Patents

Literature

43results about How to "Ensure coating uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

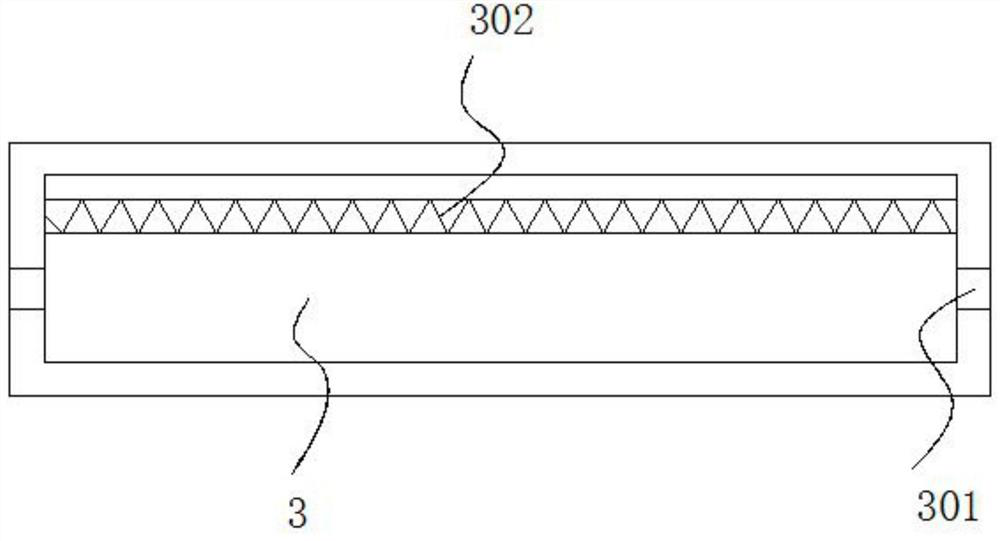

Lithium-ion battery and preparation method thereof

ActiveCN106207087AEnsure coating uniformityEasy to prepareMaterial nanotechnologyFinal product manufactureHigh temperature storageHigh energy

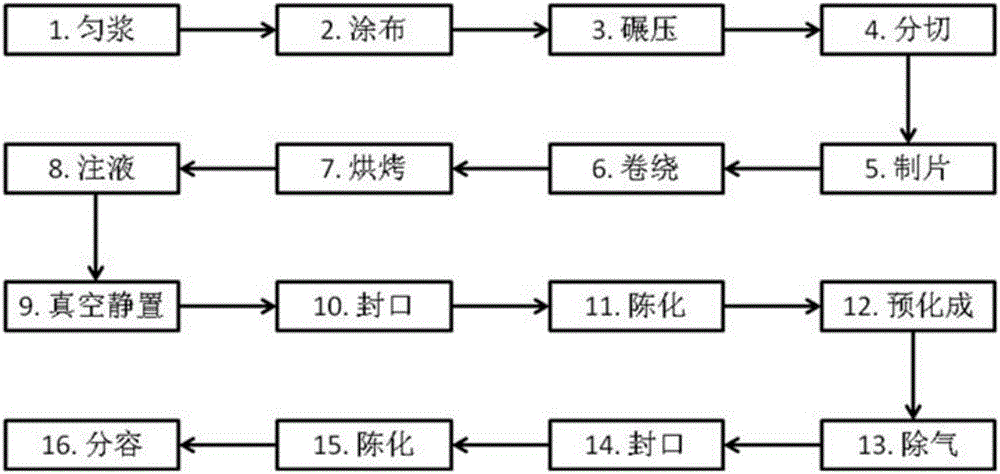

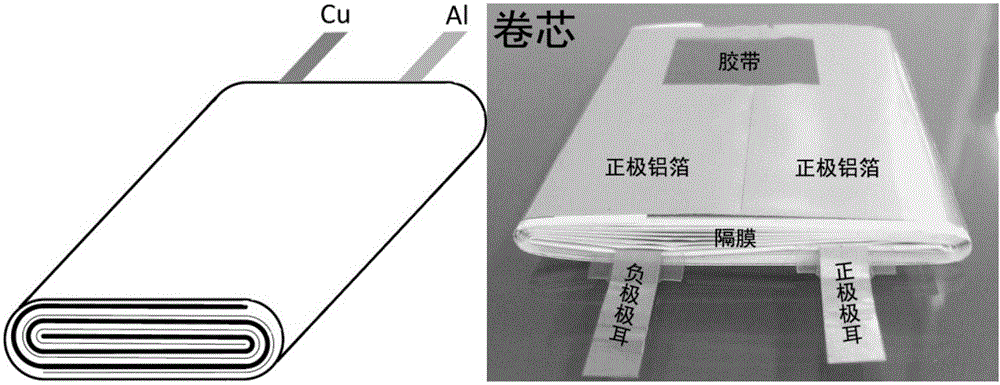

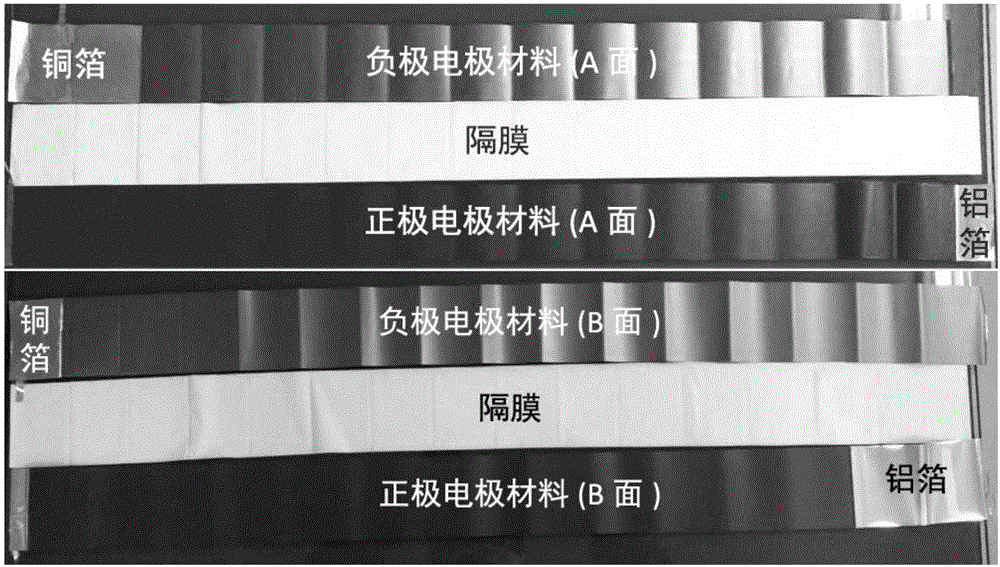

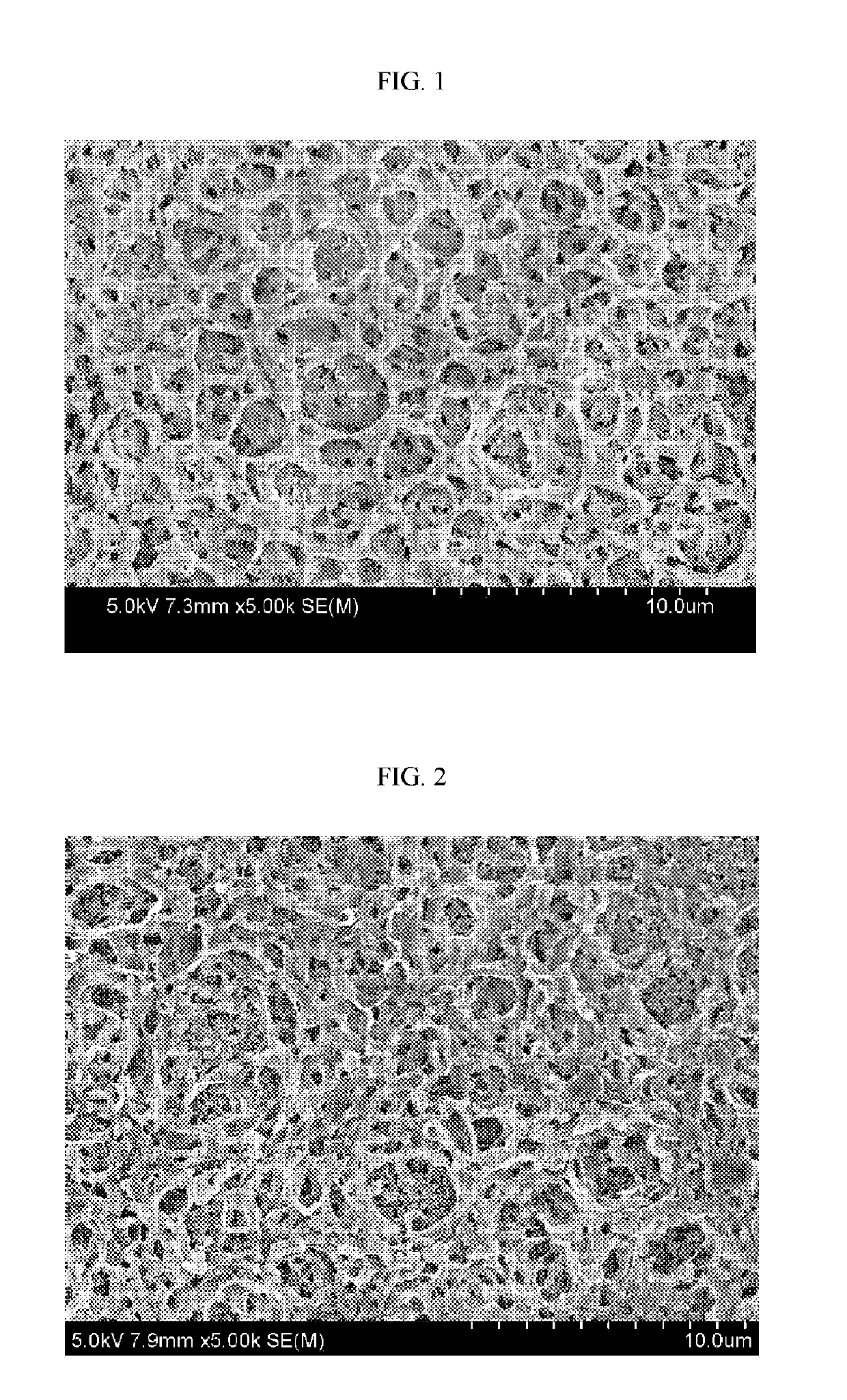

The invention relates to a lithium-ion battery and a preparation method thereof. The lithium-ion battery comprises (1) a positive plate, (2) a negative plate, (3) a membrane, (4) an electrolyte and (5) an aluminum-plastic packaging film, wherein surface modification treatment is carried out on at least one of the manufactured positive plate and negative plate in a coiled coating manner; and a layer of nanofilm evenly coats the surface of an electrode material of at least one of the positive plate and the negative plate and an area, which is not covered with the electrode material, of a current collector corresponding to the plate. Meanwhile, the invention discloses preparation methods of the positive plate, the negative plate and the battery. The preparation method of the lithium-ion battery is simple, efficient and good in repeatability; the prepared lithium-ion battery has good cycle performance, high-temperature storage performance and safety performance in extreme cases of puncture and the like; and large-scale production of the high-energy density and high-safety lithium-ion battery can be really achieved.

Owner:BERZELIUS (NANJING) CO LTD +1

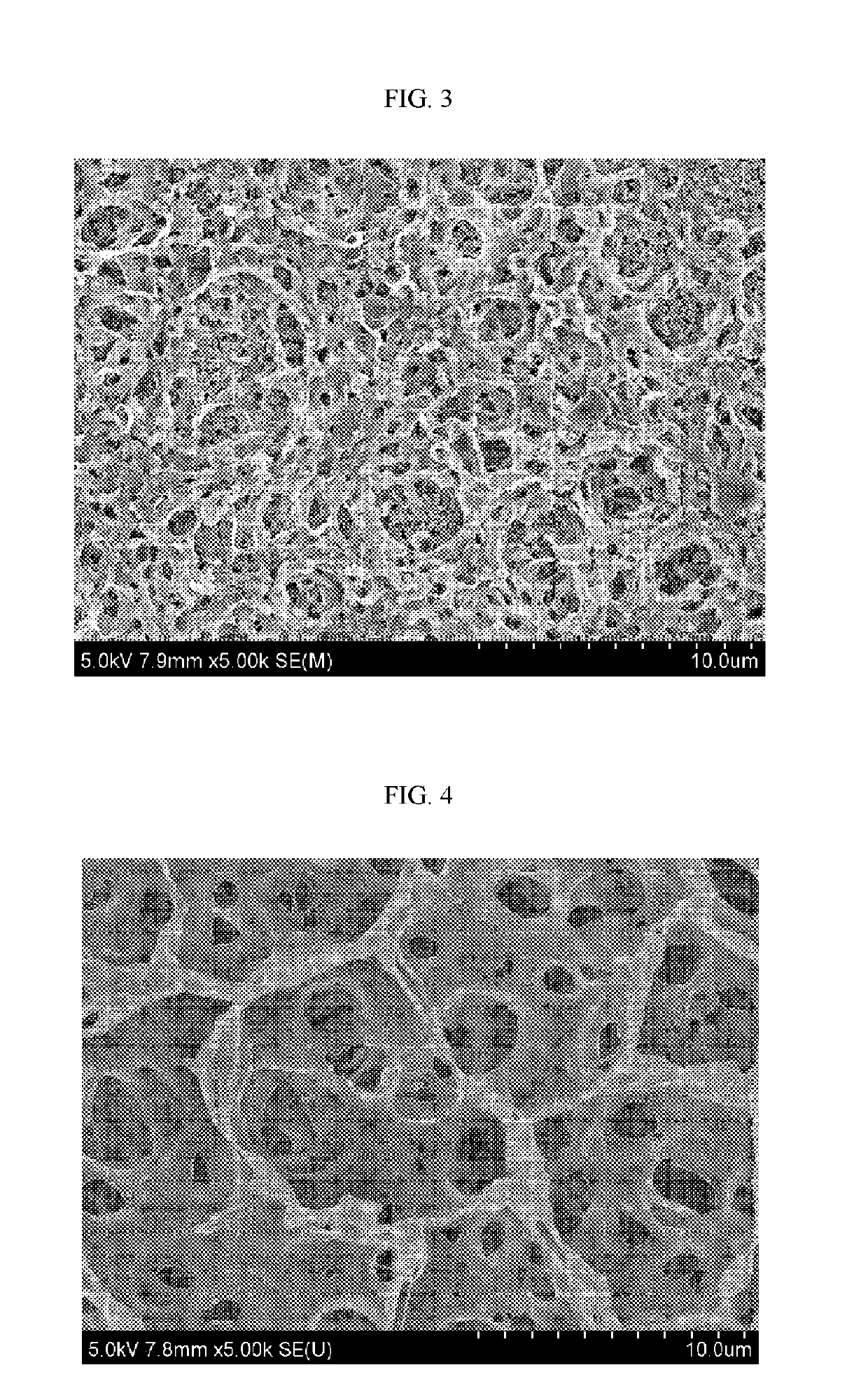

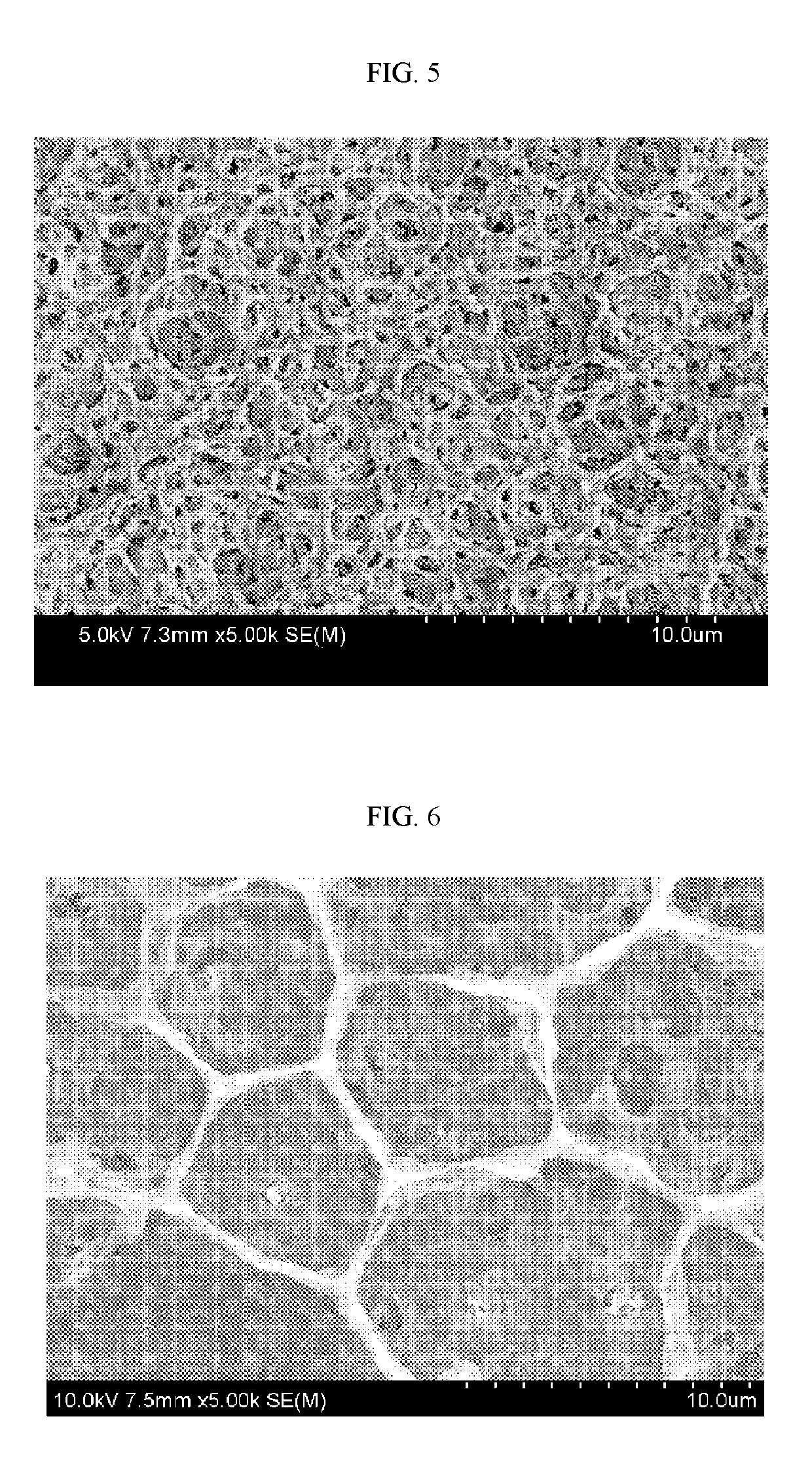

Separator and electrochemical device including the same

ActiveUS20190131604A1Improve adhesionIncreased porous structureSolid electrolytesFinal product manufactureNon solventPorous coating

Disclosed are a separator and an electrochemical device including the same. The separator includes: a porous polymer substrate having a plurality of pores; a separator base including a porous coating layer formed on at least one surface of the porous polymer substrate, and including a plurality of inorganic particles and a binder polymer disposed partially or totally on the surface of the inorganic particles to connect and fix the inorganic particles with each other; and an adhesive porous layer formed on at least one surface of the separator base and including an adhesive resin which shows adhesive property through heating at a temperature lower than the melting point of the porous polymer substrate, wherein the adhesive porous layer is provided with a porous structure formed by phase separation caused by the evaporation rate of a solvent and that of a non-solvent, when applying and drying a coating composition including the adhesive resin, the solvent and the non-solvent on at least one surface of the separator base.

