Low-sensitivity and high-strength octogen-based composite material and preparation method thereof

A technology for octogen and composite materials, which is applied in the field of low-sensitivity and high-strength octogen-based composite materials and their preparation, which can solve the problem that the safety performance and mechanical properties of the energy-containing composite cannot be achieved, and the safety performance and mechanical properties are difficult to balance and increase. Problems such as the interfacial interaction between explosive crystals and polymer binders, to achieve the effects of easy scale-up preparation, improved mechanical properties, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

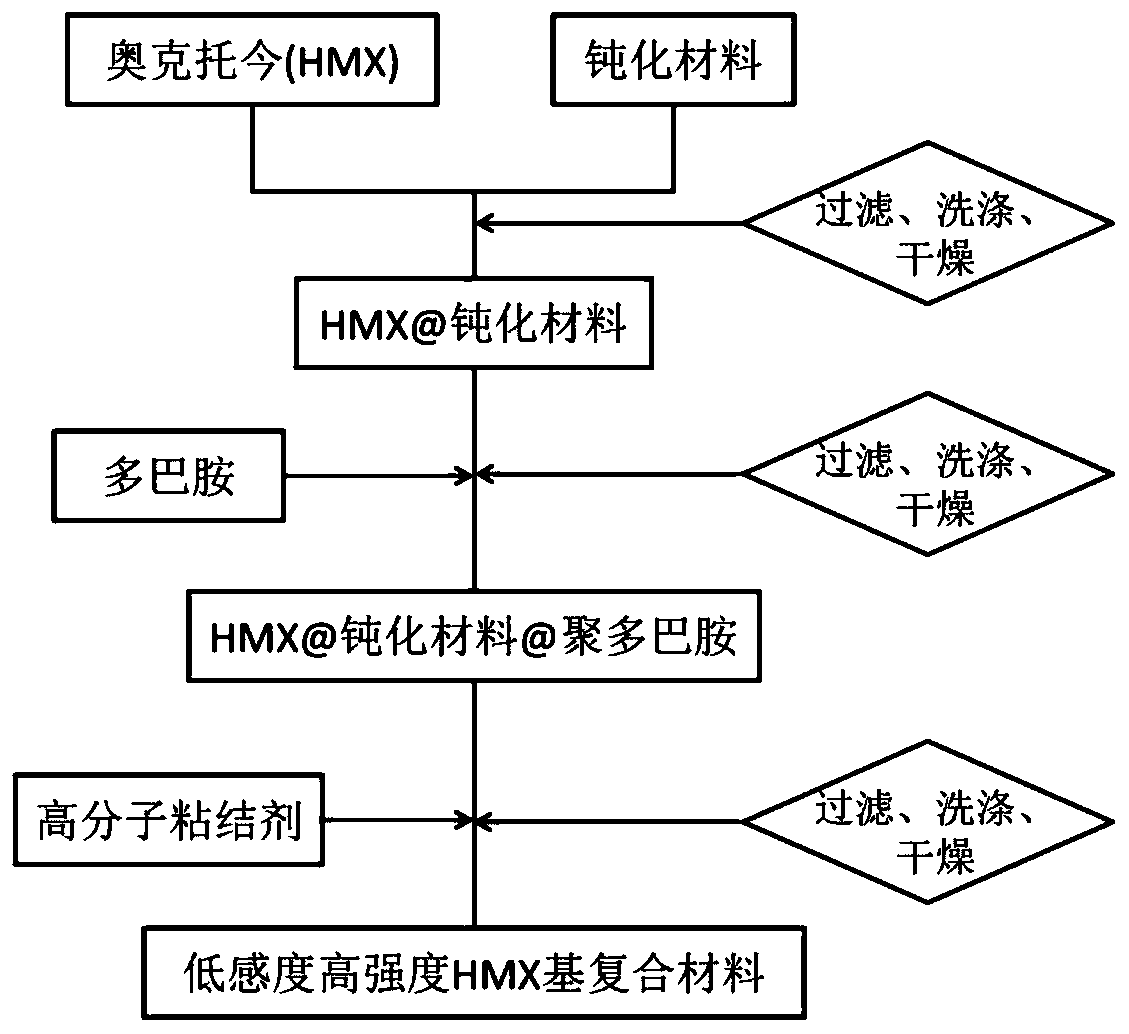

[0029] like figure 1 As shown, step 1: add 90g octogen (HMX) into ultrapure water, ultrasonically disperse for 30min, and then add 10g nano-energy-containing material crystal 1,3,5-triamino-2 after ultrasonic dispersion for 30min, 4,6-Trinitrobenzene (TATB) aqueous suspension, ultrasonic treatment for 30min, suction filtration, washing and drying to obtain HMX@TATB core-shell structure explosive particles;

[0030] Step 2: Add 100 g of the core-shell structure explosive particles obtained in step (1) to 3 L of buffered aqueous solution with a pH of about 8.5, stir mechanically, add 6 g of dopamine hydrochloride, in-situ polymerize and coat for 6 hours, filter, wash, dry Drying to obtain HMX@TATB@PDA one-core double-shell structure explosive particles whose inner shell is passivation material TATB and outer shell is interface modifier polydopamine (PDA);

[0031] Step 3: granulation by water suspension method: take 95g of the one-core and double-shell structure explosive parti...

Embodiment 2

[0033] Step 1: Add 80 g of Octochrome (HMX) to the dichloroethane solution of the polyurethane-polyester copolymer (Estane), stir mechanically for 30 minutes, filter, and dry; add the surface-treated Octane to the solution. In ultrapure water, ultrasonically dispersed for 30min, then add 20g of nano-energy material crystal 1,3,5-triamino-2,4,6-trinitrobenzene (TATB) aqueous suspension after ultrasonic dispersion for 30min, ultrasonically After treatment for 30min, suction filtration, washing and drying to obtain HMX@TATB core-shell structure explosive particles;

[0034] Step 2: Add 100 g of the core-shell structure explosive particles obtained in step (1) to 3 L of buffered aqueous solution with a pH of about 8.5, stir mechanically, add 6 g of dopamine hydrochloride, in-situ polymerization and coating for 3 hours, suction filtration, washing, drying Drying to obtain HMX@TATB@PDA one-core double-shell structure explosive particles whose inner shell is passivation material TATB...

Embodiment 3

[0037] Step 1: Add 99.5g of Octogen (HMX) to ultrapure water, stir mechanically at 450rpm for 12min, heat up to 40°C, then dropwisely add 25g of 2% No. 58 petroleum ether solution of paraffin, suction filtration , washing and drying to obtain HMX@58 paraffin core-shell structure explosive particles;

[0038] Step 2: Add 100 g of the core-shell structure explosive particles obtained in step (1) to 3 L of buffered aqueous solution with a pH of about 8.5, stir mechanically, add 6 g of dopamine hydrochloride, in-situ polymerization and coating for 3 hours, suction filtration, washing, drying Drying to obtain HMX@58 paraffin@PDA one-core and double-shell structure explosive particles whose inner shell is the passivation material No. 58 paraffin, and the outer shell is the interface modifier polydopamine (PDA);

[0039] Step 3: granulation by water suspension method: take 95g of the single-core double-shell structure explosive particles obtained in step (2) and add it to 90mL of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com