Low-sensitivity ultrafine ammonium perchlorate composite material and preparation method thereof

A technology of composite materials and ammonium perchlorate, which is applied in the direction of ammonium perchlorate composition and explosives, can solve the problems of increased friction sensitivity of propellant grains, difficult control of product quality, and insignificant desensitization effect, etc., to achieve easy Scale-up preparation, good particle dispersion and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

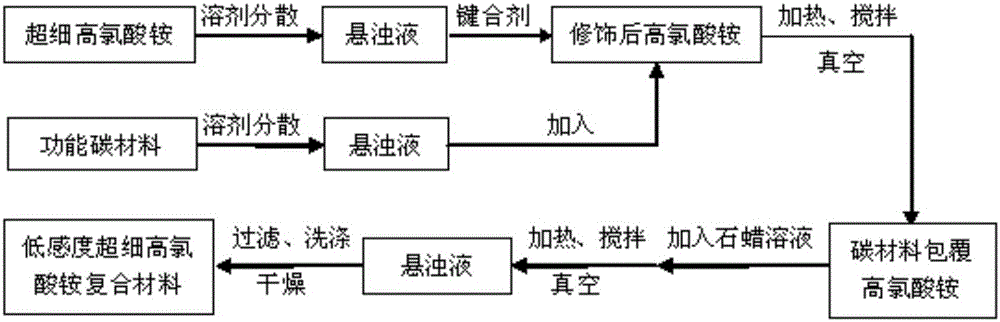

Method used

Image

Examples

Embodiment 1

[0031] Weigh 20g of superfine ammonium perchlorate, add it to 40g of cyclohexane, and ultrasonically disperse it at a frequency of 60kHz for 5 minutes and then stir it into a suspension. Dissolve 0.05g of bonding agent LBA-306 in 2.5g of methanol and add to high The ammonium chlorate suspension was heated to 45° C., stirred at 400 rpm, and treated at a vacuum of 50 mbar for 5 minutes to obtain the ammonium perchlorate suspension modified by the bonding agent.

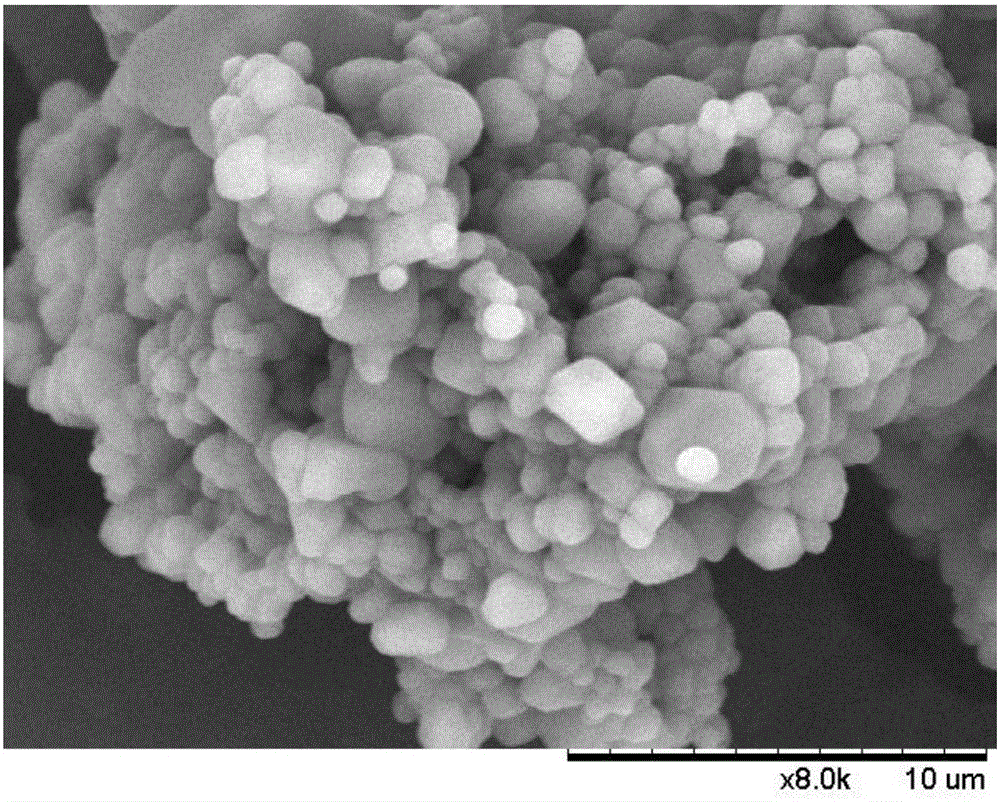

[0032] Weigh 0.4g of graphite, add it to 5g of cyclohexane, and ultrasonically disperse it at a frequency of 100kHz for 10min, then stir it into a suspension, add it to the ammonium perchlorate suspension modified by the bonding agent, and heat it at 45°C, Apply 50mbar vacuum treatment at 400rpm for 15min, filter the material, wash with cyclohexane, and dry at 50°C for 48h to obtain 19.4g of low-sensitivity ultrafine ammonium perchlorate composite product, as shown in the scanning electron microscope figure 2 shown. I...

