Material conveying device applied to coal blending machine

A technology for conveying devices and materials, applied in the direction of conveyors, transportation, packaging, packaging, etc., can solve problems such as the loose molecular structure of coal, the impact on the health of workers, and damage to the production site, so as to achieve easy promotion and implementation, and control of coke quality , to reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment A material conveying device applied to a coal blender

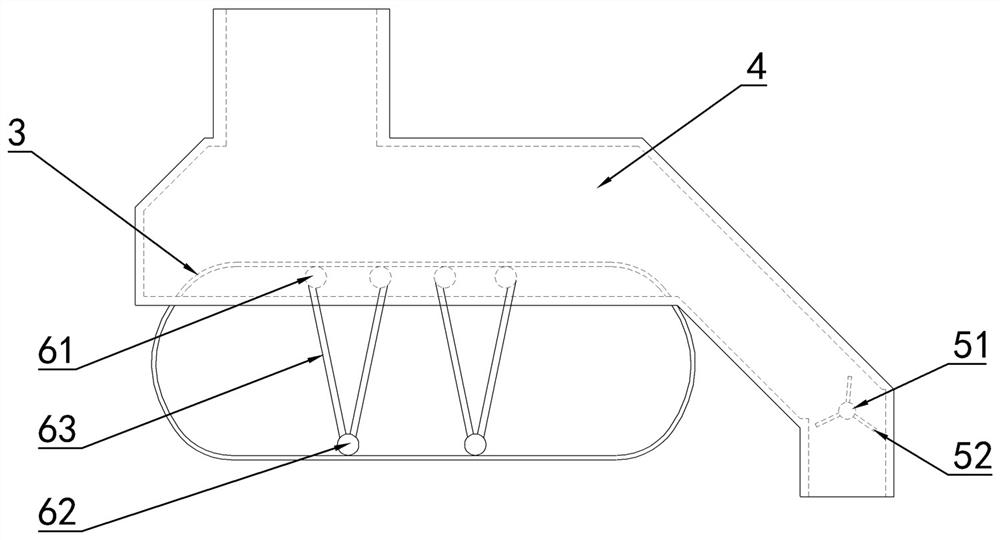

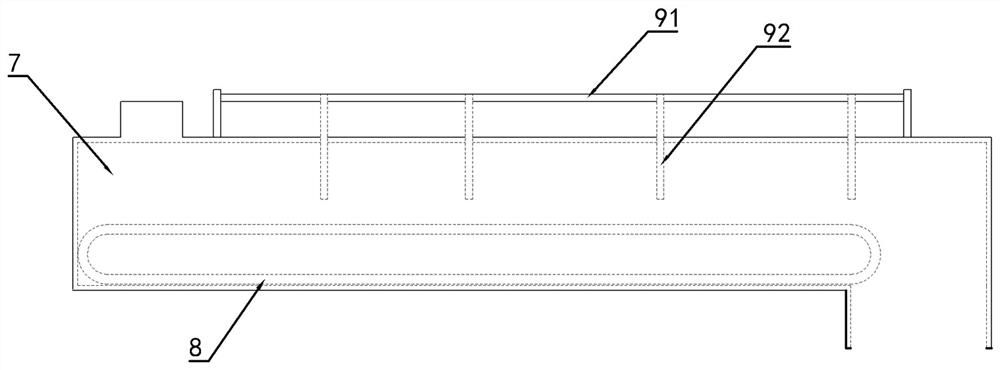

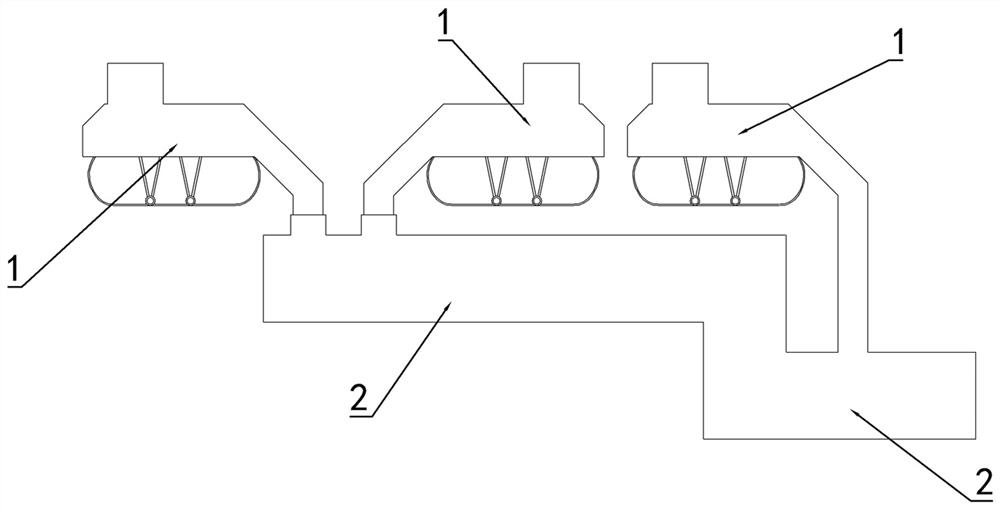

[0030] Such as Figure 1 to Figure 3 As shown, this embodiment includes at least one group of weighing mechanism 1 and material delivery mechanism 2 that cooperate with each other, wherein, the upper half of the weighing belt 3 in the weighing mechanism 1 is sealed by the sealing unit 4, and the upper half of the weighing belt 3 in the weighing mechanism 1 is sealed by the sealing unit 4, The material conveying belt 8 is arranged in the closed shell 7, and the discharge port of the sealing unit 4 is connected with the feed port of the closed shell 7 in the material transport mechanism 2, and the whole device forms a closed working environment. In this embodiment, different single types of coal can be weighed and transported in a completely closed environment, so as to avoid the generation of dust in the coal blending work and reduce the damage and pollution of the work site by coal dust.

[0031] 1. Wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com