Biomass gas-carbon co-production rotary gasification furnace

A technology of biomass gas and gasifier, applied in the direction of gasification process, biofuel, coke oven, etc., can solve the problem of energy-saving and environmental protection production concept of renewable energy production line, lack of uniform internal gas treatment, production line process completion time Lengthening and other problems, to achieve the effect of reducing gas homogenization process, high gas homogenization performance, and shortening production hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

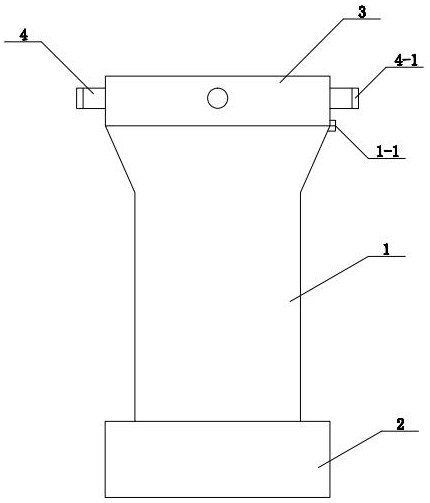

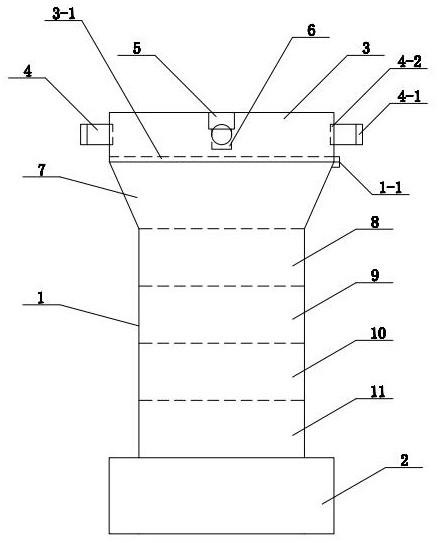

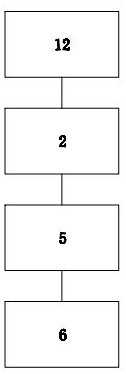

[0019] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a gas-carbon cogeneration furnace body 1, a control base 2, an upper cover body 3, an air outlet pipe 4, a motor 5, a propeller 6, a drying chamber 7, and a pyrolysis chamber 8 , oxidation bin 9, reduction bin 10, ash outlet bin 11, control computer 12; hinge 1-1, sealing ring 3-1, connection nozzle 4-1, flue gas filter screen 4-2; described carbon cogeneration The lower part of the furnace body 1 is provided with a control base 2, and the carbon cogeneration furnace body 1 is fixed on the control base 2, and the upper cover body 3 is installed on the upper part of the carbon cogeneration furnace body 1, and the upper cover body 3 is provided with a gas outlet pipe at the front, rear, left, and right sides 4. A motor 5 is installed above the inside of the upper cover body 3, and a propeller 6 is rotated and connected to the bottom of the motor 5; the interior of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com