Method for coating RDX cyclotrimethylene trinitramine and HMX cyclotetramethylene tetranitramine and coating material thereof

A coating material and coating technology, applied in the field of applied chemistry, can solve problems such as reducing sensitivity, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

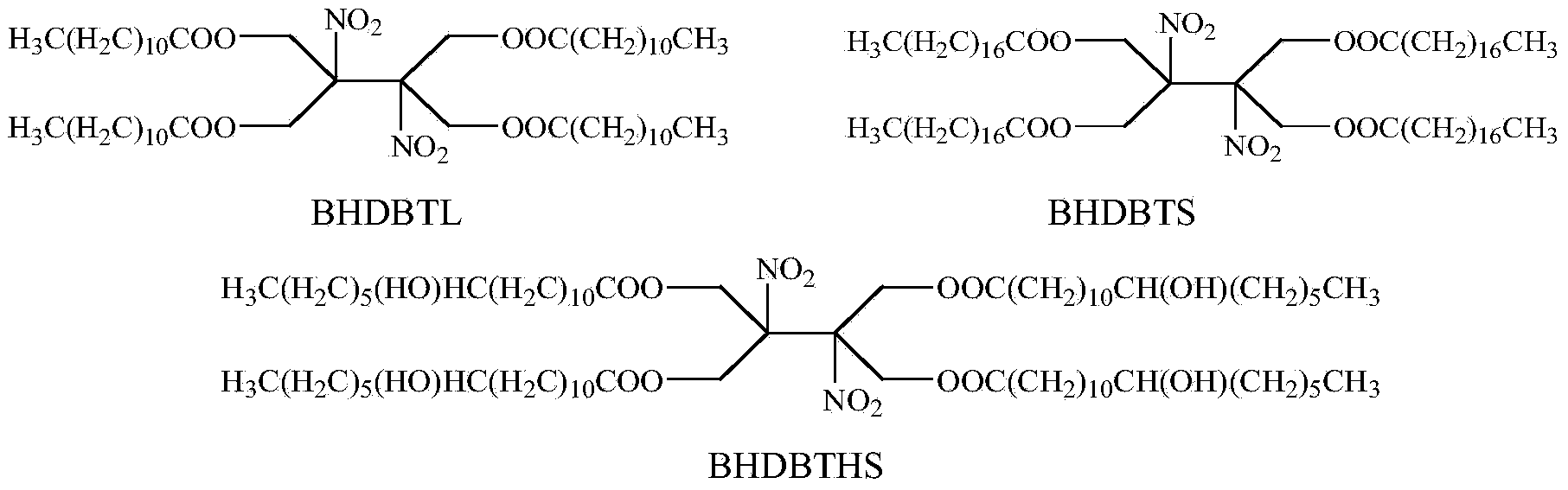

[0020] Preparation of BHDBTL

[0021] 2,3-Dihydroxymethyl-2,3-dinitro-1,4-butanediol (1mmol, 0.24g), lauric acid (6mmol, 1.2g), dichloromethane 10mL, DCC (5mmol, 1.03 g), DMAP (0.2mmol, 0.024g), stirring at room temperature, followed by TLC, stop the reaction when the reaction of 2,3-dimethylol-2,3-dinitro-1,4-butanediol is complete. 100mL (2×50mL) CHCl 3 For product extraction, collect CHCl 3 phase, concentrated under reduced pressure, and the crude product was recrystallized from methanol and then recrystallized from acetone. The yield was 78.8%.

[0022] Preparation of 3% BHDBTL coated RDX

[0023] Add 5g of RDX to 30mL of acetone, add 0.15g of BHDBTL, stir at 50°C for 0.5h, drop the mixture into rapidly stirring water with a thermos dropper, after the dropwise addition, stir for 5min, filter and dry at 50°C to obtain Modified RDX-3%BHDBTL.

Embodiment 2

[0025] Preparation of 4% BHDBTL-coated RDX

[0026] Add 5g of RDX to 35mL of acetone, add 0.2g of BHDBTL, stir at 50°C for 0.5h, drop the mixture into rapidly stirring water with an insulated dropper, after the dropwise addition, stir for 5min, filter and dry at 50°C to obtain Modified RDX-4%BHDBTL.

Embodiment 3

[0028] Preparation of 5% BHDBTL-coated RDX

[0029] Add 5g RDX to 40mL of acetone, add 0.25g BHDBTL, stir at 50°C for 0.5h, drop the mixture into rapidly stirring water with a thermos dropper, after the dropwise addition, stir for 5min, filter and dry at 50°C to obtain Modified RDX-5%BHDBTL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com