Patents

Literature

94results about How to "Low impact sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

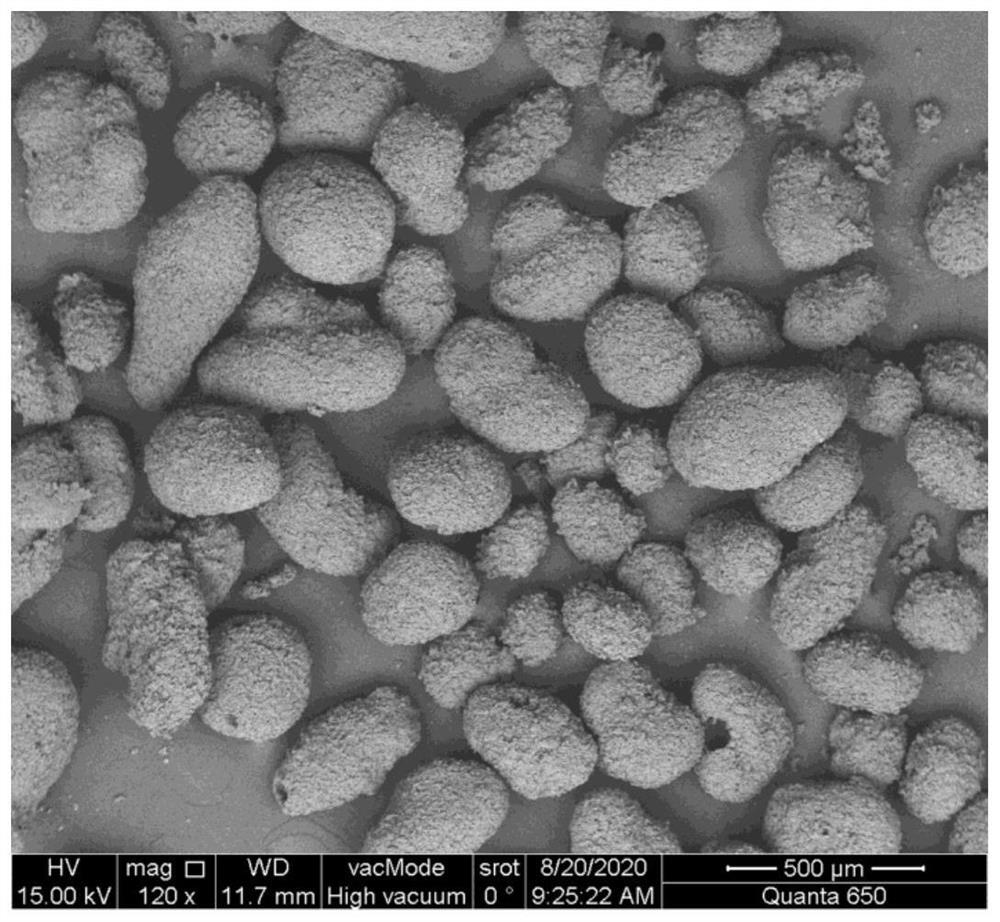

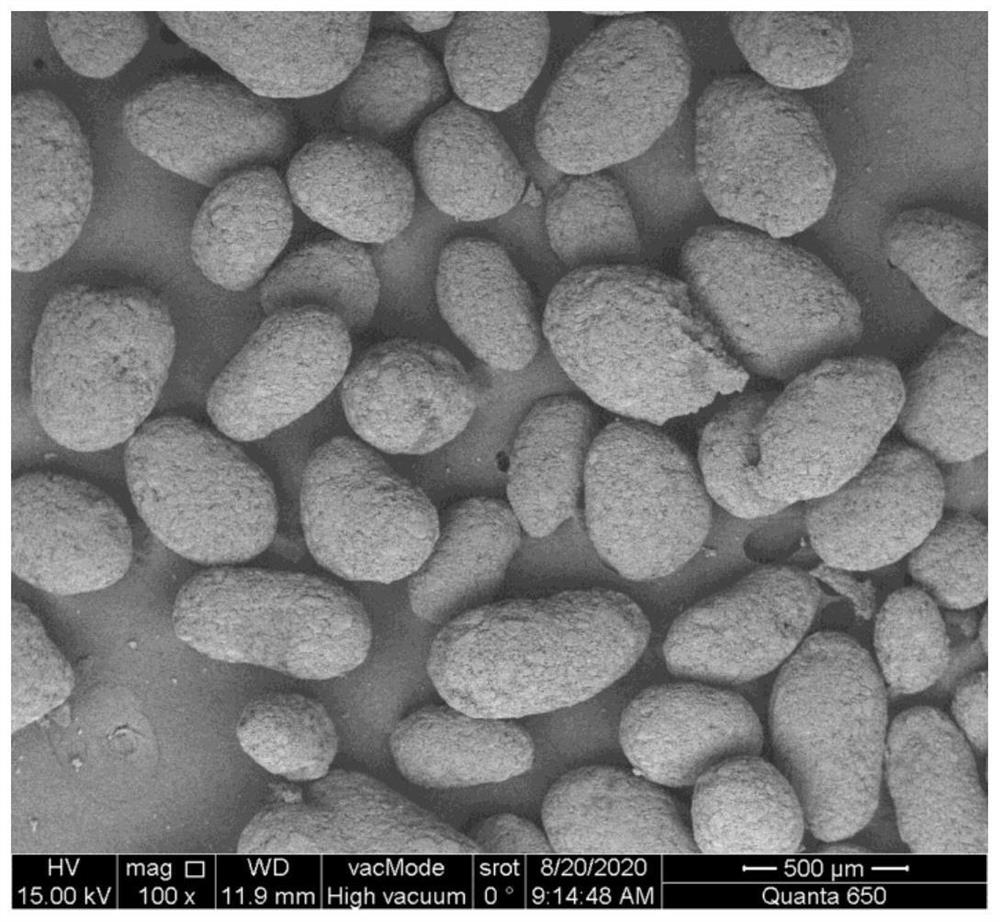

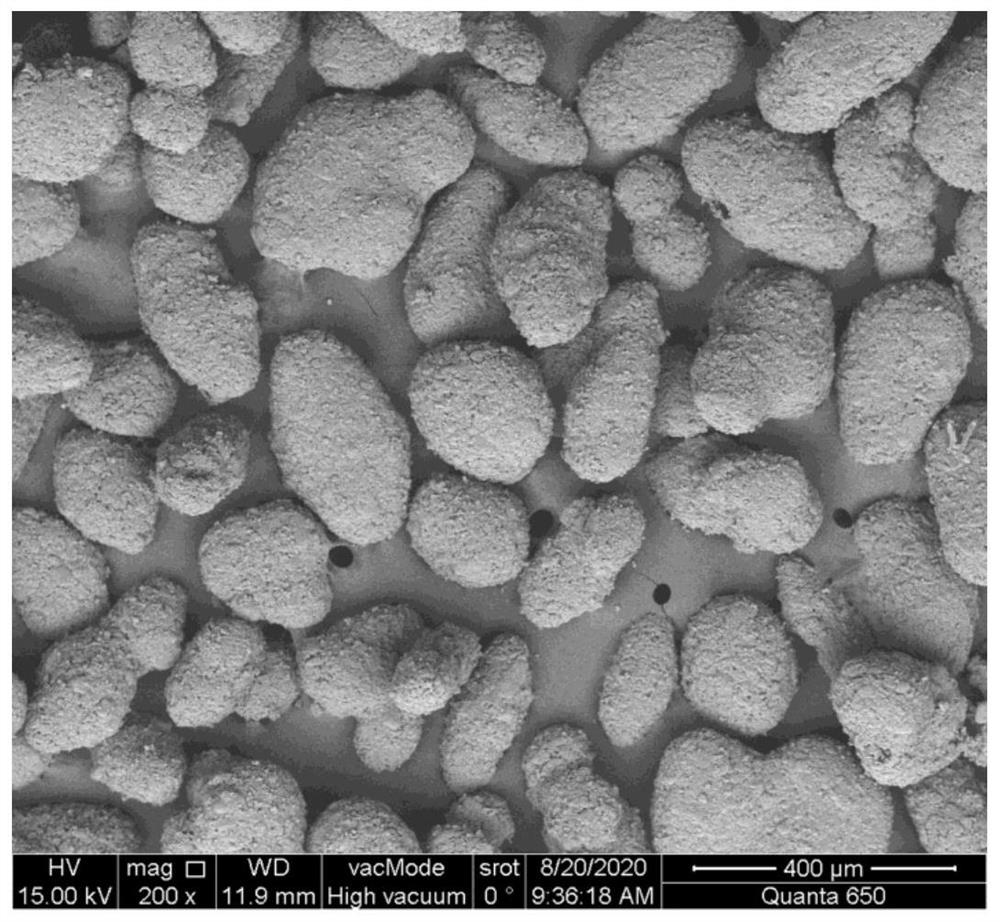

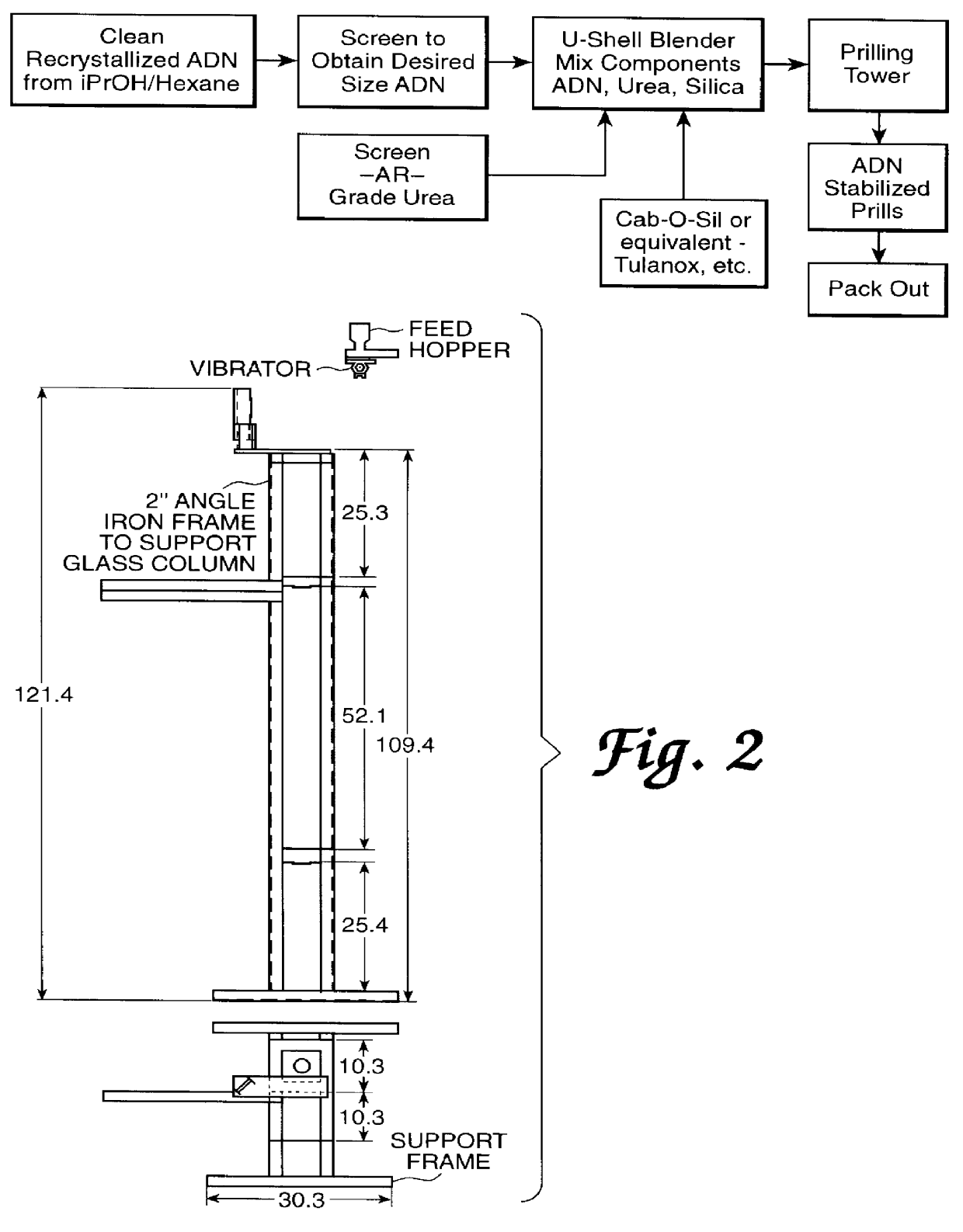

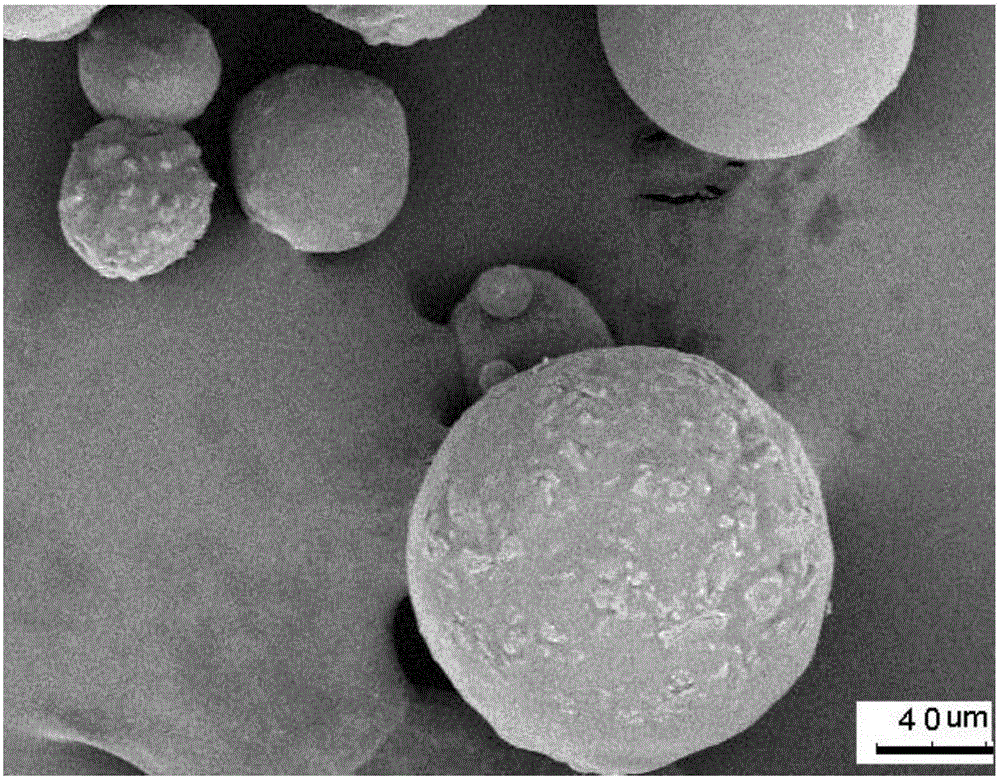

Thermally-stabilized prilled ammonium dinitramide particles, and process for making the same

InactiveUS6136115ALow impact sensitivityImprove propertiesLoomsWoven fabricsCounter currentPelletizing

