An offshore thermal oil steam delivery pipe

A technology for conveying pipes and thermal oil recovery, which is applied to protect pipes, hoses, pipes, etc. through heat insulation, which can solve the problems of easy damage of straight pipes and deformation of steam conveying pipes, and achieve the effect of long service life and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

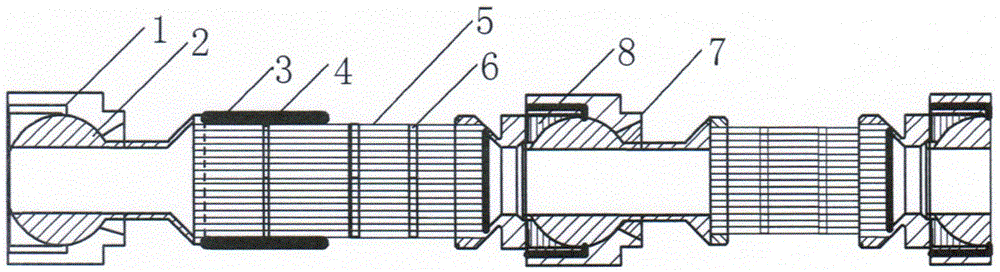

[0011] As shown in the figure, the conveying pipe is composed of multiple pipe bodies with connecting caps 1 and threaded joints 7 .

[0012] A spherical head 2 is provided in the connection cap.

[0013] A spherical gasket 8 is housed in the threaded joint.

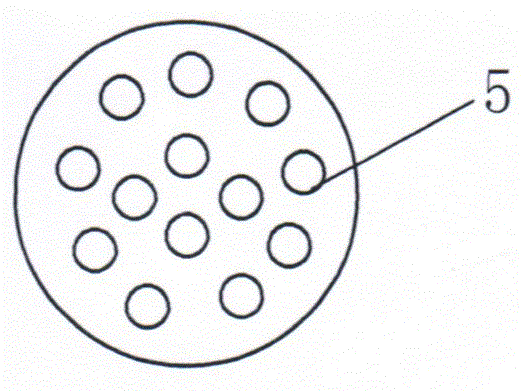

[0014] Between the connecting cap and the threaded joint, a plurality of thin air-guiding tubes 5 are set through the movable ring 6, and an insulating mineral wool felt 3 is wrapped outside the air-guiding thin tube group, and a steel wire guard 4 is wrapped outside the insulating mineral wool felt.

[0015] The thin air-guiding tubes are arranged in the conveying pipe at annular intervals, and the distance between adjacent thin air-guiding tubes is between 10 mm and 20 mm.

[0016] The thin air guide tube is a seamless stainless steel or carbon steel tubular body.

[0017] The working principle of the present invention:

[0018] Since the tube body is composed of many thin tubes, the tube diameter is small and can p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com