HMX explosive microsphere containing cross-linked fluorine polymer coating layer and preparation method of HMX explosive microsphere

A technology of fluoropolymer and coating layer, which is applied in the field of composite material preparation, can solve the problems of incomplete coating of HMX and difficult further improvement of safety performance, and achieve the effect of inhibiting large-scale agglomeration, improving interface performance and maintaining energy level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

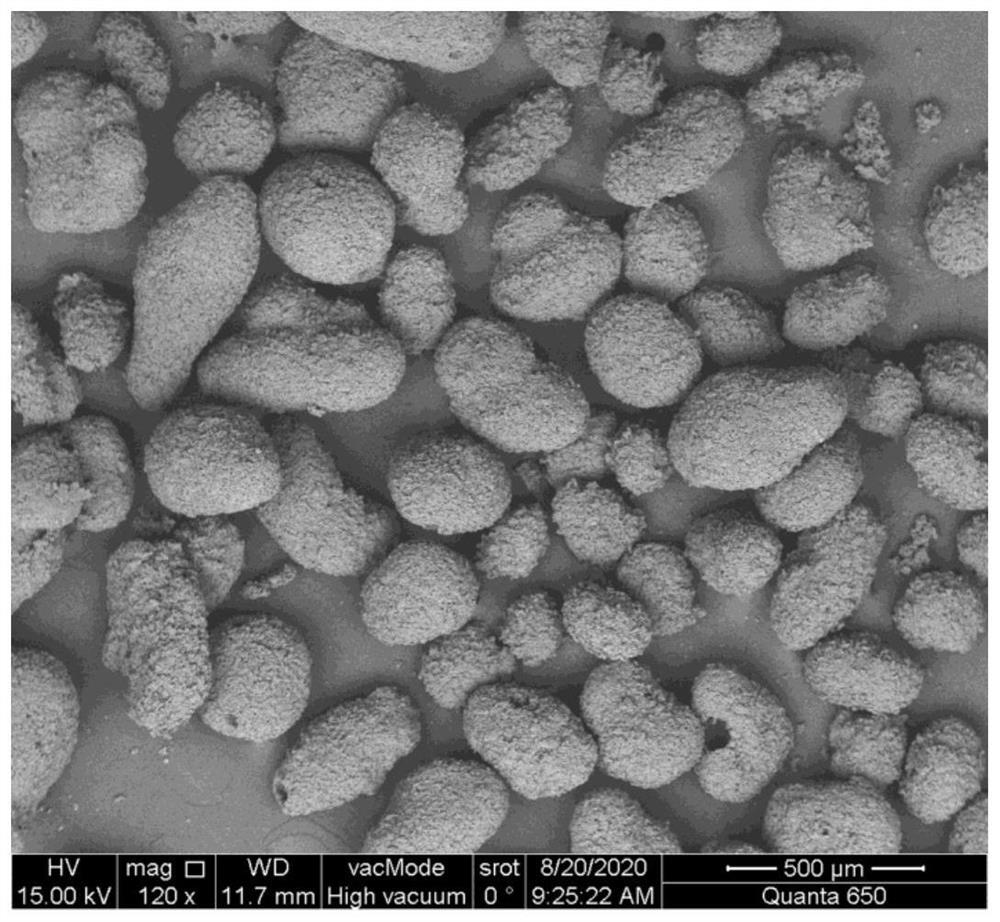

[0034] Containing the preparation method of the HMX explosive microsphere of 5.0wt% cross-linked fluoropolymer coating layer:

[0035] Step 1: Weigh 0.5g of functionalized carboxyl-terminated fluorocarbon prepolymer (number-average molecular weight is 2000g / mol, carboxyl content is 1.05mmol / g) and add it to 25g of ethyl acetate, stir at room temperature 25°C and 400rpm until completely dissolved, set aside. Weigh 10.0 g of fine-grained HMX particles (average particle size: 9.9 μm), add it into the functionalized carboxyl-terminated fluorocarbon prepolymer solution, and stir at 400 rpm to form an oil phase suspension.

[0036] Step 2: Slowly add the oil phase suspension in Step 1 to 280 g of water phase containing 2.5% OP-10 and 2.5% PVA under mechanical stirring at 1500 rpm, and emulsify for 30 minutes to form uniform emulsion droplets.

