Method for preparing thinned potassium chlorate used for fireworks and crackers

A technology of fireworks and potassium chlorate, applied in the direction of alkali metal composition, etc., can solve the problems of reducing mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

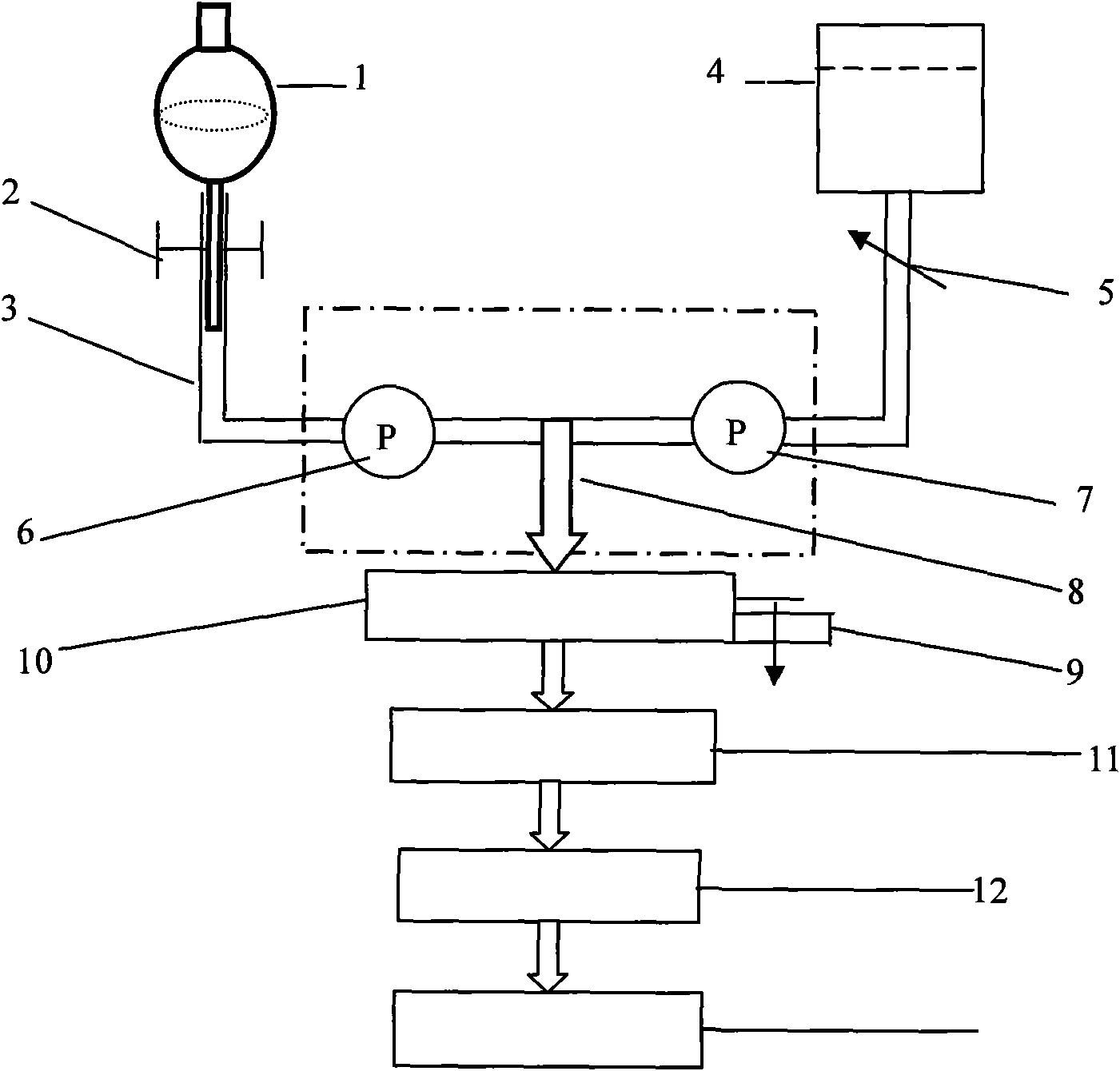

[0014] Add 0.08mol / L potassium chlorate solution into the separatory funnel, and add non-solvent absolute ethanol into the water tank. Pressure pump 1 and pressure pump 2 (see figure 1 ) are connected to the separatory funnel and the water tank respectively. Adjust the flow of pressure pump 1 to 5L / h, and adjust the flow of pressure pump 2 to 40L / h. The potassium chlorate solution and the non-solvent absolute ethanol are respectively pressed into the nozzle by the pressure pump 1 and the pressure pump 2, and a buffer device is used to collect the suspension of fine potassium chlorate particles under the nozzle. The suspension flows out of the buffer device and then flows into the filter device. It is vacuum filtered by a vacuum pump, and then the filter cake is vacuum freeze-dried to obtain fine potassium chlorate with an average particle size of 800nm.

[0015] Fine potassium chlorate particles are used as an oxidant to prepare pyrotechnic agents with sulfur, nanometer alum...

Embodiment 2

[0018] Add 0.08mol / L potassium chlorate solution into the separatory funnel, and add non-solvent absolute ethanol into the water tank. Pressure pump 1 and pressure pump 2 ( figure 1 ) are connected to the separatory funnel and the water tank respectively. Adjust the flow of pressure pump 1 to 3L / h, and adjust the flow of pressure pump 2 to 40L / h. The potassium chlorate solution and the non-solvent absolute ethanol are respectively pressed into the nozzle by the pressure pump 1 and the pressure pump 2, and a buffer device is used to collect the suspension of fine potassium chlorate particles under the nozzle. The suspension flows out of the buffer device and then flows into the filter device. It is vacuum filtered by a vacuum pump, and then the filter cake is subjected to vacuum freeze-drying to obtain refined potassium chlorate with an average particle size of 350nm.

[0019] Fine potassium chlorate particles are used as an oxidant to prepare pyrotechnic agents with sulfur, ...

Embodiment 3

[0022] Add 0.08mol / L potassium chlorate solution into the separatory funnel, and add non-solvent absolute ethanol into the water tank. Pressure pump 1 and pressure pump 2 ( figure 1 ) are connected to the separatory funnel and the water tank respectively. Adjust the flow of pressure pump 1 to 2.5L / h, and adjust the flow of pressure pump 2 to 40L / h. The potassium chlorate solution and the non-solvent absolute ethanol are respectively pressed into the nozzle by the pressure pump 1 and the pressure pump 2, and a buffer device is used to collect the suspension of fine potassium chlorate particles under the nozzle. The suspension flows out of the buffer device and then flows into the filter device. It is vacuum filtered by a vacuum pump, and then the filter cake is vacuum freeze-dried to obtain fine potassium chlorate with an average particle size of 300nm.

[0023] Fine potassium chlorate particles are used as an oxidant to prepare pyrotechnic agents with sulfur, nanometer alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com