Owner:LG ENERGY SOLUTION LTD

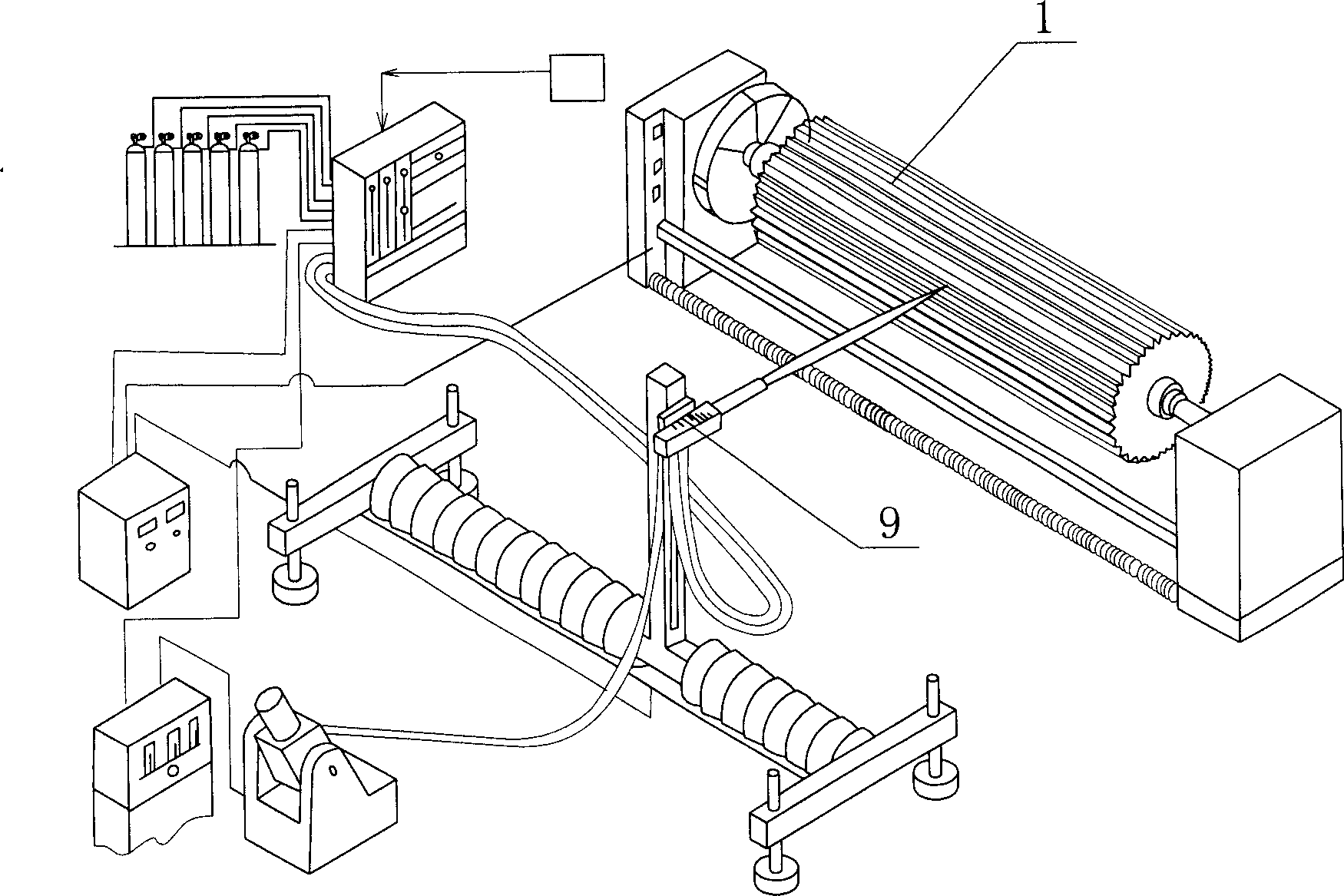

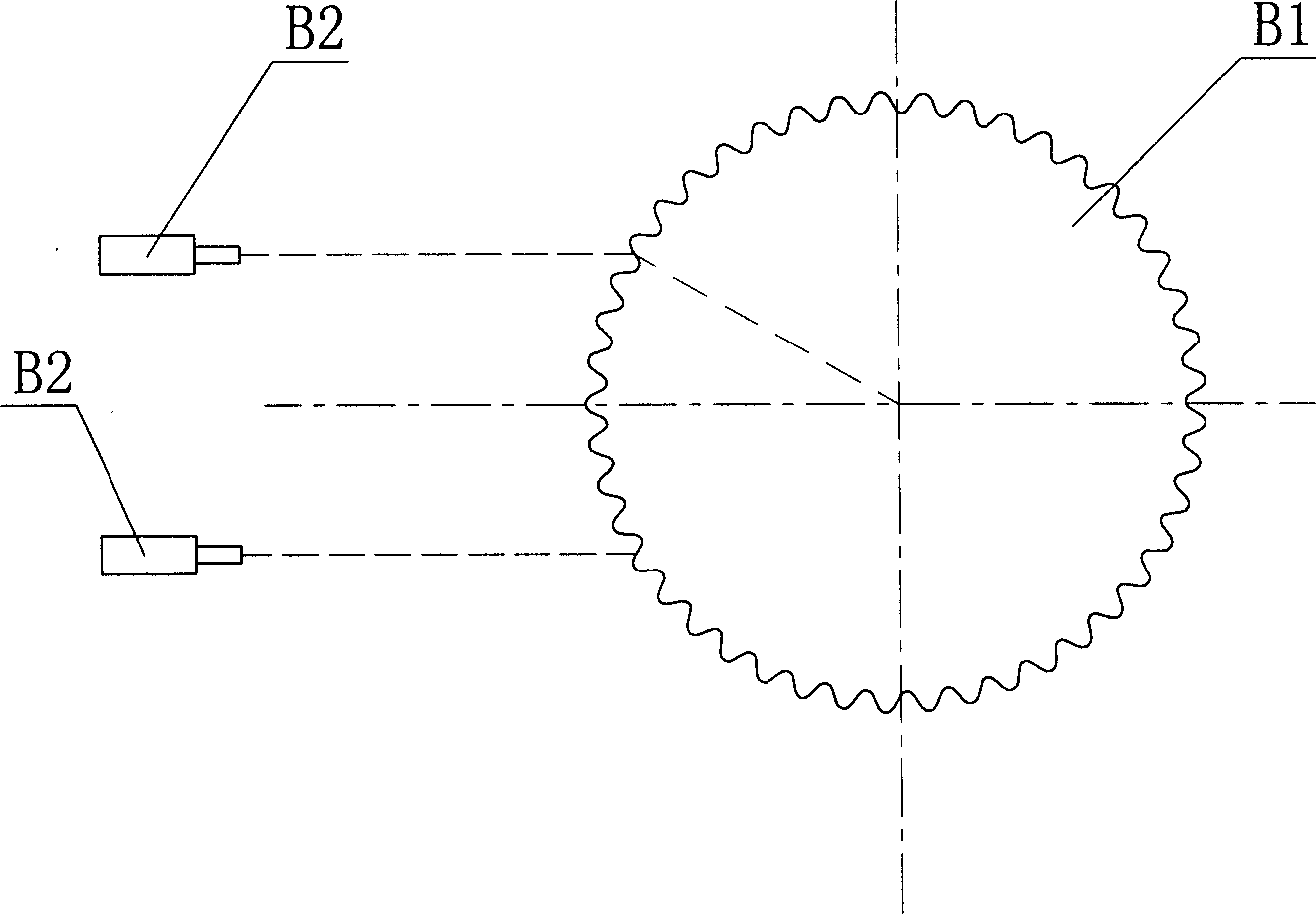

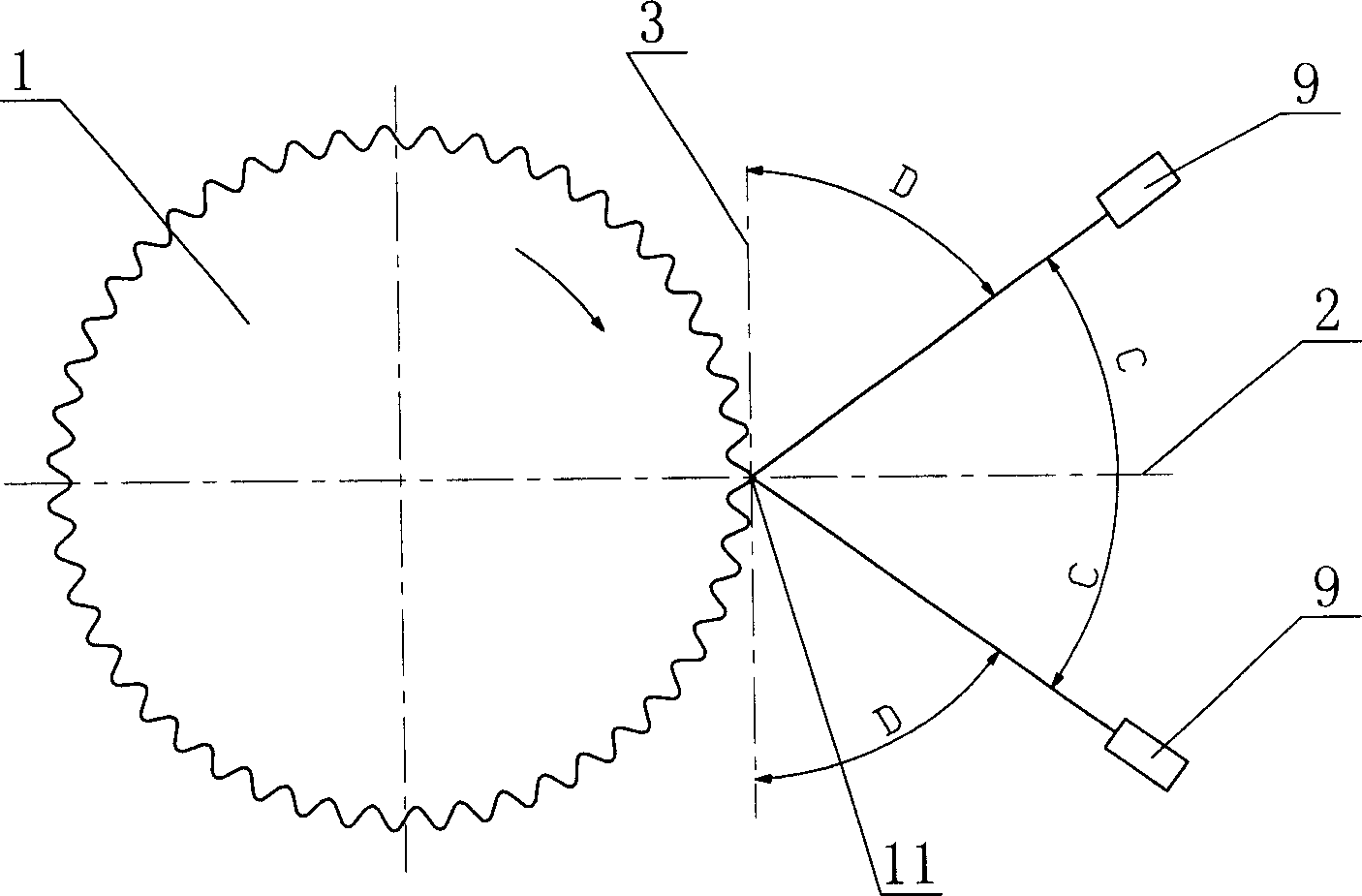

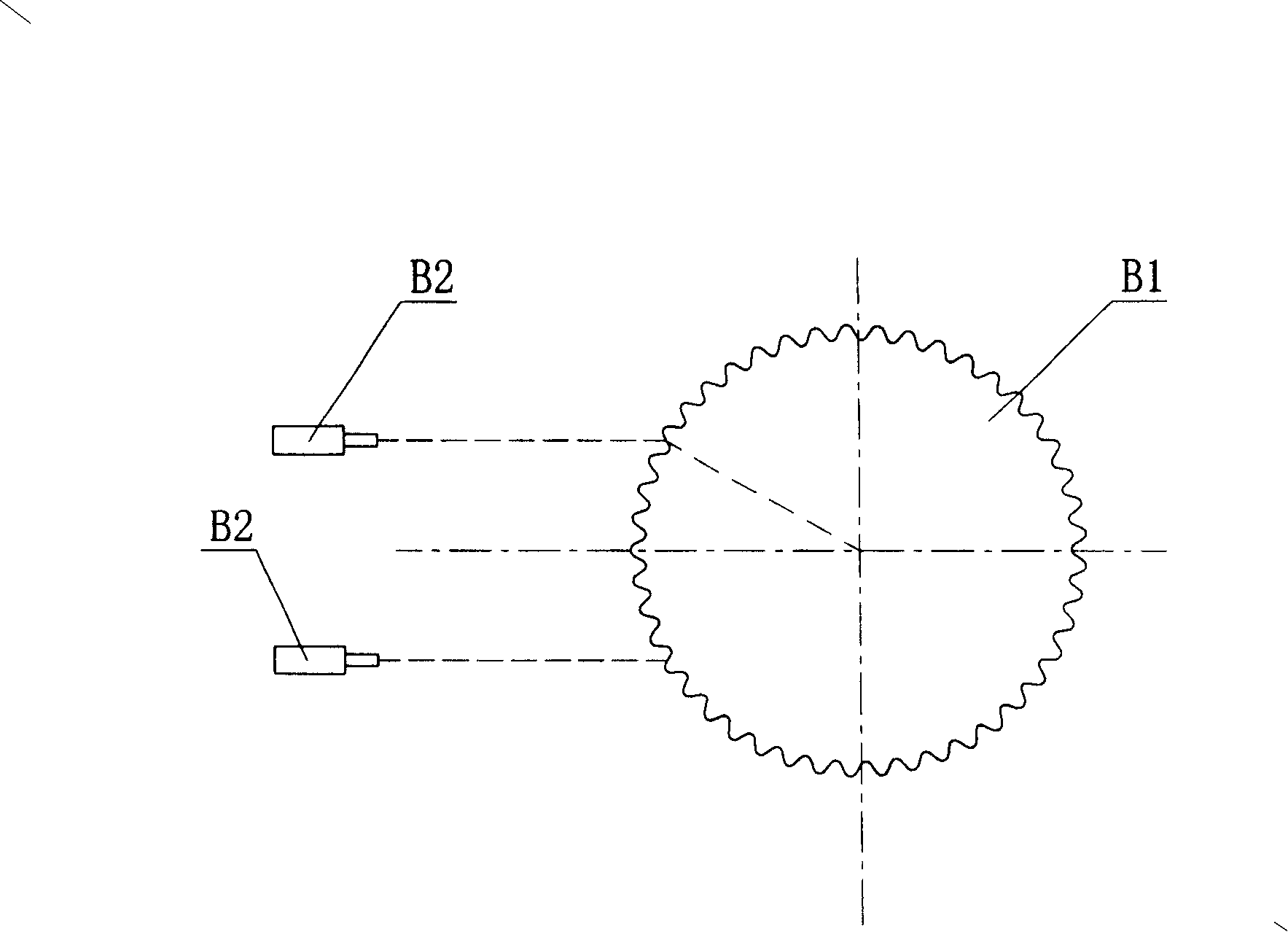

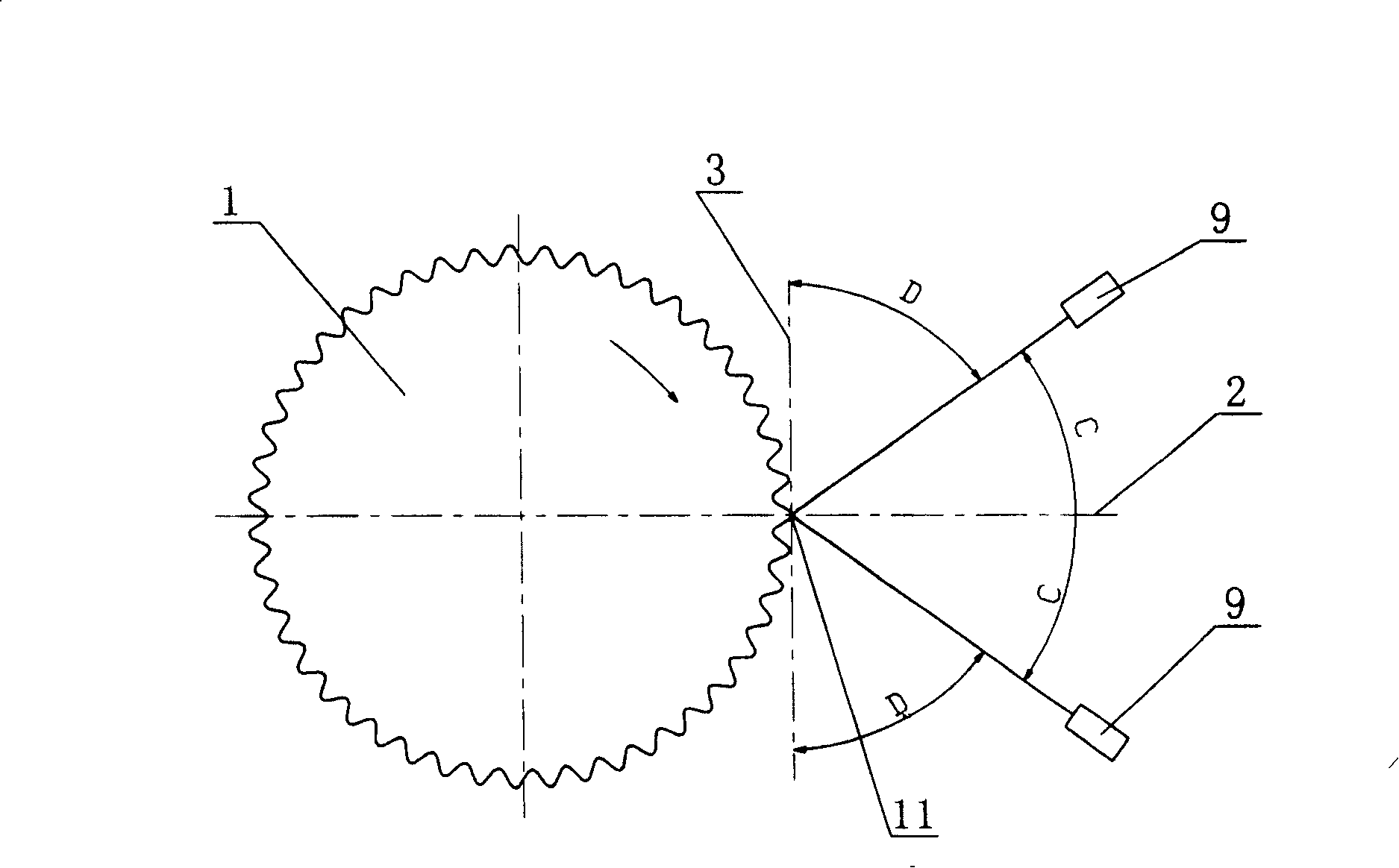

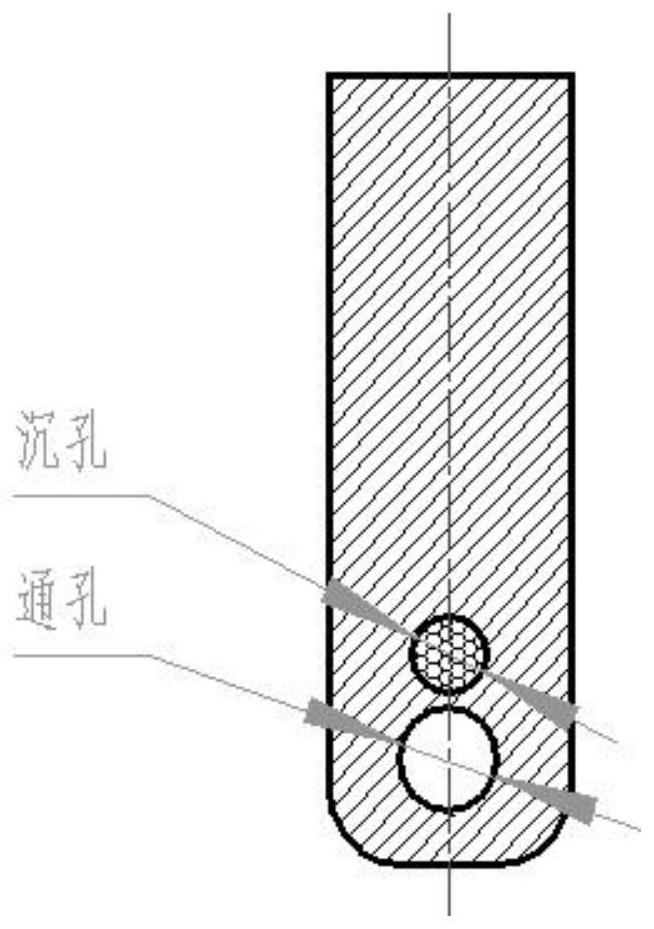

Corrugated roller hot spraying production and restoring method

ActiveCN1766152AImprove wear resistanceImprove deformation resistanceMolten spray coatingMechanical working/deformationThermal sprayingCarbonization

The thermal spraying manufacture and repair method for corrugated roller comprises: processing the gear form of roller; taking nitridation or carbonization- nitridation treatment to the gear; localized heat quenching and tempering to roller gear; taking abrasion resistant coating strengthen treatment to tooth surface. By drawing roller section gear form figure and plotting horizontal line and tangent line to calculate the spraying point and abrasion resistant coating, this invention can ensure coating evenness, obtains clean and rigid work surface, improves roller properties, and increases roller economical benefit.

Owner:GUANGDONG YUEKE NEW MATERIALS TECH CO LTD

Method for producing oriented electromagnetic steel sheet

ActiveUS20150007908A1Reduce iron lossImprove production yieldInorganic material magnetismInductances/transformers/magnets manufactureElectrical steelChemical composition

In a method of producing a grain-oriented electrical steel sheet by hot-rolling a steel slab of a chemical composition containing C: 0.001˜0.10%, Si: 1.0˜5.0%, Mn: 0.01˜1.0%, at least one of S and Se: 0.01˜0.05% in total, sol. Al: 0.003˜0.050%, N: 0.001˜0.020% by mass, subjecting to cold rolling, a primary recrystallization annealing, application of an annealing separator mainly composed of MgO and a finish annealing, a temperature rising rate S1 between 500˜600° C. in the primary recrystallization annealing is made to not less than 100° C. / s and a temperature rising rate S2 between 600˜700° C. is made to 30° C. / s˜0.6×S1° C. / s, while a total content W (mol %) of an element having an ionic radius of 0.6˜1.3 Å and an attracting force between the ion and oxygen of not more than 0.7 Å−2 included in the annealing separator to MgO is adjusted to satisfy 0.01S2-5.5≦Ln (W)≦0.01S2−4.3 to produce a grain-oriented electrical steel sheet having excellent iron loss properties and coating properties.

Owner:JFE STEEL CORP

Method of producing grain-oriented electrical steel sheet

ActiveUS9290824B2Low iron loss propertyStable formationInorganic material magnetismInductances/transformers/magnets manufactureElectrical steelChemical composition

In a method of producing a grain-oriented electrical steel sheet by hot-rolling a steel slab of a chemical composition containing C: 0.001˜0.10%, Si: 1.0˜5.0%, Mn: 0.01˜1.0%, at least one of S and Se: 0.01˜0.05% in total, sol. Al: 0.003˜0.050%, N: 0.001˜0.020% by mass, subjecting to cold rolling, a primary recrystallization annealing, application of an annealing separator mainly composed of MgO and a finish annealing, a temperature rising rate S1 between 500˜600° C. in the primary recrystallization annealing is made to not less than 100° C. / s and a temperature rising rate S2 between 600˜700° C. is made to 30° C. / s˜0.6×S1° C. / s, while a total content W (mol %) of an element having an ionic radius of 0.6˜1.3 Å and an attracting force between the ion and oxygen of not more than 0.7 Å−2 included in the annealing separator to MgO is adjusted to satisfy 0.01S2−5.5≦Ln (W)≦0.01S2−4.3 to produce a grain-oriented electrical steel sheet having excellent iron loss properties and coating properties.

