Method and device for preheating and initially melting glass raw materials

A technology of glass raw materials and glass particles, which is applied in the field of nuclear applications, can solve the problems of high cost, long time consumption, and high energy consumption, and achieve the effects of less smoke, low cost, and large heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for preheating and starting melting of glass raw materials, and specifically relates to a new start-up method for cold crucible vitrification technology for radioactive waste liquid, so as to achieve smooth start-up of cold crucible equipment, and is suitable for using cold crucible vitrification technology When processing radioactive waste, the melting of the glass material is initiated.

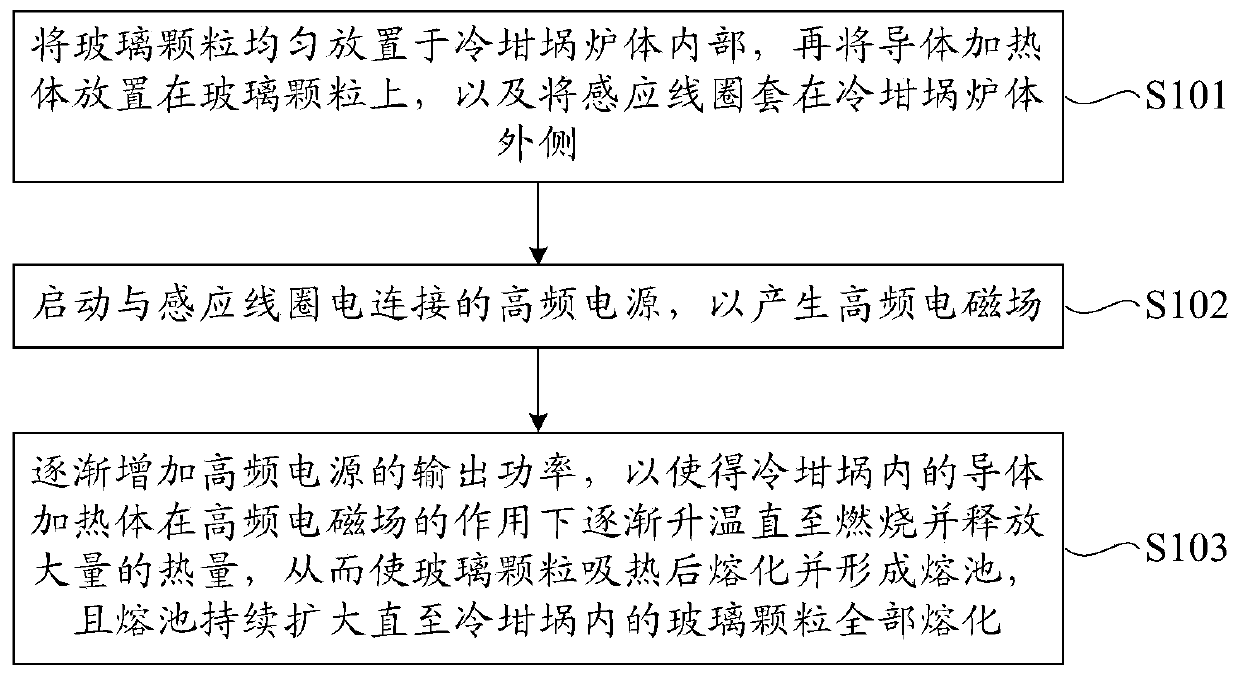

[0031] Such as figure 1 As shown, the preheating and starting method includes the following steps S101 to S103.

[0032] S101. Evenly place the glass particles inside the cold crucible furnace body, then place the conductor heating body on the glass particles, and place the induction coil outside the cold crucible furnace body;

[0033] S102. Start a high-frequency power supply electrically connected to the induction coil to generate a high-frequency electromagnetic field;

[0034] S103. Gradually increase the output power of the high-frequency pow...

Embodiment 2

[0048] This embodiment provides a glass raw material preheating start-up device, specifically related to a new type of starting device for radioactive waste liquid cold crucible vitrification technology, so as to realize the smooth start of cold crucible equipment, and is suitable for using cold crucible vitrification technology When processing radioactive waste, the melting of the glass material is initiated.

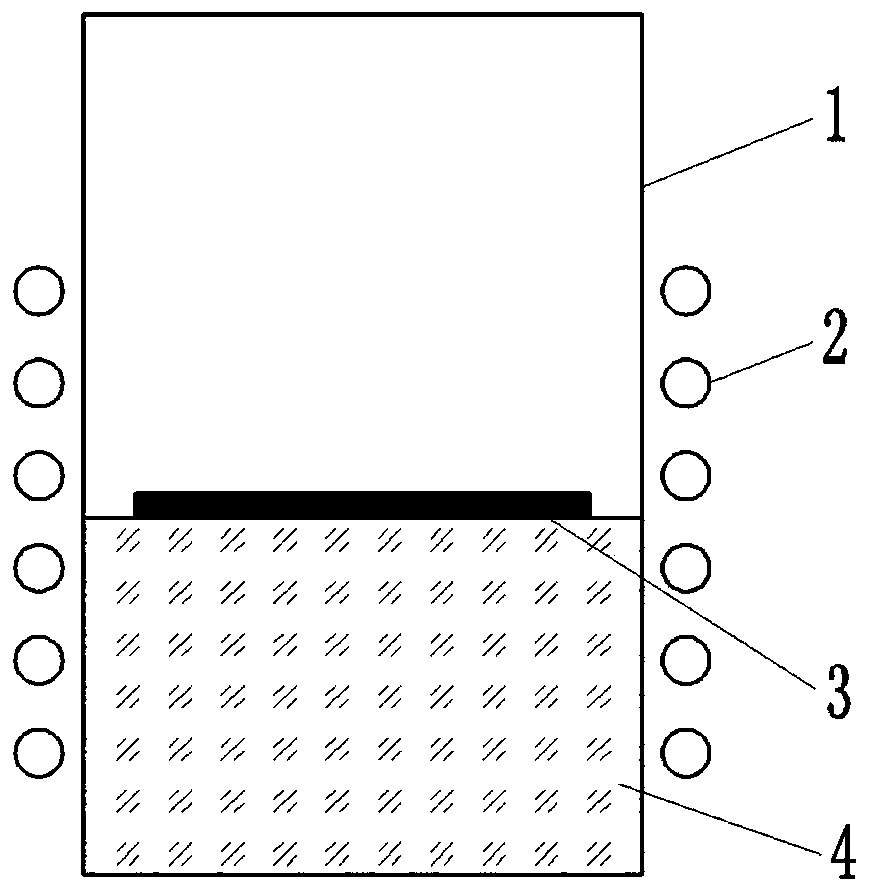

[0049] Such as figure 2 As shown, the preheating and starting device includes: a cold crucible 1, a conductor heating body 3, an induction coil 2 and a high frequency power supply (not shown in the figure). The furnace body of the cold crucible 1 contains glass particles 4, and the glass particles 4 are uniformly placed in the furnace body of the cold crucible. The conductor heating body 3 is placed on the glass granules 4 . The induction coil 2 is set on the outside of the furnace body of the cold crucible 1 . The high-frequency power supply is electrically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com