Combustion body which produces a multi-colored flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

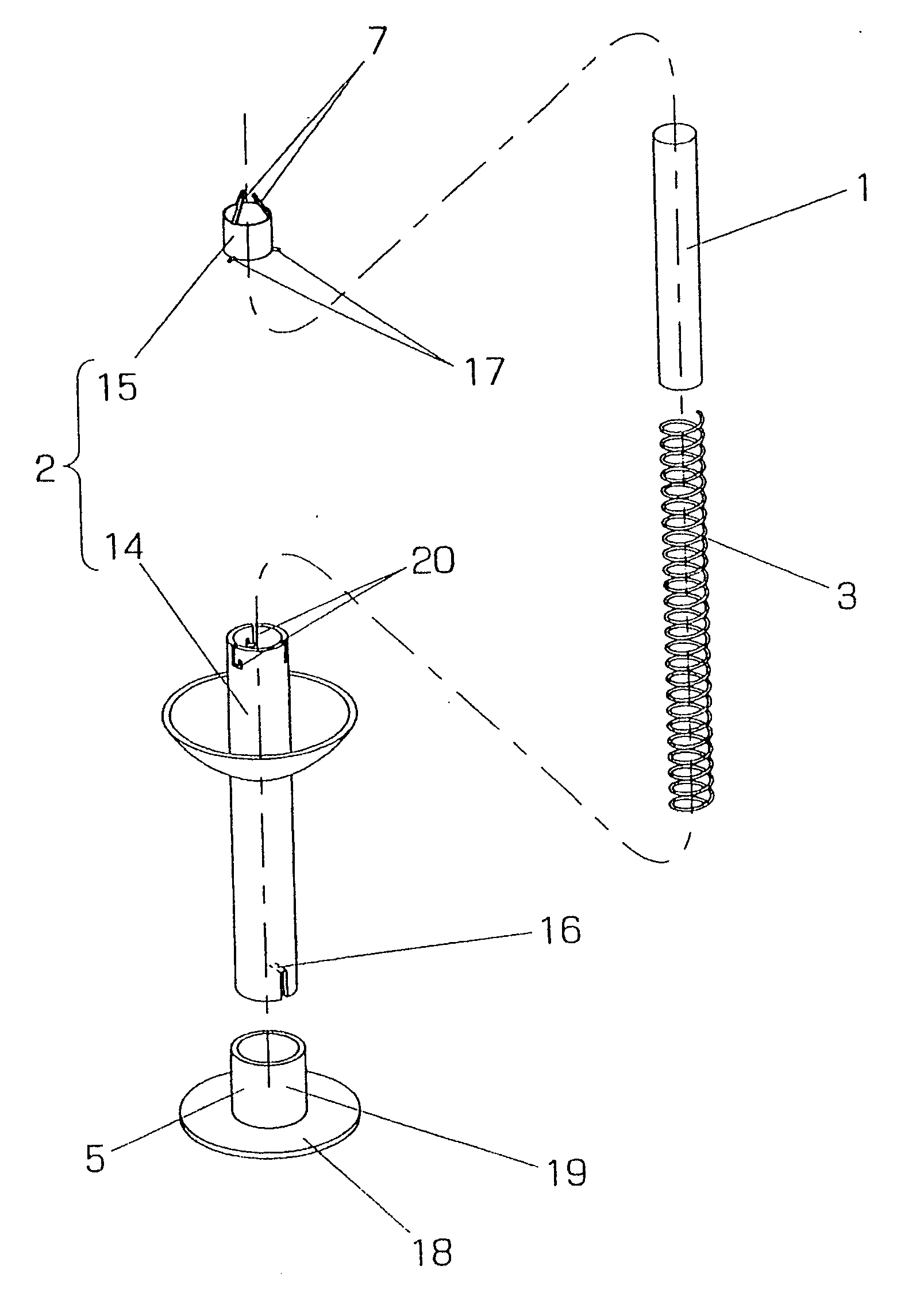

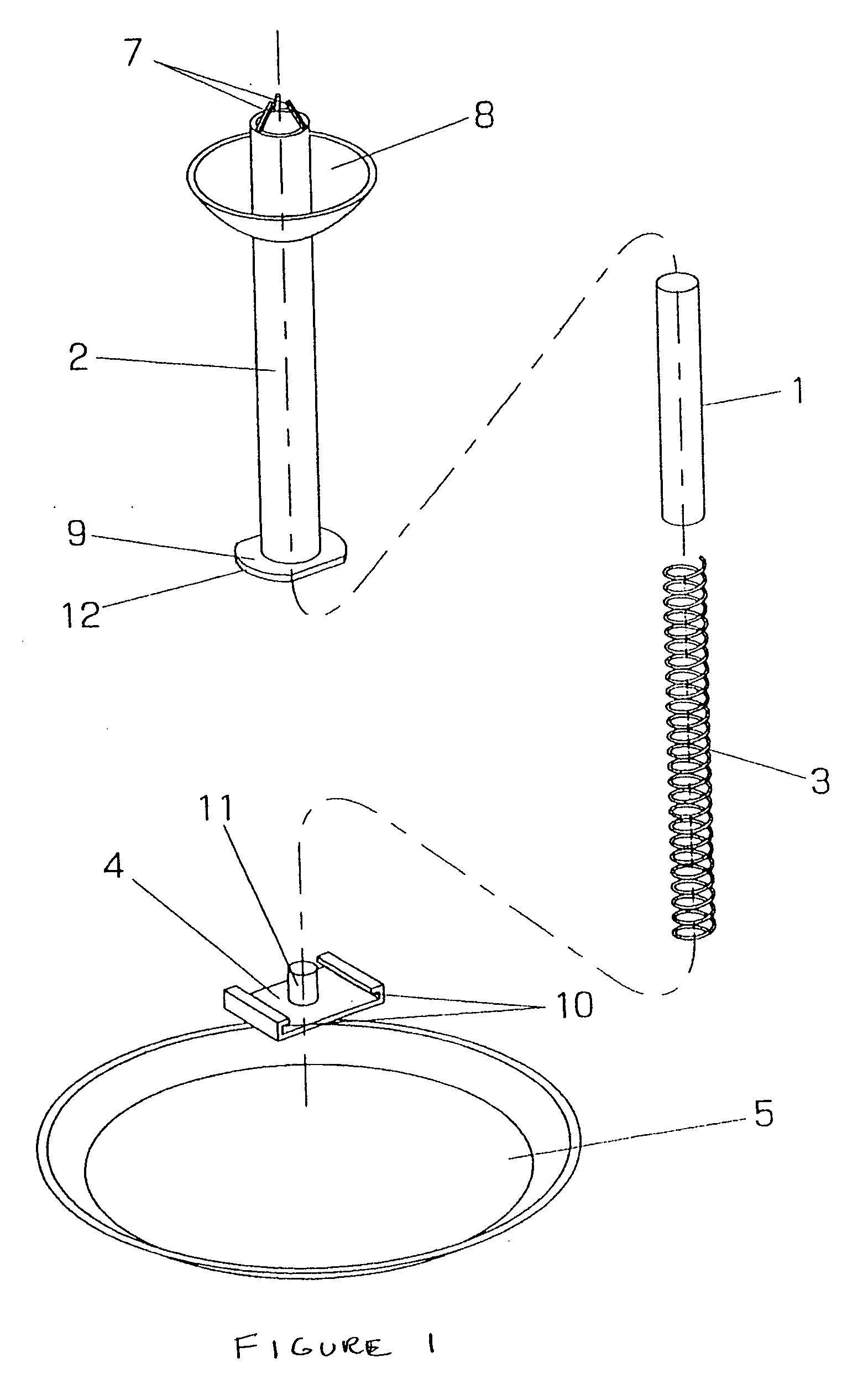

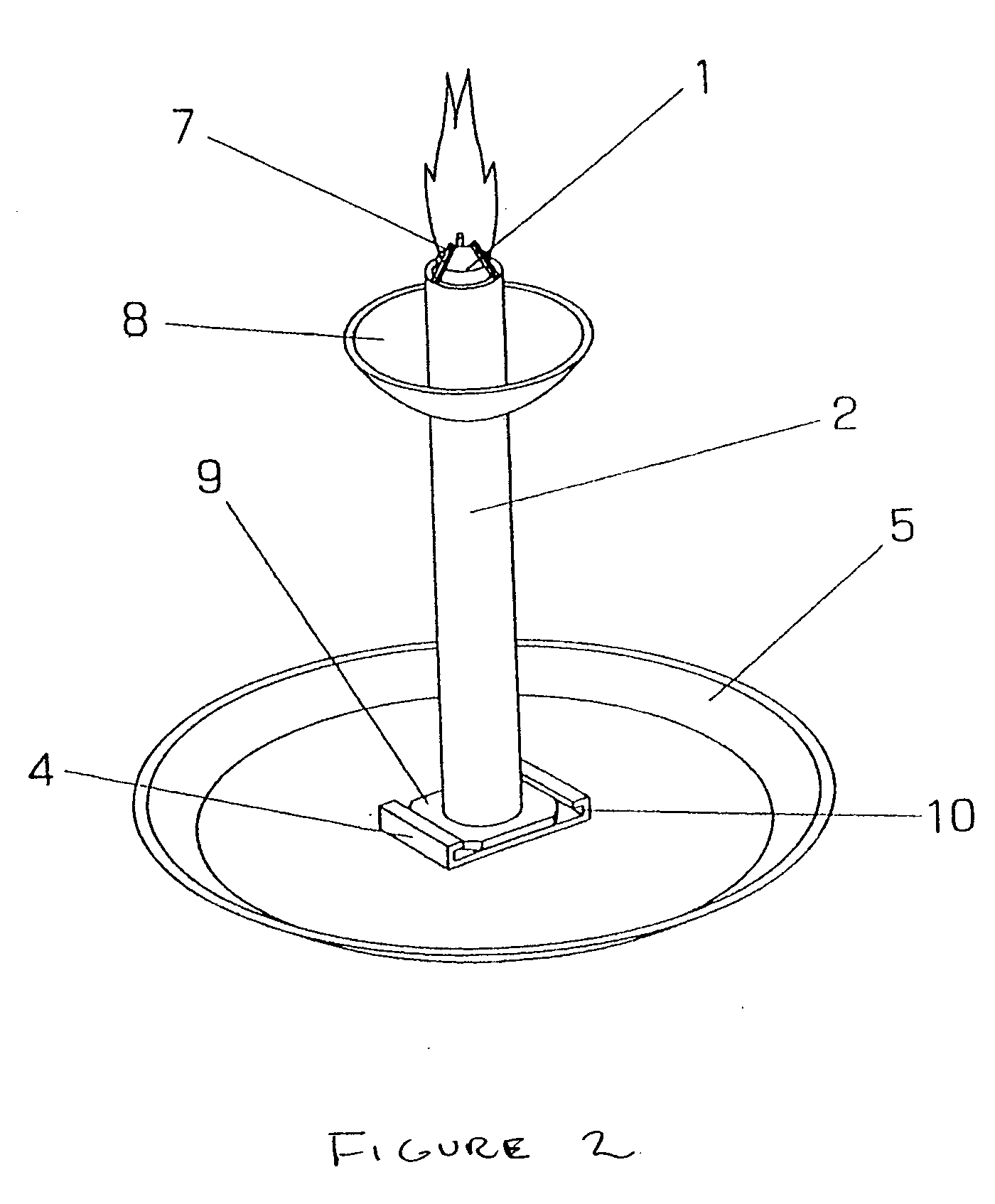

second embodiment

[0020] In the above-mentioned example of the second embodiment, the cap 15 is removed and the spring 5 and the combustion body 1 are inserted in the tube 14, and the combustion body 1 is pushed down into the tube 14 by the cap 15. The cap 15 is connected with the main body by inserting the projections 17 of the cap 15 in L-shaped slots 20 and then rotated. Because the cap 15 is pushed up by the expansion power of the spring 3, the projections 17 will be fixed in slots 20. Thus, the cap 5 will not be pushed off. The tube 14 can be held by hand or placed on the stand 5. The tip of the combustion body 1 located just above the rim of the tube 14 can be ignited. In the alternative embodiment, the stand 5 has a support pipe 19 and flat disc 18 welded together. The tube 14 can be placed inside pipe 19 for support.

third embodiment

[0021]FIG. 5 shows a third embodiment in which the main body of tube 2 is lengthened, and the spring base 5 can be fixed in the middle of the tube 2. In this example, splinters 16 are bent internally as also shown in FIG. 4, but the splinters 16 are placed in the middle of tube 2. The reference numeral 21 represents a point on tube 2 at which splinters 16 can be placed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com