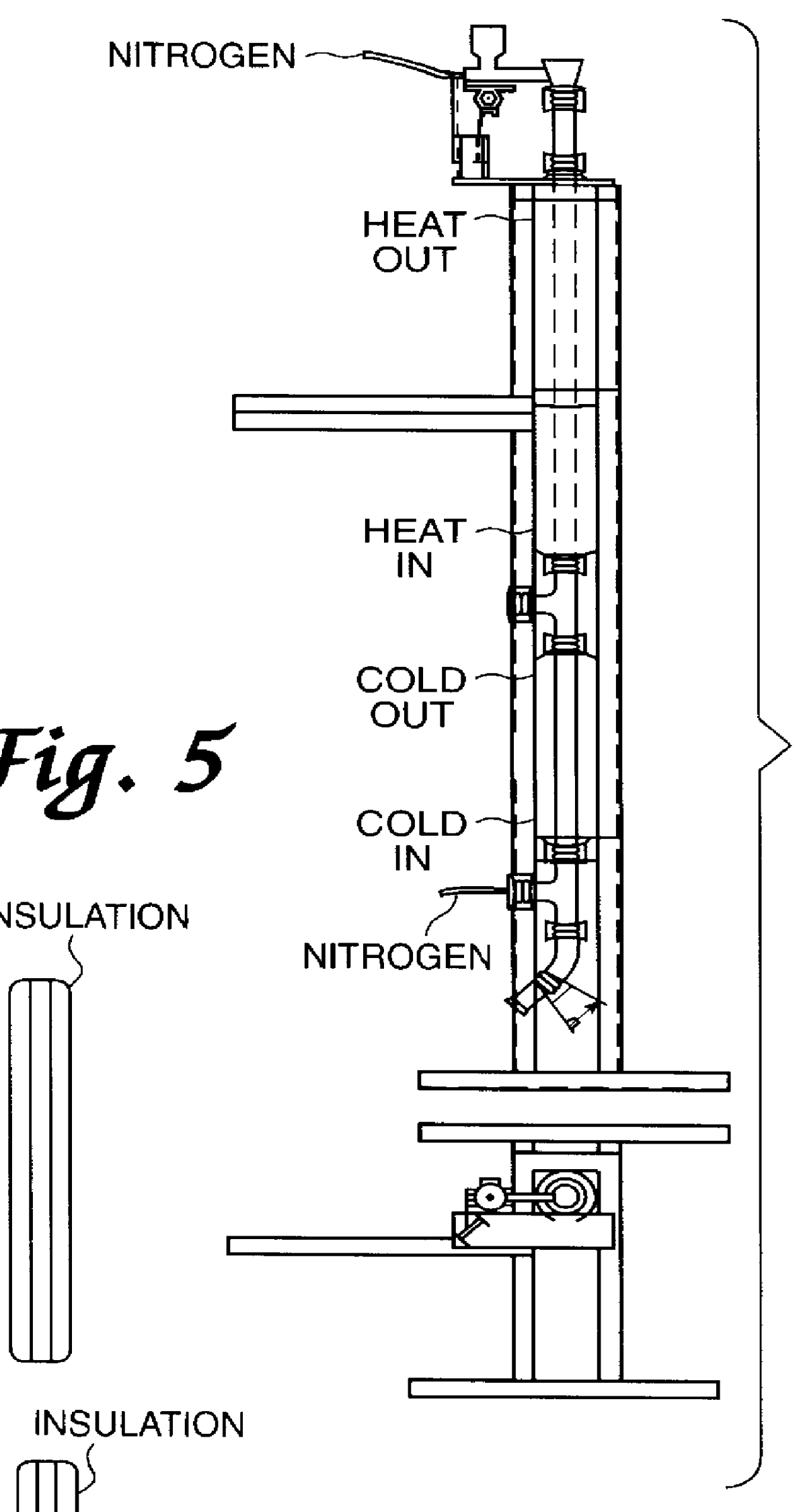

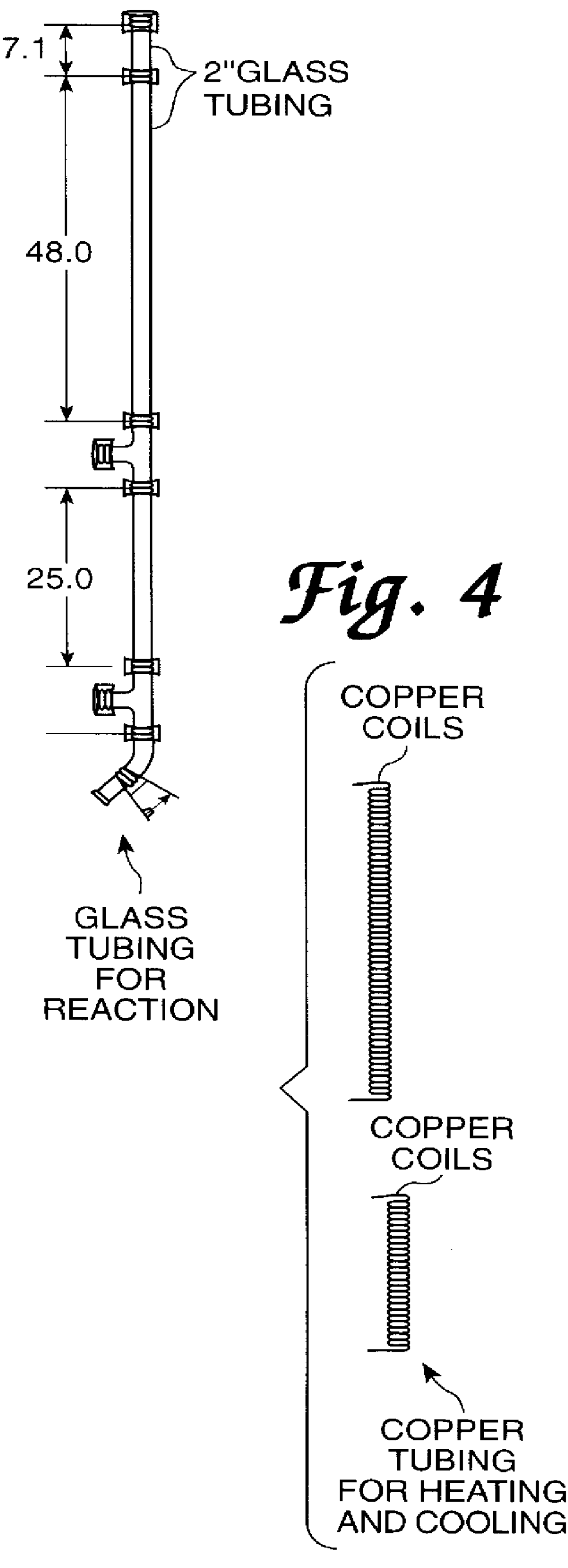

A process is disclosed for producing prills comprised of ammonium dinitramide The prills can include, if desired, one or more thermal stabilizers, and processing aid(s). Solid particulate ADN is introduced into the top of a melting column, allowed to melt to form pre-prills while passing through a hot-zone ("heated zone") in the prilling column. The pre-prills are allowed to spheridize in the presence of an upwardly blown inert medium which is counter current to the path of the ADN in the prilling column. The flow is designed not to blow the ADN out of the prilling column. The rate of spheridization (prill formation) can, if desired, be accelerated by providing additional cooling, such as refrigeration, to the cooling zone in the prilling column. The ADN prills are suitable for use in propellants.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

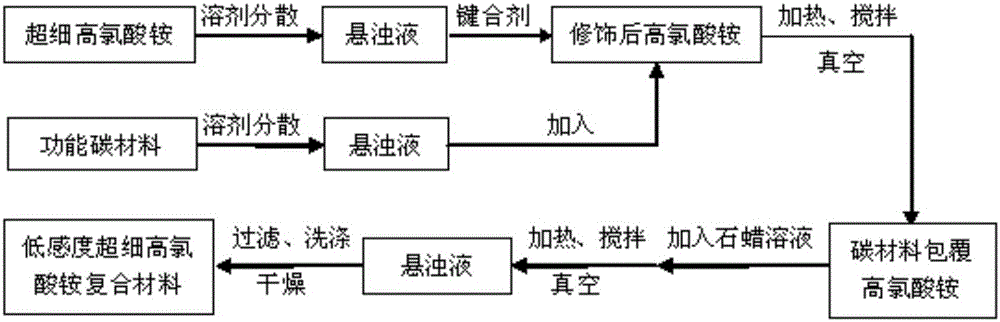

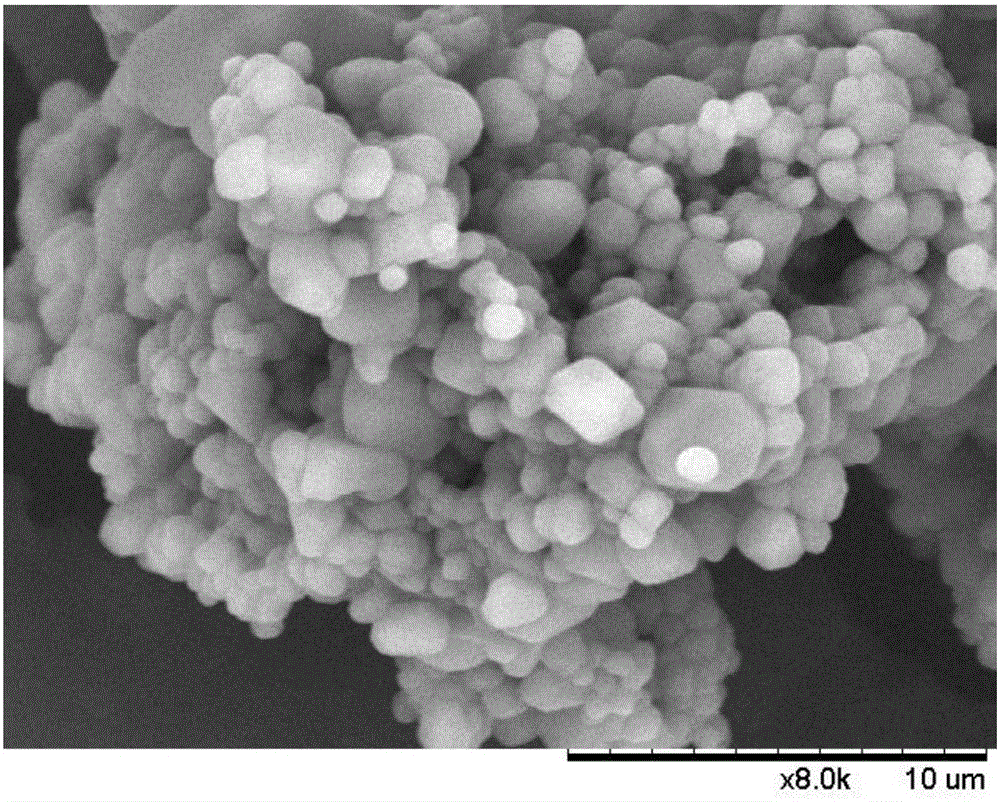

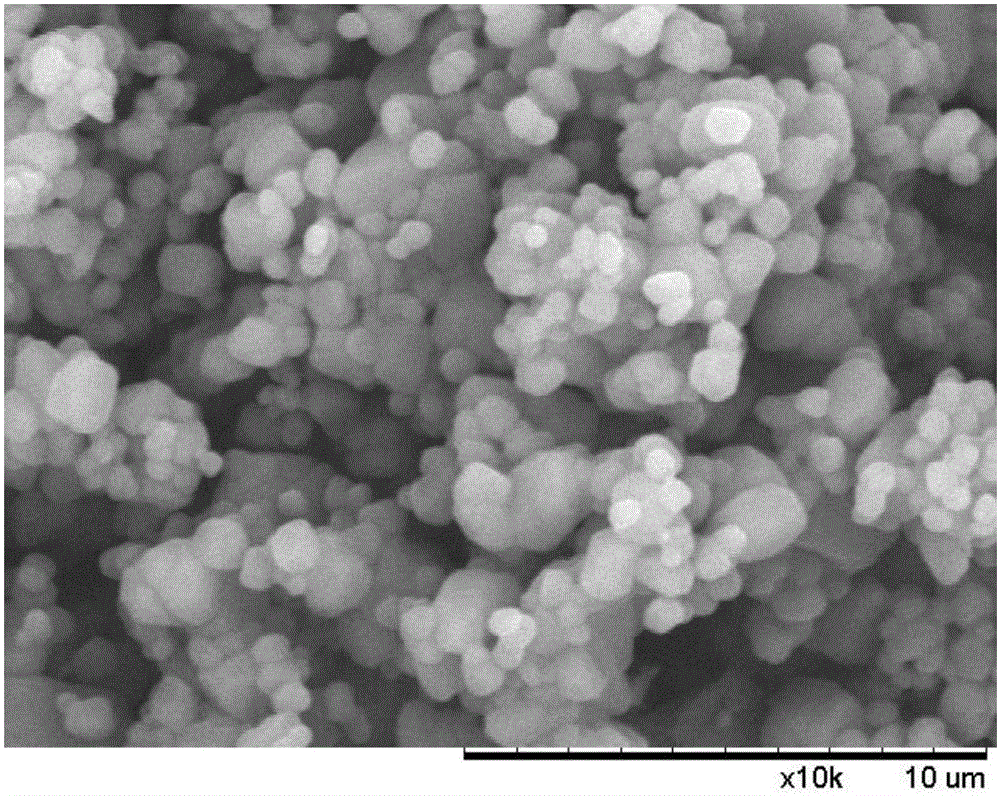

Low-sensitivity ultrafine ammonium perchlorate composite material and preparation method thereof

ActiveCN105152823ASimple processMild reaction conditionsAmmonium perchlorate explosive compositionsSmooth surfaceShock sensitivity

The invention discloses a low-sensitivity ultrafine ammonium perchlorate composite material and a preparation method thereof. The method comprises the following steps: dispersing ultrafine ammonium perchlorate in an organic solvent to form a suspension, modifying the suspension by a bonding agent under stirring, heating and vacuum conditions, coating by using a functional carbon material dispersed in an organic solvent under the stirring, heating and vacuum conditions, processing by using a paraffin / petroleum ether solution, filtering, washing, and drying to obtain the low-sensitivity ultrafine ammonium perchlorate composite material. The method is suitable for preparing low-sensitivity composite materials of various granularities and various morphologies of ultrafine ammonium perchlorate, and has the advantages of simple process flow, mild reaction conditions, good reappearance, high yield, and easy amplified preparation; and the obtained composite material has the advantages of good dispersion, smooth surface, uniform granularity distribution, and obviously reduced bumping sensitivity and friction sensitivity.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Fine-particle high-energy low-sensitivity explosive compound and preparation method thereof

ActiveCN104193564ALow mechanical sensitivitySuitable for mass productionNitroparaffin explosive compositionsFriction sensitivityOrganic solvent

The invention relates to a fine-particle high-energy low-sensitivity explosive compound and a preparation method thereof. The method comprises the following steps: mixing an explosive with a macromolecular bonder according to a weight part ratio of 100 to (2-5), and stirring at 40-60 DEG C for dissolving in an organic solvent to obtain an explosive compound solution with 5%-30% by weight of explosives; putting the explosive compound solution into an ejection tank, pumping air into the ejection tank to increase the pressure in the ejection tank to be 0.3-0.7MPa, ejecting the explosive compound solution into an explosive antisolvent with the temperature of -10 DEG C to 10 DEG C, performing centrifugal separation on a solid product, washing, and drying to obtain the explosive compound. According to the explosive compound, explosive particles are micron-sized, the CL-20 surface is densely wrapped with the macromolecular bonder in the form of an interwoven mesh shape, the impact sensitivity of the wrapped CL-20 is reduced to be 24%-40% from 100%, and the friction sensitivity is reduced to be 66%-92% from 100%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Coating explosive microspheres prepared through emulsion solidification and preparation method thereof

ActiveCN106083495AReduce sensitivityLow mechanical sensitivityExplosive working-up apparatusNon-explosive/non-thermic compositionsHigh energyOil phase

The invention discloses coating explosive microspheres prepared through emulsion solidification and a preparation method thereof. The method comprises the following steps that a macromolecule coating agent is dissolved in an organic solvent at first to obtain a solution, then, an explosive is suspended in the solution to form an even oil phase, the oil phase is added into a water phase containing an emulsifying agent with high-speed stirring to form spherical emulsion drops, the organic solvent in the spherical emulsion drops is volatilized, and the coating explosive microspheres with the explosive surfaces evenly coated with the coating agent are obtained. By means of the method, spherical micron-order coating explosive particles with good dispersity are obtained through the emulsion drops, the explosive is soaked and suspended in the macromolecule solution, the macromolecule coating agent is gradually separated out and solidified on the explosive surface, an even and tight coating layer is formed, the explosive high energy level is maintained, and meanwhile the sensitivity is greatly lowered.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Calcium sulfate composite oxidant for fireworks and crackers and preparation method thereof

The invention relates to a calcium sulfate composite oxidant for fireworks and crackers and a preparation method thereof, belonging to the technical field of chemical raw materials of the industry of the fireworks and crackers. The oxidant takes calcium sulfate and iron oxide as a main body assisted by barium nitrate, takes potassium permanganate and potassium perchlorate as initiators, and is added a small amount of an active agent. The preparation method comprises the following steps: roasting gypsum (calcium sulfate dihydrate), smashing, adding a mixed powder body of potassium permanganate and potassium perchlorate, grinding, smashing iron oxide, adding the active agent into the iron oxide powder, and then adding barium nitrate and grinding; and uniformly mixing the two types of ground powder. One of main raw materials of the invention is calcium sulfate which is non-toxic and has low price, and after being roasted the calcium sulfate, the calcium sulfate is not only an oxidant but also a moisture-proof agent and a leavening agent and also is a mechanical sensitivity buffer which is fine and smooth and slippery. Since the composite oxidant of the invention is prepared into the fireworks and crackers according to the traditional method, the fireworks and crackers has the advantages that the burning property is good, the safety is strong, the friction sensitivity and impact sensitivity are zero, and the production cost is greatly reduced.