[0037] Step 3: Maintain a stirring speed of 1500rpm, and add 0.74g of HD-100 curing agent dropwise to the emulsion system (the equivalent r...

Embodiment 2

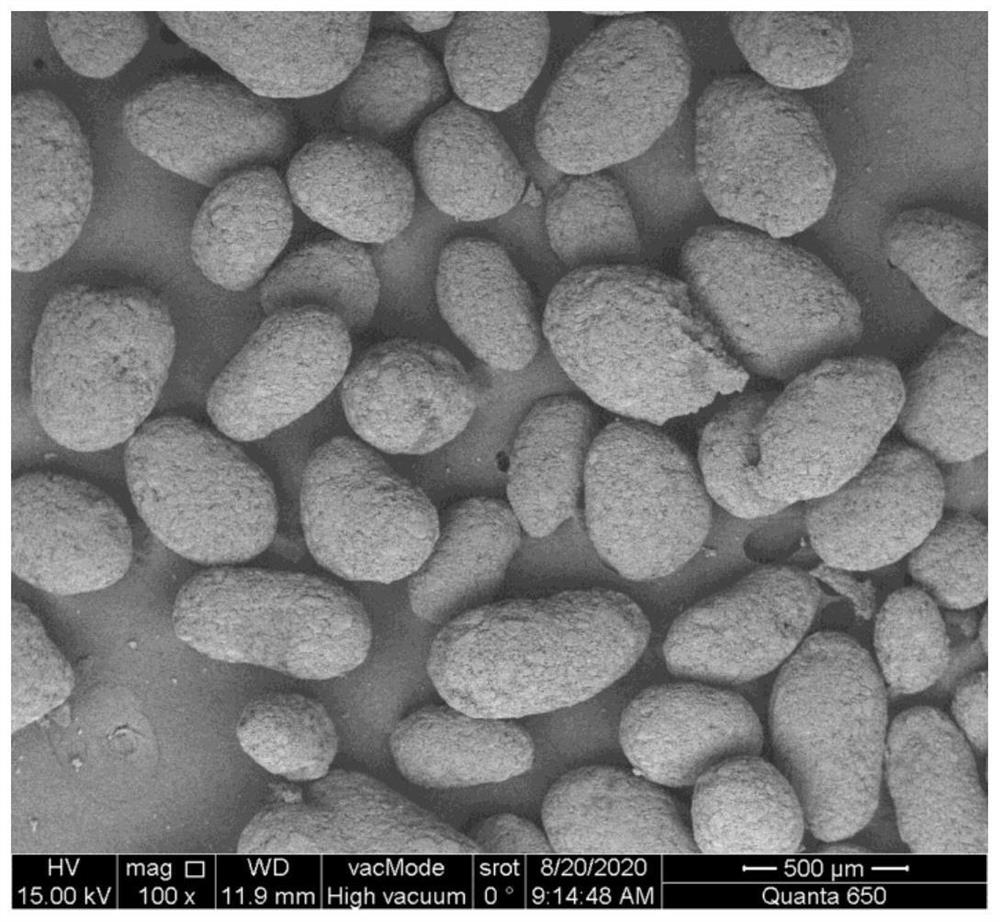

[0041] Containing the preparation method of the HMX explosive microsphere of 10.0wt% cross-linked fluoropolymer coating layer:

[0042] Step 1: Weigh 1.0 g of functionalized carboxyl-terminated fluorocarbon prepolymer (number average molecular weight is 2000 g / mol, carboxyl content is 1.05 mmol / g) and add it to 25 g of ethyl acetate, stir at room temperature 25°C and 400 rpm until completely dissolved, set aside. Weigh 10.0 g of fine-grained HMX particles (average particle size: 9.9 μm), add it into the functionalized carboxyl-terminated fluorocarbon prepolymer solution, and stir at 400 rpm to form an oil phase suspension.

[0043] Step 2: Slowly add the oil phase suspension in Step 1 to 280 g of water phase containing 2.5% OP-10 and 2.5% PVA under mechanical stirring at 1500 rpm, and emulsify for 30 minutes to form uniform emulsion droplets.

