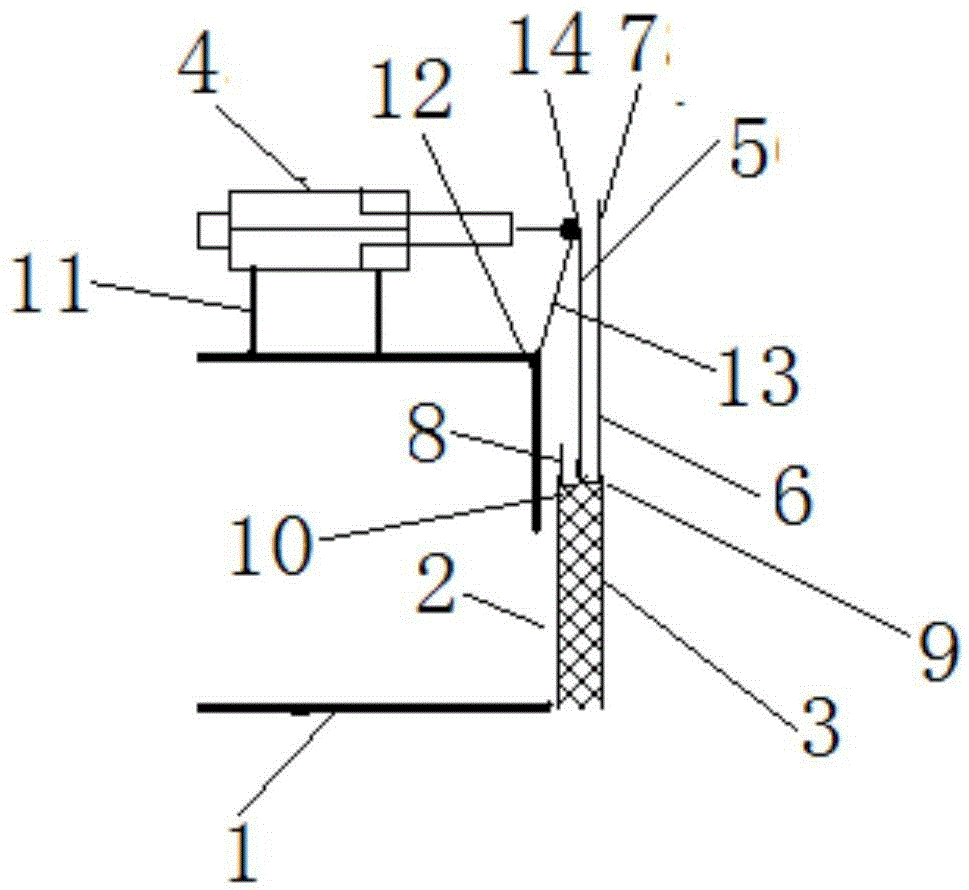

Heating furnace structure

InactiveCN105605925ASafe and reliable performanceReduce the temperatureFurnace componentsBody burningHeating furnace

The invention provides a heating furnace structure applied to the field of steel and iron smelting equipment. The heating furnace structure comprises a furnace body (1), wherein the furnace body (1) adopts a hollow structure; a furnace mouth (2) is formed in the furnace body (1); a furnace door (3) is arranged outside the furnace mouth (2); a telescopic part (4) is arranged on the furnace body (1); one end of a chain (5) is connected with the telescopic part (4); the other end of the chain (5) is connected with the furnace door (3); the telescopic part (4) adopts a structure capable of driving the furnace door (3) to lift through the chain (5); a guard plate (4) is arranged on the furnace door (3). The heating furnace structure of the invention has the advantages that the structure is simple; the problem that flame in the furnace body burns out the chain outside the furnace body and furnace parts outside the furnace body can be effectively eliminated; the phenomenon that the furnace door cannot be opened as well as a production accident resulting in a halt in production can be avoided; the production efficiency is improved effectively; the production cost is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