Owner:JFE STEEL CORP

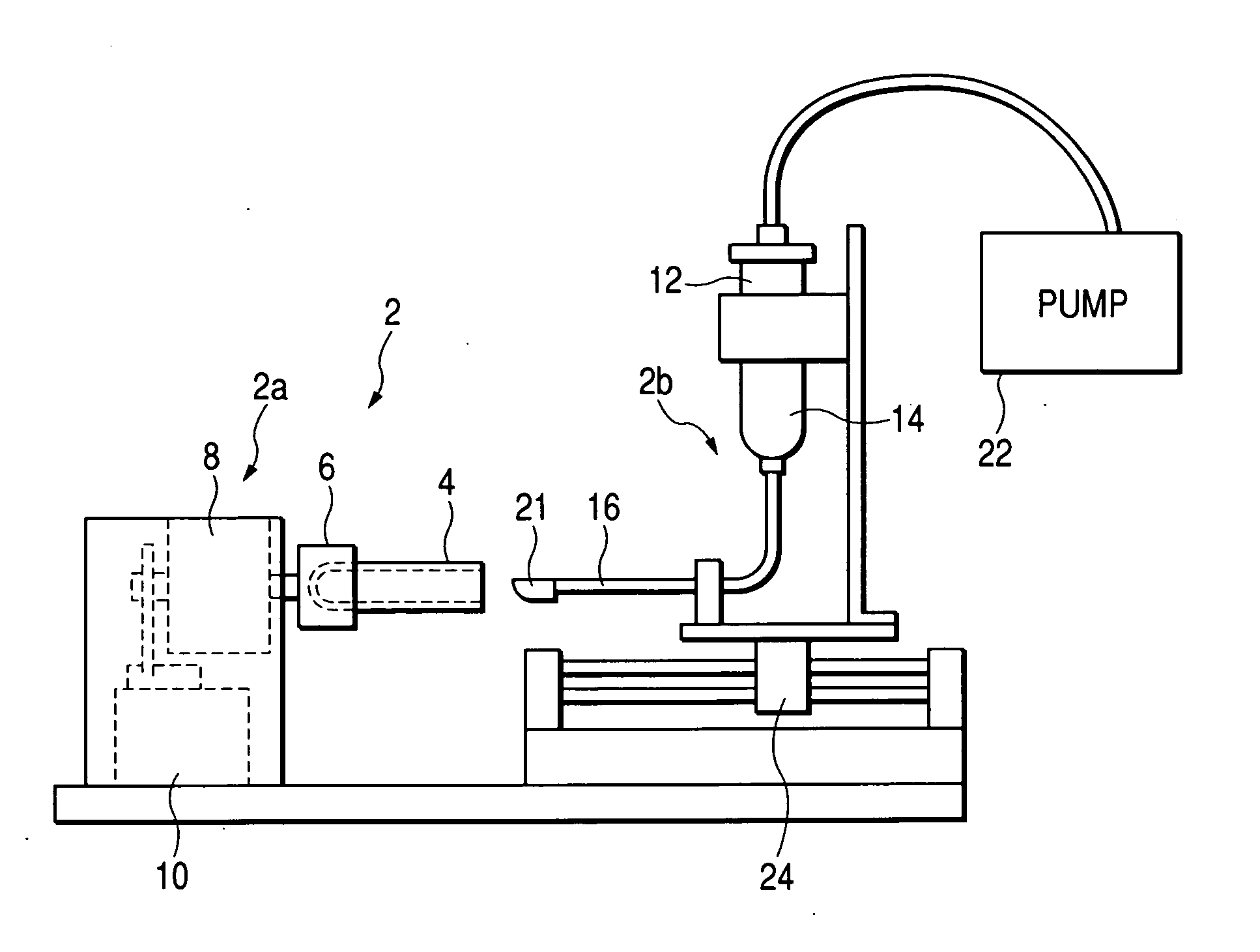

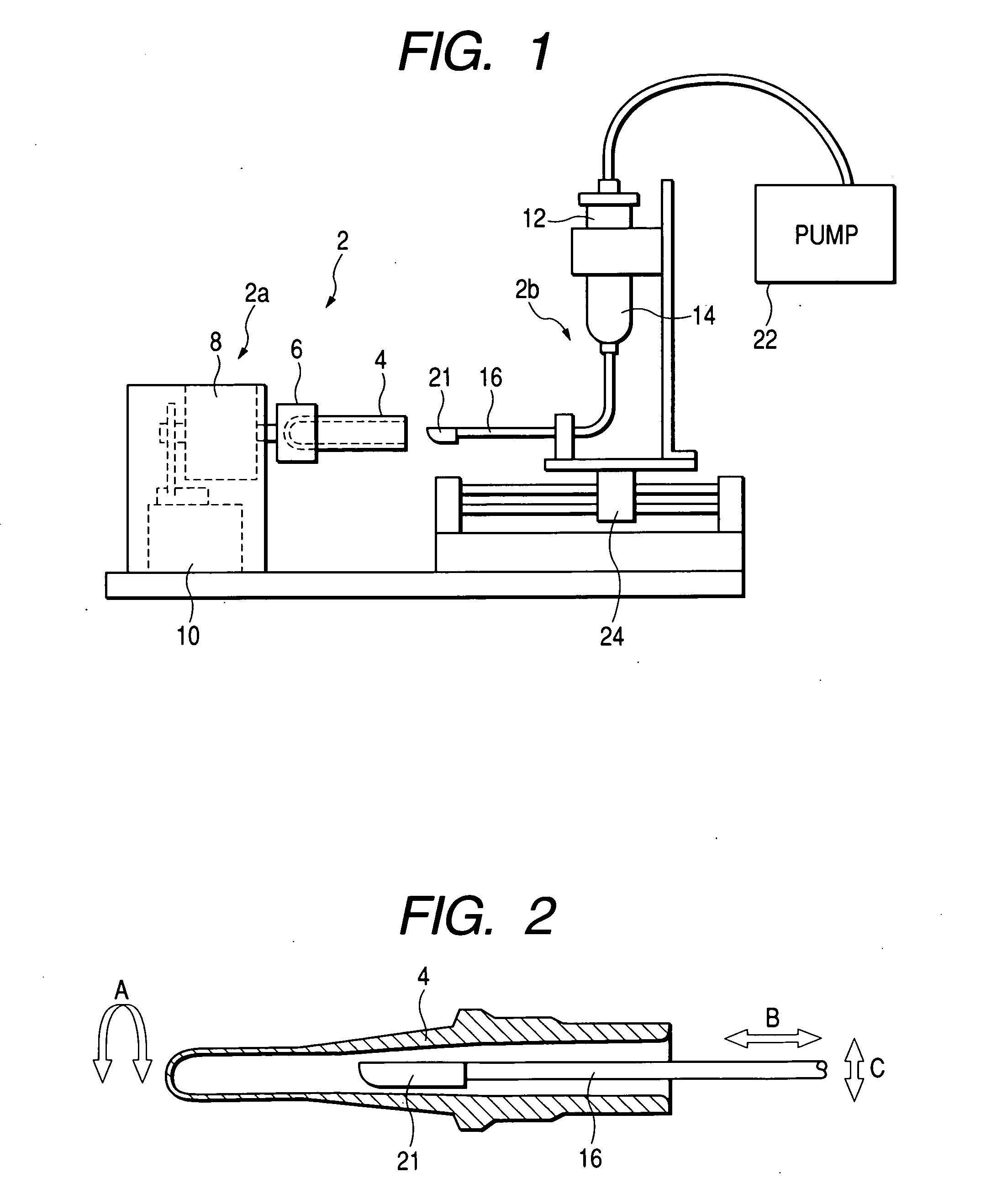

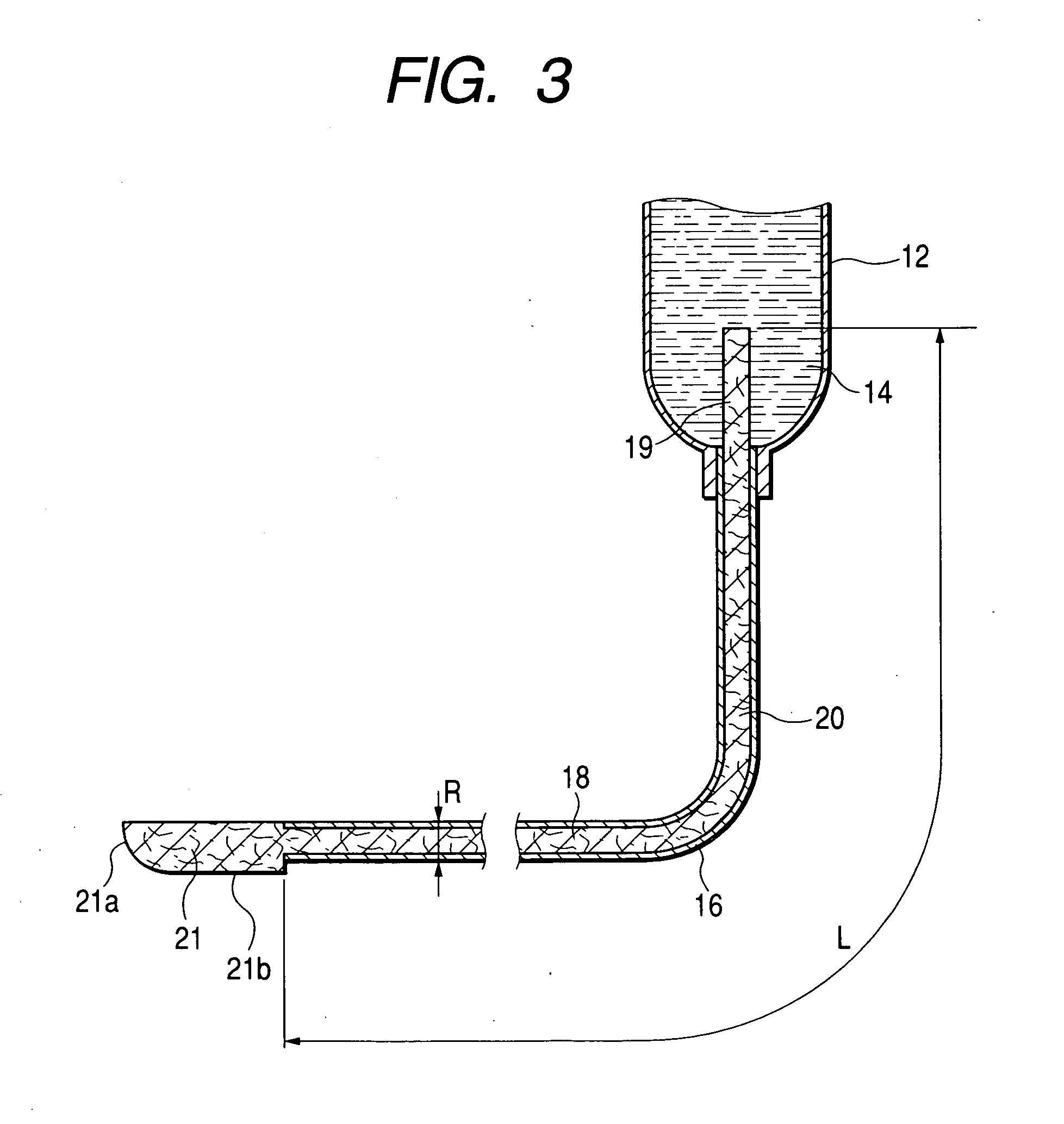

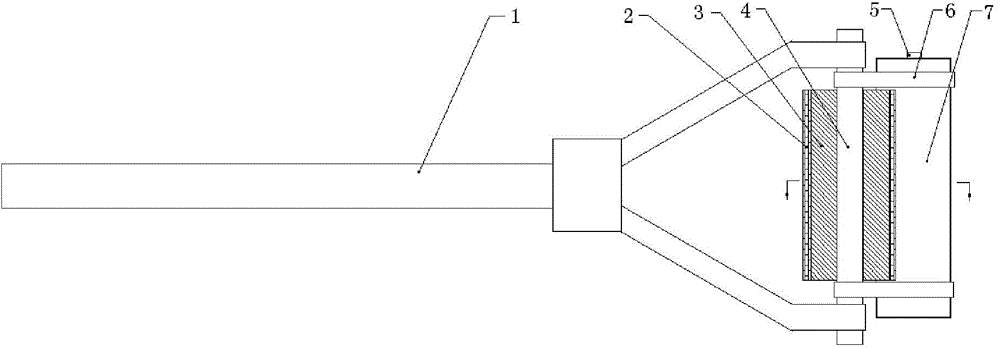

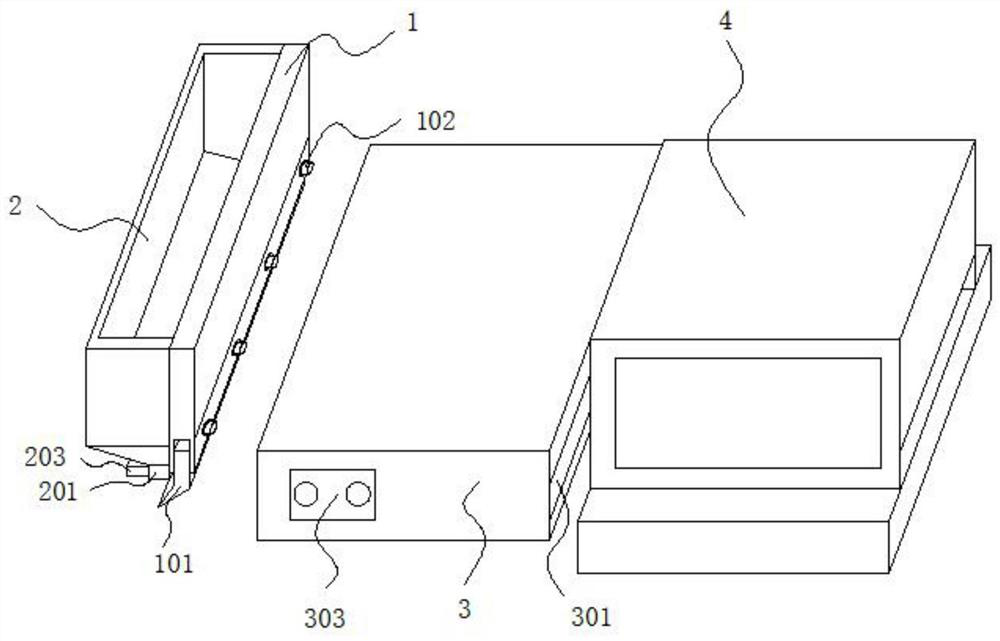

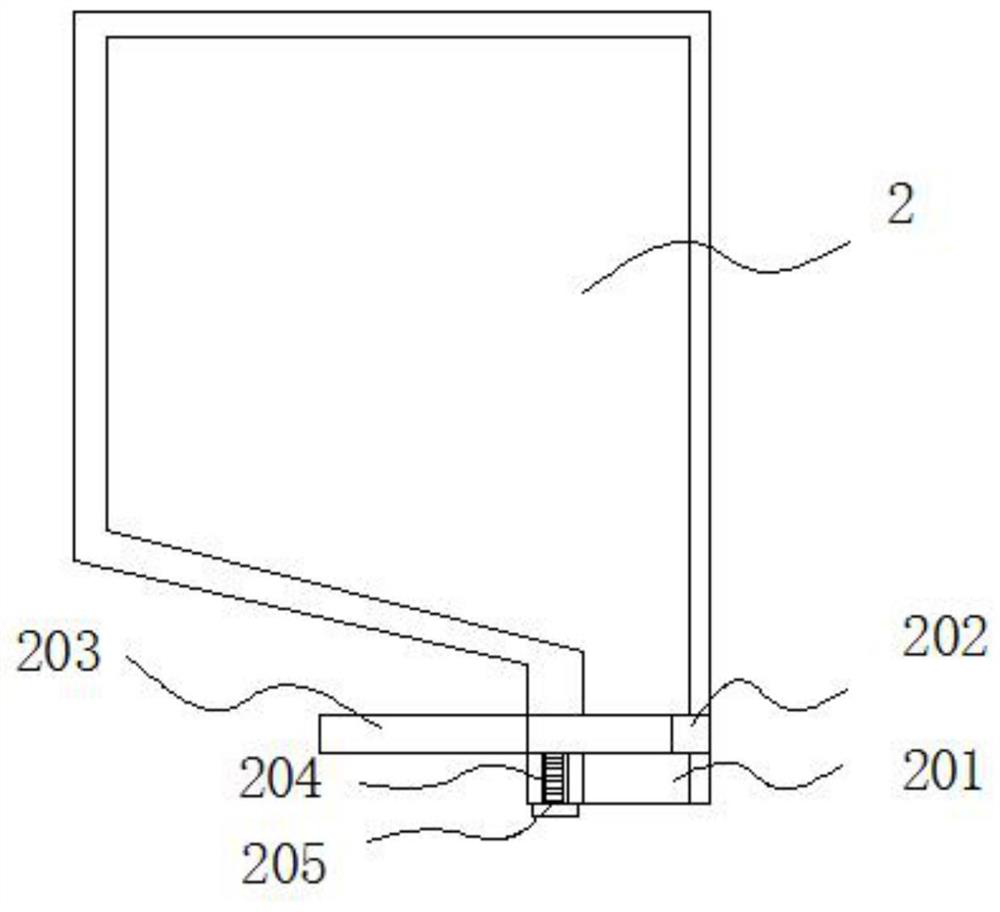

Active liquid applicator for forming active film

InactiveUS20060068095A1Ensure uniformityThickness is easy to controlPretreated surfacesCoatingsOxygen sensorSpray nozzle

An active liquid applicator is provided which is designed to coat a surface of an electronic parts such as an oxygen sensor with an active liquid for forming an electrode. The liquid applicator includes a nozzle head and a nozzle tube. The nozzle tube has disposed therein a pearmable member which produces capillary attraction of an active liquid thereinto and feed it to the nozzle head, thereby enabling formation of a thin active film on the electronic part which has the thickness controllable with high accuracy.

Owner:DENSO CORP

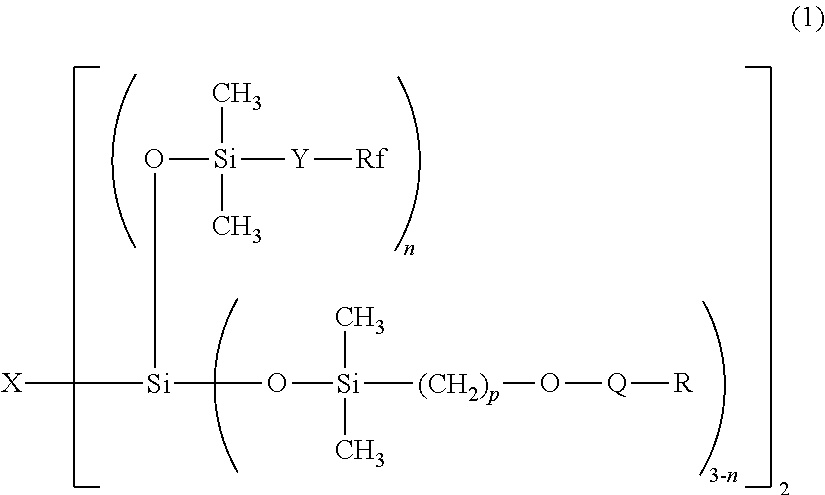

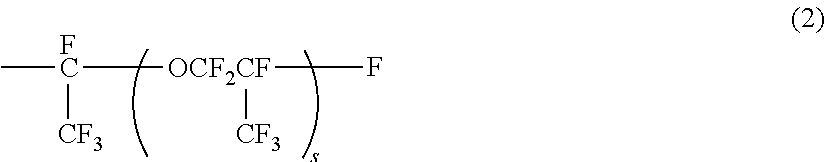

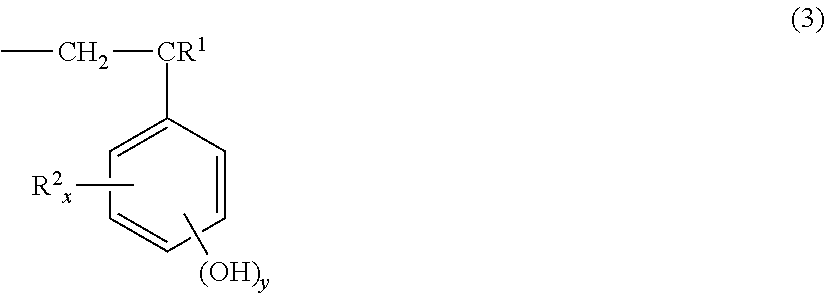

Chemically amplified positive resist composition and patterning process

InactiveUS20120184100A1Increasing the thicknessEnsure coating uniformityPhotosensitive materialsRadiation applicationsEthylene oxideAdduct

A chemically amplified positive resist composition comprising (A) a substantially alkali insoluble polymer having an acidic functional group protected with an acid labile group, (B) an acid generator, and (C) a perfluoroalkyl ethylene oxide adduct or a nonionic fluorinated organosiloxane compound is coated, exposed to UV radiation having a wavelength of at least 150 nm, and developed. The composition has advantages of uniformity and minimized edge crown upon coating, and no scum formation after development.

