Hexogen explosive crystal and preparation method thereof

A technology of RDX and explosives, which is applied in the field of RDX crystals and its preparation, achieving the effects of excellent performance, easy scale-up and preparation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

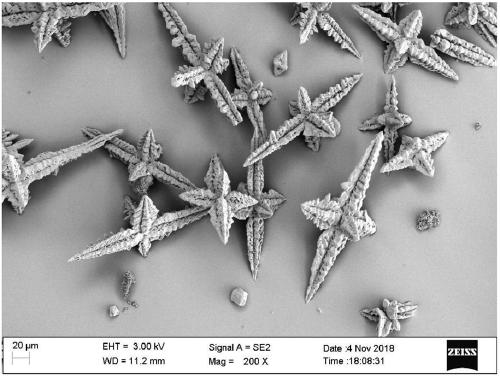

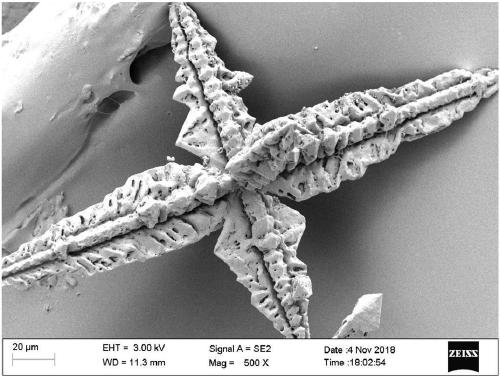

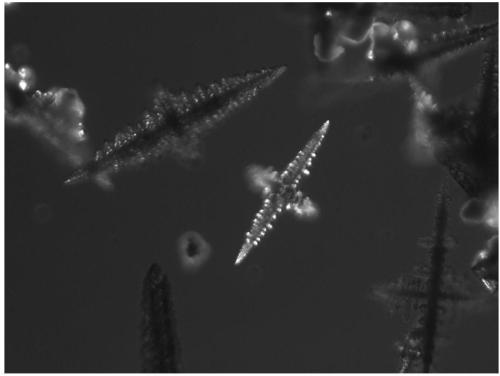

[0031] Weigh 100g of Hexogen explosives, 500g of zirconia ball milling beads, 150g of deionized water, and 0.05g of alkylphenol polyoxyethylene ether, put them together in a planetary ball milling tank, mill at room temperature for 2 hours at a speed of 450rpm, filter, Washing with deionized water, adopting freeze-drying, and drying it under the condition of vacuum degree of 10mba to obtain fine RDX powder. Weigh 0.2g of refined RDX powder, add it to 20g of the neutral red dye solution with a mass concentration of 0.4% prepared in advance, pour it into a stainless steel reactor, seal it, heat it to 115°C, and react for 4.5h. Take out and cool the reactor, filter the explosive, wash it with deionized water, and dry it to obtain RDX crystals with a light red color and a specific cross shape, and the reaction yield is 95.7%. The BAM impact sensitivity tester is used to test the impact sensitivity of explosives, and the impact sensitivity value is increased from 7.5J of the raw ma...

Embodiment 2

[0034] Weigh 500g of RDX, 2000g of zirconia ball milling beads, 550g of deionized water, and 0.25g of polyoxyethylene sorbitan monolaurate, put them together in a planetary ball mill jar, and ball mill at room temperature at a speed of 300rpm 6h, filtered, washed with deionized water, freeze-dried, and dried under the condition of vacuum degree of 1mba to obtain fine RDX powder. Weigh 10g of refined RDX explosive powder, add it to 100g of neutral red dye solution with a mass concentration of 1% prepared in advance, pour it into a stainless steel reaction kettle, seal it, heat it to 125°C, and react for 6h. Take out and cool the reactor, filter the explosive, wash it with deionized water, and dry it to obtain a light red crystal of RDX explosive with a specific cross shape, and the reaction yield is 96.3%. The BAM impact sensitivity tester was used to test the impact sensitivity of explosives, and the impact sensitivity value was increased from 7.5J to 17.5J from the raw materi...

Embodiment 3

[0037] Weigh 200g of Hexogen explosives, 2000g of zirconia ball milling beads, 600g of deionized water, and 0.1g of alkylphenol polyoxyethylene ether, put them together in a planetary ball milling tank, mill at room temperature at a speed of 200rpm for 4.5h, filter , washed with deionized water, freeze-dried, and dried under the condition of a vacuum of 4mba to obtain a refined RDX powder. Weigh 1g of the refined RDX powder, add it to 200g of saffron T dye solution with a mass concentration of 0.2% prepared in advance, pour it into a stainless steel reaction kettle, seal it, heat it to 150°C, and react for 3h. Take out and cool the reactor, filter the explosive, wash it with deionized water, and dry it to obtain a light red crystal of RDX explosive with a specific cross shape, and the reaction yield is 97.1%. The BAM impact sensitivity tester is used to test the impact sensitivity of explosives, and the impact sensitivity value is increased from 7.5J to 15.5J from the raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com