Polyurethane coated modified potassium chlorate and preparation method and applications thereof

A technology of potassium chlorate and polyurethane, applied in the direction of alkali metal composition, etc., can solve the problems of poor discharge effect and high price and cost, and achieve the effects of improving thermal safety and stability, low cost, and reducing mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

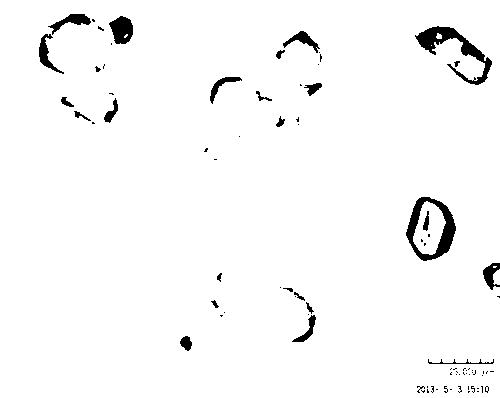

[0031] a kind of like figure 1 The polyurethane-coated modified potassium chlorate of the present invention is shown, the polyurethane-coated modified potassium chlorate has a core-shell structure, potassium chlorate is used as the core, polyurethane is used as the coated shell, and the mass ratio of polyurethane to potassium chlorate is 0.1:1. The polyurethane-coated modified potassium chlorate is in the shape of spherical particles, and the average particle size is between 30 μm and 35 μm.

[0032] The above-mentioned polyurethane-coated modified potassium chlorate of the present embodiment is prepared by coating polyurethane material on the surface of potassium chlorate particles by in-situ polymerization, and the specific preparation includes the following steps:

[0033] 1. Raw material preparation and pretreatment:

[0034] Potassium chlorate, polypropylene glycol, dimethylol propionic acid, butylene glycol, triethylamine, toluene diisocyanate and xylene are the main ra...

Embodiment 2

[0045] A polyurethane-coated modified potassium chlorate of the present invention, the polyurethane-coated modified potassium chlorate has a core-shell structure, potassium chlorate is used as the core, polyurethane is used as the coated shell, and the mass ratio of polyurethane to potassium chlorate is 0.05:1. The polyurethane-coated modified potassium chlorate is in the shape of spherical particles, and the average particle size is between 30 μm and 35 μm.

[0046] The above-mentioned polyurethane-coated modified potassium chlorate of the present embodiment is prepared by coating polyurethane material on the surface of potassium chlorate particles by in-situ polymerization, and the specific preparation includes the following steps:

[0047] 1. Raw material preparation and pretreatment:

[0048] Potassium chlorate, polypropylene glycol, dimethylol propionic acid, butylene glycol, triethylamine, toluene diisocyanate and acetone are the main raw materials, among which, polyprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com