Owner:谢新佑

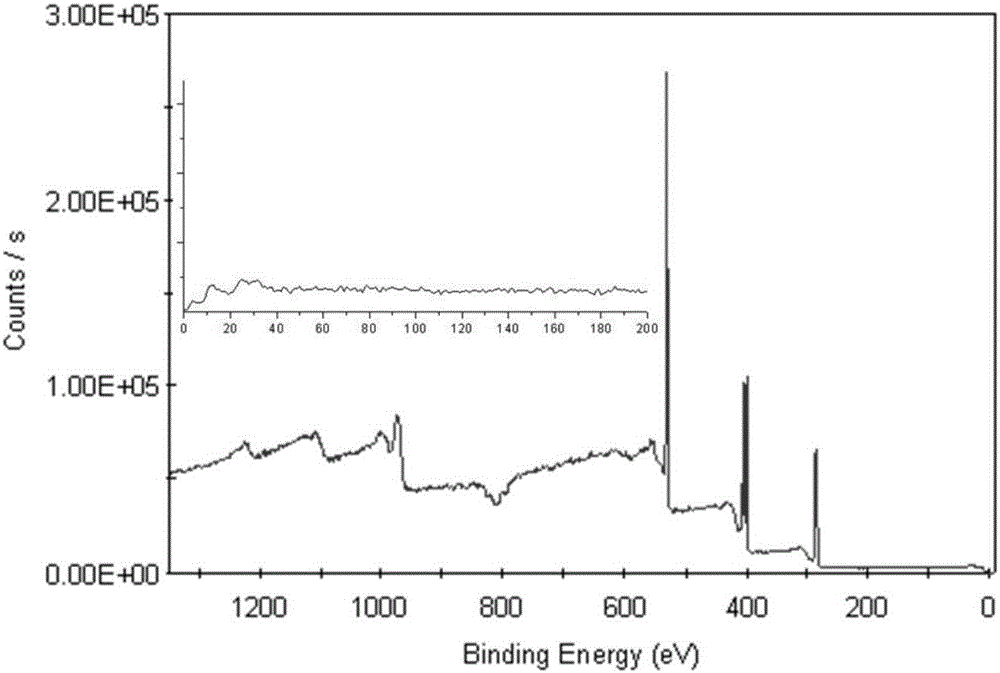

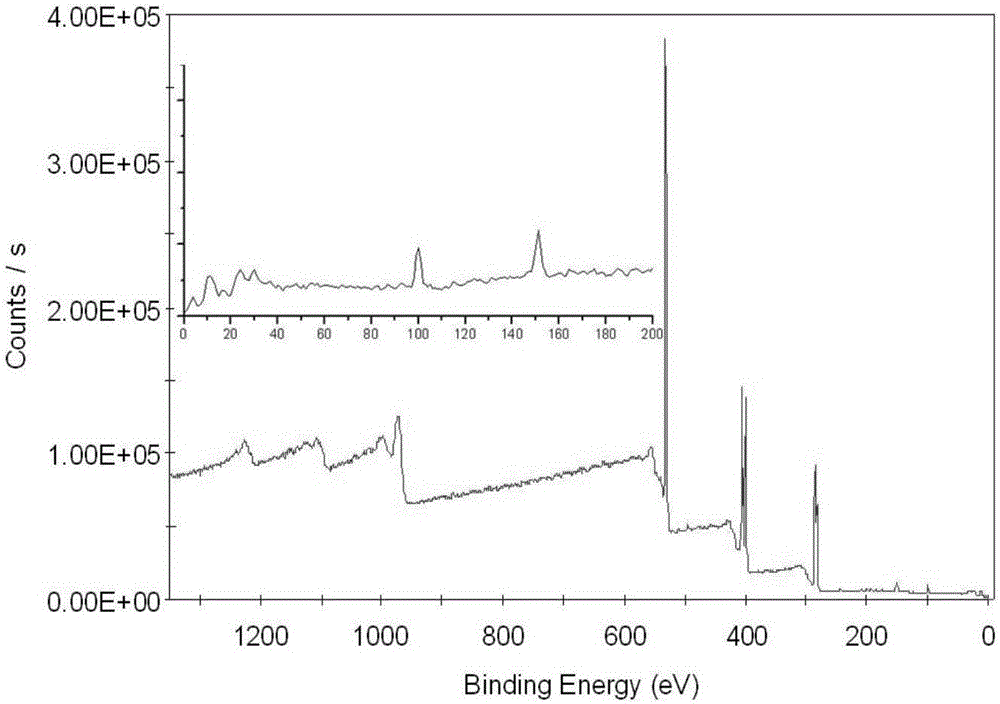

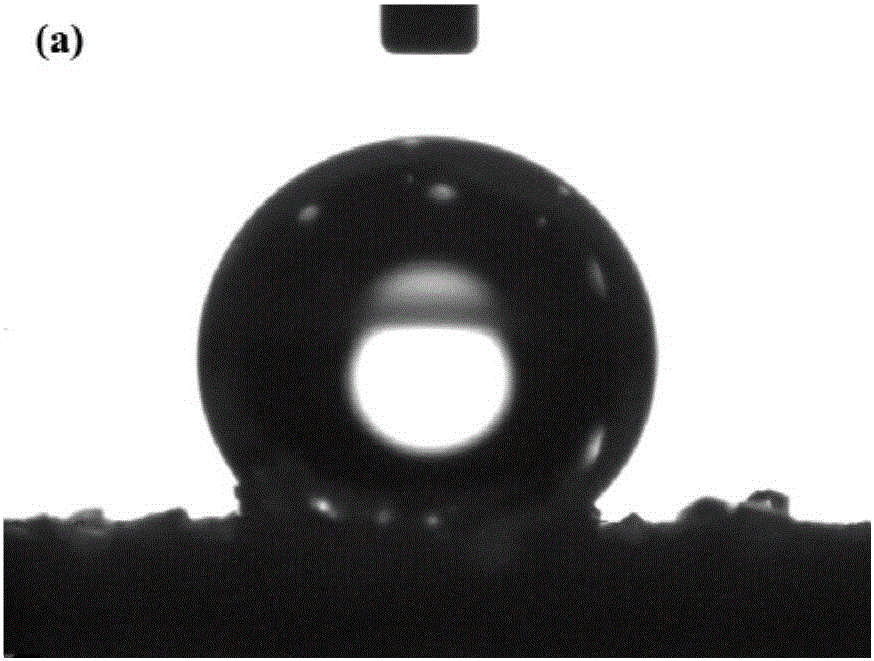

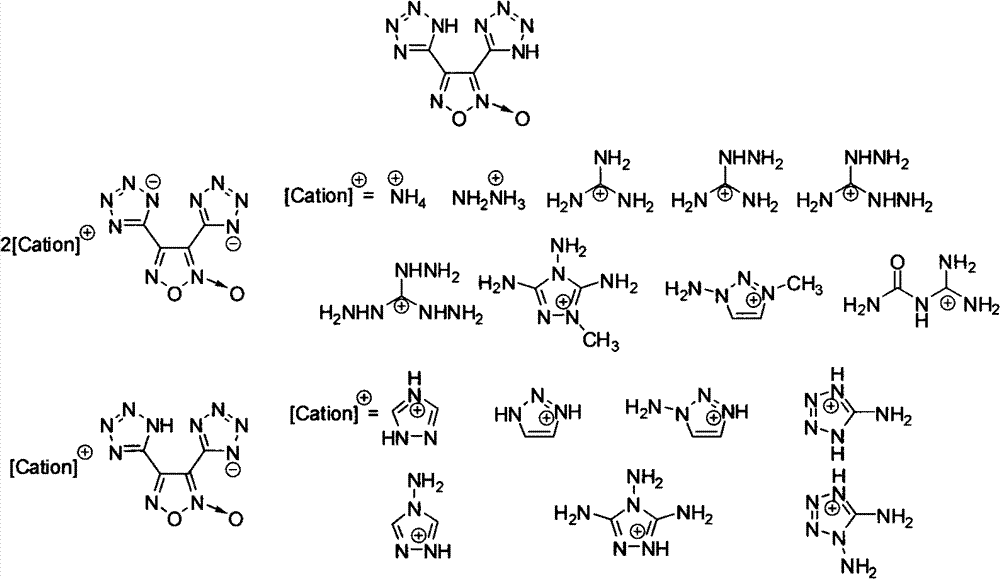

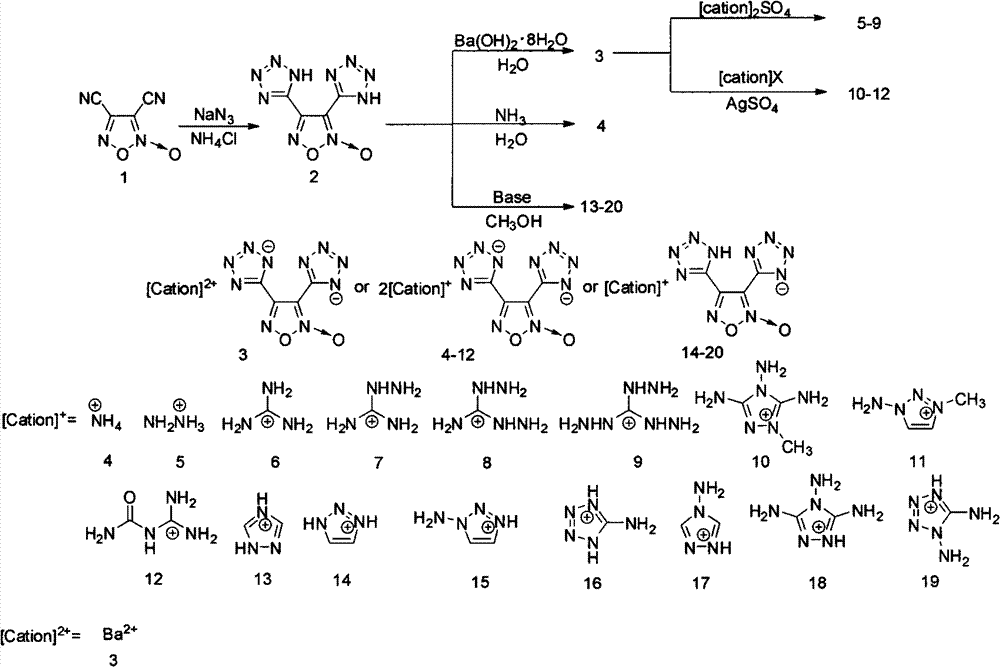

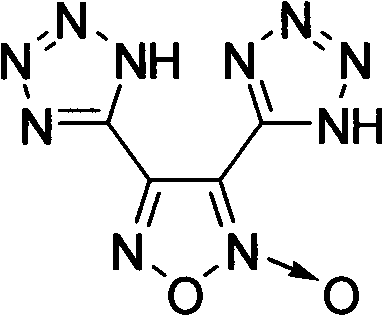

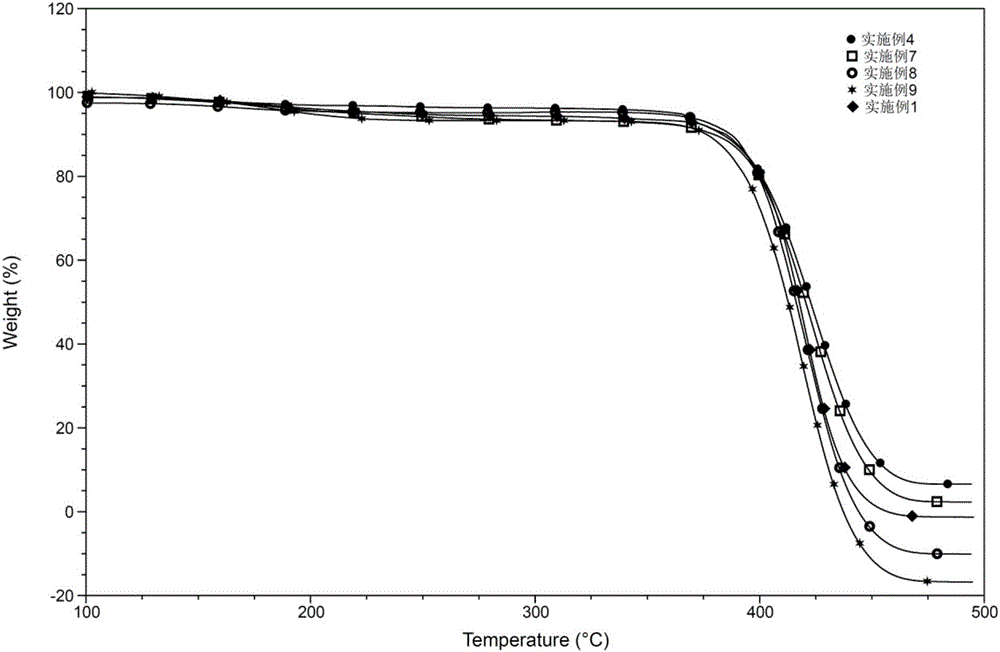

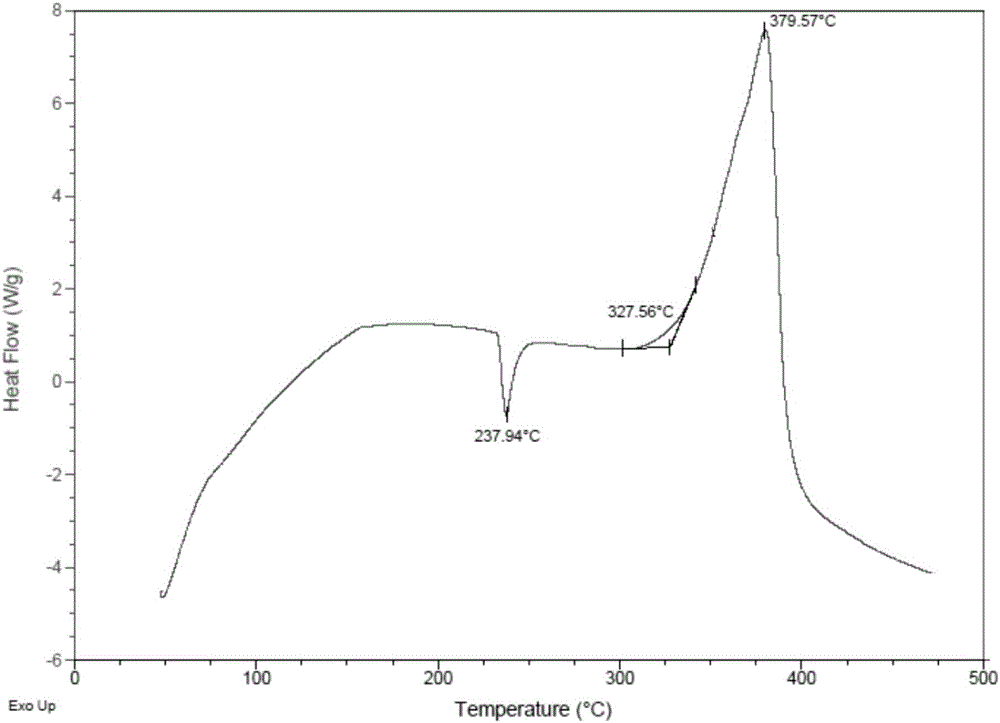

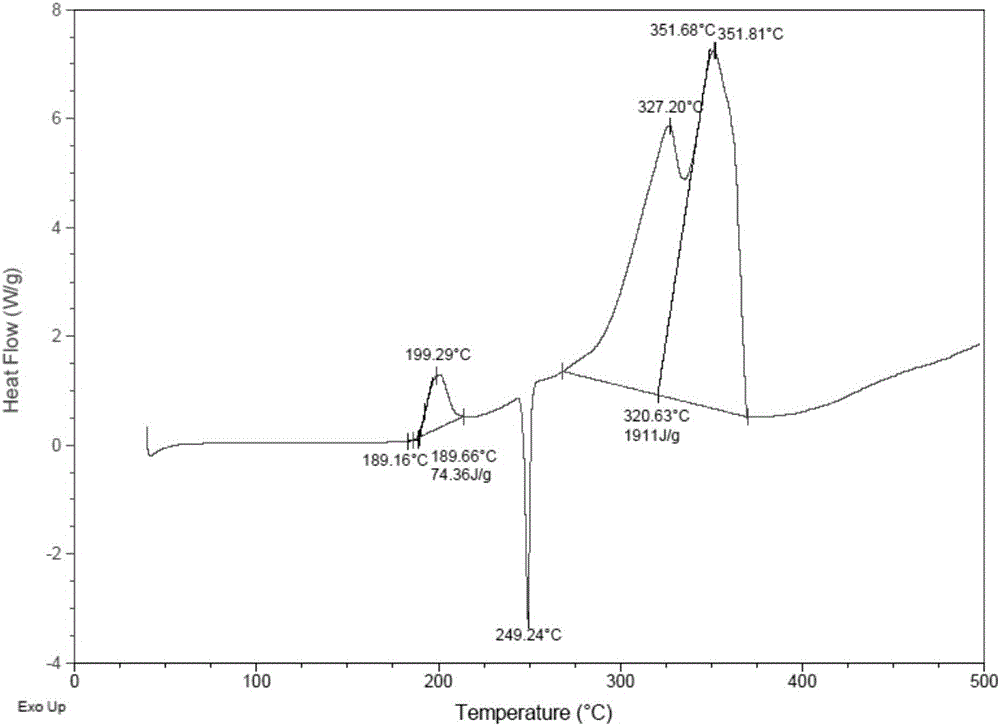

Energy containing ionic salts of 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan and preparation method thereof

