Preparation method of nitrified chitosan and application thereof

A technology of nitrating chitosan and chitosan, which is applied in the field of energetic materials and polymer materials, can solve the problems of nitrating chitosan performance and application research, low nitration substitution degree, etc., and achieve high substitution degree and nitration substitution degree The effect of improving and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 3.0g of chitosan (deacetylation degree is 90%) to -3°C, 15mL of acetic anhydride, add 12mL of fuming nitric acid under stirring, then add 0.02mL of concentrated sulfuric acid, react at 2°C for 4h Stop the reaction, add 60 mL of ice water, filter and transfer the precipitate to saturated NaHCO 3 After soaking in the solution for 20 hours, filter, wash and dry in vacuum to obtain light yellow nitrated chitosan with a yield of 86%.

[0027] The elemental analysis result of the reactant obtained in this embodiment: C: 28.62%, H: 3.66%, N: 20.24%. The degree of nitration substitution is about 1.86. The impact sensitivity is >26J.

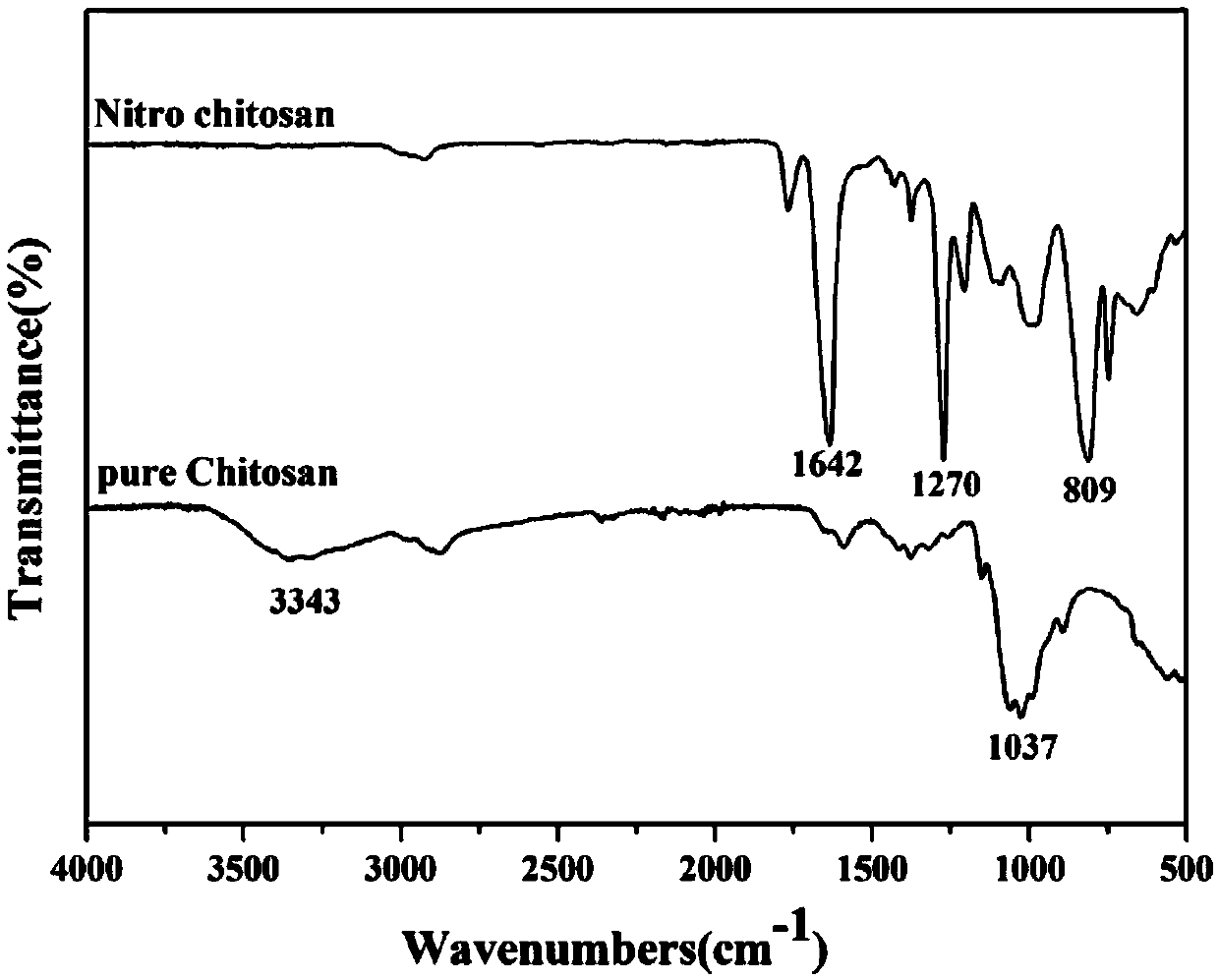

[0028] figure 1 It is the FT-IR curve chart of the chitosan of embodiment 1 and nitrated chitosan. The results show that: the three wavelengths (1642, 1270, 809cm) corresponding to the nitrate group (nitro) -1 ) exist, proving that nitrification has occurred.