Owner:SHIN ETSU CHEM IND CO LTD

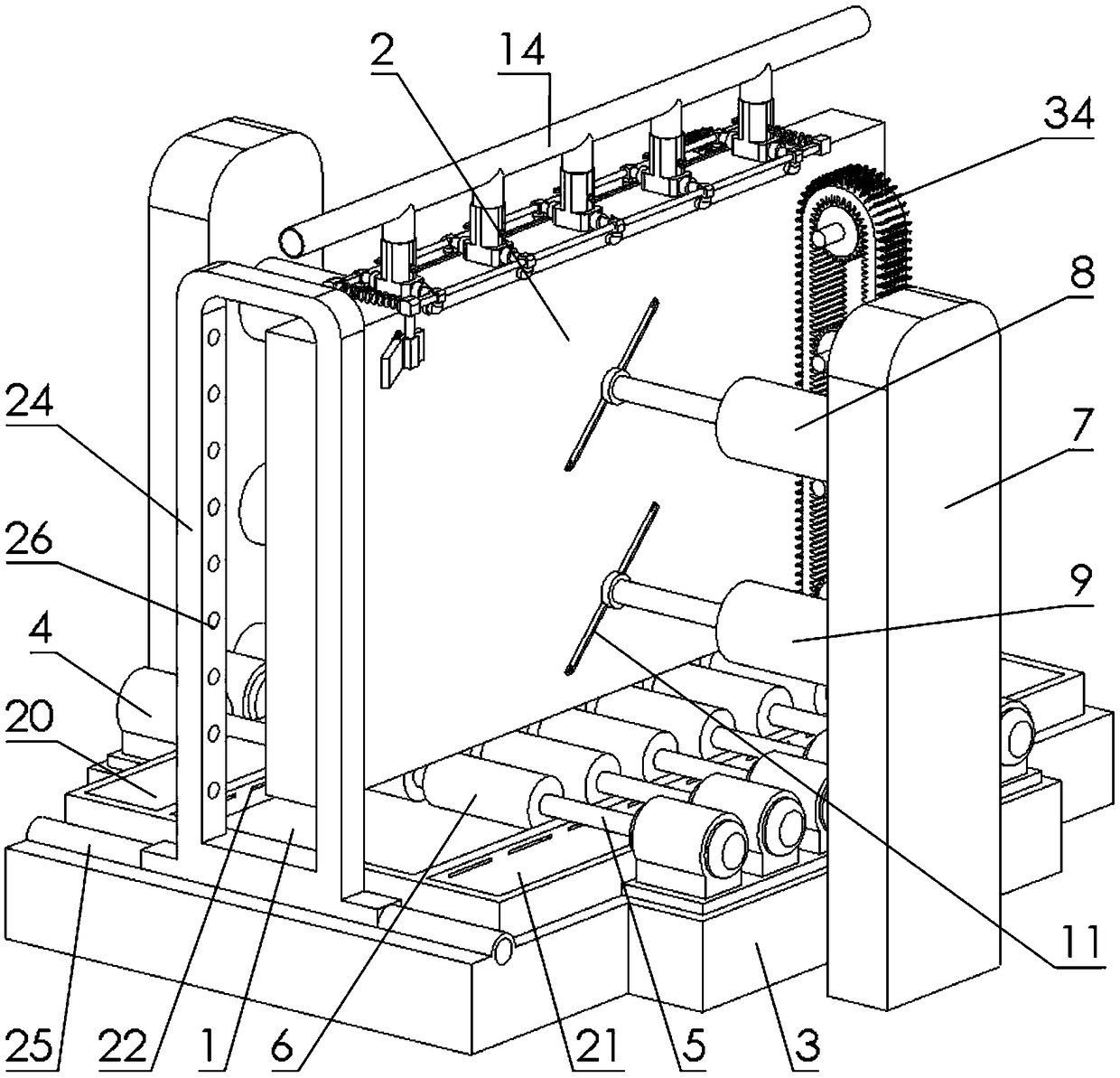

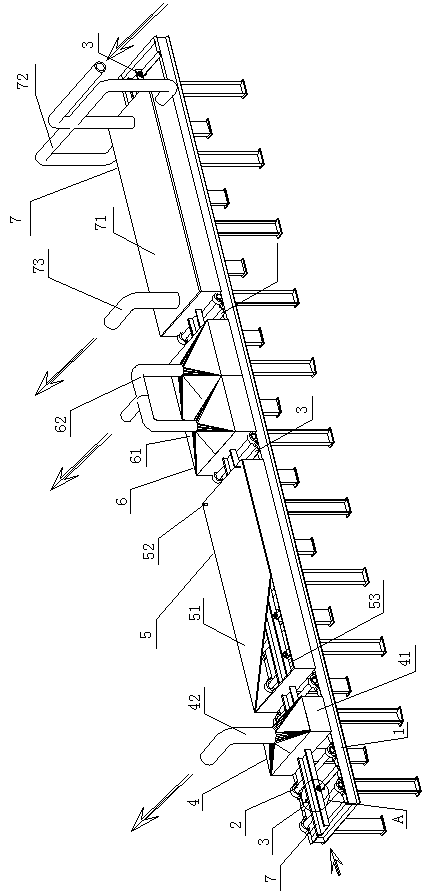

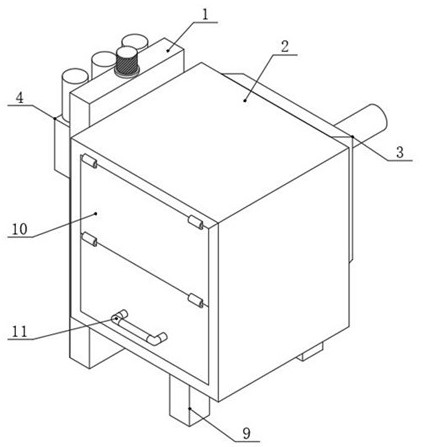

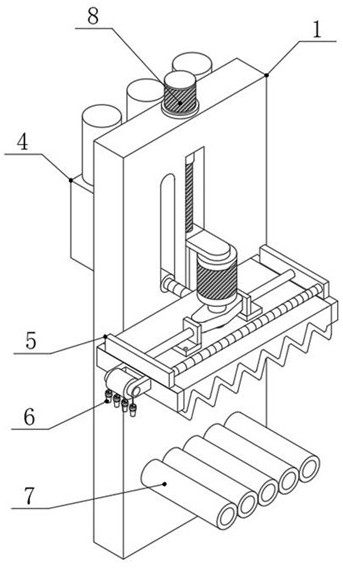

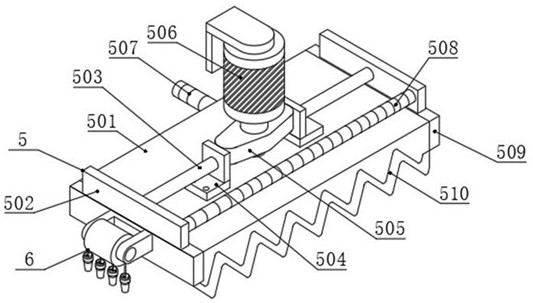

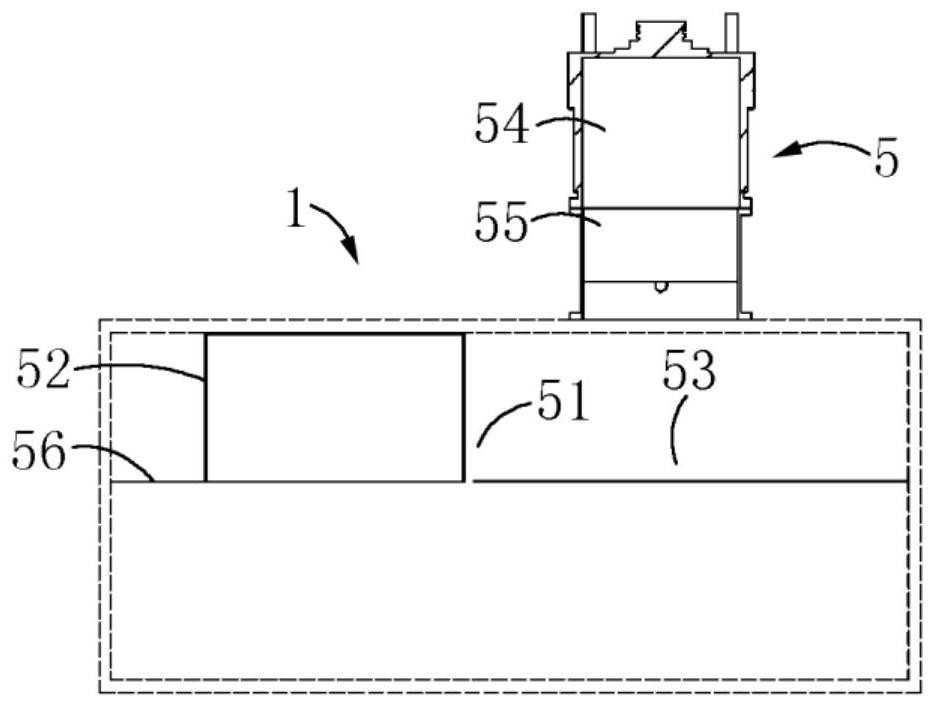

Wood processing equipment

The invention discloses wood processing equipment which comprises a wood-based panel to be processed. A glue collecting tank and glue standing tanks arranged on two sides of the glue collecting tank are arranged under the wood-based panel; a motor base is arranged on the outer sides of the glue standing tanks; motors are uniformly arranged on the motor base at intervals along the longitudinal direction; a glue discharging device is arranged above the wood-based panel; glue scraping devices are arranged on two sides of the wood-based panel; a glue coating device is arranged at the discharging end of the wood-based panel; and the wood-based panel is provided with a preheating frame in front of a feeding end. The wood processing equipment provided by the invention can be used for quickly preheating, gluing, scraping and coating the wood-based panel, is applicable to panels with different width sizes, and is comprehensive and uniform in coating; glues can be recycled; single-sided and two-sided glue coating is optional; the whole process is automatic and controllable; and the wood processing equipment is reliable to run and high-efficiency in operation.

Owner:湖南省杨林木业有限公司

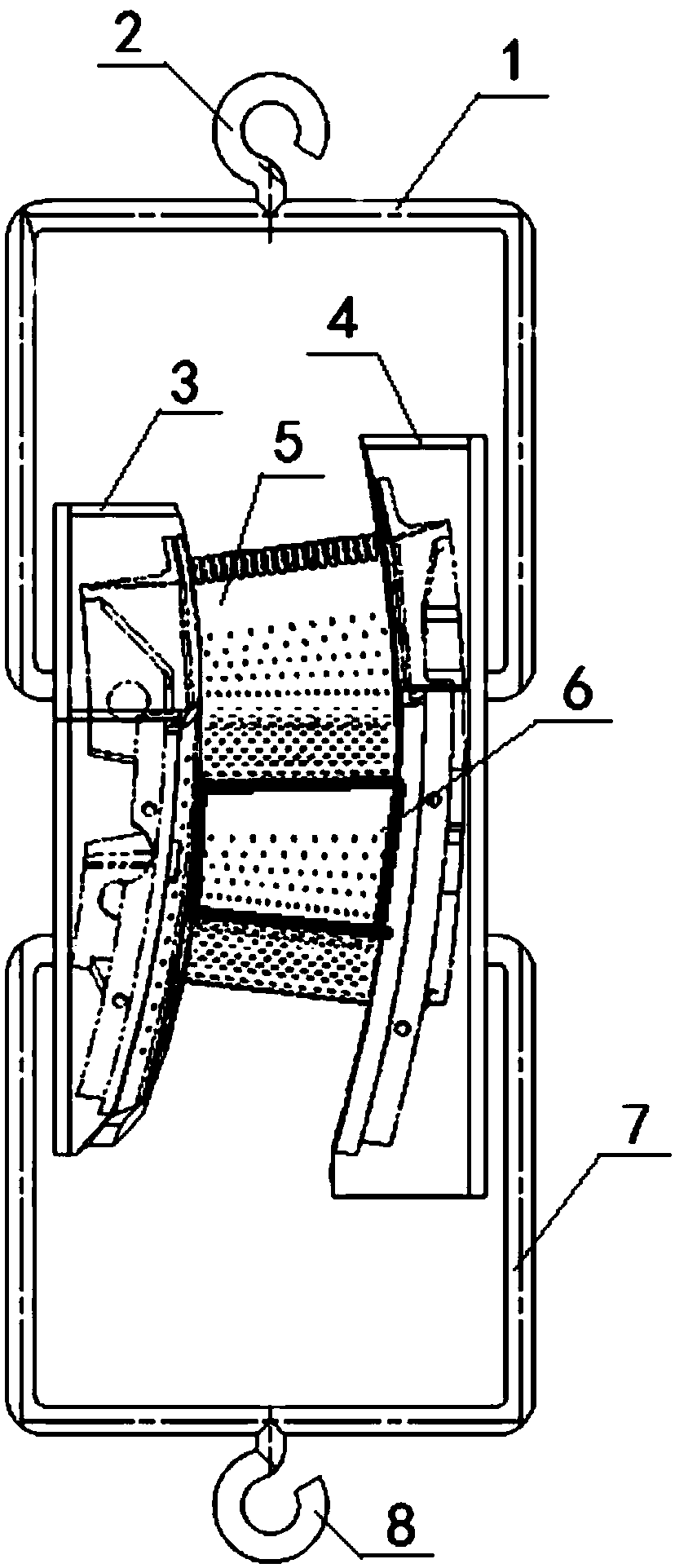

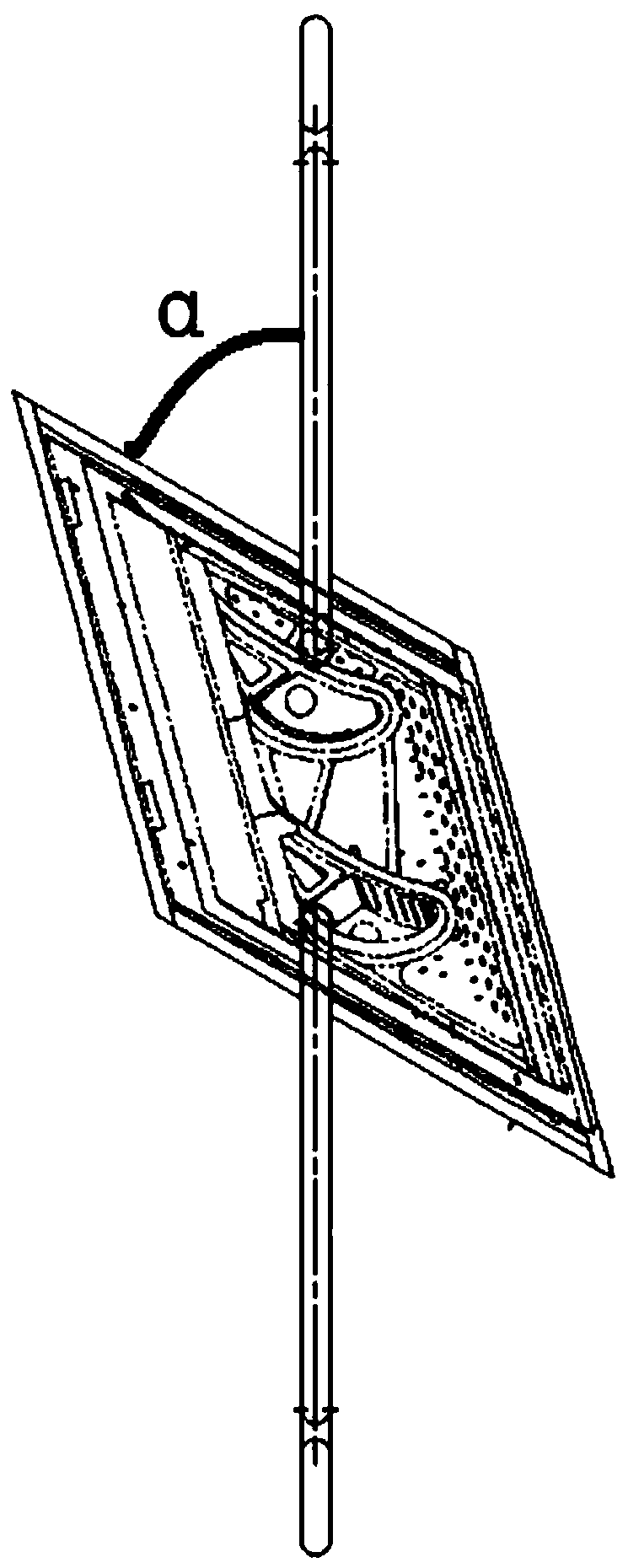

Protecting device and method for angle-variable coating layers of turbine guide blades

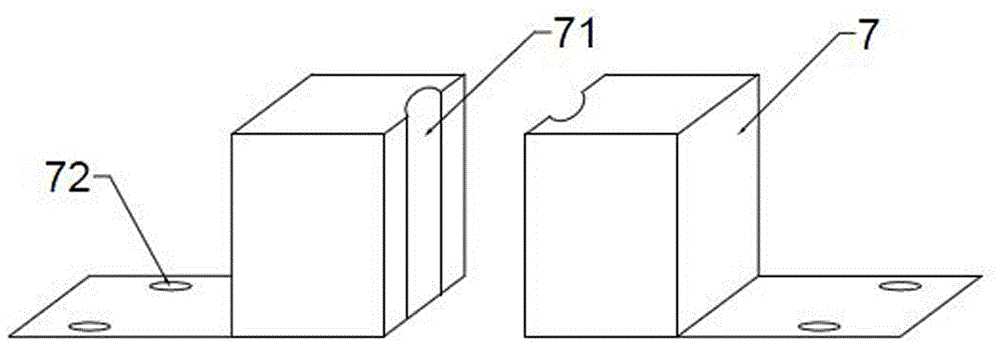

InactiveCN109457223AEffective protectionGuaranteed coating thicknessVacuum evaporation coatingSputtering coatingTurbineCoating

The invention discloses a protecting device and method for angle-variable coating layers of turbine guide blades. The protecting device comprises an inner edge plate protecting box sleeving an inner edge plate of a turbine guide blade, and an outer edge plate protecting box sleeving an outer edge plate of the turbine guide blade; the upper sides of the inner edge plate protecting box and the outeredge plate protecting box are connected with upper clips; the lower sides of the inner edge plate protecting box and the outer edge plate protecting box are connected with lower clips; the upper clips are connected with upper lifting hooks; the lower clips are connected with lower lifting hooks; the inner edge plate protecting box and the outer edge plate protecting box are positioned on the sameplane; the upper clips and the lower clips are positioned on the same plane; and an included angle between the plane of the inner edge plate protecting box and the outer edge plate protecting box andthe plane of the upper clips and the lower clips is 35-55 degrees. The whole runner surfaces of the turbine guide blades can be effectively coated; in particular, the thickness and the uniformity ofthe coating layers on throat way parts of the turbine guide blades are guaranteed; and non-coating areas are effectively protected.

Owner:AECC AVIATION POWER CO LTD

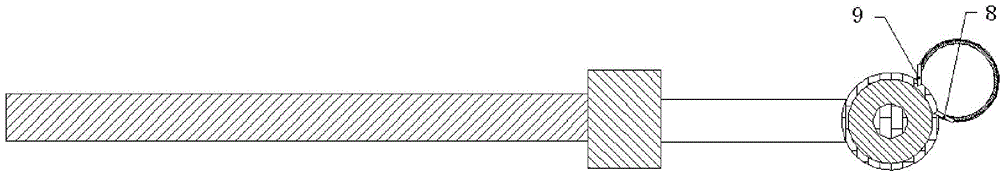

Novel paint roller

InactiveCN105772355AUniform humidityFewer dipping stepsLiquid surface applicatorsCoatingsBristleEngineering

The invention provides a novel paint roller. The novel paint roller comprises a rotating shaft, a drum, an elastic brush bristle sleeve, a tank and a brush handle; the rotating shaft is inserted in the drum in a penetrating mode, and is slidingly connected with the drum; the elastic brush bristle sleeve coats the drum; the tank is arranged on the rotating shaft; and the rotating shaft is arranged on the brush handle. The novel paint roller has the following beneficial effects that the drum rotates around the rotating shaft to coat paint of the elastic brush bristle sleeve on an object; the elastic brush bristle sleeve in the tank is wetly dipped in the tank arranged on the rotating shaft; the drum rotates out the part, wetly dipped by the paint, of the elastic brush bristle sleeve, and the paint is coated on the object, so that the paint dipping step is reduced; and excessive paint on the elastic brush bristle sleeve is scraped off by a scraper tightly pressed on the elastic brush bristle sleeve, so that the paint falling is prevented, the uniform wettability of the elastic brush bristle sleeve is kept, and the coating uniformity is guaranteed.