Embodiment 2

[0034] Weigh 20g of ultra-fine ammonium perchlorate, add it to 180g of toluene, disperse ultrasonically at 20kHz for 5 minutes and then stir to form a suspension. Dissolve 0.05g of bonding agent LBA-332 in 10g of acetone and add it to ammonium perchlorate The suspension was heated to 70° C., stirred at 750 rpm, and treated at a vacuum of 180 mbar for 10 minutes to obtain an ammonium perchlorate suspension modified with a bonding agent.

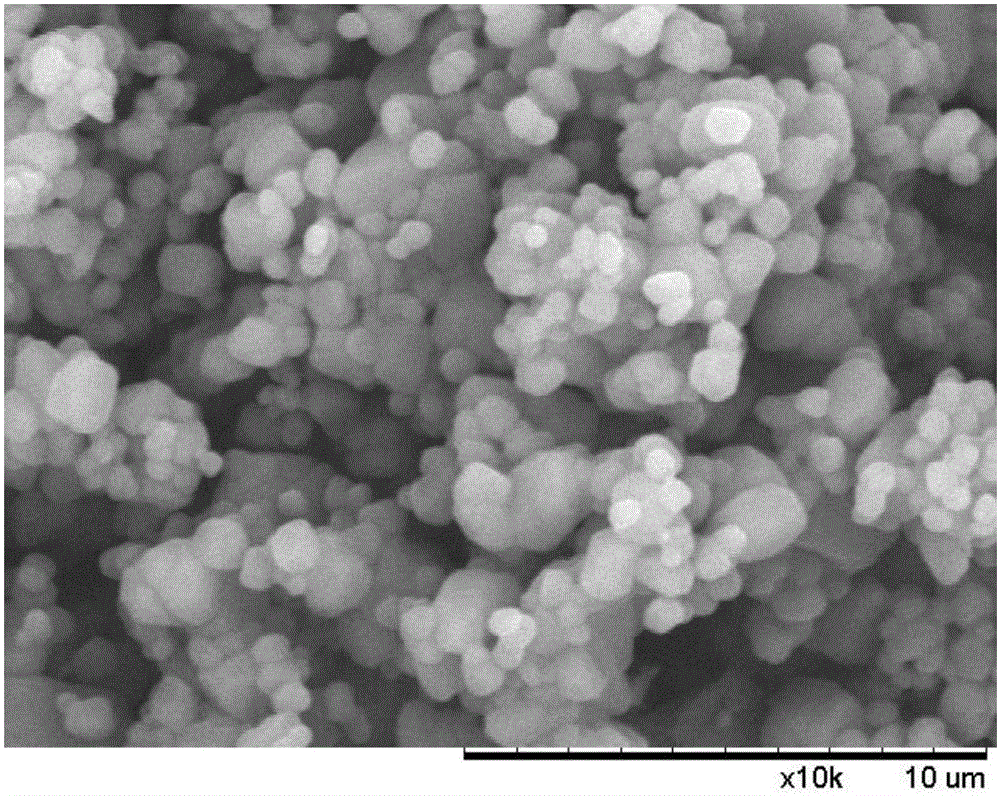

[0035] Weigh 0.4g of graphene oxide, add it to 40g of toluene, and ultrasonically disperse it at 100kHz for 10 minutes, then stir it into a suspension, add it to the ammonium perchlorate suspension modified by the bonding agent, and heat it at 70°C, Apply 180mbar vacuum treatment at 600rpm for 15min, filter the material, wash with toluene, and dry at 80°C for 12h to obtain 19.1g of low-sensitivity ultrafine ammonium perchlorate composite product, as shown in the scanning electron microscope image 3 shown. In the mechanical sensitivity test, ...

Embodiment 3

[0037] Weigh 50g of ultra-fine ammonium perchlorate, add it to 150g of n-heptane, disperse ultrasonically at 80kHz for 5min and then stir to form a suspension, dissolve 0.13g of bonding agent LBA-603 in 10g of chloroform, add into the ammonium perchlorate suspension, heated to 60° C., stirred at 600 rpm, and treated at a vacuum of 120 mbar for 8 minutes to obtain the ammonium perchlorate suspension modified by the bonding agent.

[0038] Weigh 0.5g of graphene, add it to 5g of n-heptane, disperse it ultrasonically at 80kHz for 10min, and then stir it into a suspension, add it to the ammonium perchlorate suspension modified by the bonding agent, and heat it at 60°C 120mbar vacuum treatment for 15min under 200rpm, adding 25g of 2% paraffin / petroleum ether solution to the suspension, continuing to apply vacuum treatment for 15min at this temperature, filtering the material, washing with n-heptane, and After drying at 60°C for 24 hours, 48.4g of low-sensitivity ultrafine ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com