Limited-antimony-content and antimony-free modacrylic / aramid blends for improved flash fire and arc protection

a technology of antimony-free modacrylic/aramid blends and limited antimony-content, which is applied in the field of limited antimony-free modacrylic/aramid blends for improving flash fire and arc protection, can solve the problems of not providing a category 2 arc rating for fabrics in the range of 186, and the difference in burn injury is huge, and the effect of reducing the risk of arc injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

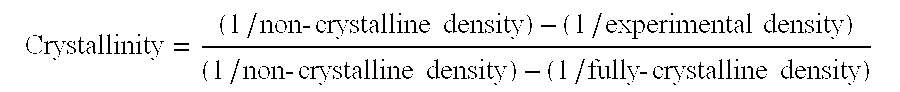

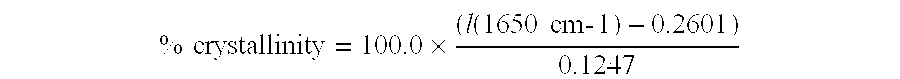

[0058]This example illustrates the surprising increase in fabric arc rating with the use of antimony-free modacrylic fiber. A durable arc and thermal protective fabric (Item 1) is prepared having in the both warp and fill airjet spun yarns of intimate blends of Nomex® type 300 fiber, Kevlar® 29 fiber, and antimony-free modacrylic fiber. Nomex® type 300 is poly(m-phenylene isophthalamide)(MPD-I) having a degree of crystallinity of 33-37%. The modacrylic fiber is ACN / polyvinylidene chloride co-polymer fiber having no measured antimony (known commercially as Modacrylic SE made by Keneka). The Kevlar® 29 fiber is poly(p-phenylene terephthalamide) (PPD-T) fiber.

[0059]A picker blend sliver of 65 weight percent of Nomex® type 300 fiber, 10 weight percent of Kevlar® 29 fiber, and 25 weight percent of modacrylic fiber is prepared and is made into spun staple yarn using cotton system processing and an airjet spinning frame. The resultant yarn is a 21 tex (28 cotton count) single yarn. Two sin...

example 2

[0064]The general procedure of Example 1 is repeated to make and test three different fabrics and garments, except that three different modacrylic fibers were used and nylon fiber was also included in the yarn blend. Item 2 contains modacrylic fiber having a low antimony content of 1.2% (made by Fushun Rayva Fiber Company, Wanghua District, Fushun, China). Item B contains modacrylic fiber having an antimony content of 9.9% (known commercially as Protex®C). Item C contains modacrylic fiber having an antimony content of 4.1% (known commercially as Protex®M). The fiber compositions and arc testing performance is shown in Table 2.

[0065]

TABLEMeta-Para-AntmonyBasisArcArcAramidAramidNylonModacrylicContentWeightRatingResistanceItem(wt. %)(wt. %)(wt. %)(wt. %)(%)(oz / yd2)(cal / cm2)(cal / cm2 / oz / yd2)2201010601.29.617.61.8B25105604.18.711.41.3C25105609.98.79.81.1

example 3

[0066]Examples 1 and 2 are repeated except 2 weight percent of the Nomex® meta-aramid fiber is replaced with an antistatic fiber that is a carbon-core nylon-sheath fiber known commercially as P140. The resultant fabric is converted into single-layer protective coveralls with predicted performance similar to Examples 1 & 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of crystallinity | aaaaa | aaaaa |

| potential exposure time | aaaaa | aaaaa |

| potential exposure time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com