InactiveCN103483330AImprove thermal stabilityLow impact sensitivityOrganic chemistryOrganic compound preparationFurazanDetonation

The invention discloses energy containing ionic salts of 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan and a preparation method thereof, and belongs to the technical field of energy containing materials. The preparation method is as follows: mixing 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan barium salt with an equal-molar sulfate of a corresponding cation, filtering precipitates, and evaporating out a filtrate to obtain the target product. The preparation method is simple and easy to industrialize. Nine energy containing ionic salts related in the invention are high in thermostability (Td: 213-289 DEG C), the degree of percussion sensitivity of most compounds is greater than 15J, all the energy containing ionic salts have excellent calculation detonation performance and are potential energy containing materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

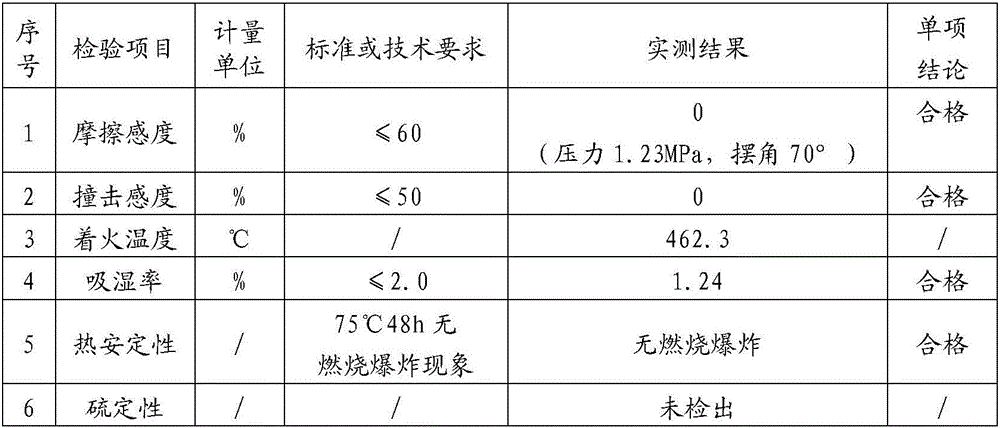

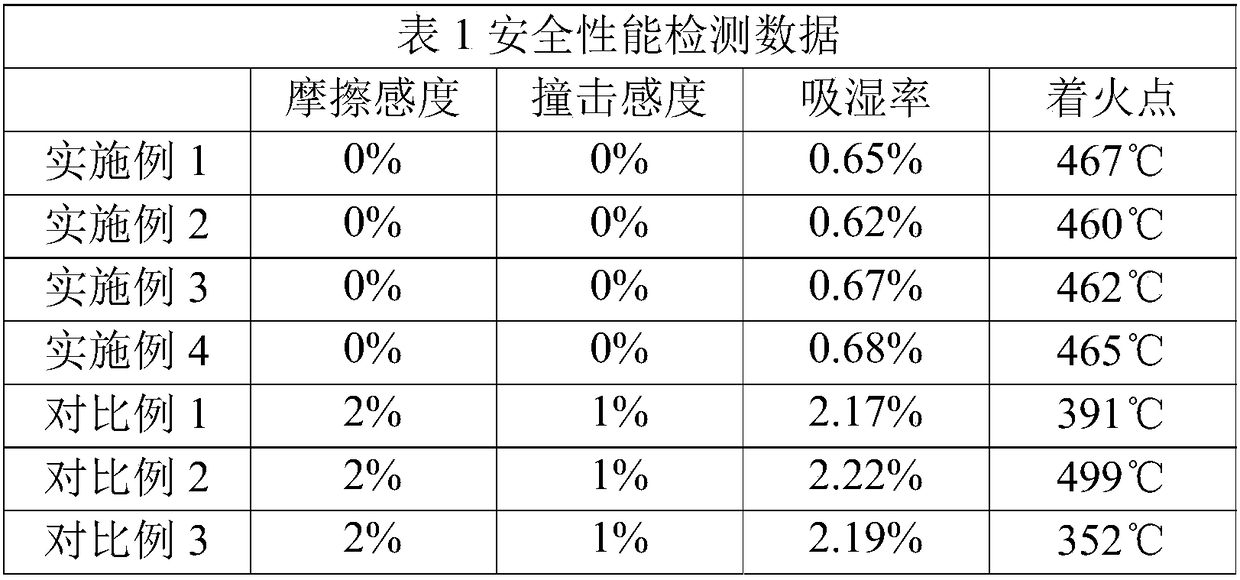

Fireworks detonating agent without chlorate and perchlorate

InactiveCN1640856ALow moisture absorptionReduced friction sensitivityExplosivesDecompositionFireworks

The firework exploding and sounding agent without chlorate and perchlorate comprises composite oxidant, inflammable sulfur, easy-to-burn aluminum powder and density regulating agent, and features the composite oxidant comprising potassium nitrate 10-50 wt%, barium nitrate 50-90 wt% and potassium permanganate 0-25 wt%. The firework exploding and sounding agent has also added pH regulating agent boric acid and deactivating agent magnesia or stearic acid. The firework exploding and sounding agent has high heat stability, no decomposition under 75 deg.c and minus 25-35 deg.c for 48 hr, friction sensitivity lower than 60 %, knocking sensitivity lower than 50 %, no burning and explosion in falling test and sympathetic detonation test, high fire approaching performance and no special requirement in firing line, and may be used in type B and type C firework products.

Owner:刘青春

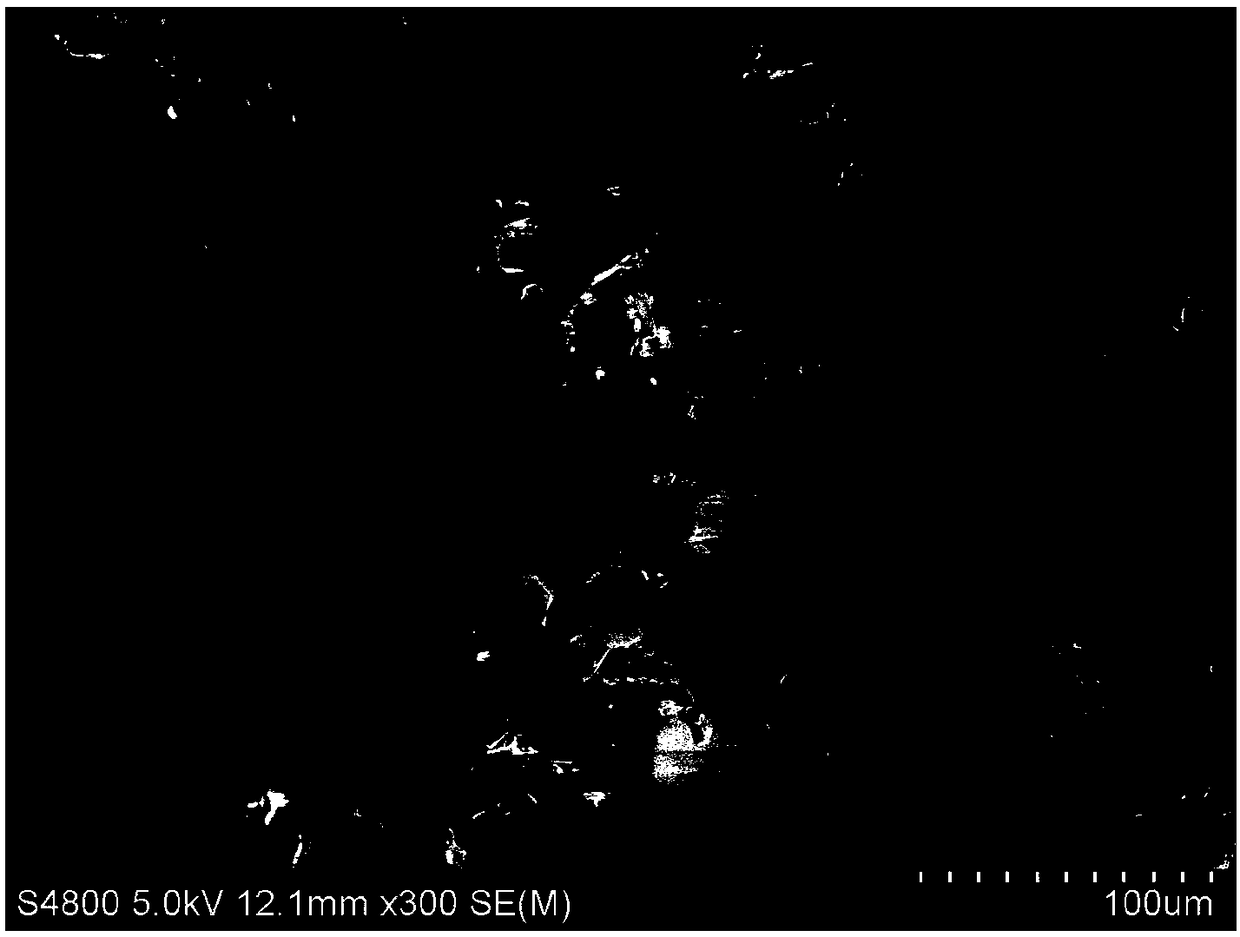

HMX coated with GO (graphene oxide) through electrostatic self-assembly and preparation method of HMX

ActiveCN106431792ACover tightlyUniform covering thicknessExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsThermal treatmentSelf-assembly

The invention discloses a preparation method of HMX coated with GO (graphene oxide) through electrostatic self-assembly. The preparation method comprises steps as follows: cleaned HMX is taken and added to n-hexane or toluene, an amino silane coupling agent is dropwise added, the mixture is stirred for reflux at the temperature of 75-120 DEG C for 8-12 h, then, cleaning is performed with ethanol, thermal treatment is performed at the temperature of 75-80 DEG C for 6-8 h, and amino-modified HMX is obtained; an HMX solution and a GO solution are mixed and stirred until GO is completely separated out, then, filtration, washing and drying are performed, and the HMX coated with GO through electrostatic self-assembly is obtained. The friction sensitivity and the collision sensitivity of the coated HMX are both reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

3,4-bis(1-hydro-5-tetrazolyl)furoxan ionic salt containing energy and preparation method thereof

InactiveCN102952124AImprove thermal stabilityLow impact sensitivityOrganic chemistrySmoke/mist generationSolventOrganic base

The invention provides a 3,4-bis(1-hydro-5-tetrazolyl)furoxan ionic salt containing energy and a preparation method thereof, which belongs to the technical field of energy materials. A synthetic method for the 3,4-bis(1-hydro-5-tetrazolyl)furoxan ionic salt comprises the following steps: subjecting 3,4-bis(1-hydro-5-tetrazolyl)furoxan and equimolar organic base to an acid-base neutralization reaction to obtain corresponding ionic salts or 3,4-bis(5-tetrazolyl)furoxan barium salt and equimolar sulfate of corresponding cations (wherein a part of sulfate is prepared through a reaction of a chlorine salt or an iodine salt and silver sulfate); filtering a precipitate; and removing a solvent in a filtrate through steaming so as to obtain a target product. The synthetic method provided by the invention is simple and is easy for industrialization. 16 energy-containing salts prepared in the invention have good heat stability, calculated detonation performances of all the energy-containing salts are much better than those of TNT, and a part of the energy-containing salts have detonation performances close to those of RDX, but have a degree of percussion sensitivity lower than that of RDX and can be used as a green substitute for RDX.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Organic carbon powder explosive reducing agent

The invention discloses an organic carbon powder explosive reducing agent, which is prepared from the following ingredients in parts by weight: 28 to 32 parts of terephthalic acid, 8 to 12 parts of ammonium benzoate, 8 to 12 parts of calcium benzoate, 38 to 42 parts of hydrogen potassium terephthalate and 8 to 12 parts of simple substance carbon. The reducing agent provided by the invention has the advantages of safety, stability and environment protection.

Owner:杨厚煌 +1

Propellant powder and preparation method

InactiveCN108947748AReduced friction sensitivityLow impact sensitivityExplosive working-up apparatusNitrated explosive compositionsMoisture absorptionShock sensitivity

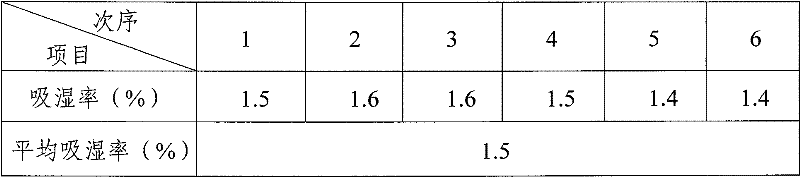

The invention provides propellant powder and a preparation method. The propellant powder comprises 30-50 parts of potassium permanganate, 8-20 parts of a binding agent, 10-20 parts of potassium hydrogen phthalate and 20-40 parts of a combustible agent, wherein the combustible agent is a mixture of nitrocotton and charcoal powder. The propellant powder has low friction sensitivity and impact sensitivity, low moisture absorption rate and strong thrust and meanwhile reduces the environmental pollution.

Owner:胡惠娟

Method for using microwave drying detonator

InactiveCN101221009ADoes not increase impact sensitivityLow impact sensitivityDrying solid materials with heatHearth type furnacesDetonatorEngineering

The invention relates to a method which uses microwaves to dry explosive. The method is that an undried finished detonator with 5 to 20 percent of water content is equally laid onto a drying plate, and the material thickness is 15 to 30mm, then the detonator is put into a microwave to carry out microwave drying in a condition with the vacuum degree of 0.080 to 0.085 MPa and the microwave power of 500 to 5000W. The drying method of the invention is suitable for drying RDX, HMX, PETN, NQ and TNT, etc. various single compound explosives. The complete drying time of the explosive is between 1000 and 2000s, which is far less than a normal static plate drying method by 7 to 8 hours, and the water content of the explosive is less than 0.01 percent after being dried.

