Induced crystallization method of ammonium salt

A technology for inducing crystallization and ammonium salt, which is applied in the directions of ammonium perchlorate composition, the generation of compressed gas, the composite component of explosives, etc. Impact sensitivity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

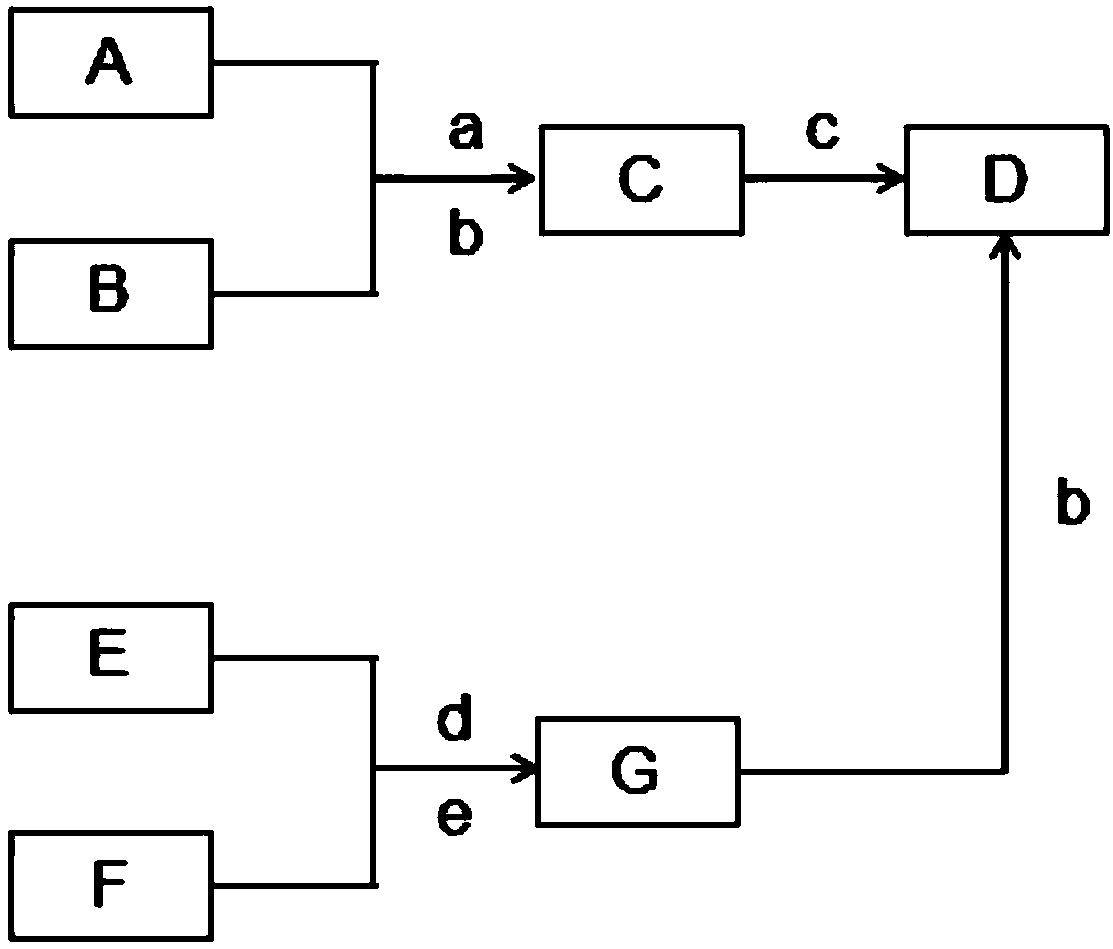

Method used

Image

Examples

Embodiment 1

[0020] Preparation graphene mass fraction is the graphene / ADN composite material of 2.5‰ (graphene accounts for graphene and ADN total mass percentage), the inorganic energy-containing ammonium salt in the present embodiment is ADN, good solvent is ethanol, and poor solvent to dichloromethane.

[0021] The first step is to prepare a graphene dispersion. According to the calculation, add 11.2mg graphene and 150ml dichloromethane into the flask, and ultrasonically disperse for 6 hours under the condition of constant stirring at 150r / min. The ultrasonic dispersion power is 40W. After 0.5h, a graphene / dichloromethane dispersion was obtained.

[0022] The second step is to prepare an ADN / ethanol solution, completely dissolving 3g of ADN in 15ml of ethanol, stirring and dissolving at a temperature of 60°C, the magnetic stirring rate is 500r / min, and the concentration is close to saturation.

[0023] In the third step, take 2 / 3 of the upper graphene dispersion in the first step in a...

Embodiment 2

[0025] Preparation graphene mass fraction is the graphene / AP composite material of 5‰ (the percentage that graphene accounts for graphene and AP total mass), the inorganic energy-containing ammonium salt in the present embodiment is AP, and good solvent is deionized water, The poor solvent is ethanol.

[0026] The first step is to prepare a graphene dispersion. According to the calculation, add 22.5mg of graphene and 150ml of ethanol into the flask, ultrasonically disperse for 6h under the condition of constant stirring at 150r / min, the ultrasonic dispersion power is 40W, and stand for 0.5h after the dispersion , to obtain a graphene / ethanol dispersion.

[0027] The second step is to prepare AP / deionized water solution, completely dissolve 3gAP in 15ml deionized water, stir and dissolve at a temperature of 60°C, the magnetic stirring rate is 500r / min, and the concentration is close to saturation.

[0028] In the third step, take 2 / 3 of the upper graphene dispersion in the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com