Rotating component for transmitting electricity, gas, liquid and rotating power during rotating

A rotary power and gas technology, applied in electrical components, flexible/rotatable wire connectors, circuits, etc., can solve the problems of small torque and power, and it is difficult to meet the power demand of large machine tools, so as to achieve the effect of meeting the power demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

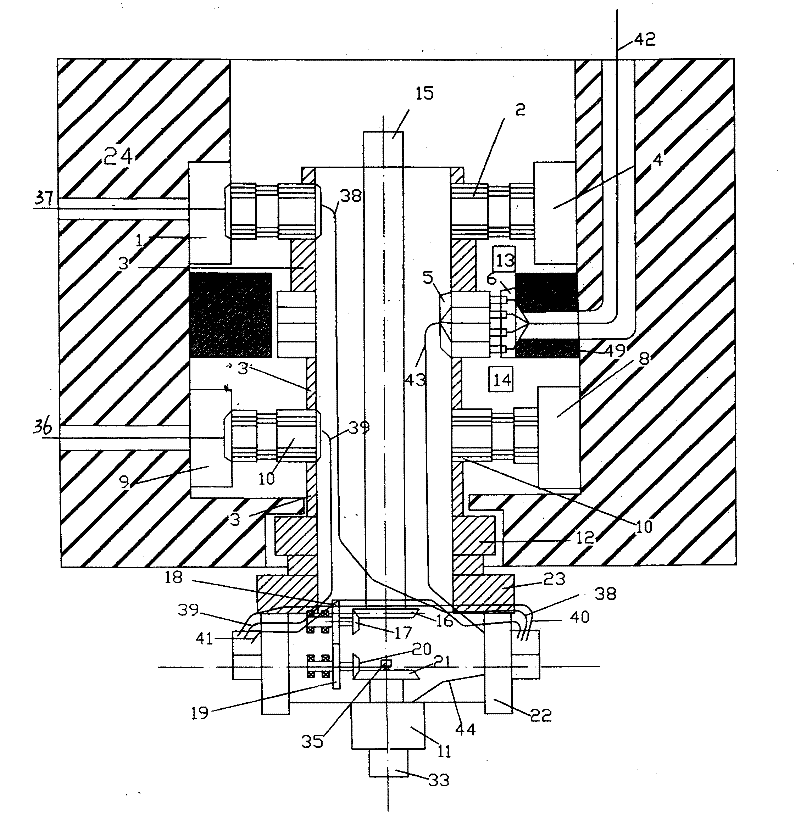

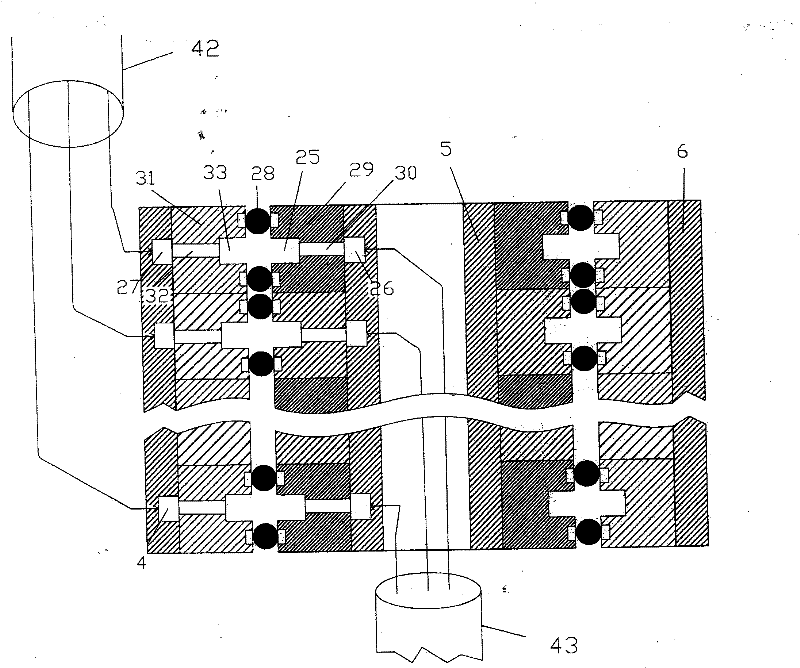

[0021] Such as figure 1 As shown, a rotating part that transmits electricity, gas, liquid and rotational power in rotation provided by the present invention includes the rotating shaft body 3 arranged in the metal shell 24, and the ram can be used as a The metal shell 24, the rotating shaft shaft body 3 is arranged on the shaft body seat 23, the rotating shaft body 3 is provided with the rotating shaft 15, and the headstock 11 swinging around the swing shaft 22 is arranged at the bottom of the rotating shaft shaft body 3 , On the spindle box 11, a spindle 33 for installing a tool is provided.

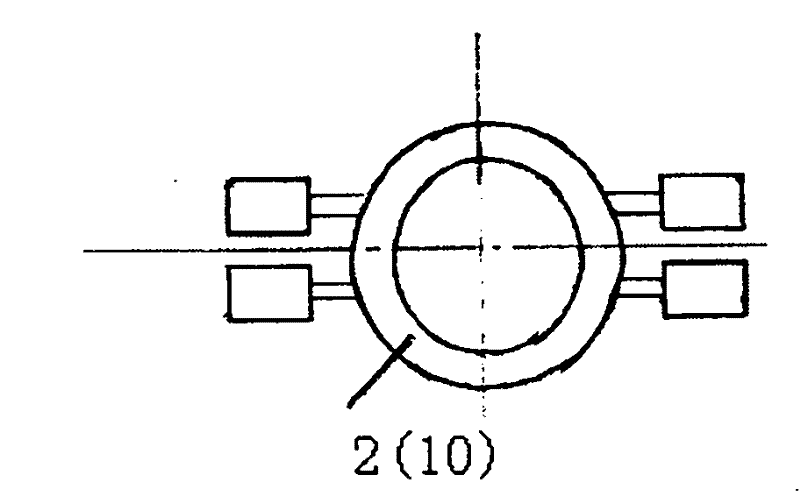

[0022] At least three layers of upper conductive slip ring 2 and lower conductive slip ring 10 are respectively set on the upper and lower parts of the rotating shaft body 3, and at least three layers of upper carbon brushes are respectively arranged on the upper and lower parts of the metal housing 24. And the lower carbon brush, the number of layers of the upper carbon brush is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com