Electronic ignition delay detonator

A technology of electronic ignition and delayed detonator, which is applied in the direction of weapon accessories, blasting tubes, fuzes, etc., can solve problems such as blind fire or lost guns, accidental explosion, and electronic control module failure, so as to improve stability, reliability, and powerful Effects of resistance, high ignition reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

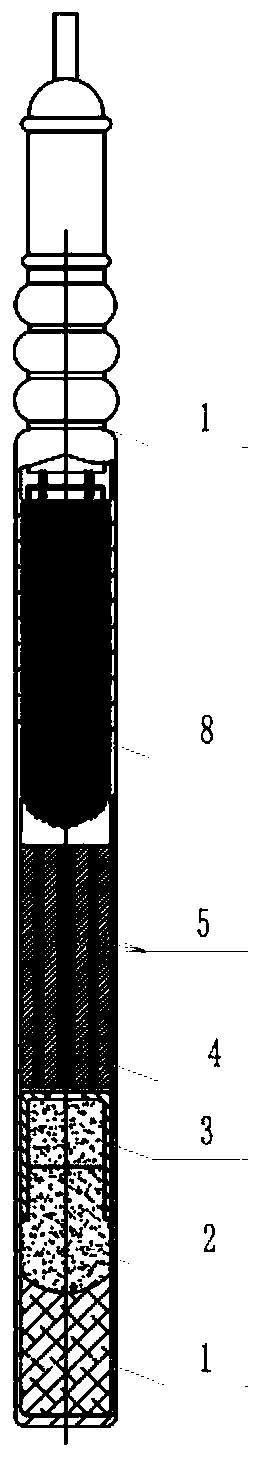

[0031] This embodiment provides an electronic ignition delay detonator, such as figure 1 As shown, it includes an electronic control module, an electric ignition charge 6, a pyrotechnic delay body 4 and a basic detonator.

[0032] The electronic control module is an electronic module composed of components made of analog circuits or digital circuits or analog circuits / digital circuits, with power supply functions, address code and password registers, communication and control functions, and energy release functions. The module is fixed and electrically connected with the electric ignition powder head 6 to form an electronic ignition part 7, and the exterior of the electronic ignition part 7 is wrapped in plastic to form a cylindrical plastic column to form a glue-sealed electronic ignition part 8.

[0033] The electronic igniter 7 has address code storage function, switch control password storage function, timing and control switch function, communication function with detonat...

Embodiment 2

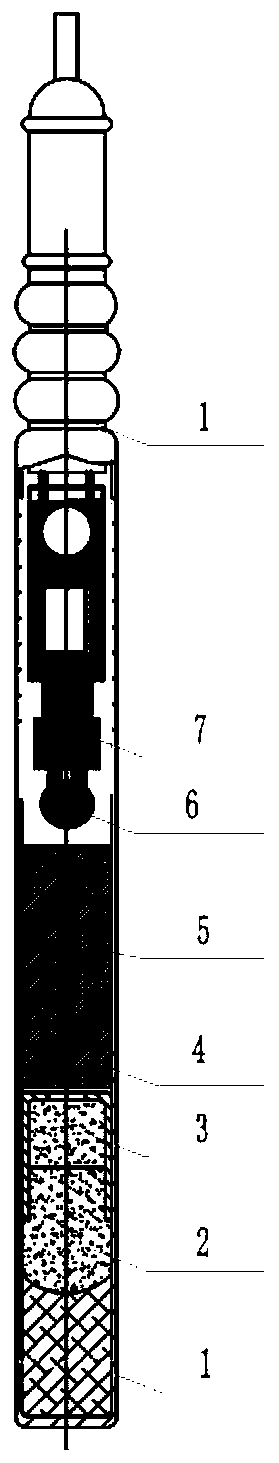

[0043] Such as figure 2 As shown, the electronic control module is fixed and electrically connected with the electric igniter tip 6 to form an electronic igniter 7, and the exterior is not wrapped with plastic. The pyrotechnic delay body 4 of the second embodiment adopts a single-core delay body. Other structures and uses are consistent with Embodiment 1.

Embodiment 3

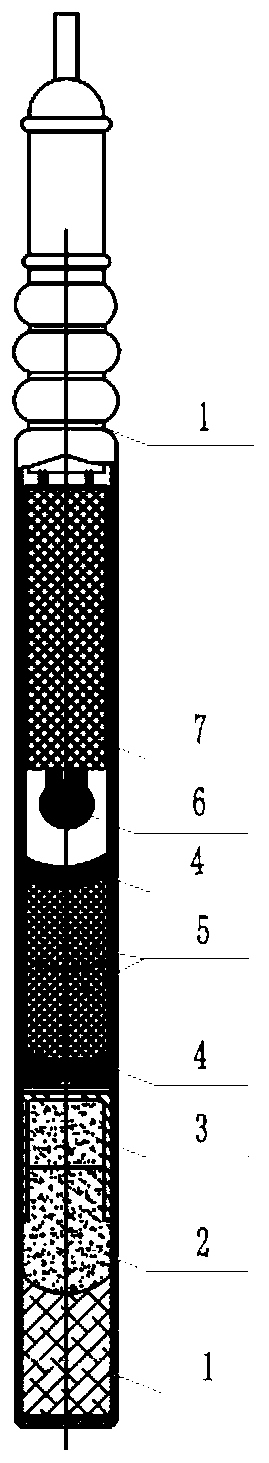

[0045] Such as image 3 As shown, the exterior of the electronic control module is wrapped in plastic to form a cylindrical plastic column, and the plastic column fills the matching gap between the electronic ignition part 7 and the base detonator shell 1 . The delay charge 5 is filled in the bottom of the closed end of the pyrotechnic type delay body 4 shell, and the delay charge 5 is opposite to the electric ignition charge head 6 . Other structures and uses are consistent with Embodiment 1. The structural assembly of the third embodiment is simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com