Coating explosive microspheres prepared through emulsion solidification and preparation method thereof

A technology of explosives and emulsions, applied in the field of coated explosive microspheres and its preparation, can solve problems such as poor safety performance and incomplete coating, and achieve the effects of reduced sensitivity, good reproducibility, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation method of HMX explosive coated microspheres prepared with TPEE as coating agent:

[0042] Step 1: Weigh 1.0 g of polyether ester TPEE and 30 g of methylene chloride, stir at 35° C. and 500 rpm until completely dissolved, and cool to room temperature for later use. Weigh 4.0 g of HMX explosive, add it to the TPEE solution, and stir at 400 rpm to form an oil phase suspension.

[0043] Step 2: The HMX explosive suspension in Step 1 is slowly added to 150 g of an aqueous phase containing 2.0% PVA under mechanical stirring at 1000 rpm, and emulsified for 15 minutes to form uniform emulsion droplets.

[0044] Step 3: Volatilize the solvent dichloromethane at 38°C and a stirring speed of 300 rpm from the emulsion in Step 2. After the solvent evaporates for 3 hours, the solid product in the water is centrifuged, washed, and dried to obtain spherical HMX 4.9g of explosive coated microspheres.

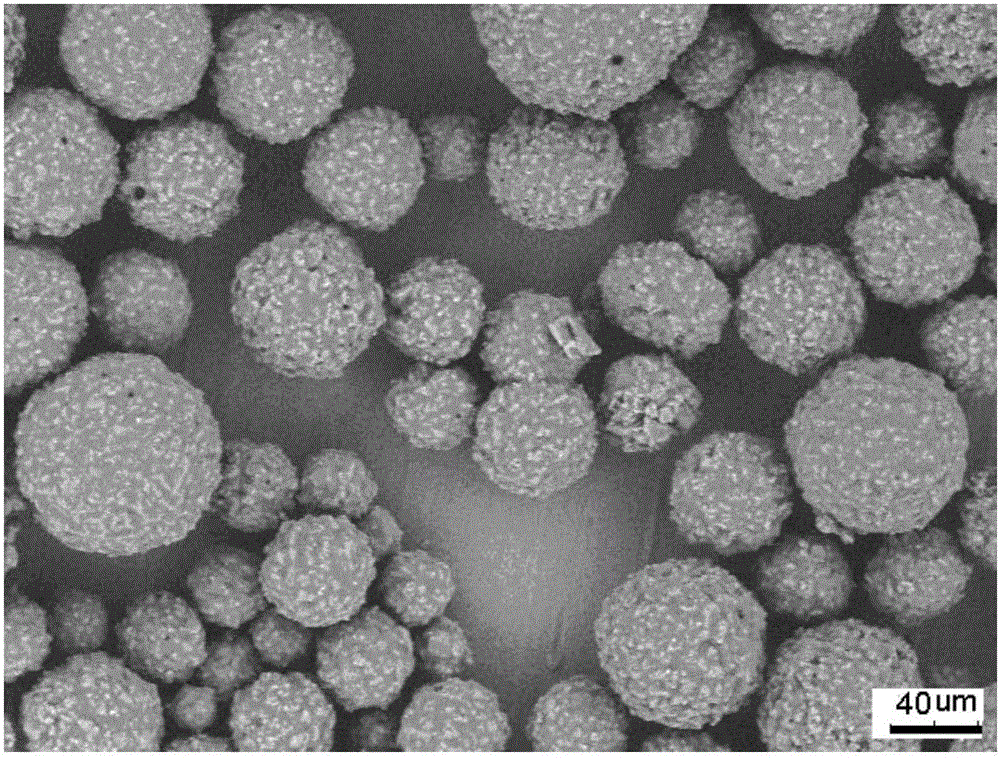

[0045] The product effect diagram of this embodiment is as follows figure 1 As s...

Embodiment 2

[0047] Preparation method of HMX explosive coated microspheres prepared with SAN as coating agent:

[0048] Step 1: Weigh 1.0 g of SAN styrene-acrylonitrile copolymer and 50 g of ethyl acetate, stir at 50° C. and 250 rpm until completely dissolved, and cool to room temperature for later use. Weigh 5 g of HMX explosive, add it to the SAN solution, and stir at 450 rpm to form an oil phase suspension.

[0049] Step 2: The HMX explosive suspension in Step 1 is slowly added to 250 g of an aqueous phase containing 1.0% PVA and 0.5% SDS under mechanical stirring at 1200 rpm, and emulsified for 18 minutes to form uniform emulsion droplets.

[0050] Step 3: Volatilize the solvent ethyl acetate under the conditions of 50℃ and 450rpm stirring speed of the emulsion in Step 2. After the solvent has evaporated for 4 hours, the solid product in the water is centrifuged, washed and dried to obtain spherical HMX 5.9g of explosive coated microspheres.