Owner:TIANJIN LARGE WHOLE PAPER COLOR PRINTING TECH CO LTD

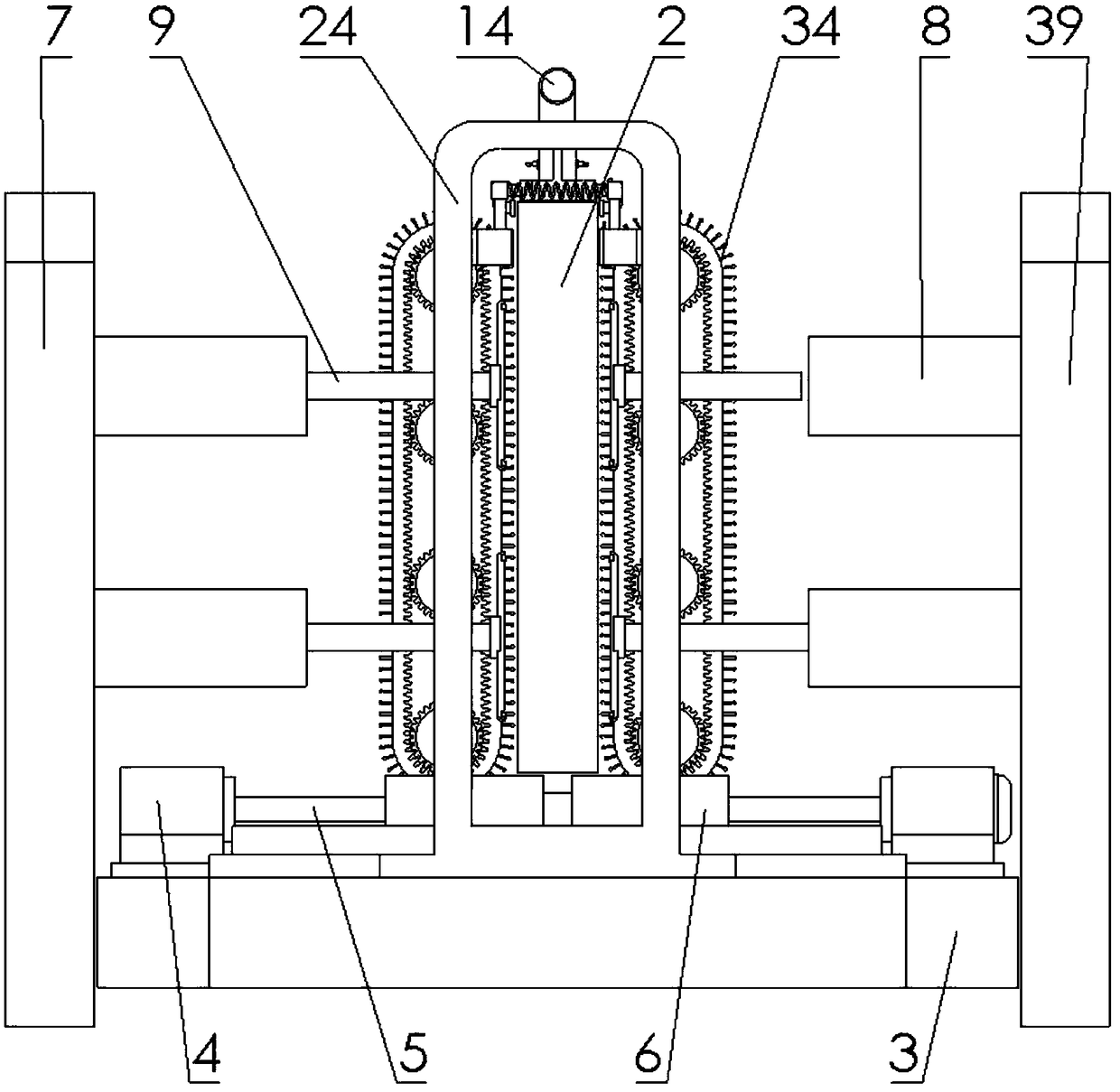

Thin-walled cold-formed steel assembly line coating equipment

ActiveCN103008177AEasy to operateQuality improvementPretreated surfacesCoatingsAssembly lineEngineering

The invention discloses thin-walled cold-formed steel assembly line coating equipment which comprises a frame, wherein the top of the frame is provided with a conveying deice; and the top end of the frame is sequentially provided with a pretreatment device, a preheating treatment device, a coating device and a drying treatment device from the input end to the output end of the conveying device. The thin-walled cold-formed steel assembly line coating equipment is simple in structure and convenient to operate and use, the thin-walled cold-formed steel is sequentially subjected to cleaning pretreatment, preheating treatment, coating treatment and drying treatment, to complete a coating process, poison gas is not exhausted in the coating process, the environmental pollution is extremely low, and the coated thin-walled cold-formed steel is high in anti-rust quality; and moreover, only the mold coating size and shape are required to be changed, and the equipment can be suitable for sections of various section bars and is wide in application range.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

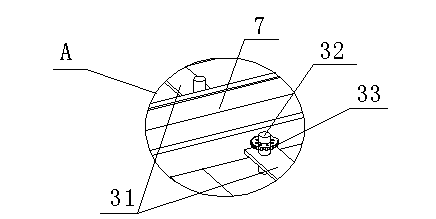

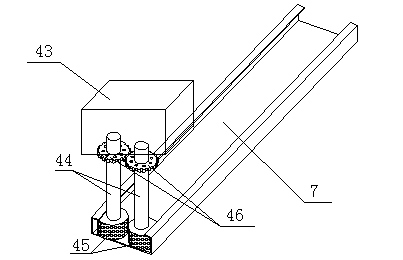

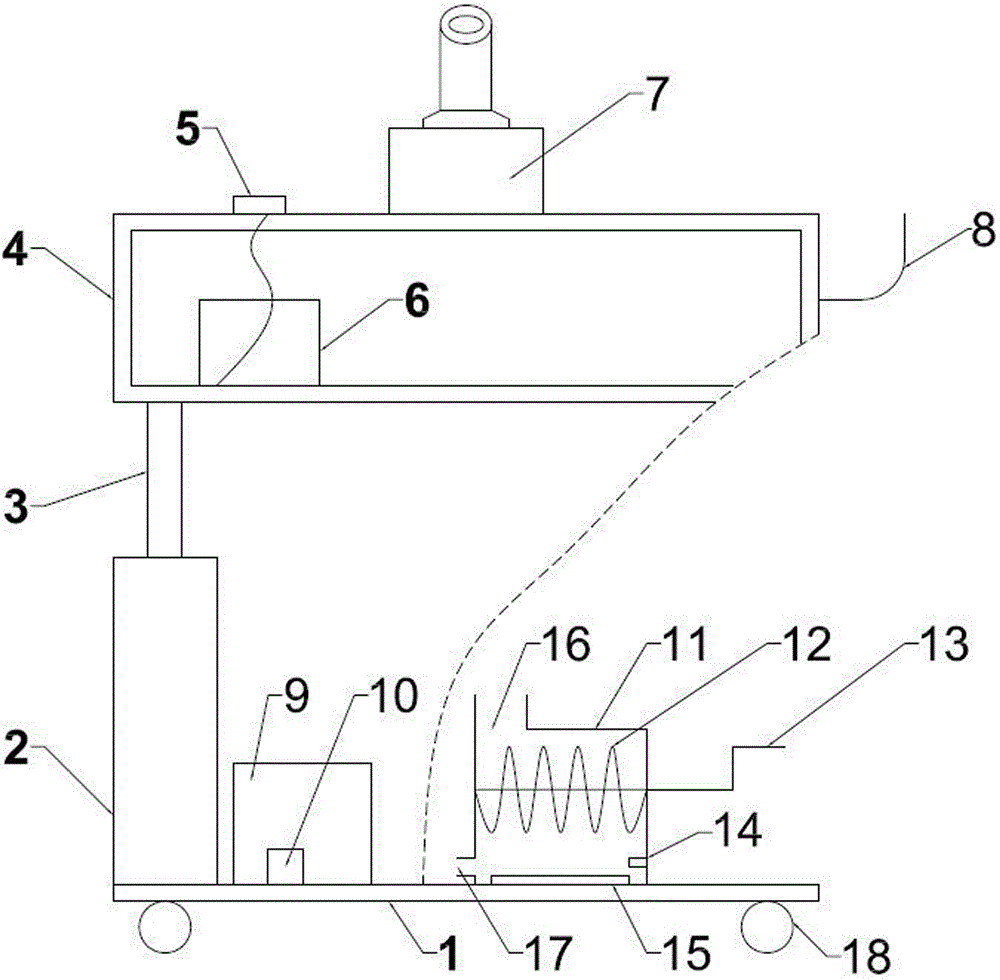

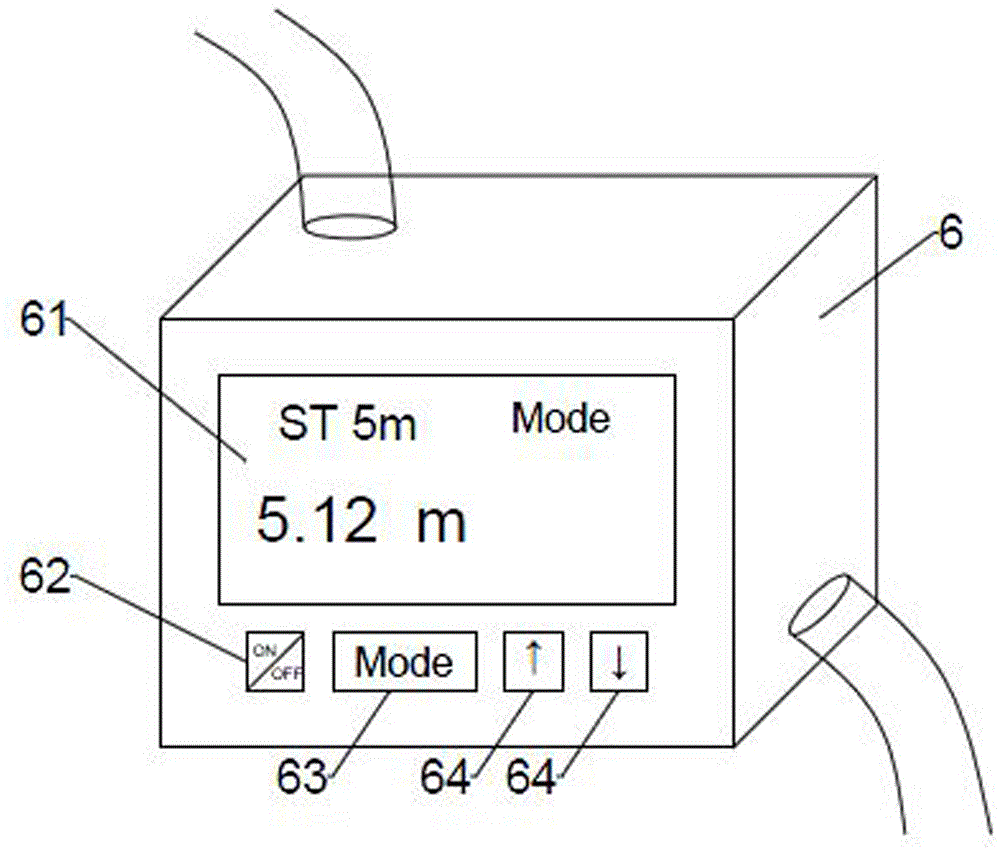

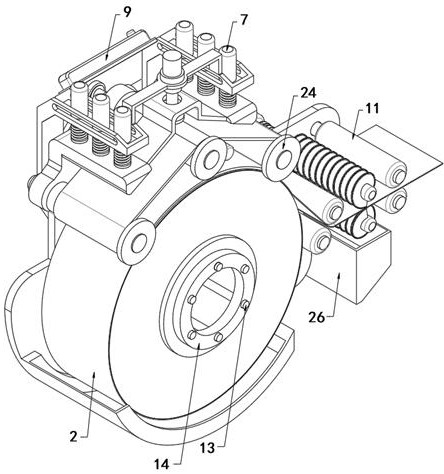

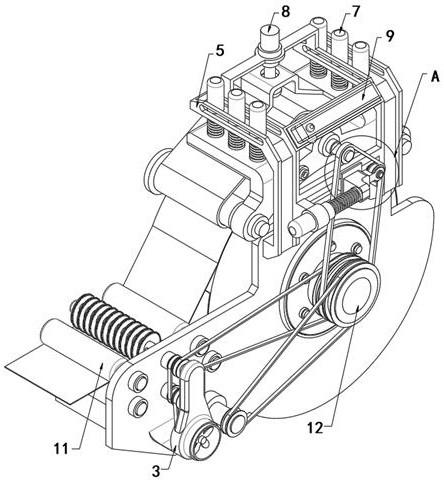

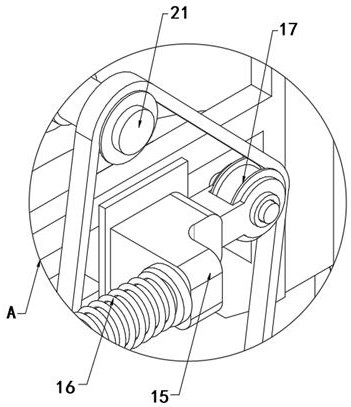

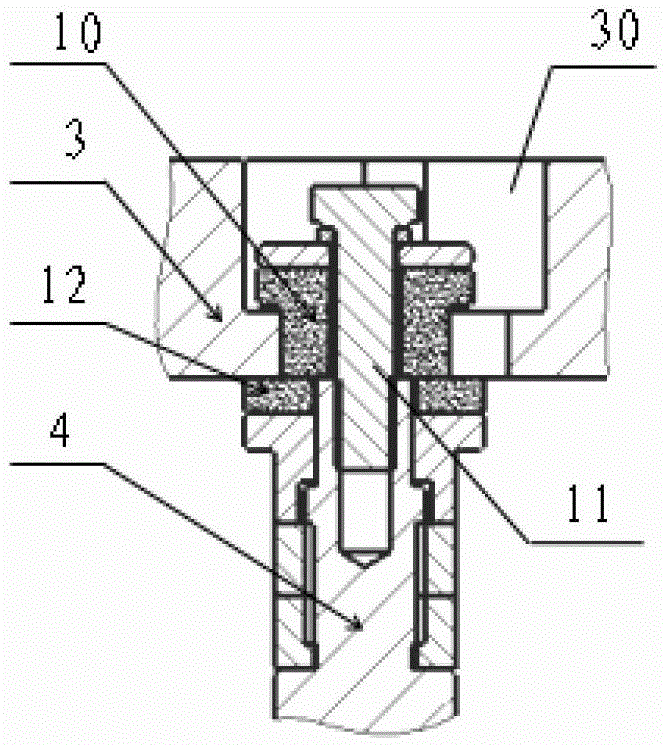

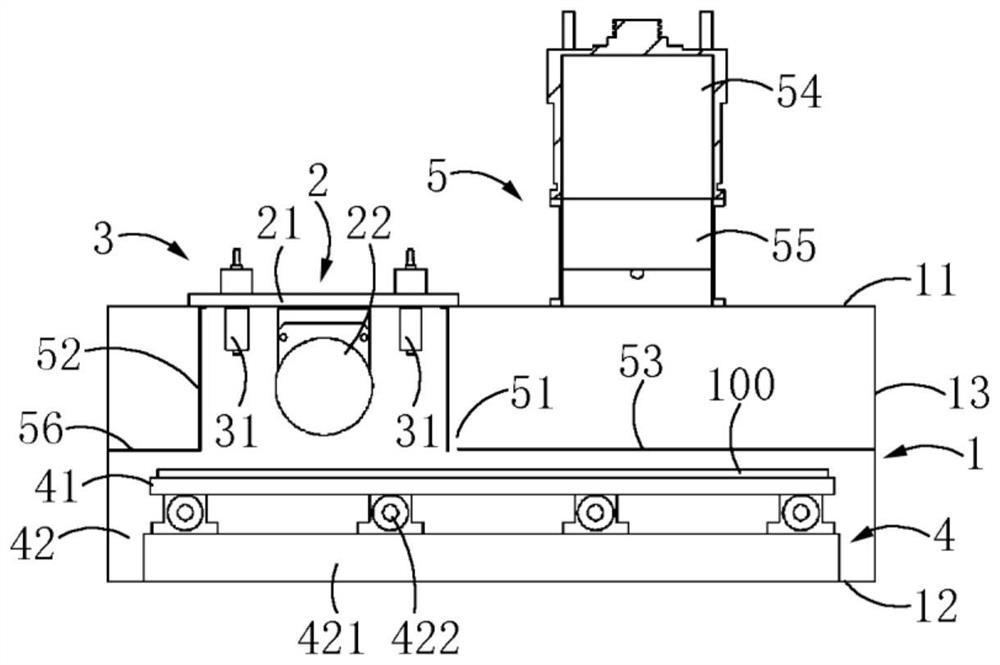

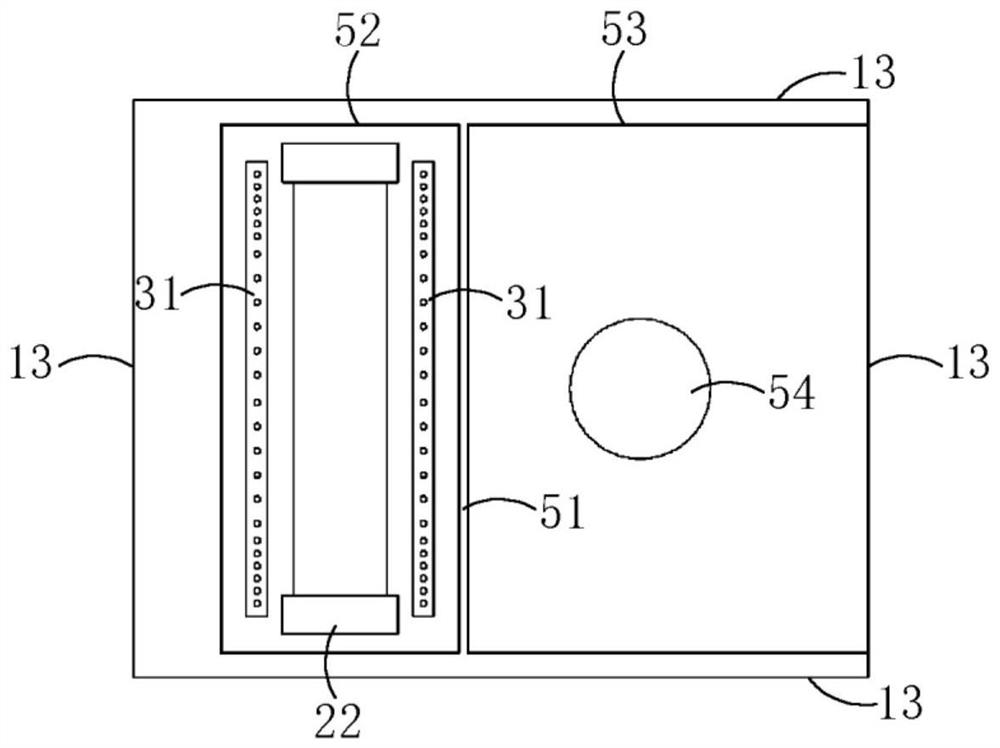

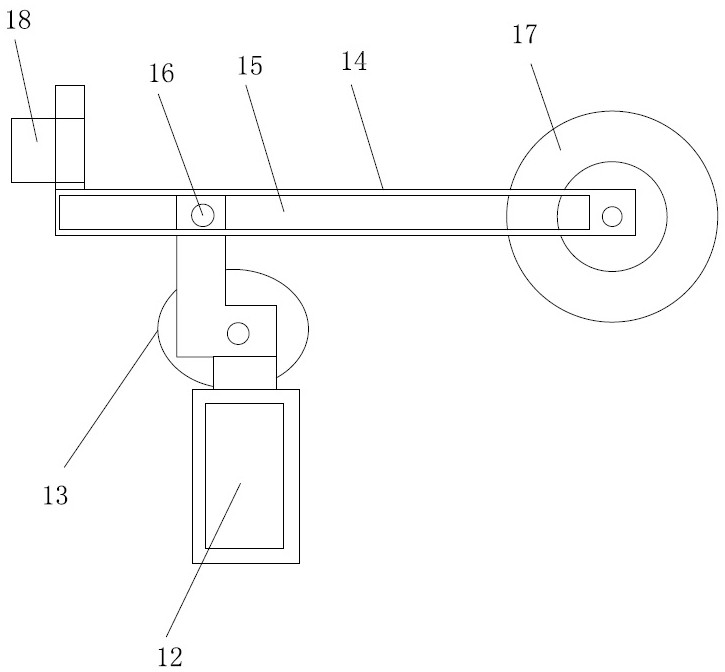

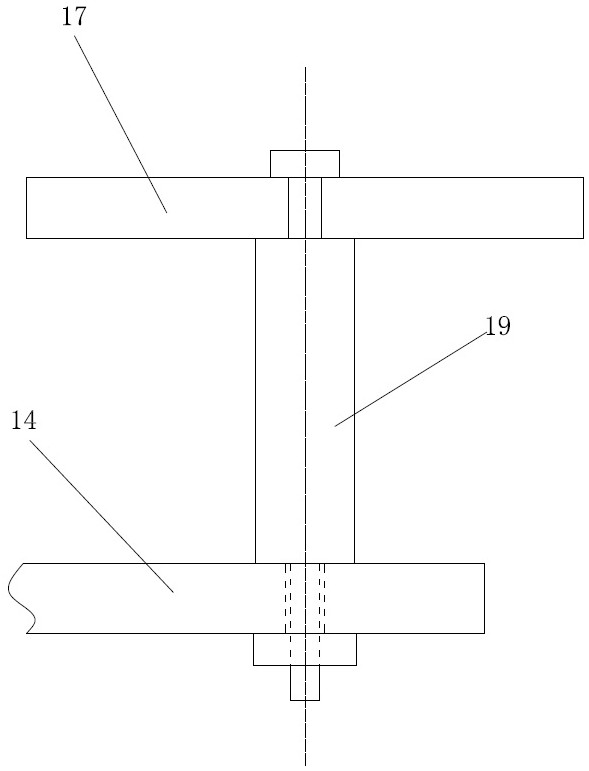

Self-adjustment type spraying equipment carrier platform

ActiveCN105817363AGuaranteed uniformityEnsure coating uniformitySpraying apparatusEngineeringMaterial storage

The invention relates to a self-adjustment type spraying equipment carrier platform. The platform is characterized in that the platform comprises a bottom plate (1), a power cabinet (9), a material storage tank (11) and a hydraulic cylinder (2) are arranged on the bottom plate (1), a support body (4) is connected to an output shaft (3) of the hydraulic cylinder (2), an infrared distance meter (5), a spray gun tube fixing table (7) and a push rod (8) are arranged on the support body (4) respectively, and a group of universal wheels (18) are arranged at the bottom of the bottom plate (1). The self-adjustment type spraying equipment carrier platform is simple in structure, convenient to operate and capable of achieving real-time accurate control over spraying height, the spraying uniformity is guaranteed, the manual work intensity is reduced, and the spray construction efficiency is greatly improved.

