Combined backflow incense burner

A combination and incense burner technology, which is applied in the field of daily necessities, can solve the problems of concentrated smoke emission, not beautiful enough, and unable to spread evenly, and achieve the effect of preventing fire hazards, overall beautiful appearance, and firm support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

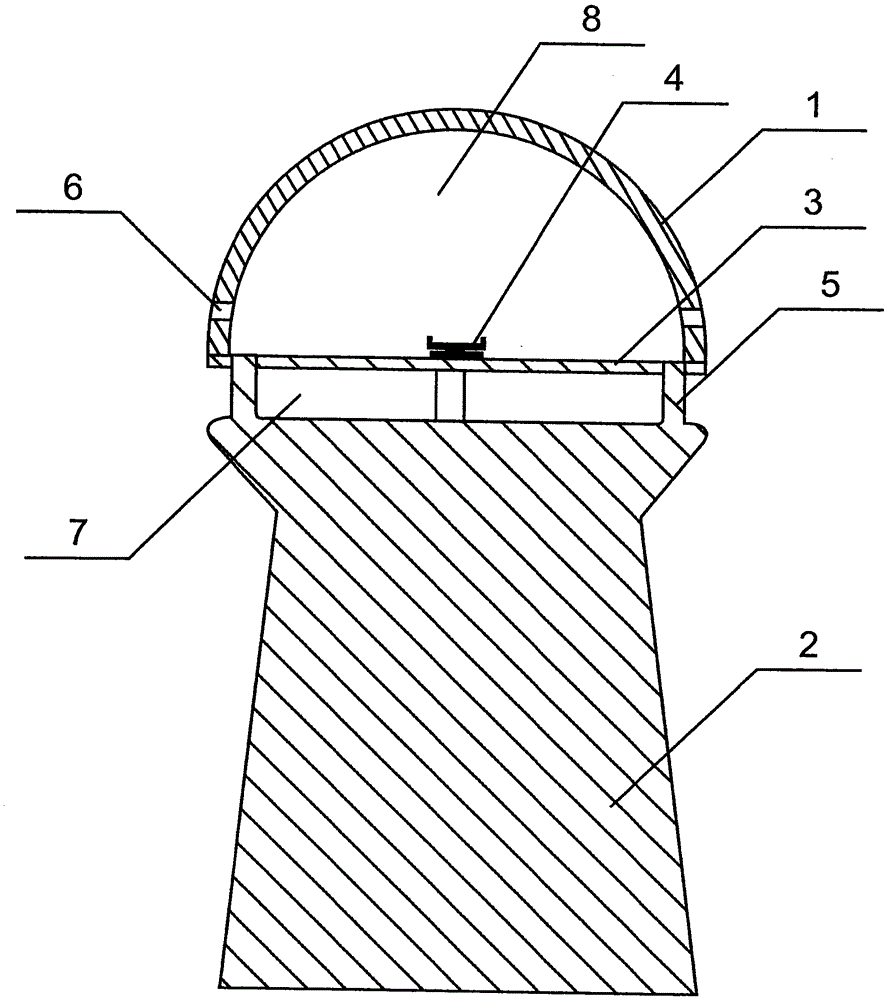

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0023] A combined backflow incense burner, which is composed of an incense burner cover 1, a base 2, a ventilation net 3, an incense holding bracket 4, a bracket 5, an air guide hole 6, a ventilation and backflow space 7, and a combustion and convection space 8;

[0024] The combined backflow incense burner, the upper end of its base 2 and the lower end of the support 5, the upper end of the support 5 and the ventilation net 3, and the central part of the ventilation net 3 and the incense holder 4 are all fixedly connected, and the top of the ventilation net 3 is placed There is an upper cover 1 of the incense burner, and the upper cover 1 of the incense burner is provided with an air guide hole 6, and a ventilation and backflow space 7 is formed between the base 2 and the ventilation net 3, and a combustion and convection space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com