Owner:ZHONGBEI UNIV

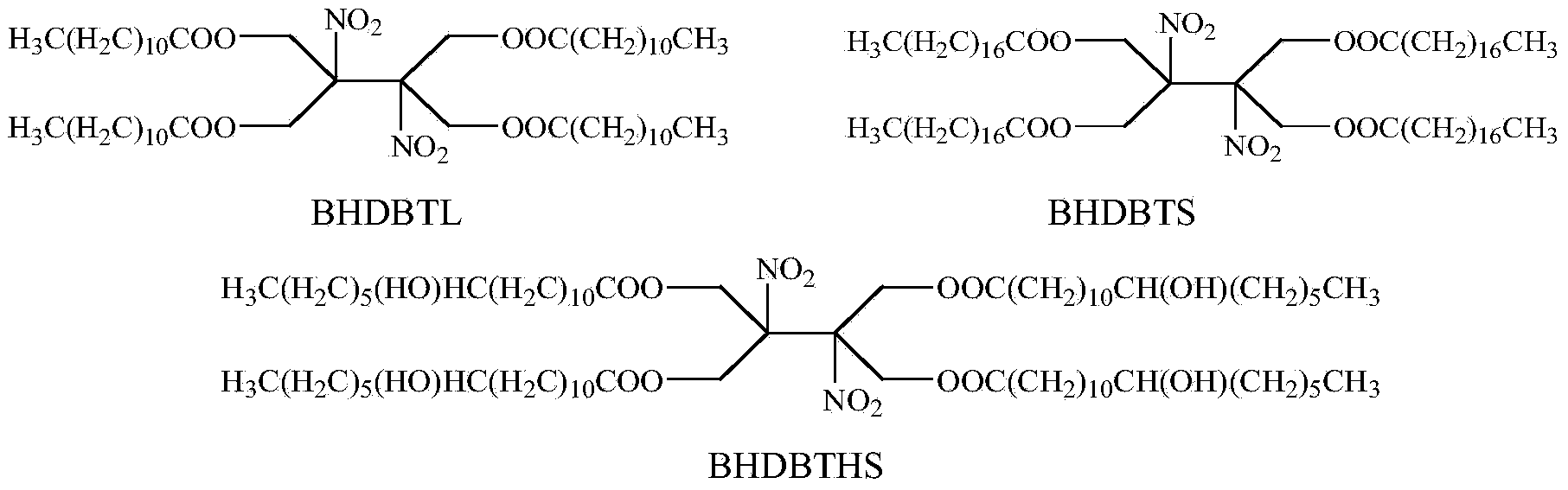

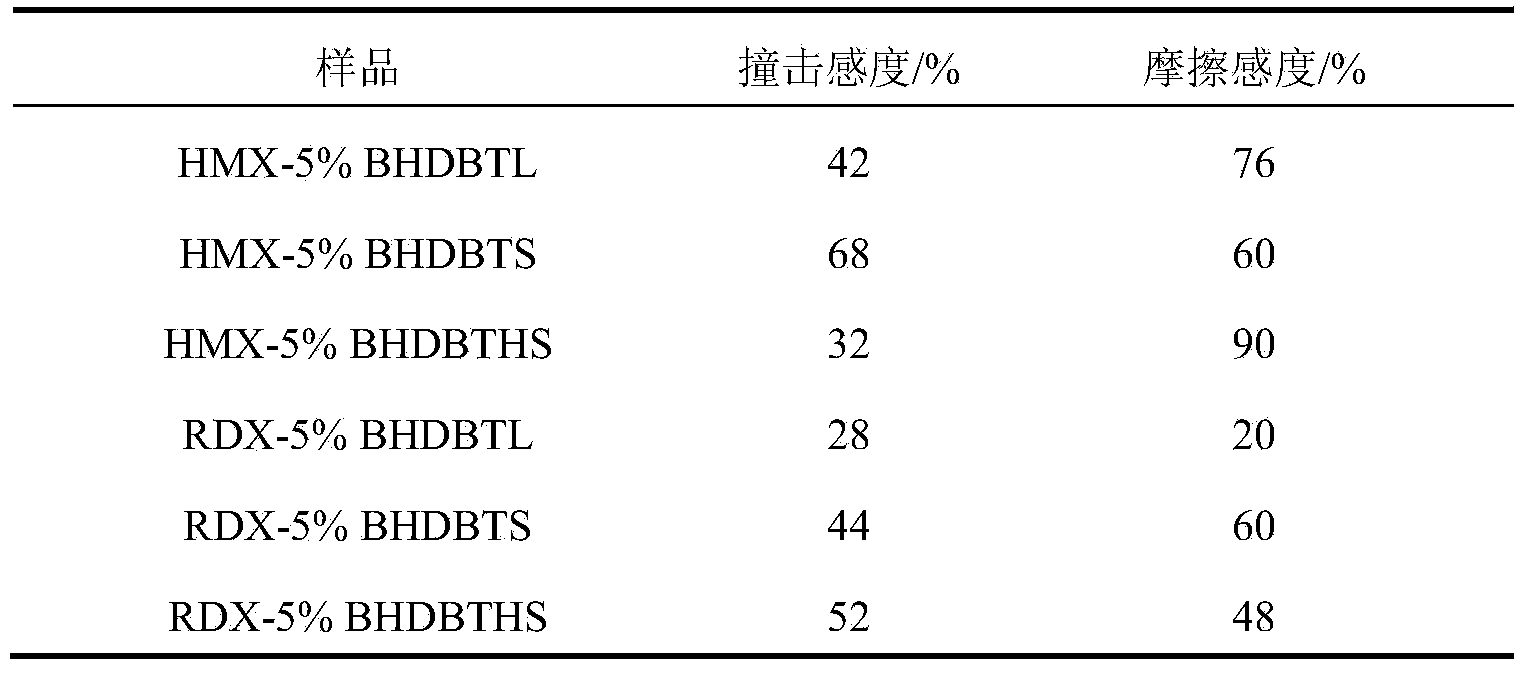

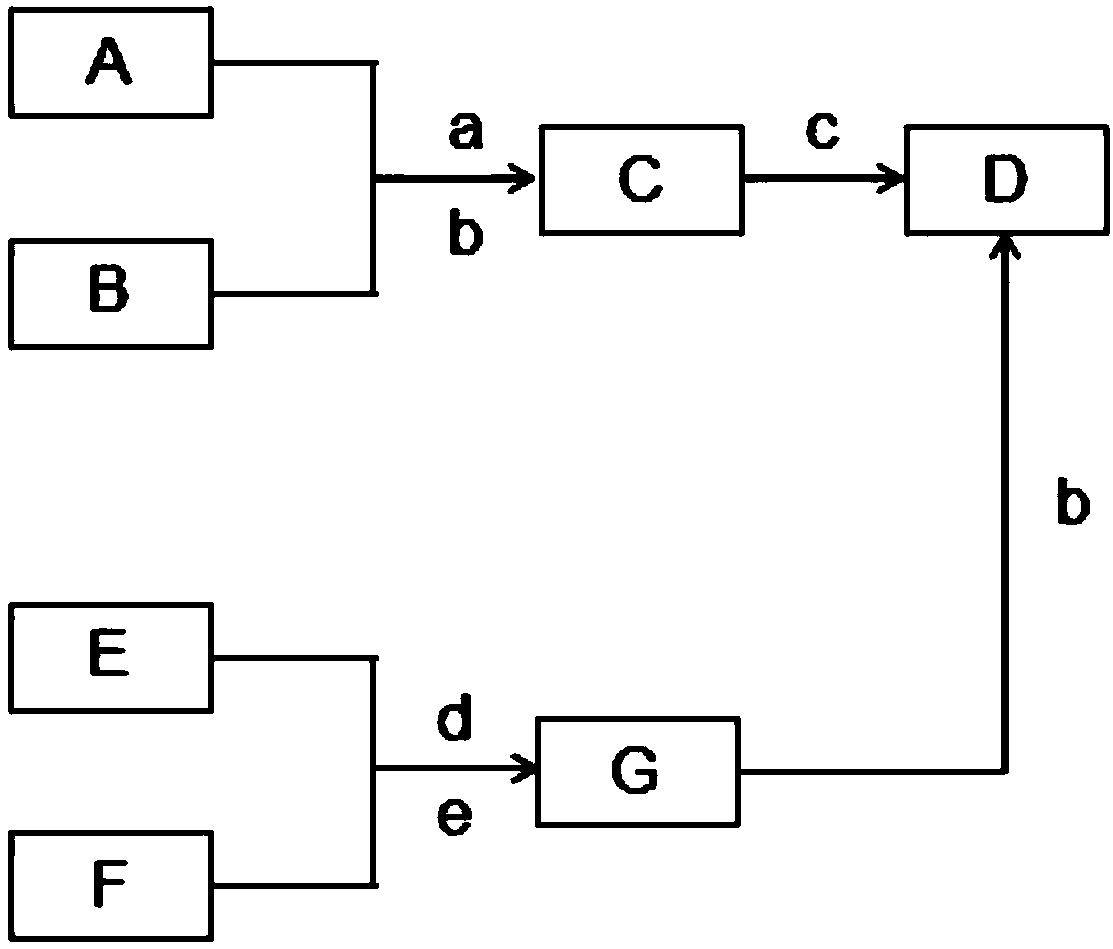

Method for coating RDX cyclotrimethylene trinitramine and HMX cyclotetramethylene tetranitramine and coating material thereof

ActiveCN103641670AImprove performanceLow impact sensitivityNon-explosive/non-thermic compositions1,4-ButanediolHydroxystearic Acid

The invention discloses a method for coating RDX cyclotrimethylene trinitramine and HMX cyclotetramethylene tetranitramine and a coating material thereof. The coating material is 2, 3-dihydroxymethyl-2, 3-binitro-1, 4-butanediol tetralaurate, 2, 3-dihydroxymethyl-2, 3-binitro-1, 4-butanediol tetrastearate or 2, 3-dihydroxymethyl-2, 3-binitro-1, 4-butanediol tetra(12-hydroxystearic acid) ester. The method for coating RDX and HMX comprises the following steps: adding RDX or HMX and the wrapping material into acetone or DMSO (Dimethylsulfoxide); fully stirring; heating to 50 DEG C; dropwise adding the mixed liquor by a heat preserving dropper to quickly stirred water; and filtering and drying to constant weight. Compared with conventional inertial materials, the adopted coating material comprises two nitro groups in the molecular structure, and performances of RDX and HMX coated with the wrapping material are improved to a certain extent. The mechanical sensitivity test results show that the degree of percussion sensitivity and the frictional sensitivity of RDX coated with BHDBTL, BHDBTS and DHDBTHS are remarkably lower than those of a simple substance RDX. The degree of percussion sensitivity of HMX coated with BHDBTL, BHDBTS and DHDBTHS are remarkably lower than those of a simple substance HMX and the frictional sensitivity tends to get reduced.

Owner:NANJING UNIV OF SCI & TECH

Induced crystallization method of ammonium salt

InactiveCN108409513ARegular shape structureLow impact sensitivityNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPhysical chemistryGraphite

The invention relates to an induced crystallization method of an ammonium salt and belongs to the field of processing and preparation of materials. The method comprises the following steps: taking graphene and an energy-containing inorganic ammonium salt as raw materials, carrying out induced crystallization and compounding the energy-containing organic ammonium salt on graphene to prepare a graphene / energy-containing inorganic ammonium salt composite material; the morphology of the inorganic ammonium salt can be effectively improved; and the safety of the energy-containing inorganic ammoniumsalt can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Smokeless emission chemical for fireworks

The invention relates to a smokeless emission chemical for fireworks. The smokeless emission chemical consists of the following components in parts by weight: 20-120 parts of nitrocellulose, 5-10 parts of graphite, 5-25 parts of carboxymethylcellulose, 3-40 parts of charcoaled hemp stalk powder, 3-40 parts of charcoaled fir powder, 2-30 parts of ammonium dichromate, 10-30 parts of barium nitrate and 5-40 parts of potassium perchlorate. The smokeless emission chemical produces smoke only after being burnt, which is 80% less than that of fireworks made from conventional materials; the smokeless emission chemical is free from sulfur dioxide, and the riction sensitivity, collision degree, heat absorption, wet absorption and compatibility are superior to those of the common military saltpeter.

Owner:杨培江

Composite oxidant used for fireworks and crackers and preparation method thereof

InactiveCN101597195ALow impact sensitivityReduced friction sensitivityExplosivesPolyvinyl butyralFireworks

The invention relates to a composite oxidant used for fireworks and crackers and a preparation method thereof, belonging to the field of fireworks and crackers. The composite oxidant used for fireworks and crackers comprises the following components in a certain mass ratio: potassium perchlorate, potassium nitrate, ammonium perchlorate, polyvinyl butyral and catalysts. The composite oxidant is obtained by the following steps: carrying out the evaporation crystallization on the components of the composite oxidant respectively; grinding and mixing the components and precipitating a layer of polyvinyl butyral outside the mixed components. The crackers are obtained by preparing the composite oxidant, sulfur, aluminum powder and perlite powder into a pyrotechnic composition. By testing, the mechanical sensitivity, hygroscopicity and cracker sound level of the pyrotechnic composition conform to the national standards.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

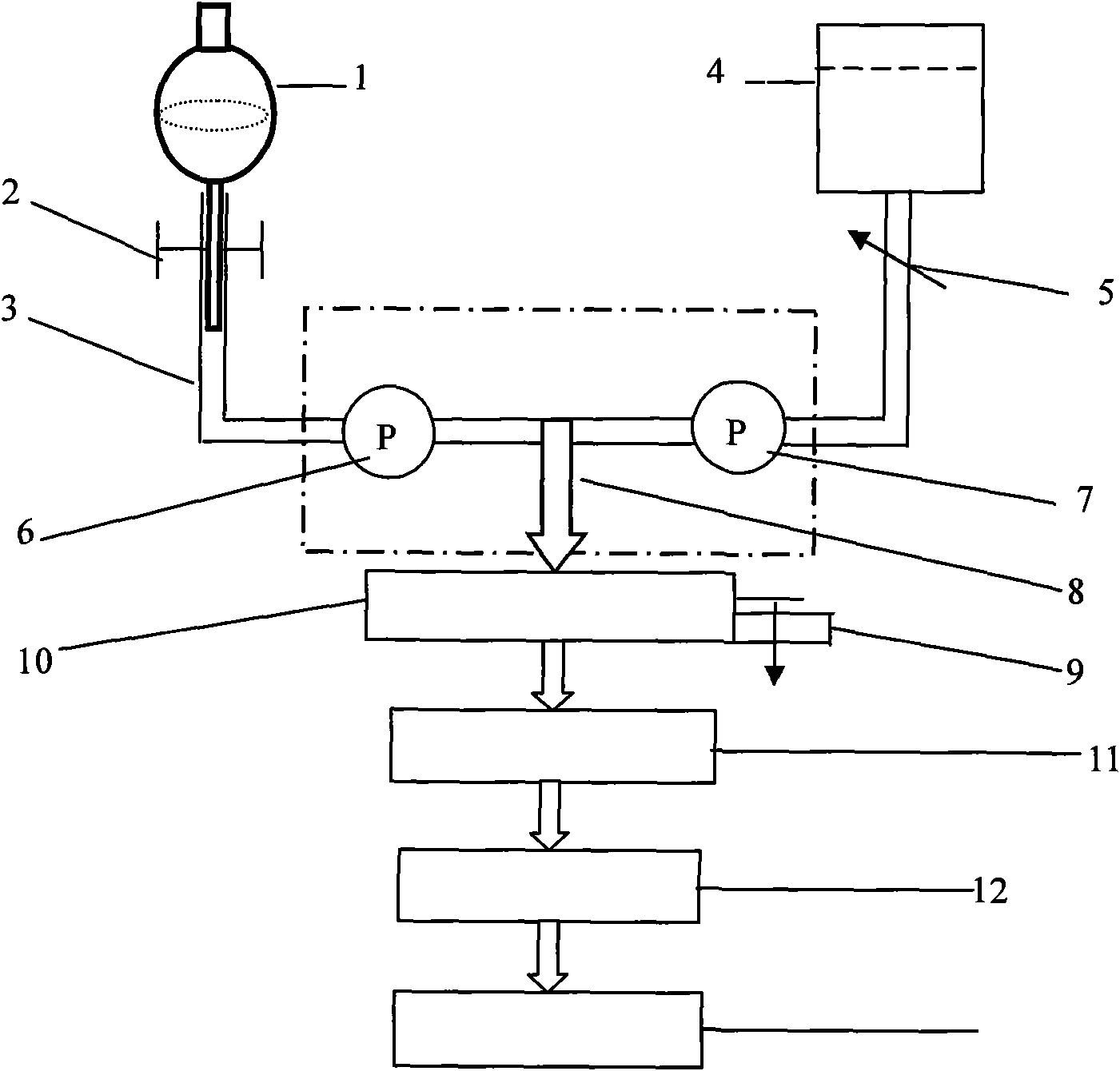

Method for preparing thinned potassium chlorate used for fireworks and crackers

The invention relates to a method for preparing thinned potassium chlorate used for fireworks and crackers, and belongs to the field of fireworks and crackers. The method comprises the following steps: adding potassium chlorate solution into a separating funnel, adding a non solvent into a water tank, and controlling the volume ratio of the potassium chlorate solution and the non solvent by adjusting the volume flow rate of a pressure pump 1 and a pressure pump 2; mixing the potassium chlorate solution and the non solvent through a nozzle, and then separating out potassium chlorate particles from the water solution; forming suspension of the thinned potassium chlorate particles by the separated potassium chlorate particles under the dispersion action of jet flow; and then after the suspension flows out from a buffering device and then enters a filter device, filtering the suspension, and freeze-drying filter cakes to obtain the thinned potassium chlorate particles. The thinned potassium chlorate, sulfur, nano aluminum powder and perlite powder are prepared into pyrotechnic compositions to form crackers. Through test, both the impact sensitivity of the pyrotechnic compositions and the sound-level value of the crackers conform to national standard requirements.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Polyurethane coated modified potassium chlorate and preparation method and applications thereof

InactiveCN103242113AExcellent flexibility and cushioningLow costAlkali metal salt explosive compositionsToluene diisocyanatePotassium chlorate

The invention discloses a kind of polyurethane coated modified potassium chlorate. The polyurethane coated modified potassium chlorate is of a core-shell structure, takes potassium chlorate as an inner core and takes polyurethane as a coating shell, and the mass ratio of the polyurethane to the potassium chlorate is 0.1-0.05:1. The invention also discloses a preparation method of the polyurethane coated modified potassium chlorate. The preparation method comprises the following steps: adding toluene diisocyanate and dehydrated polypropylene glycol into an organic solvent, adding potassium chlorate particles, heating, stirring, and carrying out condensed backflow; cooling a reaction system, adding a dehydrated dimethylolpropionic acid and a catalyst into the reaction system, stirring and carrying out condensed backflow; adding dehydrated butanediol into the reaction system, stirring and carrying out condensed backflow; and adding dehydrated triethylamine, and after the obtained object is fully stirred, carrying out solid-liquid separation, and drying obtained solid particles so as to obtain products. A polyurethane coated modified potassium chlorate product disclosed by the invention can be used as an oxidant for fireworks and crackers, and can reduce the mechanical sensitivity of potassium chlorate containing pyrotechnic compositions and increase the thermal security and stability thereof.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