Owner:ANHUI HUAGUANG PHOTOELECTRIC MATERIAL TECH GRP CO LTD +2

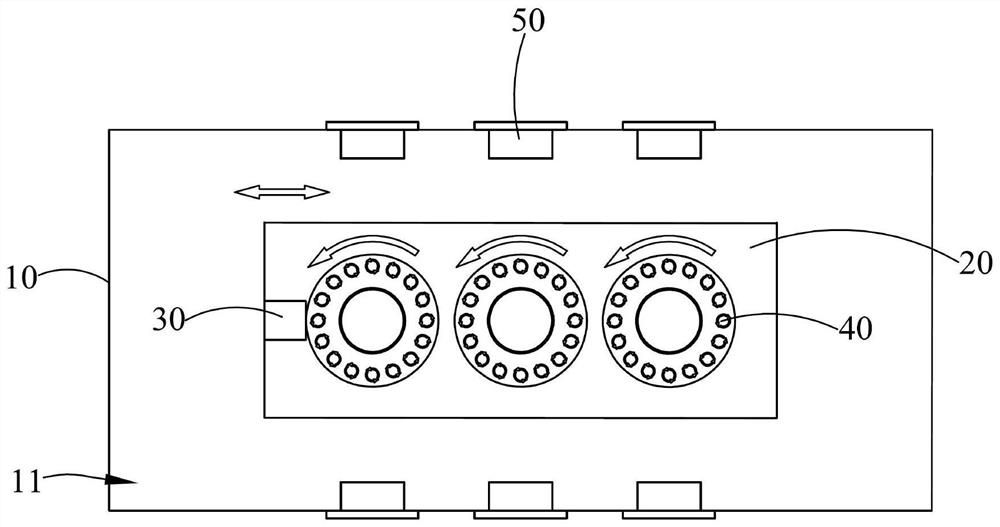

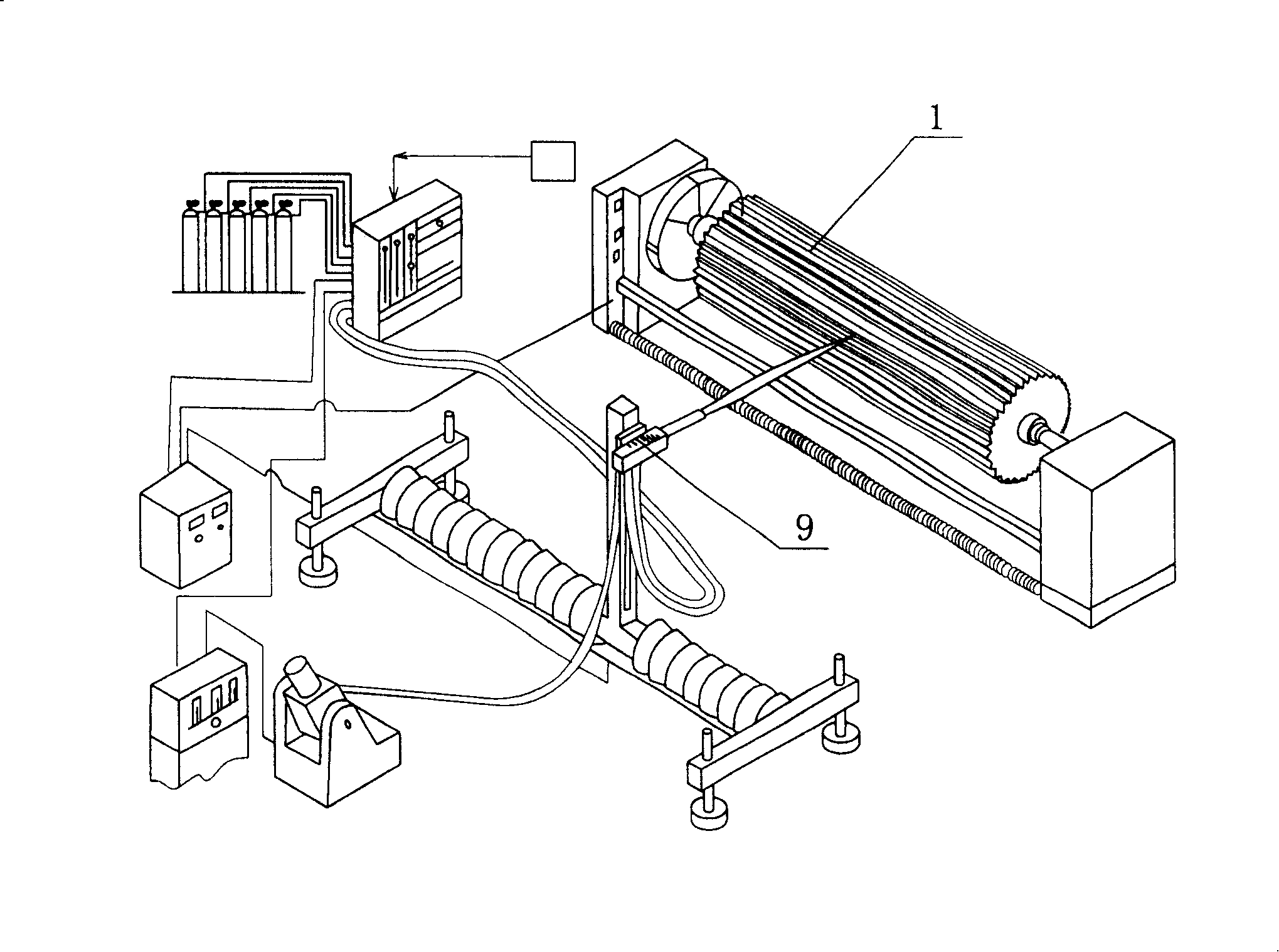

Tubular workpiece coating machine

PendingCN112458421AEnsure coating uniformityShorten coating timeVacuum evaporation coatingSputtering coatingElectric machineryStructural engineering

The invention discloses a tubular workpiece coating machine. The tubular workpiece coating machine comprises a coating bin internally provided with a coating cavity, a workpiece frame arranged in thecoating cavity in a sliding manner and a first driving motor connected with the workpiece frame to drive the workpiece frame to slide in the length direction of the coating bin. At least one tubular workpiece is borne on the workpiece frame, a plurality of cathodes are arranged in the length direction of the coating bin at intervals, the tubular workpiece coating machine further comprises a seconddriving motor arranged in the coating cavity, and the second driving motor is connected with the workpiece frame so as to drive the workpiece frame to rotate around the axis of the workpiece frame. The invention provides the coating machine suitable for the tubular workpiece.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

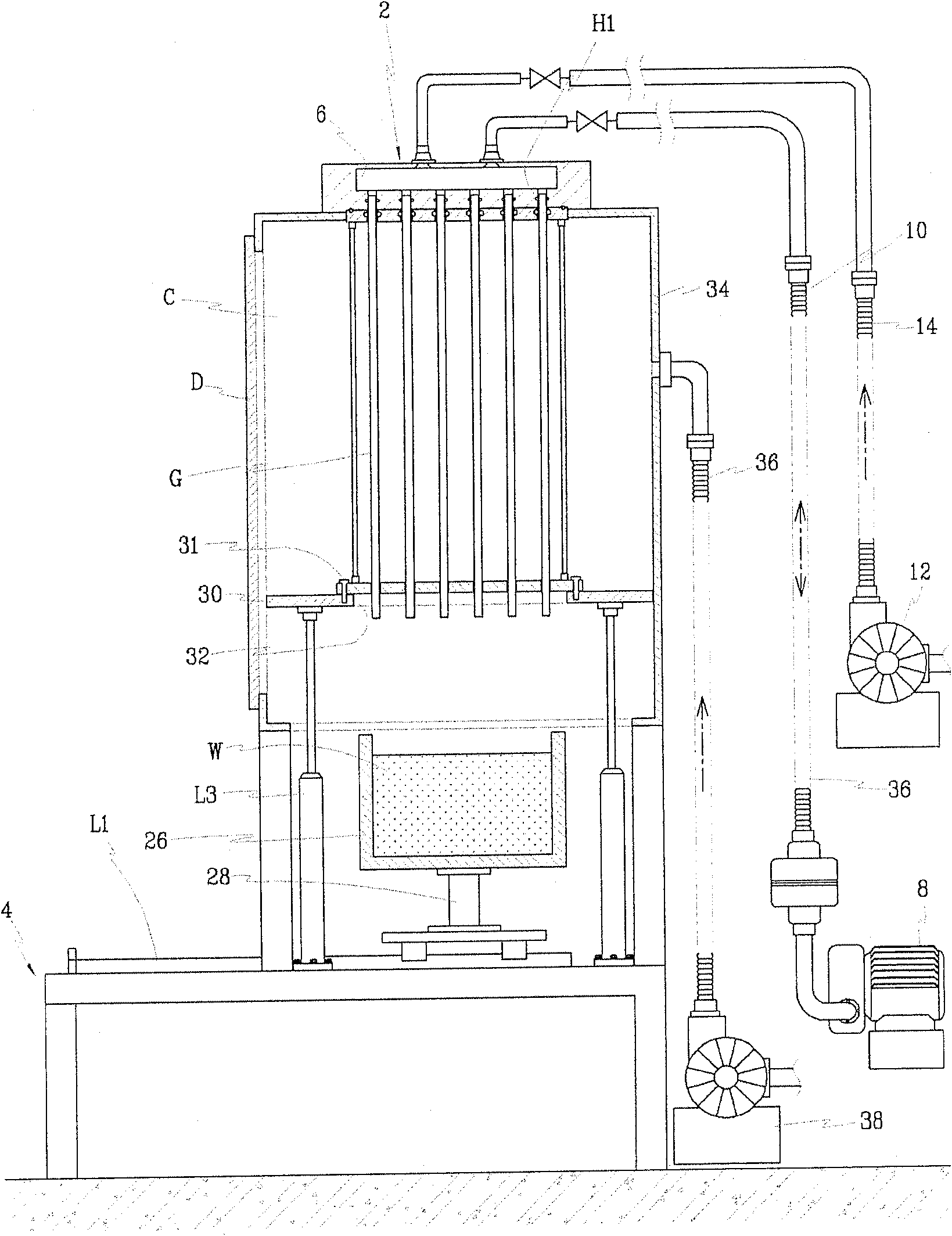

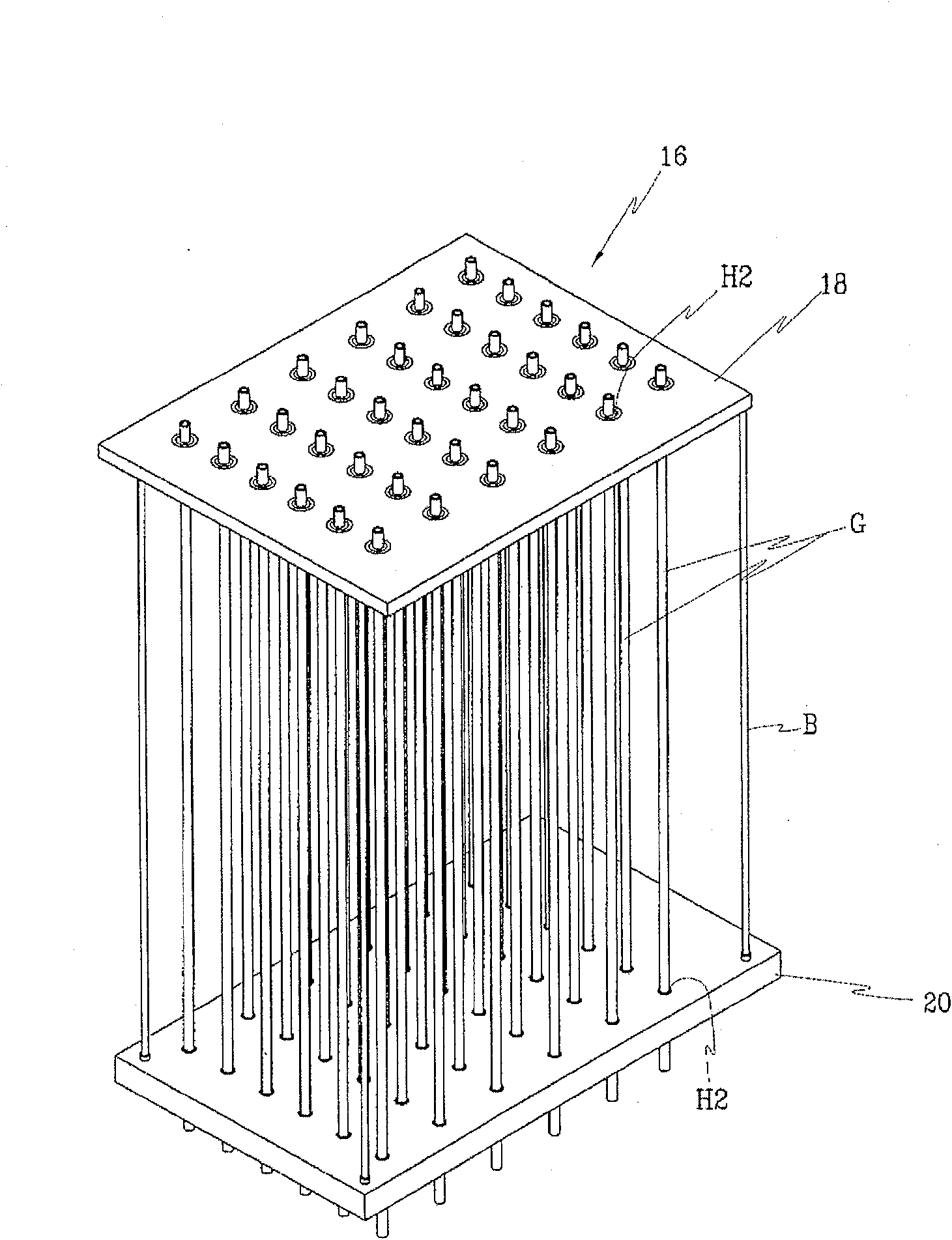

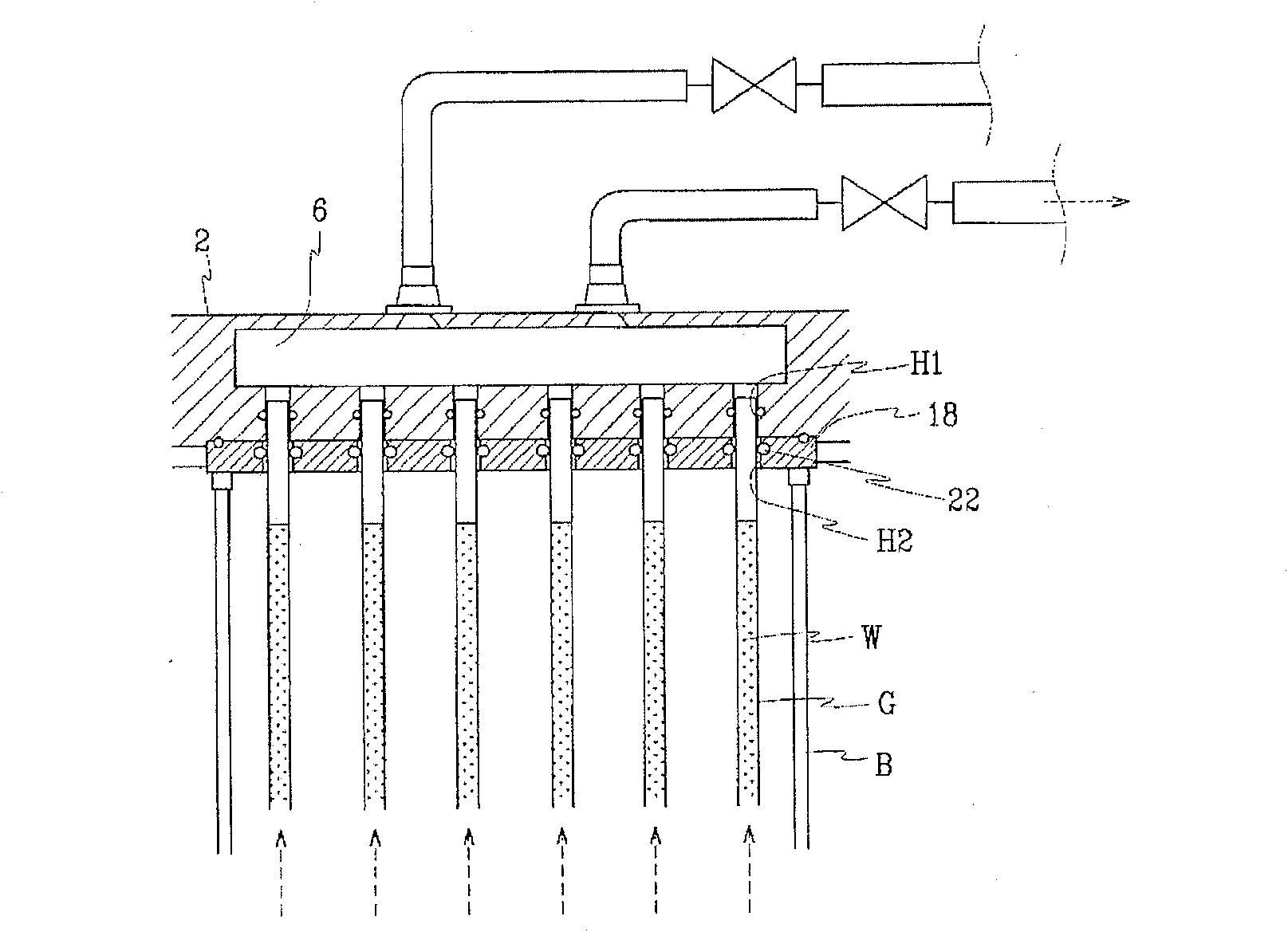

Fluorescent material coating apparatus and method of coating fluorescent substance using the same

InactiveCN100559538CKeep dryUniform drying temperatureLuminescent coatings applicationShoresSubstance usePhosphor

The invention discloses a fluorescent substance coating device for manufacturing fluorescent lamps and a coating method using the device, which comprises: a loading box for arranging a plurality of glass tubes in parallel; The distributing device of the distribution chamber provided; the fluorescent substance storage tank arranged under the plurality of glass tubes; used to lift the loading box or storage tank so that one end of the plurality of glass tubes arranged on the loading box A mobile device that can be in contact with the fluorescent substance; a negative pressure generating device that generates negative pressure inside the universal chamber so that the fluorescent substance is sucked into the glass tube; An air supply device for drying that supplies hot gas for drying so that the gas flows into the inside of the glass tube to dry the fluorescent material. Through the present invention, fluorescent liquid can be coated on the inside of a plurality of glass tubes at the same time, conveniently and quickly, and the coating of fluorescent liquid can be evenly dried.

Owner:WEIHAI DMS OPTICAL ELECTROMECHANICAL CO LTD

Optical blanking structure for refrigeration type infrared detector

InactiveCN113546814AAvoid offsetUniform coating thicknessPretreated surfacesCoatingsCoated surfaceUV curing

The invention discloses an optical blanking structure for a refrigeration type infrared detector. The optical blanking structure comprises a mounting frame and a UV curing machine, wherein a scraper is detachably connected to the bottom of the mounting frame, a storage box is fixedly connected to one side of the surface of the mounting frame, a discharging pipe is fixedly connected to the bottom of the storage box, and a chute is formed in the interior of the discharging pipe in a horizontal direction. By using the optical blanking structure disclosed by the invention, a coating is added in a direct discharging mode of the storage box, and the scraper is adopted for scraping; and compared with a traditional coating mode of a coating roller, a coating thickness and the coating uniformity on the surface of a base material can be better guaranteed, the smoothness and the glossiness of the coating are improved, and then the subsequent film forming quality is improved. The surface of a coating layer is pretreated through a high temperature generated by an electric heating wire, so that the surface of the coating layer is dried firstly, the situation that the surface coating deviates in the conveying and moving process of the base material is avoided, the disadvantage that curing o fa surface layer is unstable due to direct UV light curing is overcome at the same time, and a film forming thickness and the film forming quality of the blanking structure are further improved.

Owner:浙江焜腾红外科技有限公司

Furniture spraying equipment

ActiveCN113843066AImprove the ability to adjust and adaptHigh precisionLiquid spraying apparatusSpray nozzleEngineering

The invention discloses furniture spraying equipment, and belongs to the technical field of spraying. The furniture spraying equipment comprises a fixing frame, wherein a dustproof cover is fixedly installed on one side of the fixing frame, a spraying pump is fixedly installed on the other side of the fixing frame, a plurality of material conveying rollers are in transmission connection with the bottom of the fixing frame, the material conveying rollers are located in the dustproof cover, an opening is formed in the position, corresponding to one side of the fixing frame, of the dustproof cover, and a linear module is fixedly assembled at the position, corresponding to the opening, of one side of the fixing frame. According to the furniture spraying equipment, the relative unfolding radian of a laminating part is adjusted and controlled through the unfolding distance of the laminating part, so that the radian of the wrinkle part on the surface of furniture is effectively adapted; and in addition, a spraying material is atomized through the spraying pump and then is fed into spraying nozzles on the two sides of the bottom of the laminating part, the spraying nozzles are attached to the wrinkle part of the furniture so that the wrinkle part and the arc-shaped surface of the bottom can be subjected to quantity-controlled spraying treatment, the adjusting and adapting capacity of spraying of the wrinkle part is effectively improved, the spraying machining precision and effect are improved, and the use requirements are met.

Owner:诸城市松源木业有限责任公司

Cold rolling treatment device for high-quality steel preparation

ActiveCN114798746AFully tightenQuick take outLiquid surface applicatorsCoatingsChain linkMaterials science

The invention relates to the technical field of cold rolling treatment equipment, in particular to a cold rolling treatment device for high-quality steel preparation. A cold rolling treatment device for high-quality steel preparation comprises a machine base, a roll bearing mechanism is rotationally connected between the inner surfaces of the machine base, a cold-rolled steel strip is wound on the surface of the roll bearing mechanism, a dust suction hood, a servo motor and a top frame are fixedly installed on the surface of the machine base, and a rotating shaft is rotationally connected to the inner wall of the dust suction hood; a set of exhaust fans are fixedly installed on the circumferential side face of the rotating shaft, the output shaft end of the servo motor is in transmission connection with the roll bearing mechanism through a chain a, two sets of vertically-arranged elastic pressure exerting pieces are installed on the inner wall of the top frame, and the bottom face of the top frame is connected with a liquid coating mechanism through the two sets of elastic pressure exerting pieces. The device has the beneficial effects that through the design of the wall cleaning mechanism and the liquid coating mechanism, the device can efficiently complete rolling, cleaning and surface anti-oxidation treatment operation in the cold-rolled steel strip treatment process in an automatic mode.