[0044] Step 3: Maintain a stirring speed of 1500rpm, and add 1.47g of HD-100 curing agent dropwise to the emulsion system (the equiva...

Embodiment 3

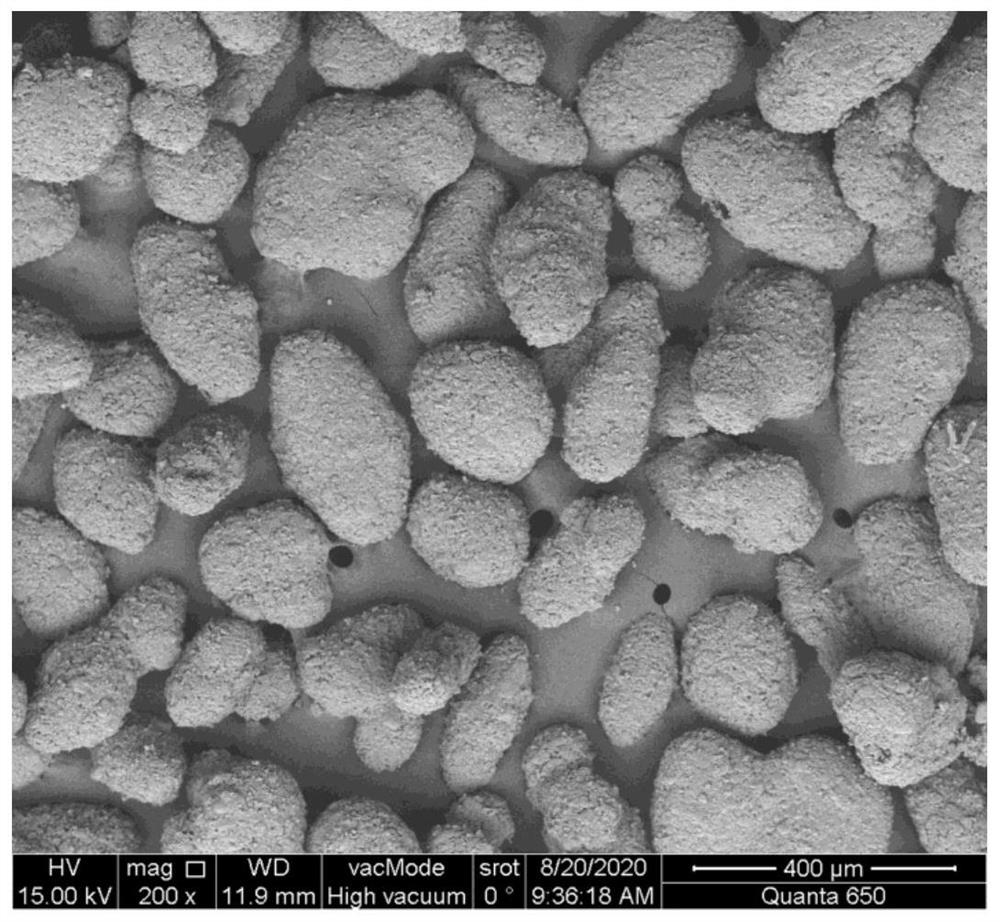

[0048] Containing the preparation method of the HMX explosive microsphere of 15.0wt% cross-linked fluoropolymer coating layer:

[0049] Step 1: Weigh 1.5g of functionalized carboxyl-terminated fluorocarbon prepolymer (the number average molecular weight is 2000g / mol, and the carboxyl content is 1.05mmol / g) and add it to 25g of ethyl acetate, and stir at room temperature at 25°C and 400rpm until completely dissolved, set aside. Weigh 10.0 g of fine-grained HMX particles (average particle size: 9.9 μm), add it into the functionalized carboxyl-terminated fluorocarbon prepolymer solution, and stir at 400 rpm to form an oil phase suspension.

[0050] Step 2: Slowly add the oil phase suspension in Step 1 to 280 g of water phase containing 2.5% OP-10 and 2.5% PVA under mechanical stirring at 1500 rpm, and emulsify for 30 minutes to form uniform emulsion droplets.

[0051] Step 3: Maintain a stirring speed of 1500rpm, and add 2.21g of HD-100 curing agent dropwise to the emulsion syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com