HMX-based boraxal-containing explosive

InactiveCN108675910AReduce topographical defectsIncrease contentExplosivesPressure gas generationMass ratioMetallurgy

The invention relates to HMX-based boraxal-containing explosive. The explosive is prepared from the following various ingredients in percentage by patent: 60-68% of HMX, 15-25% of B-A1 composite powder and 14-18% of bonding agent, wherein the mass ratio of powder B to powder Al in the B-A1 composite powder is 1:1. The explosive can be used as the main charge of high-strength and high-security ammunition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

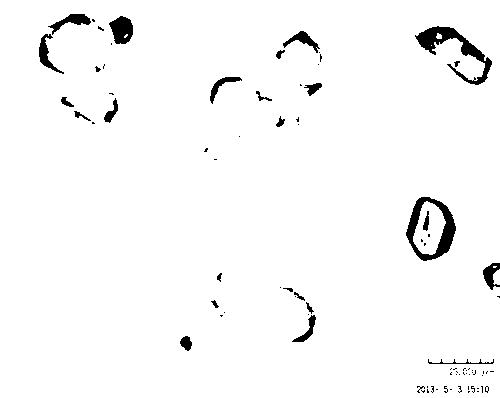

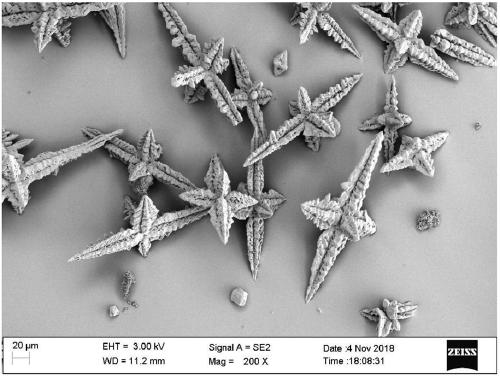

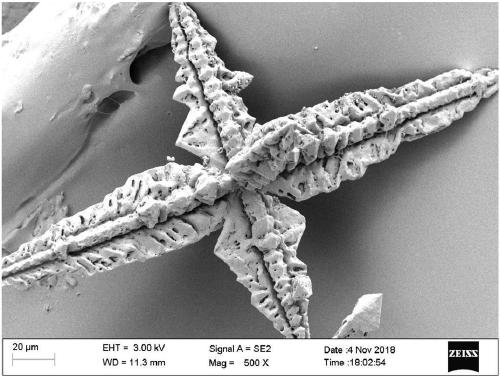

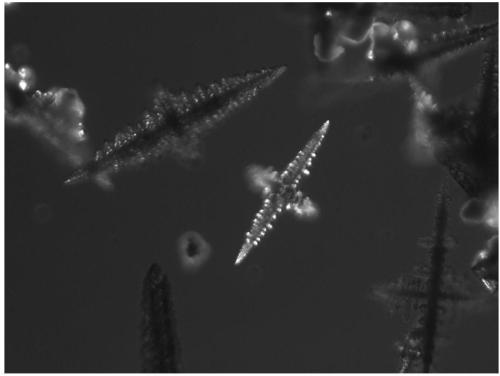

Hexogen explosive crystal and preparation method thereof

ActiveCN109305867ALow impact sensitivitySimple processExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPrillSelf-assembly

The invention discloses a Hexogen explosive crystal and a preparation method thereof. The preparation method comprises the following steps: (A) performing ball milling on the Hexogen explosive to obtain fine particle powder; (B) heating the obtained fine particle explosive powder in a dye solution, and finishing a self-assembly reaction by taking dye molecules as a template agent to obtain the Hexogen explosive crystal with specific morphology. The Hexogen explosive crystal prepared by the method has uniform morphology, all particles are of a special cross-morphology structure, and the explosive has a color while the impact sensitivity is obviously reduced in comparison with a common Hexogen explosive; the preparation method disclosed by the invention has a simple technological process, the yield reaches 95% or more, and expanded preparation is easy to implement; the obtained Hexogen explosive crystal product has an important application value in the fields such as primary explosive and micro-component charging.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

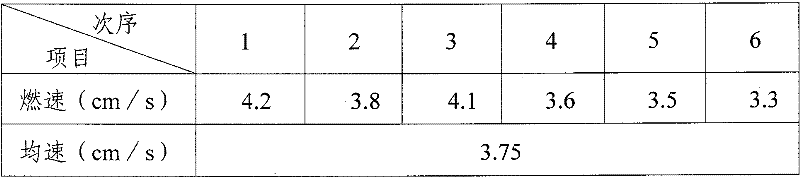

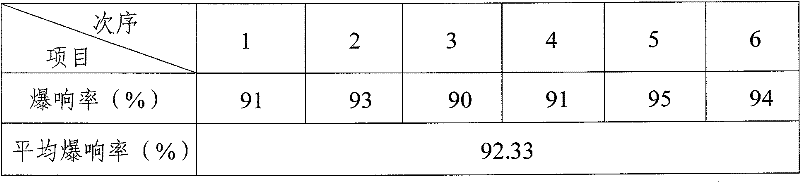

Novel potassium perchlorate paper firing line for firecrackers

InactiveCN101973828BImprove performanceIncrease burn rateInorganic oxygen-halogen salt explosive compositionsFusesFirecrackerPulp and paper industry

Owner:陕西省蒲城县新型花炮技术推广中心

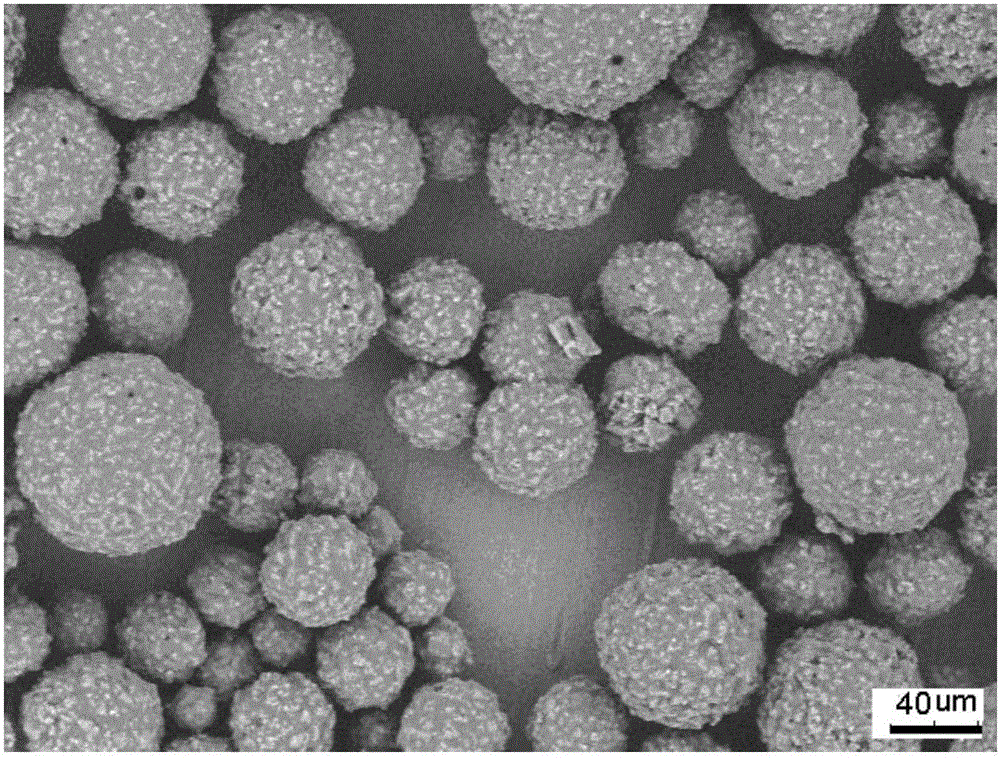

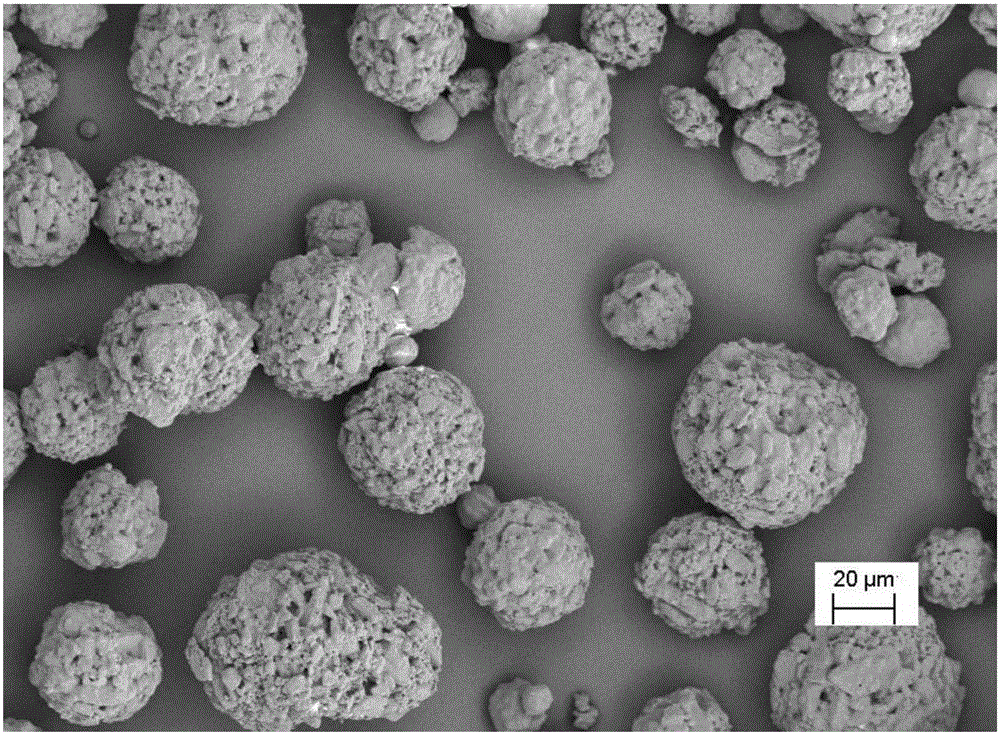

Low-sensitivity and high-strength octogen-based composite material and preparation method thereof

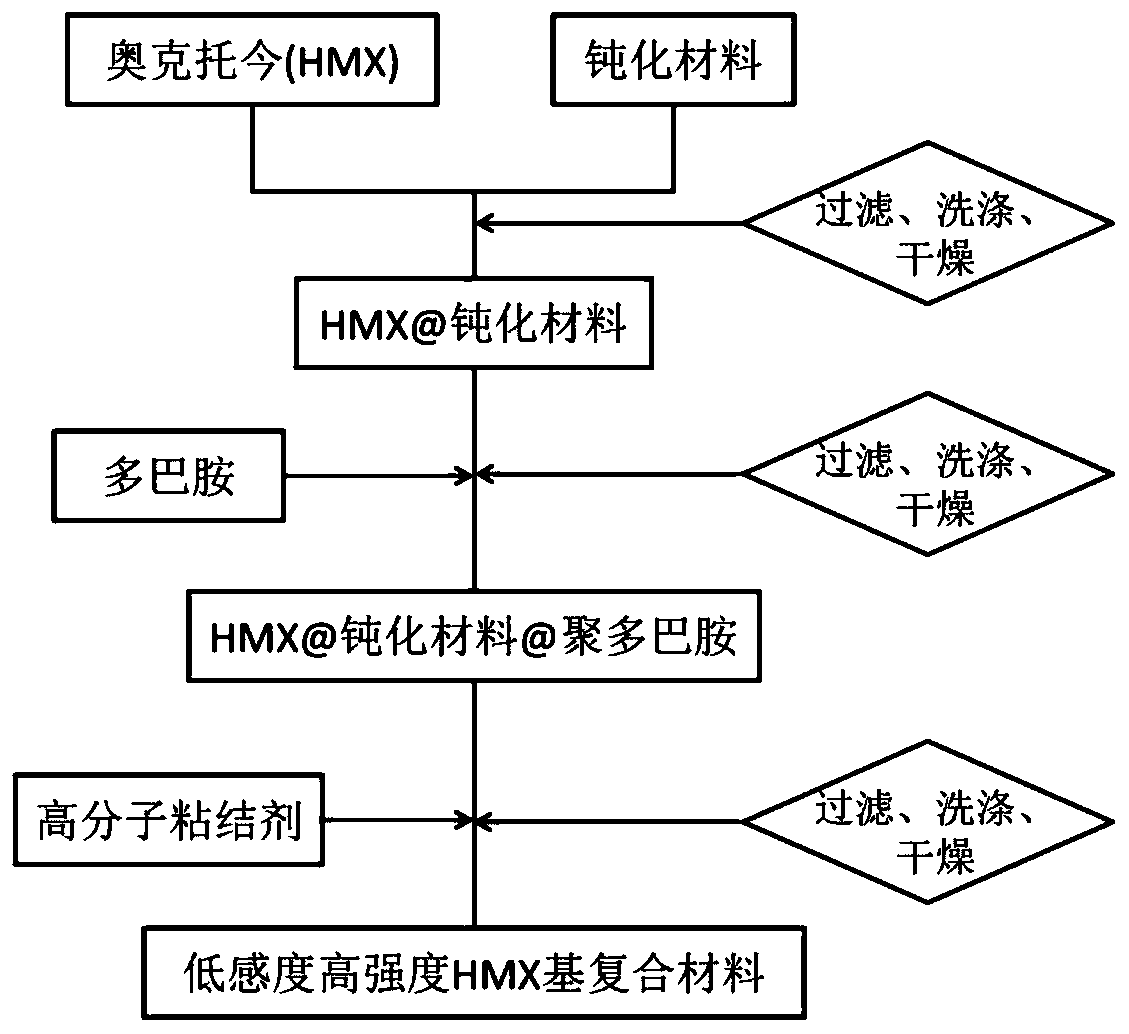

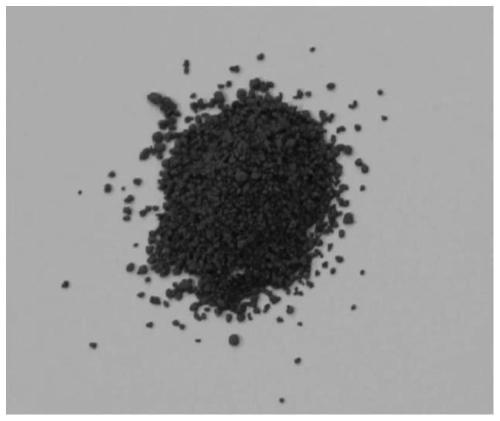

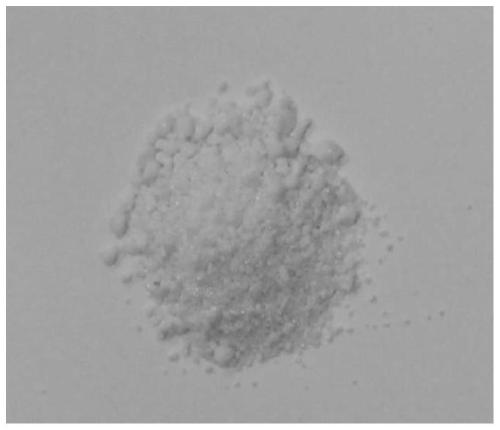

ActiveCN110204403AReduce sensitivityLow sensitivity high intensityExplosive working-up apparatusIn situ polymerizationFiltration

The invention discloses a low-sensitivity and high-strength octogen-based composite material and a preparation method thereof. The preparation method comprises the following steps: (1) adding octogeninto a certain solvent, performing uniform dispersing, performing in situ coating with a passivation material, and carrying out suction filtration, washing and drying to obtain an octogen@passivationmaterial core-shell structured explosive particles; (2) adding the octogen@passivation material core-shell structured explosive particles to an aqueous Tris solution with a pH value of 8.5, performingmechanic stirring, adding dopamine hydrochloride, and carrying out in-situ polymerization coating, suction filtration, washing and drying to obtain octogen@passivation material@polydopamine one-coredouble-shell structured explosive particles with the passivation material as the inner shell and an interface modifier polydopamine as an outer shell; and (3) adding the one-core double-shell structured explosive particles to water, performing mechanic stirring to achieve uniform dispersing, adding a polymer binder solution, and carrying out vacuum treatment, suction filtration, washing and dryingto obtain the low-sensitivity and high-strength octogen-based composite material.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