Owner:南通霄阳机械有限公司

Manufacturing method of shielding frame and ultrathin substrate film solar cell

PendingCN106253829APrevent leakageEfficient heatingFinal product manufactureSolid-state devicesEngineeringCell sheet

The invention relates to a manufacturing method of a shielding frame and an ultrathin substrate film solar cell. The shielding frame is formed by a rectangular upper frame and a rectangular lower frame, which are up-down arranged in the thickness direction, so the effect of preventing the edge and back face of the ultrathin substrate from being plated the film can be achieved, the edge packaging is more reliable and reliability of an electronic device can be ensured for the long time. Different sizes of shielding frames are used in all film plating processes, so mutual insulation is formed among all film layers, and the edge of the device is prevented from having an electric leakage. During the film plating process, the shielding frame is used for pressing the edge of the ultrathin substrate, so the periphery of the ultrathin substrate is prevented from being cocked, and the substrate can be effectively heated, thereby ensuring uniformity of the plated film and improving performance of the film electronic device. By use of the shielding frame, an edge film layer removing procedure in the traditional process is omitted, so production technique is simplified, production efficiency is improved and damage to a cell sheet possibly caused by an edge removing process is avoided.

Owner:NINGBO SANDI SOLARTECH CO LTD

Green immobilized abrasive material polished wafer and preparation method thereof

InactiveCN107350978AImprove initial tack performanceIncrease stickinessAbrasion apparatusGrinding devicesAdhesivePolyketone

The invention relates to a green immobilized abrasive material polished wafer. The green immobilized abrasive material polished wafer is characterized by being composed of a base layer and a coating layer. The base layer is a PET membrane and comprises the following components in percentages by weight: 20-50wt% of an immobilized abrasive material, 25-40wt% of starch and 25-40wt% of polyketone resin. A preparation method of the green immobilized abrasive material polished wafer provided by the invention comprises the following steps of: (1) weighing; (2) preparation of a coating liquid; (3) coating of a coating layer; and (4) curing. According to the immobilized abrasive material polished wafer provided by the invention, both the starch and the polyketone resin are taken as a green and pollution-free adhesive. Single starch as the coating layer of the adhesive is polished in an aqueous condition will be dissolved and the coating layer which is cured is easy to generate fractures. The starch and the polyketone resin which are mixed can improve the uniformity of particles of the coating layer, so that the membrane forming quality is improved, and the membrane forming speed is greatly increased, the work efficiency is increased, the process parameters are controllable, and the green immobilized abrasive material polished wafer is environmental-friendly and pollution-free and convenient to operate, and the polishing effect can be guaranteed.

Owner:TIANJIN VOCATIONAL INST

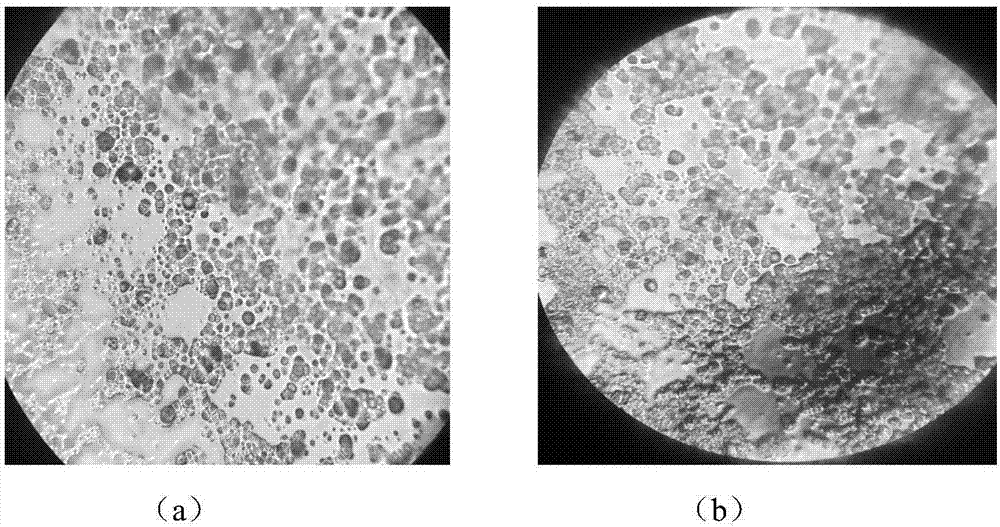

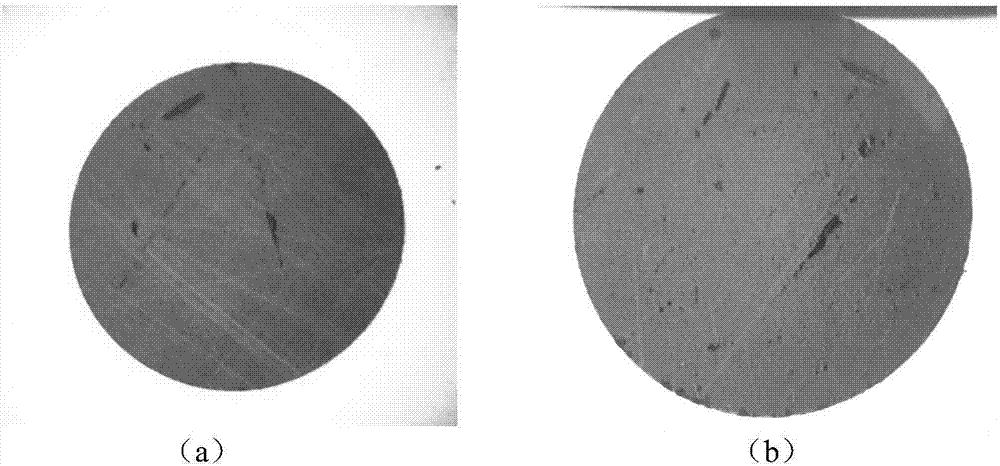

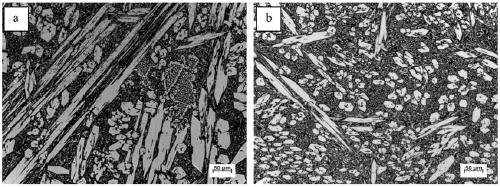

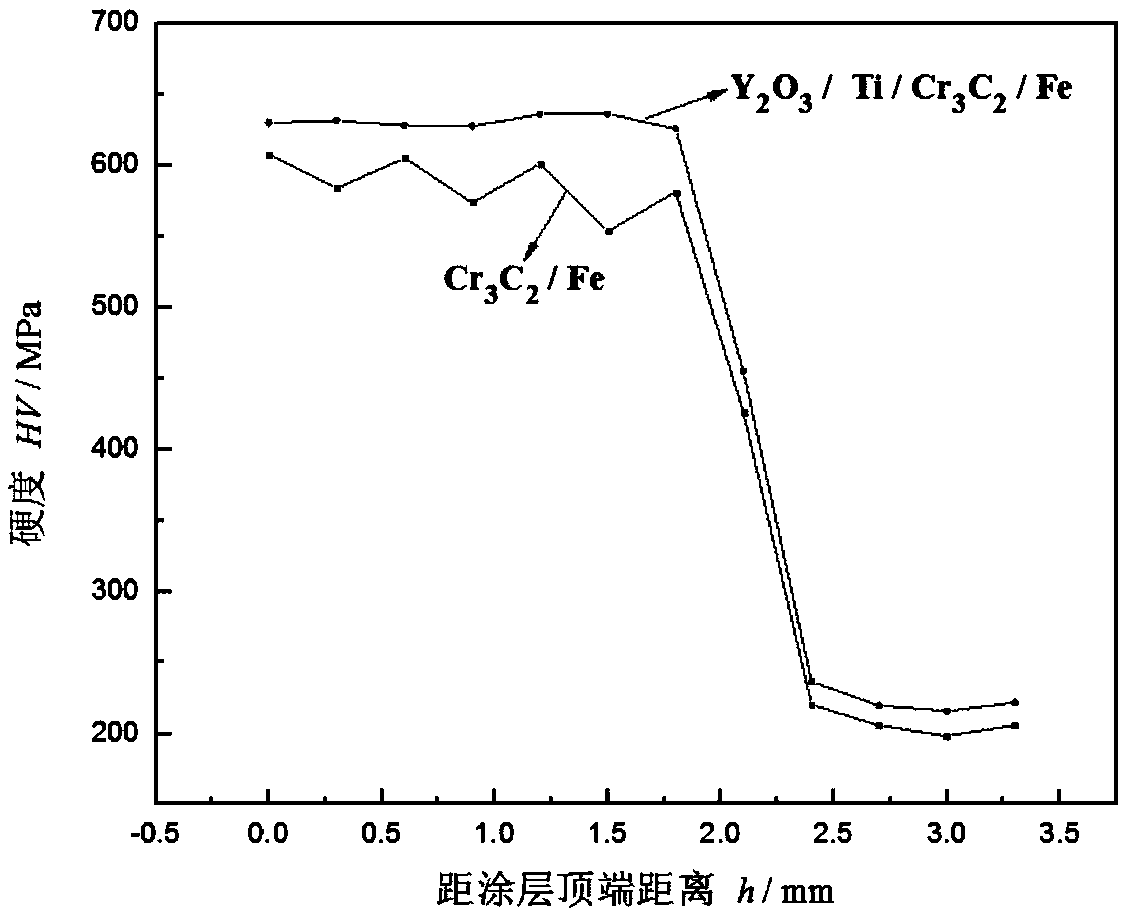

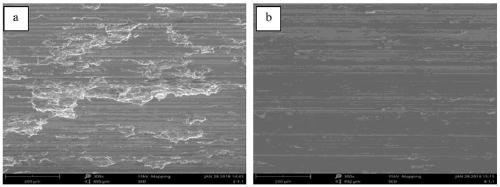

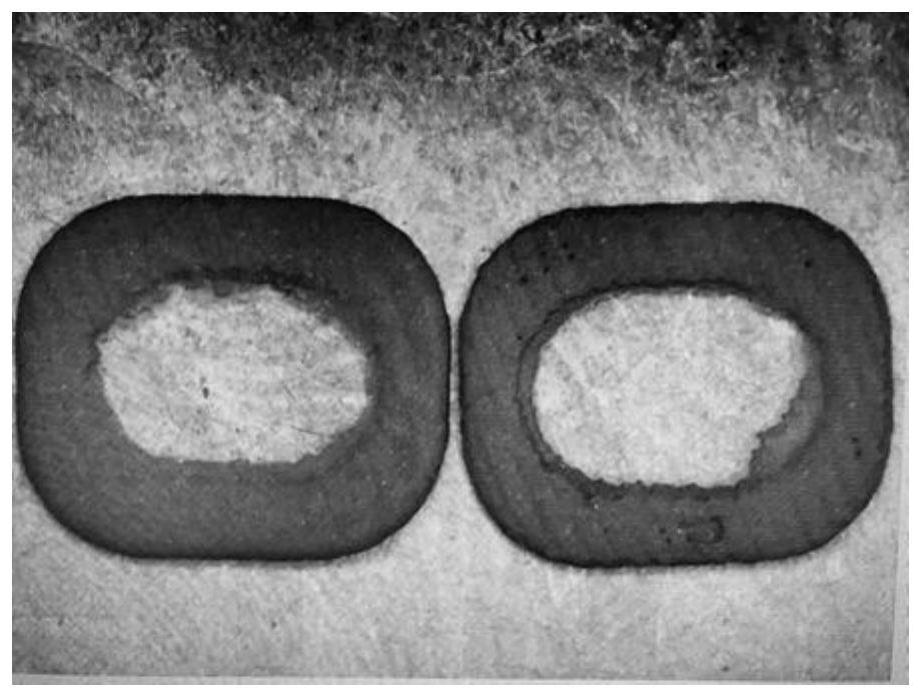

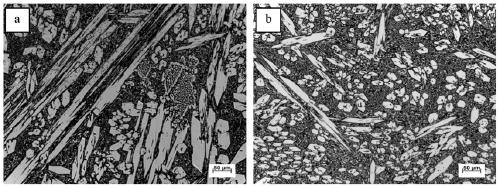

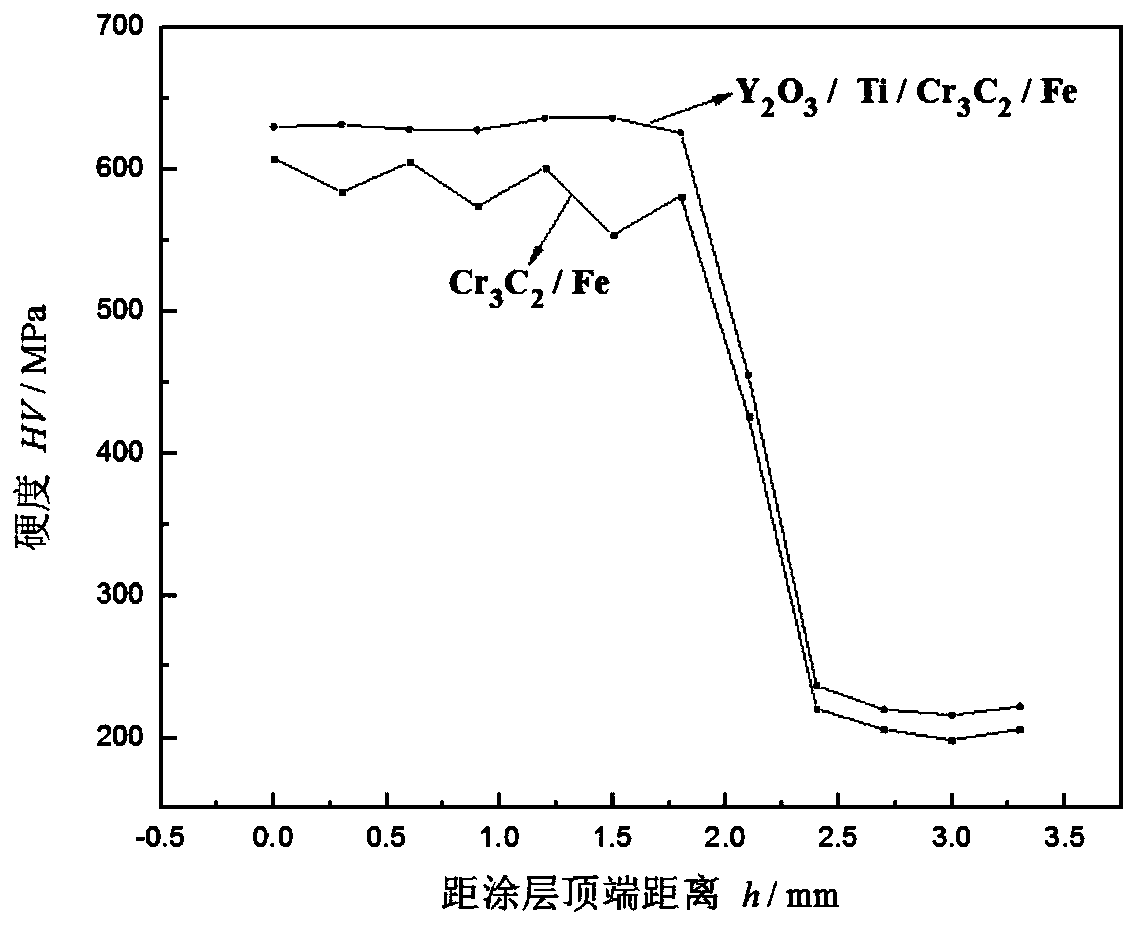

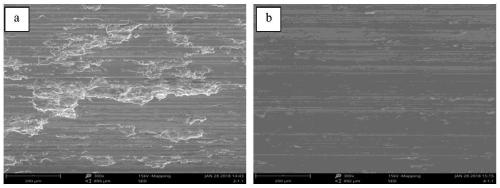

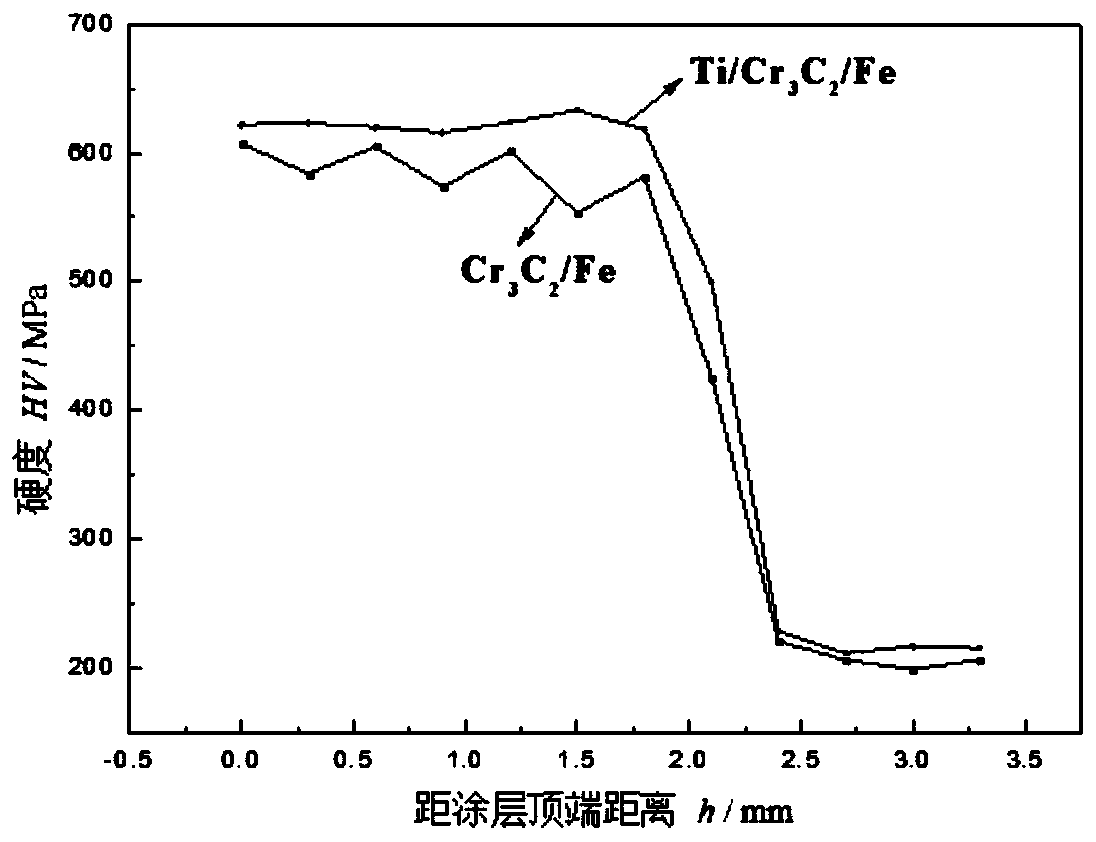

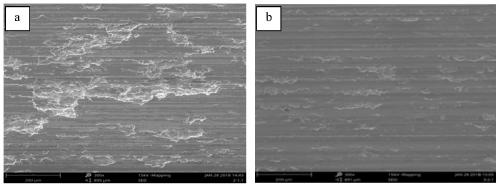

Multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and preparation method thereof

ActiveCN109023355AImprove liquidityInhibit growthMetallic material coating processesCrazingWear resistance

The invention discloses a multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and a preparation method thereof, and belongs to the technical field of surface wear-resistant coatings. The plasma surfacing iron-based hypereutectic wear-resistant coating is prepared from the following components in a plasma surfacing mode, and wherein the components comprise, by mass, 48-69% of iron-based self-fluxing alloy powder, 30-50% of micron Cr3C2 powder, 0.5-1% of micron Ti powder, and 0.5-1% of nano Y2O3 powder. The preparation method of the plasma surfacing iron-based hypereutectic wear-resistant coating comprises the following steps of substrate pretreatment, preparation and drying of composite powder, preparation of the coating and post-heat treatment.By using the technical scheme, on the basis that hardness and wear resistance of the multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating can be further improved, the process performance of the coating can be improved obviously, and cracks of the coating are effectively prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

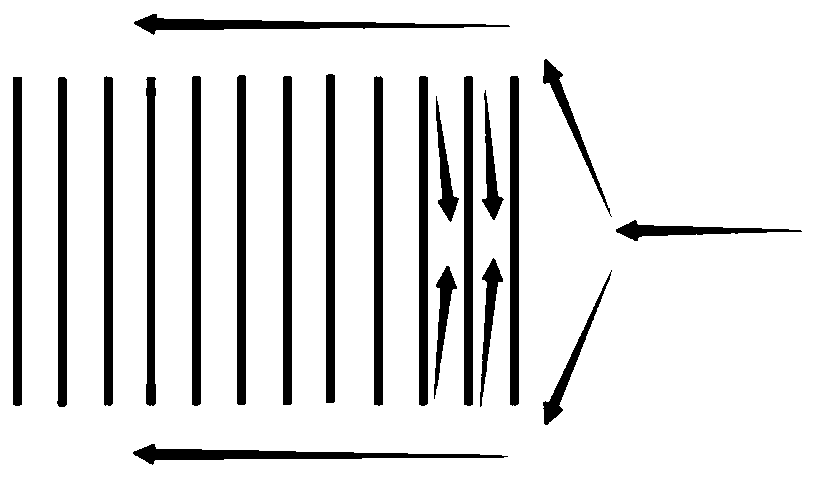

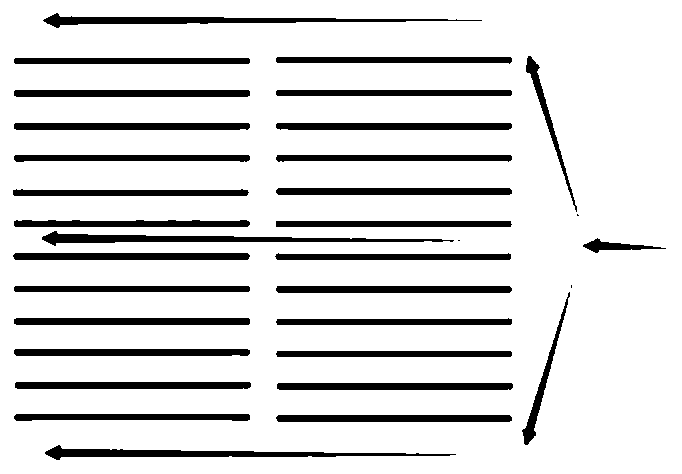

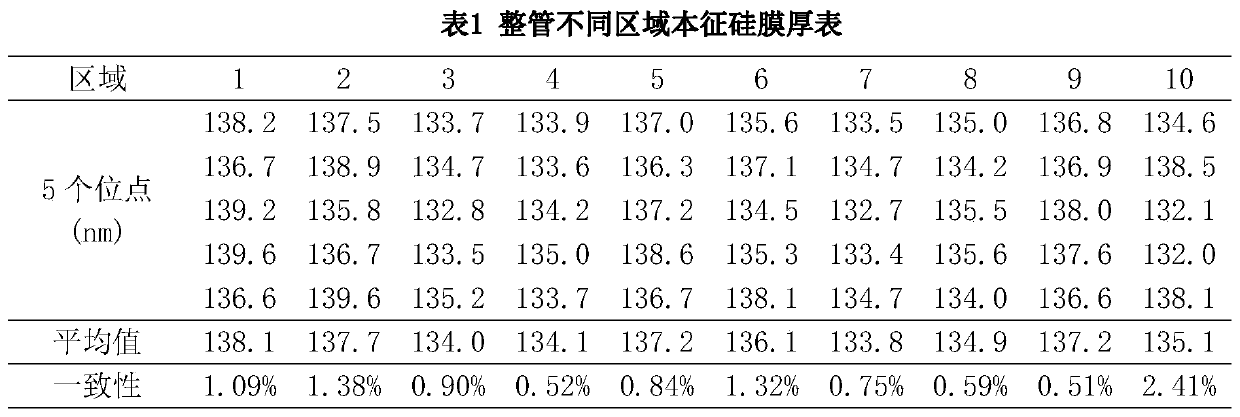

Process for horizontal coating of intrinsic silicon based on LPCVD technique

InactiveCN111286724AReduce gas turbulenceEnsure coating uniformityFinal product manufactureChemical vapor deposition coatingPhysicsSilicon chip

The invention provides a process for horizontal coating of intrinsic silicon based on an LPCVD technique. The process comprises the steps that oxidized intrinsic silicon is horizontally placed in quartz boats spaced from each other by a certain distance back to back, a furnace body is sealed, the temperature is increased, silicane is guided into the furnace body for a reaction, and nitrogen is guided into the furnace body to repel a precursor; the temperature is decreased, and the pressure returns; and the quartz boats containing silicon wafers are pulled out of a furnace tube. According to the process for horizontal coating of the intrinsic silicon based on the LPCVD technique, a horizontal wafer-insertion coating process is adopted, and compared with vertical coating, gas turbulence in the tube can be reduced, and the coating uniformity in the wafers is guaranteed; and the wafers are horizontally inserted and are horizontally overlapped by means of gravity, so that the wafers are arranged stably, the disturbance of high temperature, air flow and vibrations on the horizontally-inserted silicon wafers is small, and slight raydent coating is generated on the back sides of the silicon wafers by the air flow.