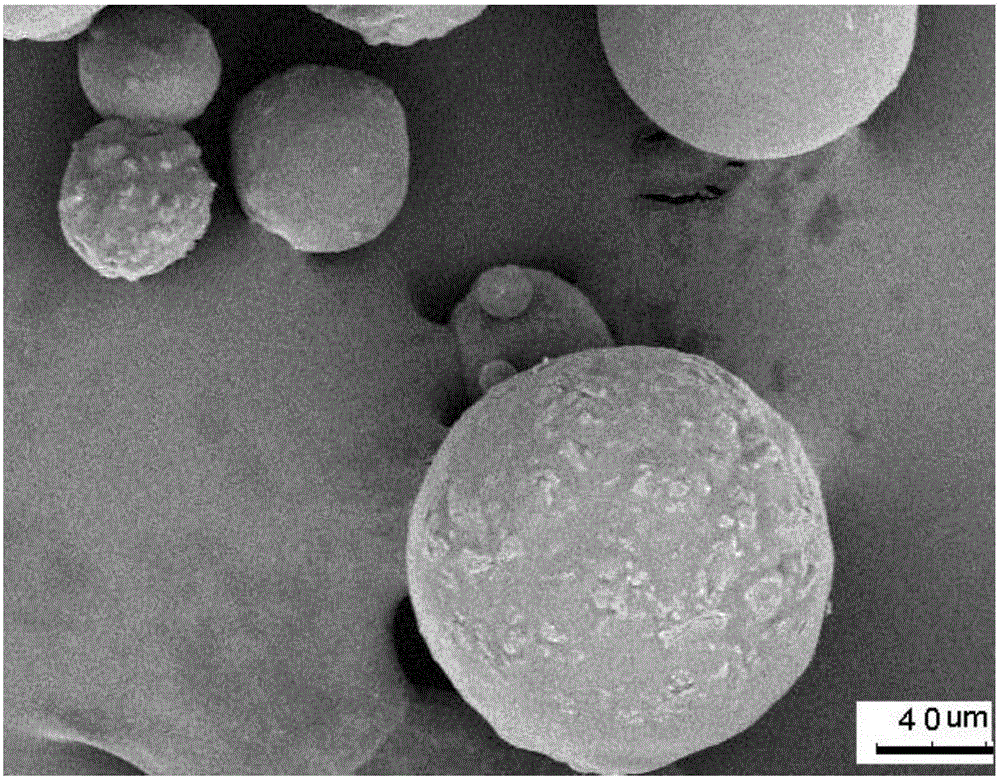

[0051] The product effect diagram of this embodi...

Embodiment 3

[0053] The preparation method of RDX explosive coated microspheres prepared with Estane5703 as the coating agent:

[0054] Step 1: Weigh 2.0 g of Estane 5703 polyurethane and 80 g of methyl ethyl ketone, stir at 50° C. and 250 rpm until completely dissolved, and cool to room temperature for later use. Weigh 20 g of RDX explosive, add it to Estane solution, and stir at 450 rpm to form an oil phase suspension.

[0055] Step 2: The RDX explosive suspension in Step 1 is slowly added to 400 g of an aqueous phase containing 1.0% PVA and 1.0% SDBS under mechanical stirring at 900 rpm, and emulsified for 12 minutes to form uniform emulsion droplets.

[0056] Step 3: Volatilize the solvent ethyl acetate under the conditions of 50°C and stirring speed of 450 rpm for the emulsion in Step 2. After the solvent evaporates for 4 hours, the solid product in the water is centrifuged, washed, and dried to obtain spherical RDX 21.6g of explosive coated microspheres.

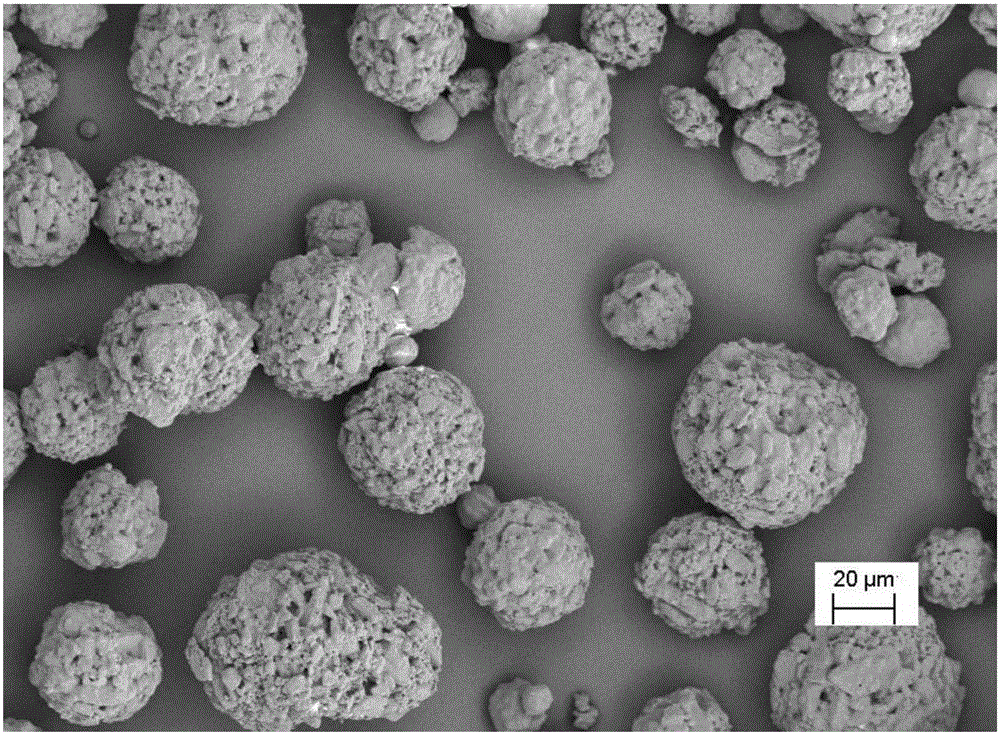

[0057] The product effect diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com