Embodiment 2

[0030] Add 5.0g of chitosan (95% deacetylation degree) to -2°C, 20mL of acetic anhydride, add 25mL of fuming nitric acid under stirring, then add 0.04mL of concentrated sulfuric acid, and heat up to 2°C, react Stop the reaction after 5h, add 200mL of ice water, filter and transfer the precipitate into saturated NaHCO 3 After soaking in the solution for 24 hours, filtering, washing and vacuum drying, light yellow nitrated chitosan can be obtained with a yield of 84%.

[0031] The elemental analysis result of the reactant obtained in this embodiment: C: 29.55%, H: 3,35%, N: 16.50%. The nitrated substitution degree of nitrated chitosan was calculated to be about 2.01. The impact sensitivity is >21J.

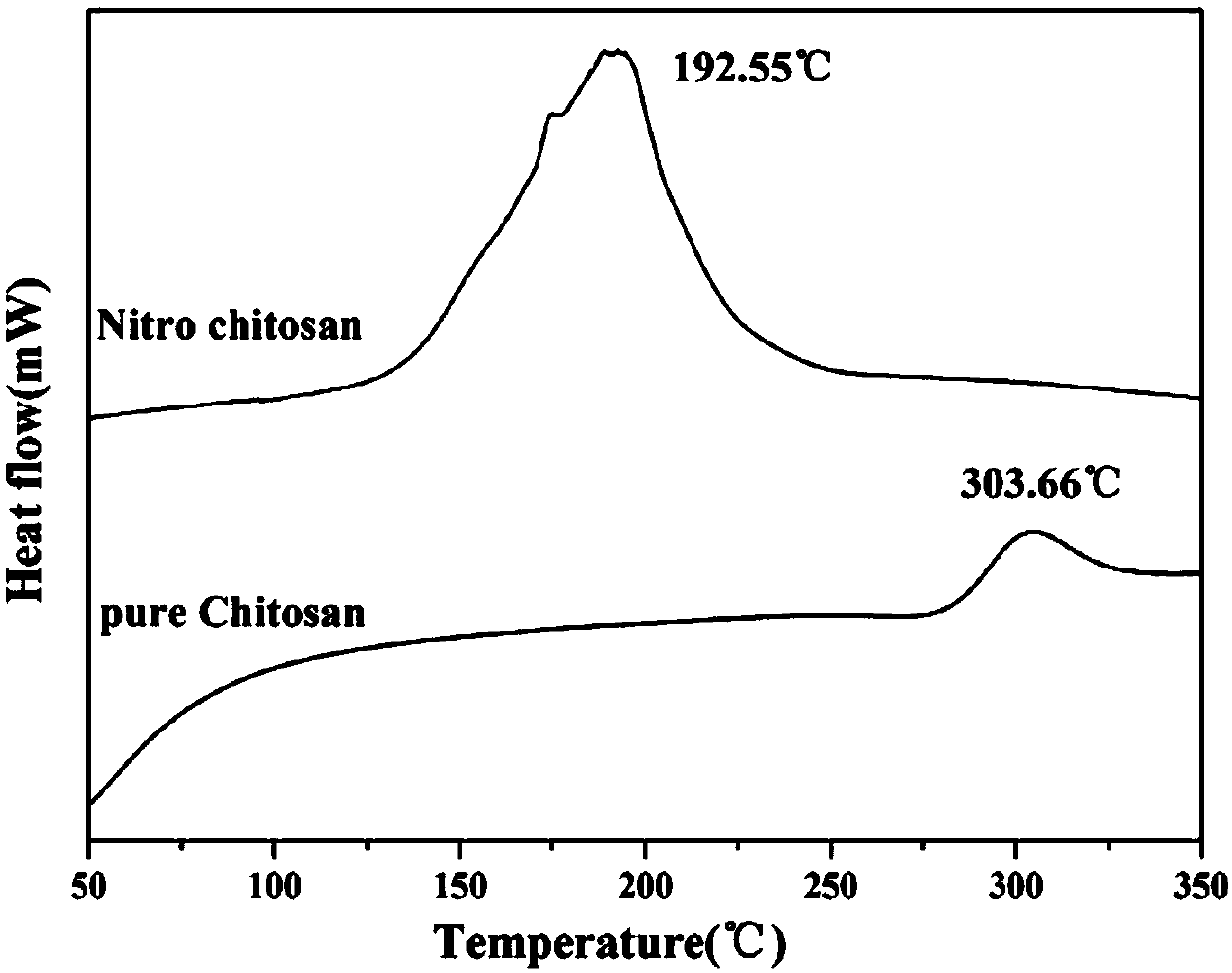

[0032] figure 2 It is the DSC curve figure of the chitosan of embodiment 2 and nitrated chitosan. The results showed that chitosan had been nitrated and had a significant exothermic decomposition with a peak temperature of 192.55°C and an exothermic heat of 2200J / g.

[0033] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact sensitivity | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com