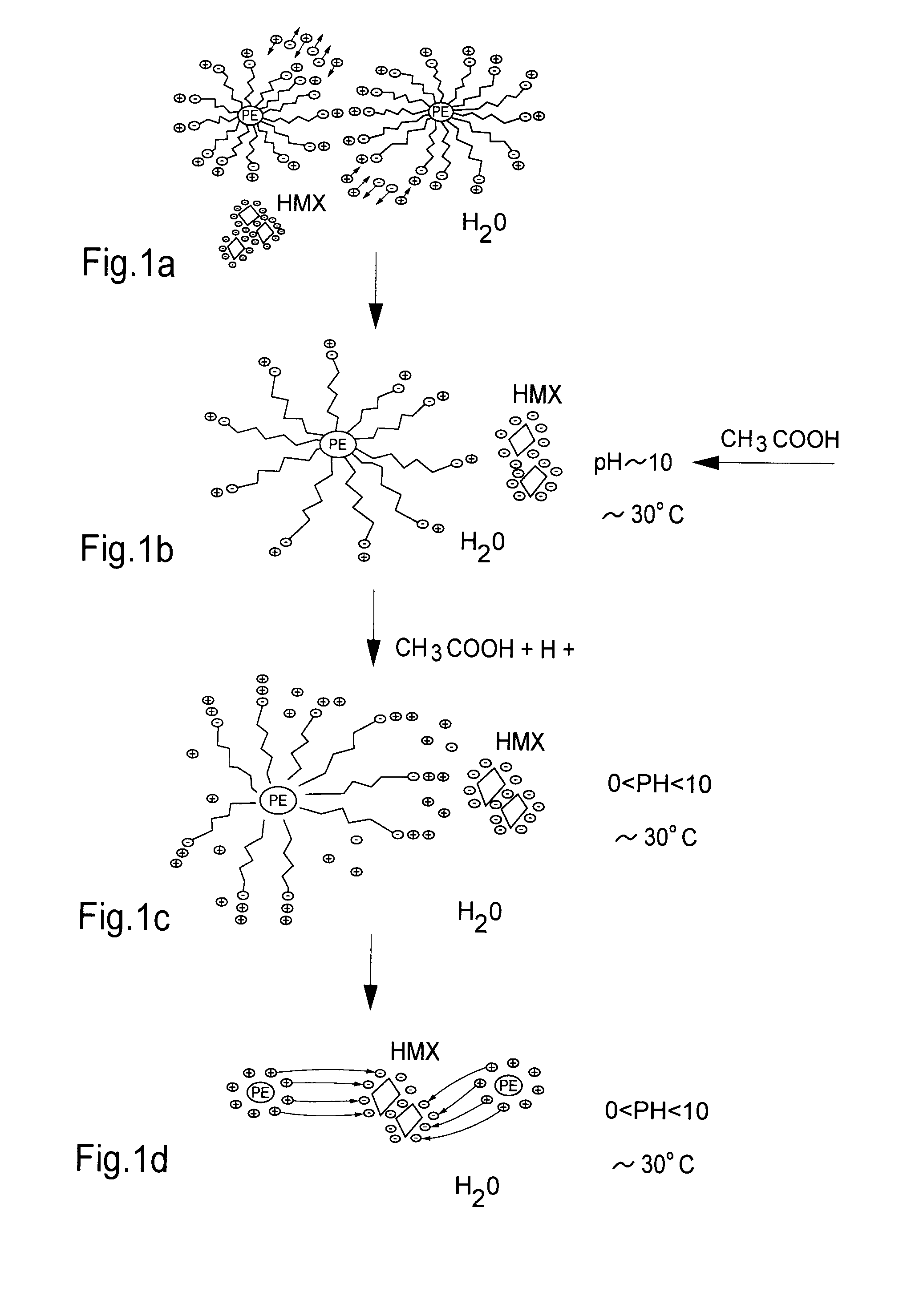

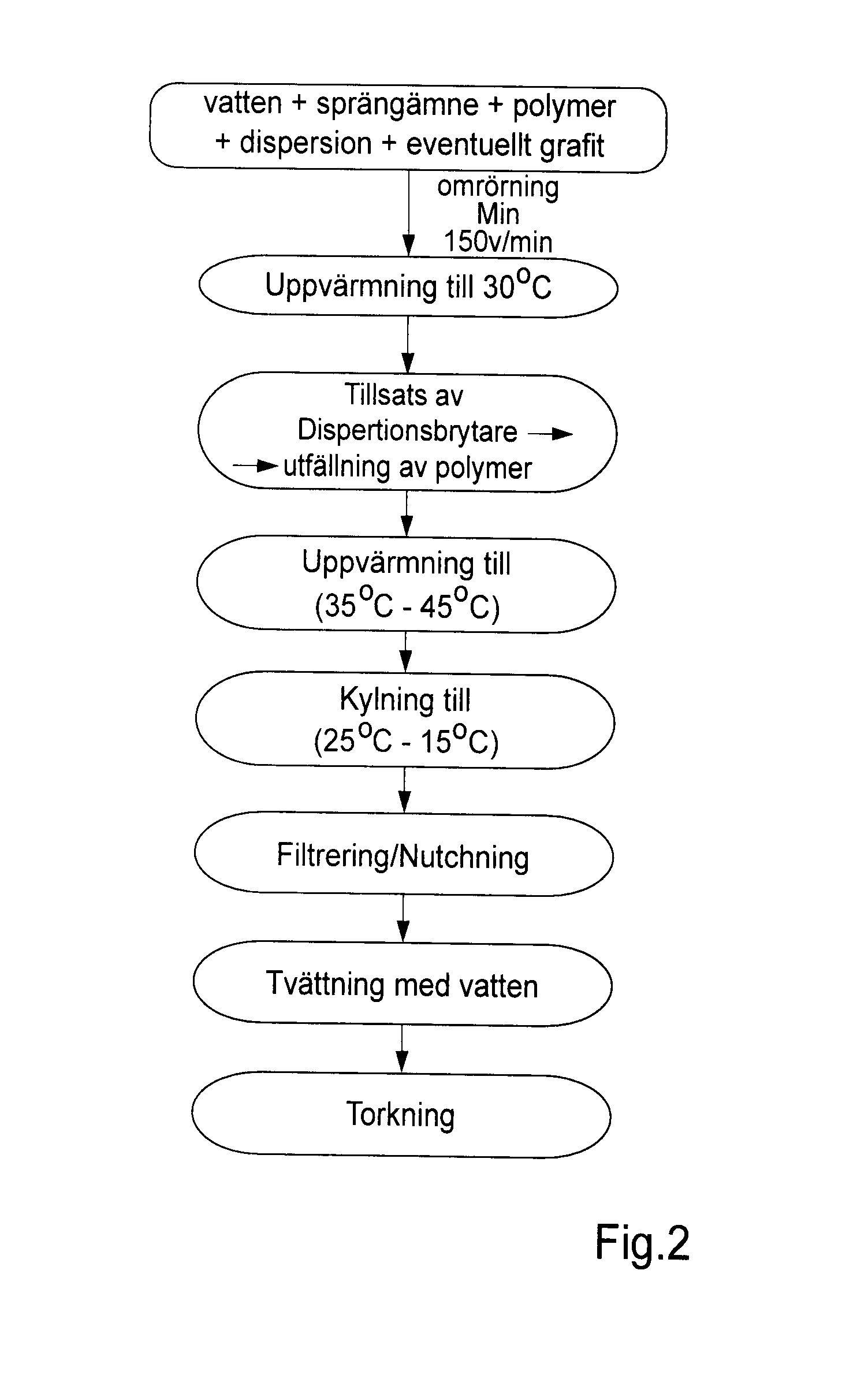

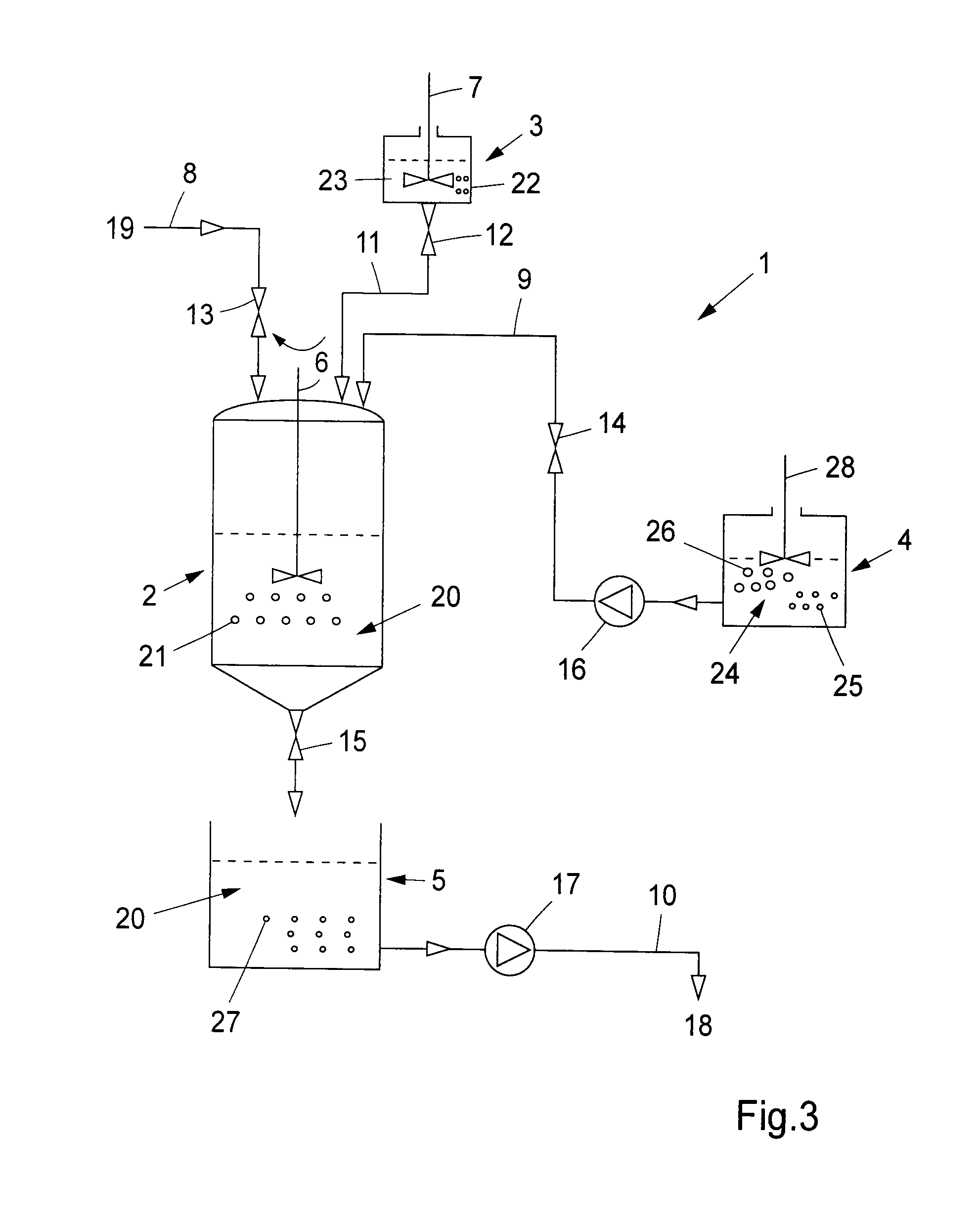

Phlegmatisation of an explosive in an aqueous suspension

ActiveUS20160137566A1High compression densityLow impact sensitivityLiquid surface applicatorsElectric shock equipmentsExplosive materialChemistry

A method for phlegmatising an explosive in an aqueous suspension including a dispersed phlegmatising agent. The phlegmatising agent is deposited on a surface of the explosive at low temperature utilizing opposite electric charges of the phlegmatising agent and the explosive. Also a device and a phlegmatised explosive.

Owner:EURENCO BOFORS

Rock powdery emulsion explosive and preparation method thereof

The invention relates to a rock powdery emulsion explosive and a preparation method thereof. The rock powdery emulsion explosive is produced by that: an emulsion is formed by mixing a water phase ingredient and an oil phase ingredient in a mixer, then the emulsion is vacuum dried to be powder, and porous granulated ammonium nitrate is added into the powder. The rock powdery emulsion explosive provided in the invention, which is a high-performance safe explosive, is simple in composition; high in explosive power; and low in toxic gas content, impact sensitivity and mechanical sensitivity. The preparation method is simple and safe, and no inert substance is added into the explosive.