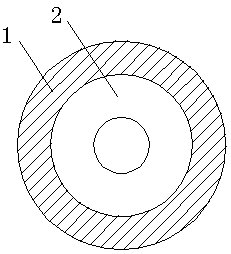

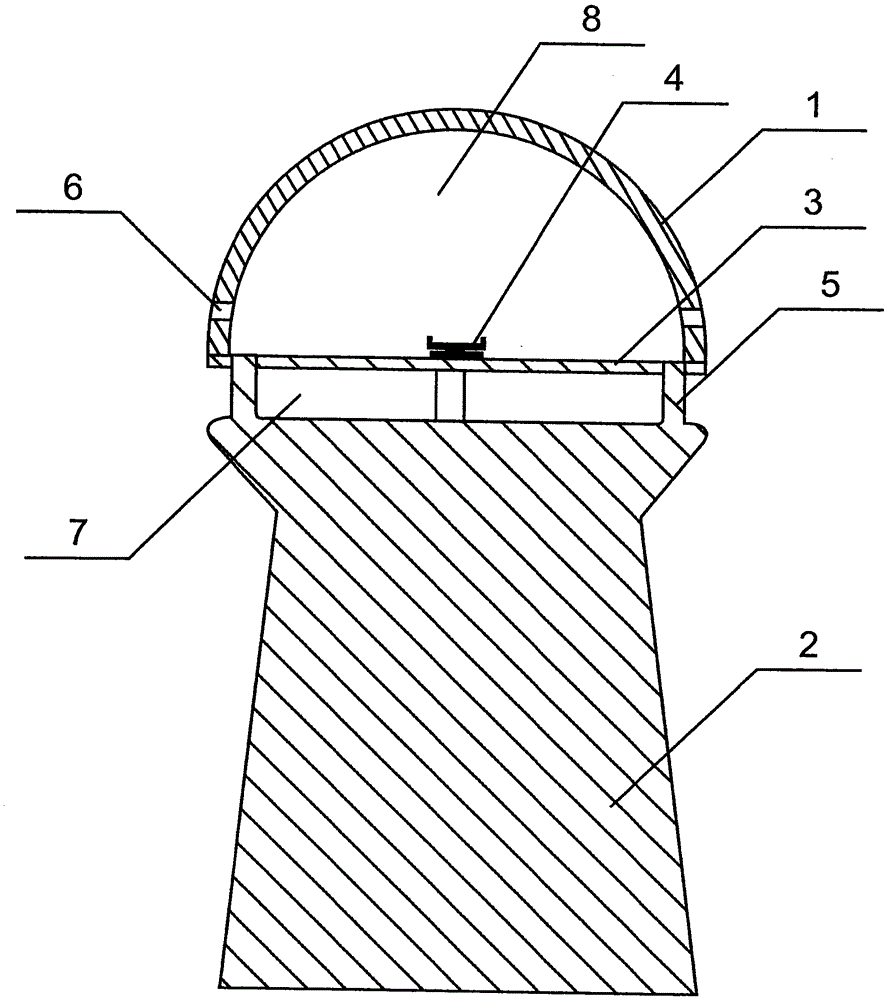

Combined backflow incense burner

The invention provides a combined backflow incense burner and relates to the technical field of daily necessities. The combined backflow incense burner is characterized in that a base, a ventilation net and an incense burner upper cover are organically combined and is composed of the incense burner upper cover, the base, the ventilation net, an incense containing bracket, a support, gas guide holes, a ventilation and backflow space and a burning and convection space, wherein the upper end of the base is fixedly connected with the lower end of the support, the upper end of the support is fixedly connected with the ventilation net, the central position of the ventilation net is fixedly connected with the incense containing bracket, the incense burner upper cover is arranged on the ventilation net, the gas guide holes are formed in the incense burner upper cover, the ventilation and backflow space is formed between the base and the ventilation net, and the burning and convection space is formed between the incense burner upper cover and the ventilation net. The combined backflow incense burner is used for incense body burning and is unique and novel in concept, simple and ingenious in structure, convenient and quick to use, stable and reliable in effect, easy to manufacture, low in cost and convenient to popularize.

Owner:黄耀生 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com