Owner:SICHUAN YAHUA IND GRP

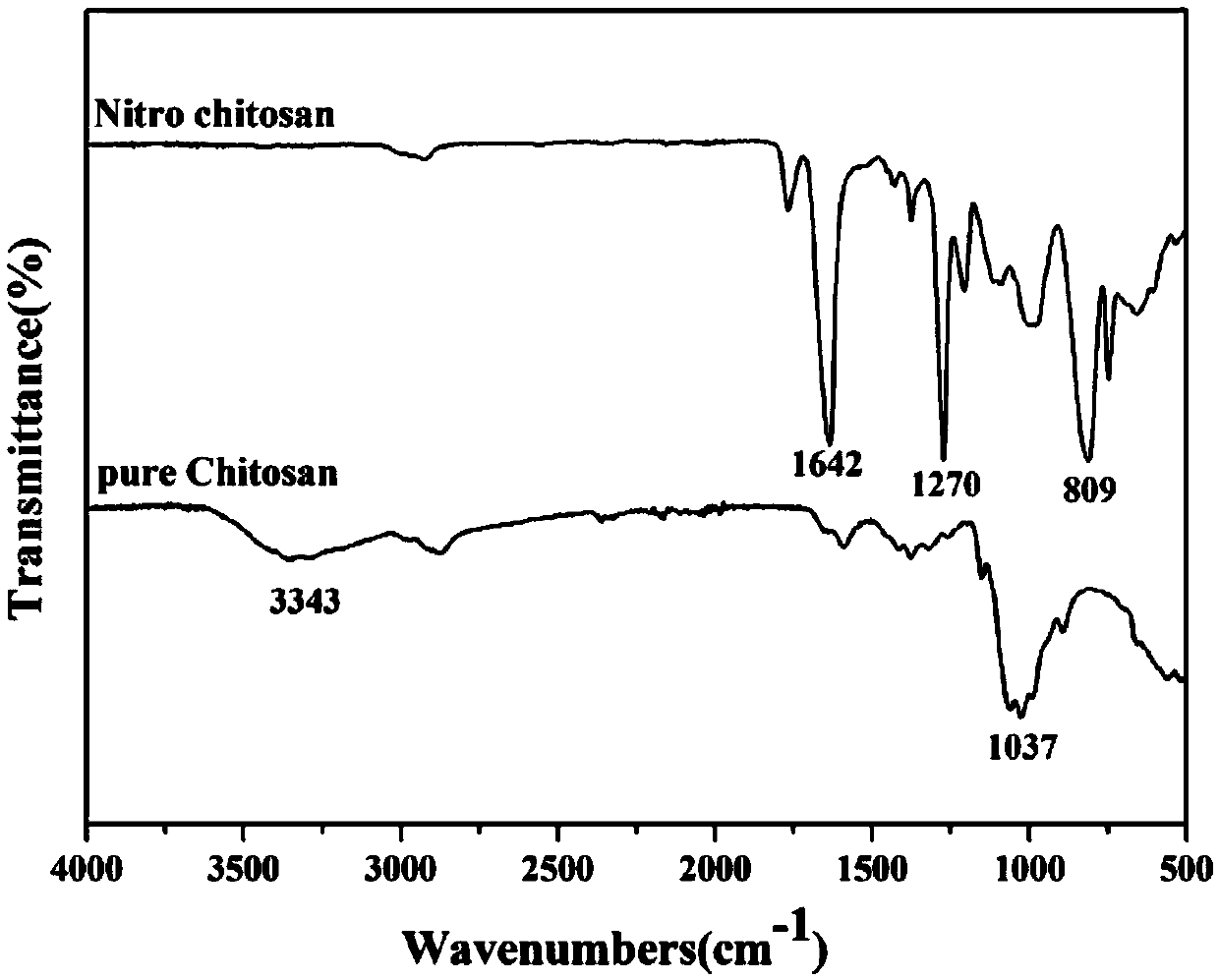

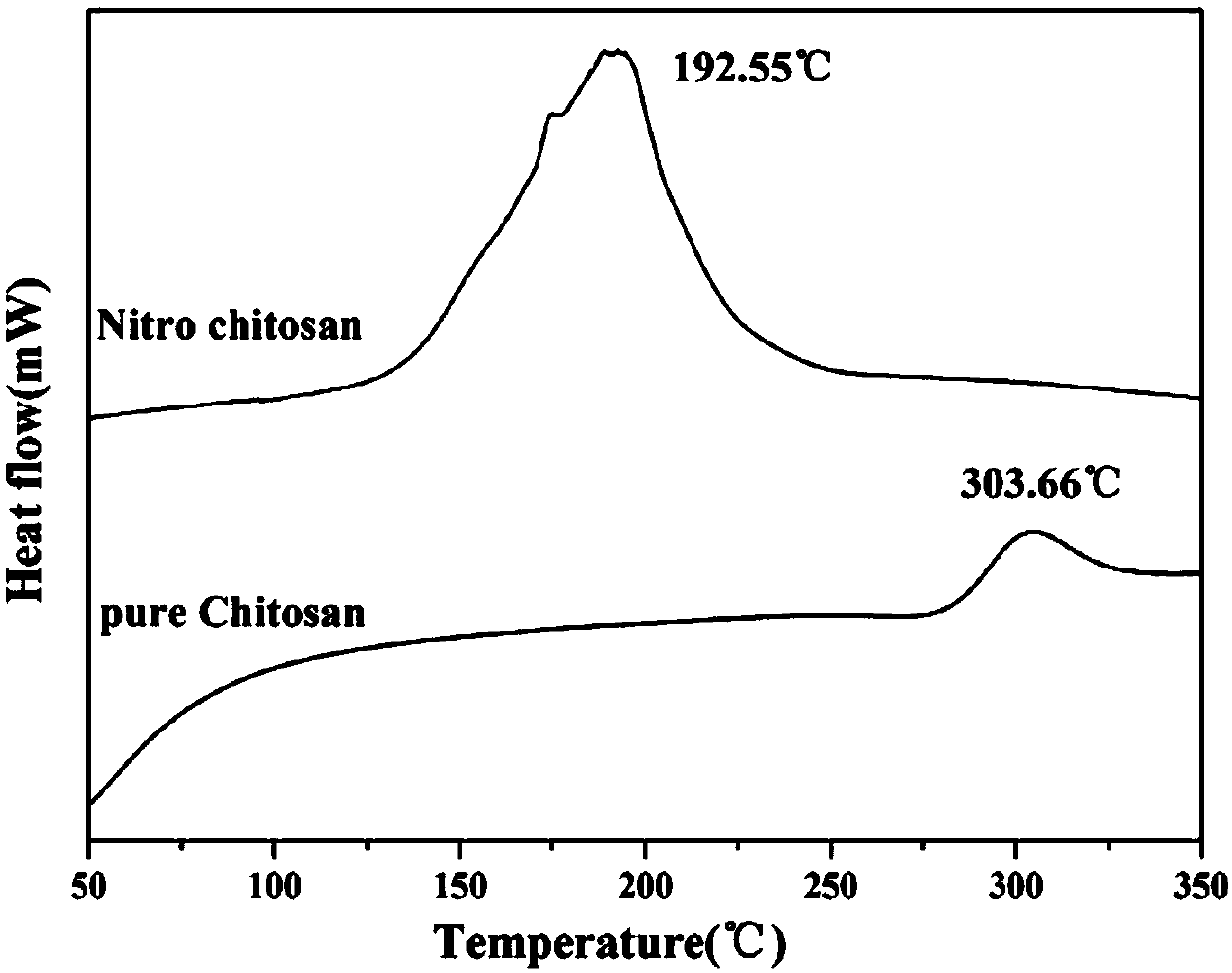

Preparation method of nitrified chitosan and application thereof

ActiveCN109627358AHigh degree of substitutionLarge heat releaseStarch/sugar nitrate explosive compositionsAcetic anhydrideDecomposition

The invention relates to a preparation method of nitrified chitosan and application thereof. The related application is the application of nitrated chitosan as an energetic material, and the nitrification substitution degree of the nitrified chitosan is greater than 1.8. The related preparation method comprises the steps of adding chitosan into acetic anhydride according to the formula amount, adding fuming nitric acid in the stirring process, then adding concentrated sulfuric acid, executing reaction at a low temperature for a suitable time, and then conducting post-treatment on a reactant toobtain the nitrified chitosan. sugar. The nitrified chitosan prepared by the preparation method has large released decomposition heat amount and low sensitivity.

Owner:NORTHWEST UNIV(CN)

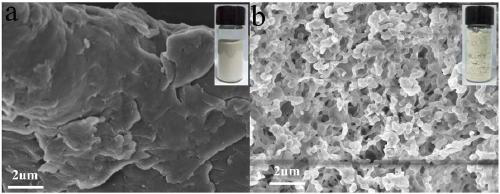

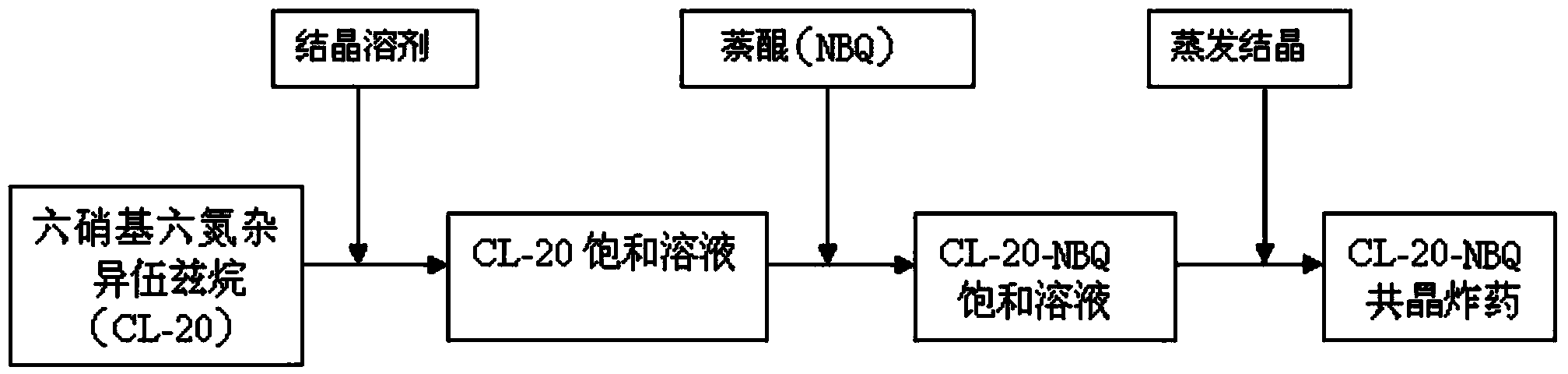

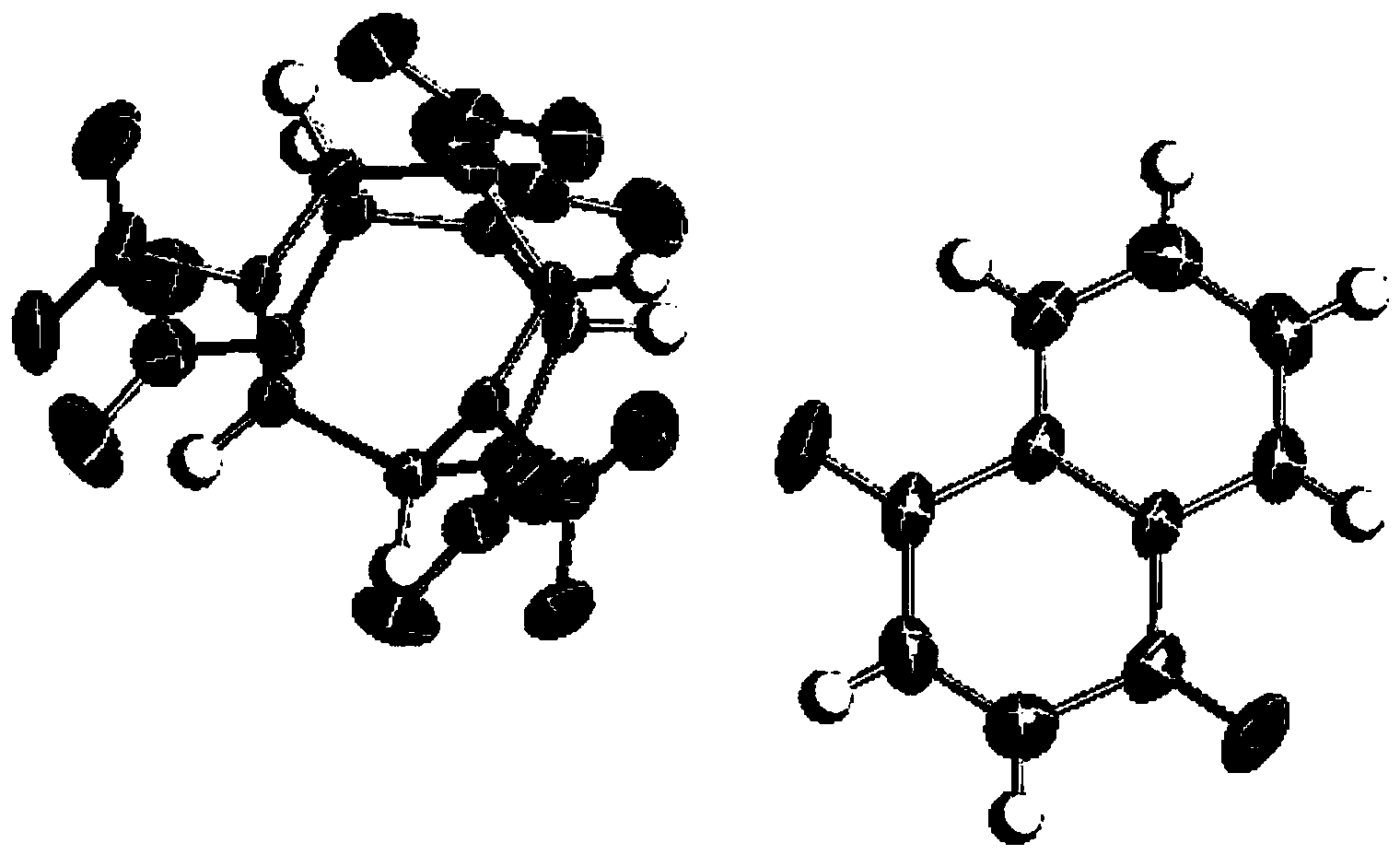

Preparation method for hexanitrohexaazaisowurtzitane and naphthoquinone co-crystallized explosive

ActiveCN103396273ALow impact sensitivityImprove securityNitroparaffin explosive compositionsSynthonNaphthoquinone

The present invention discloses a preparation method for a hexanitrohexaazaisowurtzitane and naphthoquinone co-crystallized explosive, wherein a crystallization solvent is adopted to prepare a hexanitrohexaazaisowurtzitane and naphthoquinone saturated solution, the saturated solution is placed into a beaker to evaporate the solvent in a constant temperature incubator, and crystallization is performed to obtain the hexanitrohexaazaisowurtzitane and naphthoquinone co-crystallized explosive. According to the present invention, high sensitivity CL-20 and NBQ form co-crystal through intermolecular interactions so as to significantly reduce impact sensitivity of the pure component CL-20, and substantially increase safety performance; and the intermolecular interaction law of co-crystal molecules is further understood, and the obtained effective synthon can be provided for guiding co-crystal design.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Vinylferrocene oligomer catalyst for catalyzing decomposition of ammonium perchlorate

ActiveCN105817263AHigh in ironHigh impact sensitivityOrganic-compounds/hydrides/coordination-complexes catalystsMetallocenesOligomerCatalytic decomposition

The invention discloses a vinylferrocene oligomer catalyst for catalyzing decomposition of ammonium perchlorate. The vinylferrocene oligomer catalyst which has high iron content (24.3-26.3%) and a molecular weight in a range of 400-5000 is synthesized by taking vinylferrocene as a polymerization monomer through anionic polymerization, and thevinylferrocene oligomer catalyst is applied to the catalytic decomposition of the ammonium perchlorate. The catalyst is nonvolatile, has remarkable catalytic effect for the thermal decomposition of the ammonium perchlorate, and has extremely low impact sensitivity (10-14%) with an ammonium perchlorate binary mixture system, wherein the impact sensitivity is far low than the high sensitivity (98%) of commonly used catocene corresponding systems; the catalyst can be used as a new catalyst for catalyzing the decomposition of the ammonium perchlorate, and is applied to various solid propellants and gas generating agents which take the ammonium perchlorate as an oxidizing agent.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

HMX explosive microsphere containing cross-linked fluorine polymer coating layer and preparation method of HMX explosive microsphere

ActiveCN112457144ABoost energy levelsInhibition of mass reunionsNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPolymer scienceExplosive Agents

The invention belongs to the technical field of composite material preparation, and discloses an HMX explosive microsphere containing a cross-linked fluorine polymer coating layer and a preparation method of the HMX explosive microsphere. The HMX explosive microsphere containing the cross-linked fluorine polymer coating layer is of a structure with fine-grained HMX particles as a core and a cross-linked fluorine polymer as a shell. The average particle size of the HMX explosive microsphere containing the cross-linked fluorine polymer coating layer is 100 [mu]m-500 [mu]m, wherein the average particle size of the fine-grained HMX particles is 500 nm to 50 [mu]m, the cross-linked fluorine polymer coating layer accounts for 5%-15% of the HMX explosive microsphere containing the cross-linked fluorine polymer coating layer in percentage by mass, the impact sensitivity characteristic drop height of the HMX explosive microsphere containing the cross-linked fluorine polymer coating layer is 52.8-87.9 cm, and the friction sensitivity of the HMX explosive microsphere containing the cross-linked fluorine polymer coating layer is 12-48%. The preparation method disclosed by the invention integrates an emulsifying solvent evaporation coating technology and an in-situ polymerization coating technology.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Method for coating TKX-50 with nitroguanidine

ActiveCN108409512ASimple production and preparation equipmentEasy to operateNon-explosive desensitisers/phlegmatisersNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsCoated surfaceNitroguanidine

The invention relates to a method for coating TKX-50 with nitroguanidine, and belongs to the field of energy-containing materials. The method comprises the following steps of recrystallizing and coating a macromolecular polymer coated with the TKX-50 by a solution suspension method; firstly, coating the TKX-50 explosive by the passivated nitroguanidine explosive by a solution recrystallizing method, and controlling the nucleating and growth process of energy-containing crystal to improve the form of the coated surface of the energy-containing crystal; then, coating a layer of macromolecular polymer to the coated surface of the nitroguanidine. The method has the advantages that the problem of compatibility between the macromolecule and the surface of the TKX-50 explosive is solved, the explosion property of the TKX-50 explosive self is maintained, and the mechanical sensing degree is reduced; the technology and method have not been reported in the explosive passivating field, and the passivated TKX-50 explosive is a head of high-energy explosive mixture.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of perdeuterated CL-20

InactiveCN111471052AHigh yieldHigh purityIsotope introduction to heterocyclic compoundsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAcetic acidPtru catalyst

The invention relates to a preparation method of perdeuterated CL-20, and belongs to a synthesis technology of a deuterated energetic material. According to the method, deuterated N,N'-di-tert-butyl ethane-1,2-diimine and deuterated benzylamine are used as raw materials, deuterated acetic acid is used as a catalyst to synthesize an intermediate product that is deuterated hexabenzyl hexaazaisowurtzitane. Compared with a traditional method, the yield of the deuterated hexabenzyl hexaazaisowurtzitane is obviously increased; by adopting the deuterated hexaacetyl hexaazaisowurtzitane as a nitrification precursor for nitrification, the product does not contain impurities such as pentanitromonoformyl hexaazaisowurtzitane, and the obtained deuterated CL-20 is high in purity. Compared with common CL-20, the prepared perdeuterated CL-20 has better detonation performance and improved safety and better facilitates practical application.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Energy containing ionic salts of 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan and preparation method thereof Energy containing ionic salts of 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan and preparation method thereof](https://images-eureka.patsnap.com/patent_img/9439210a-12cf-48f6-9cbf-136ad7c878a4/BSA00000732461400021.PNG)

![Energy containing ionic salts of 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan and preparation method thereof Energy containing ionic salts of 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan and preparation method thereof](https://images-eureka.patsnap.com/patent_img/9439210a-12cf-48f6-9cbf-136ad7c878a4/BSA00000732461400022.PNG)

![Energy containing ionic salts of 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan and preparation method thereof Energy containing ionic salts of 4, 4'-bi [3, 3'-(1-H-5-tetrazolium)] furazan and preparation method thereof](https://images-eureka.patsnap.com/patent_img/9439210a-12cf-48f6-9cbf-136ad7c878a4/BSA00000732461400031.PNG)