Owner:SHENZHEN LAPLACE ENERGY TECH CO LTD

Corrugated roller hot spraying production and restoring method

ActiveCN100406609CImprove wear resistanceImprove deformation resistanceMolten spray coatingPretreated surfacesThermal sprayingCarbonization

The thermal spraying manufacture and repair method for corrugated roller comprises: processing the gear form of roller; taking nitridation or carbonization- nitridation treatment to the gear; localized heat quenching and tempering to roller gear; taking abrasion resistant coating strengthen treatment to tooth surface. By drawing roller section gear form figure and plotting horizontal line and tangent line to calculate the spraying point and abrasion resistant coating, this invention can ensure coating evenness, obtains clean and rigid work surface, improves roller properties, and increases roller economical benefit.

Owner:GUANGDONG YUEKE NEW MATERIALS TECH CO LTD

Mo-Mn metallization method for high-reliability small-size sapphire

The invention discloses a high-reliability small-size sapphire Mo-Mn metallization method. The method comprises the following steps: (1) preparing a jewel piece silk-screen printing metallization paste; (2) metallization coating of small-size sapphire; and (3) metallization sintering of the small-size sapphire. The special small-size jewel piece printing table designed by the patent of the invention can enhance the firmness of jewel pieces and prevent paste from hanging edges; a small-size jewel piece screen printing plate made of a nylon material is adopted, the resilience force of a screen is increased, metallization paste adhesion is prevented, and the coating uniformity of a small-size sapphire metallization layer is jointly guaranteed through the method. According to the metallization paste, the optimal specific formula of the metallization paste is screened out through a large number of experiments, in addition, on the basis that terpilenol and ethyl cellulose serve as binders in the metallization paste, polyvinyl alcohol is added, and shrinkage of a metallization layer can be effectively improved.

Owner:NANJING SANLE GROUP

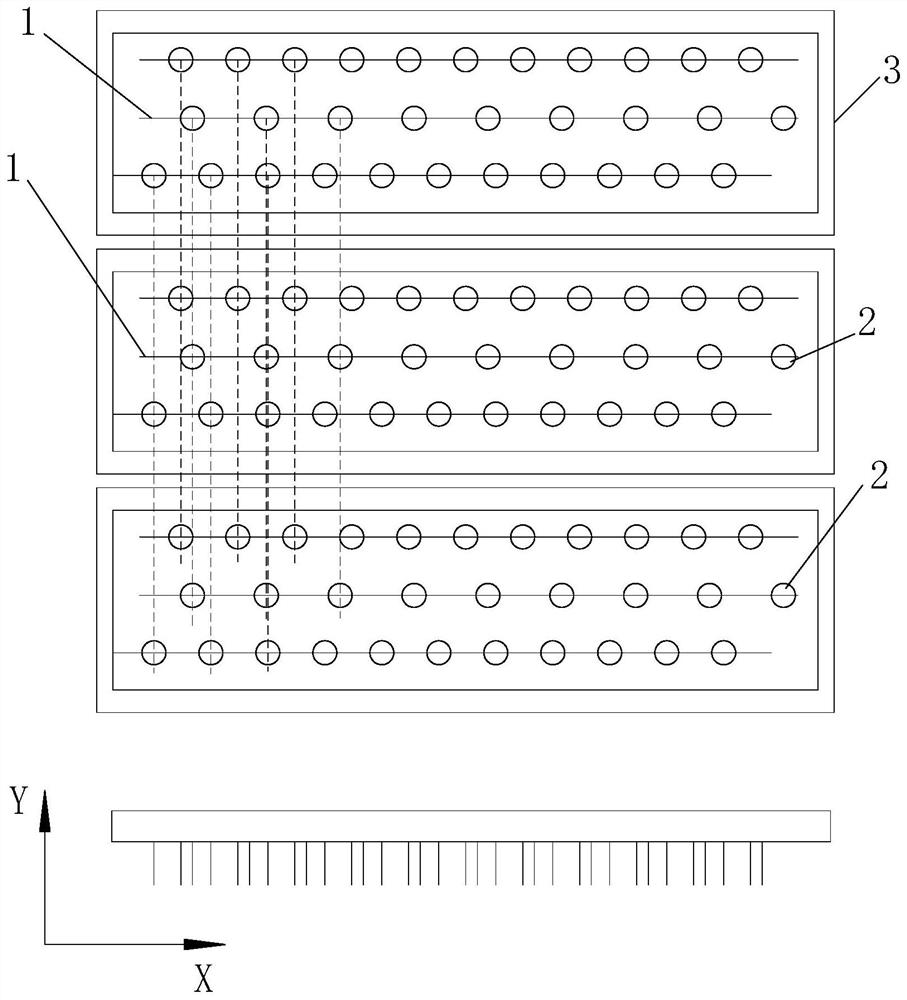

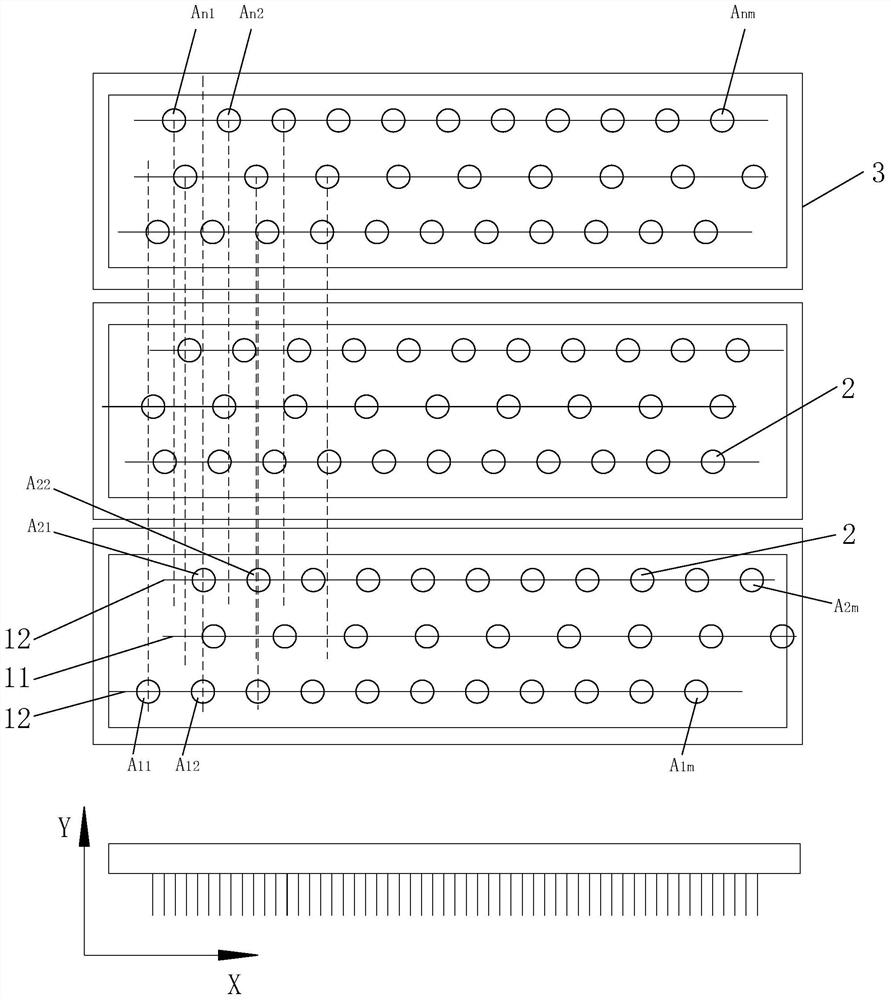

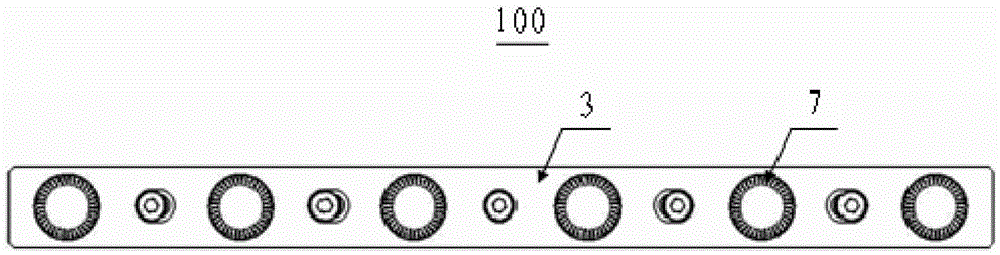

Flat plate type PECVD equipment microwave iron source process gas spraying device

PendingCN111748802AEnsure coating uniformityGuaranteed uniformityChemical vapor deposition coatingGas supplyMaterials science

The invention discloses a flat plate type PECVD equipment microwave iron source process gas spraying device. The device comprises multiple ion sources arranged in the Y axis direction, the ion sourcescomprise multiple gas supply pipes, multiple gas spray holes are formed in the gas supply pipes in the X axis direction, X-axis coordinates of all the gas spray holes for conveying same process gas are different and arranged at equal intervals after superposition, according to the gas spraying device, due to the fact that the number of the gas spray holes in the same length is greatly increased,the interval between two gas spray points is very small, equivalently, the number of the gas spray holes can be multiplied on a gas spray pipe on the same length, the gas spray holes are distributed at equal distances, similarly, gas spray of the whole gas supply pipe is in linear state, and gas is very uniform.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

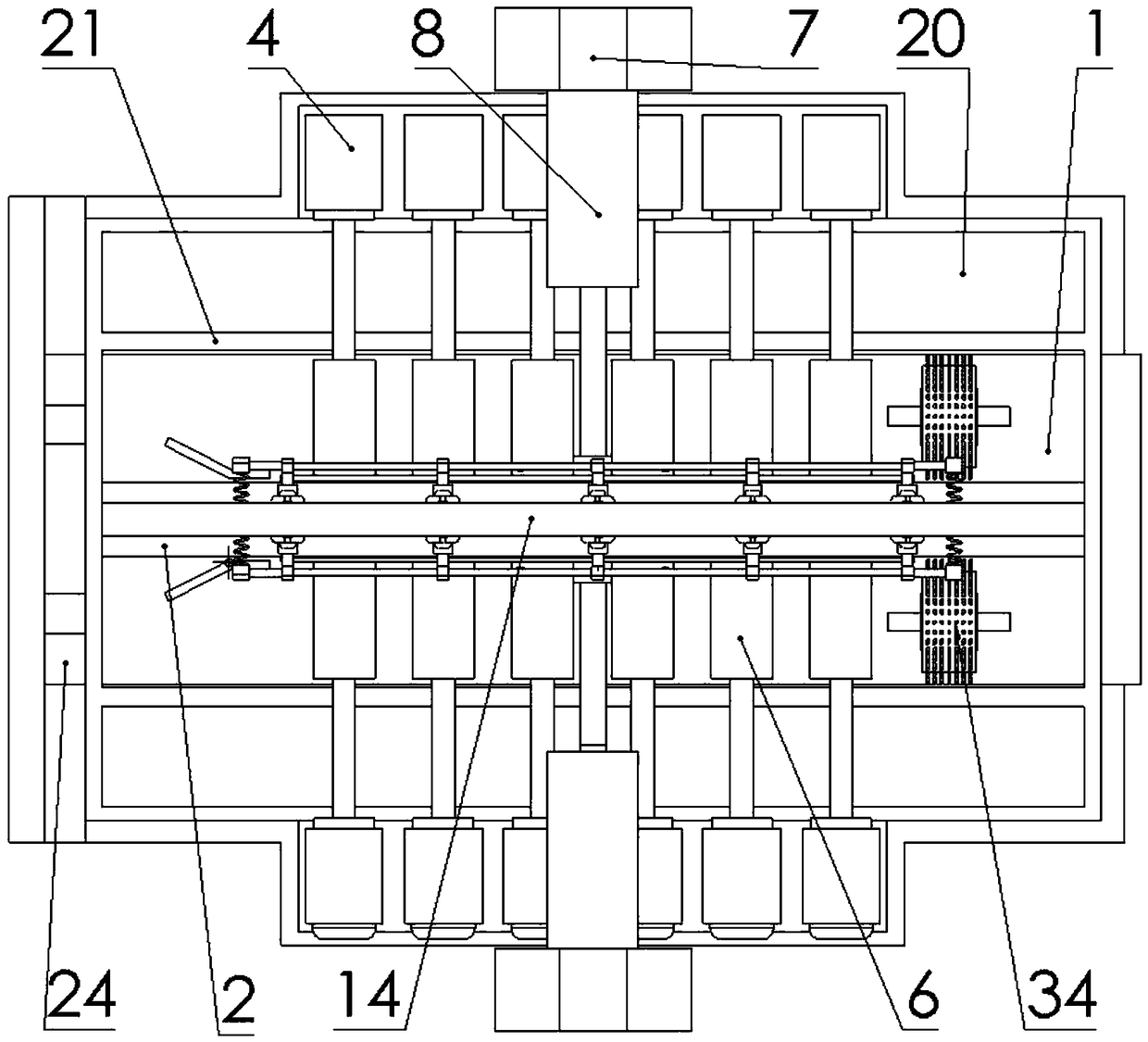

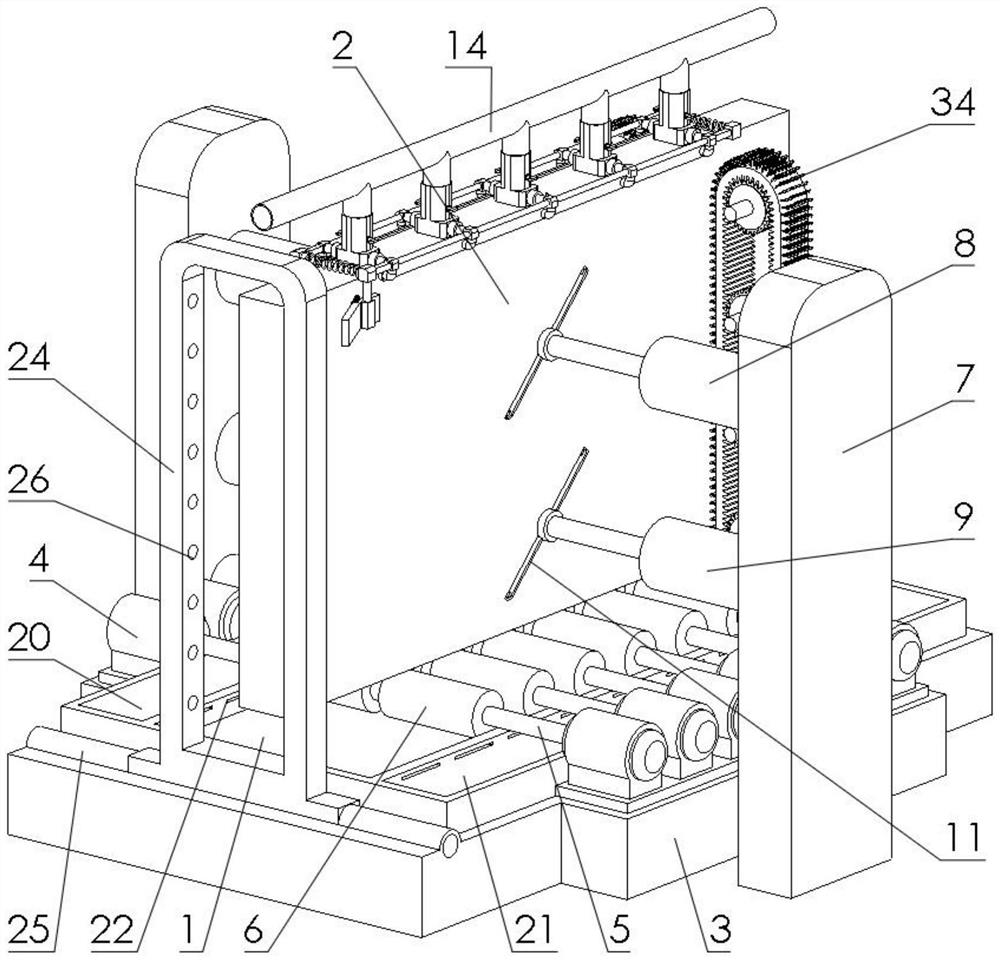

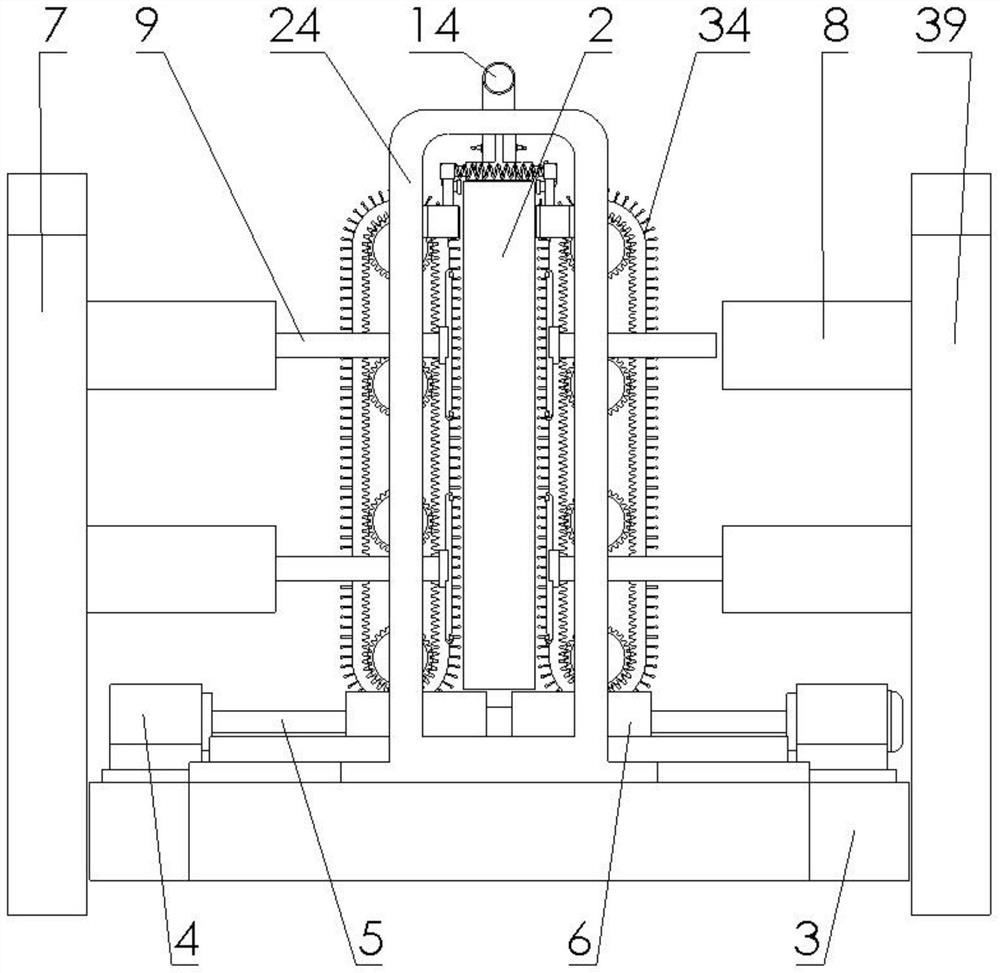

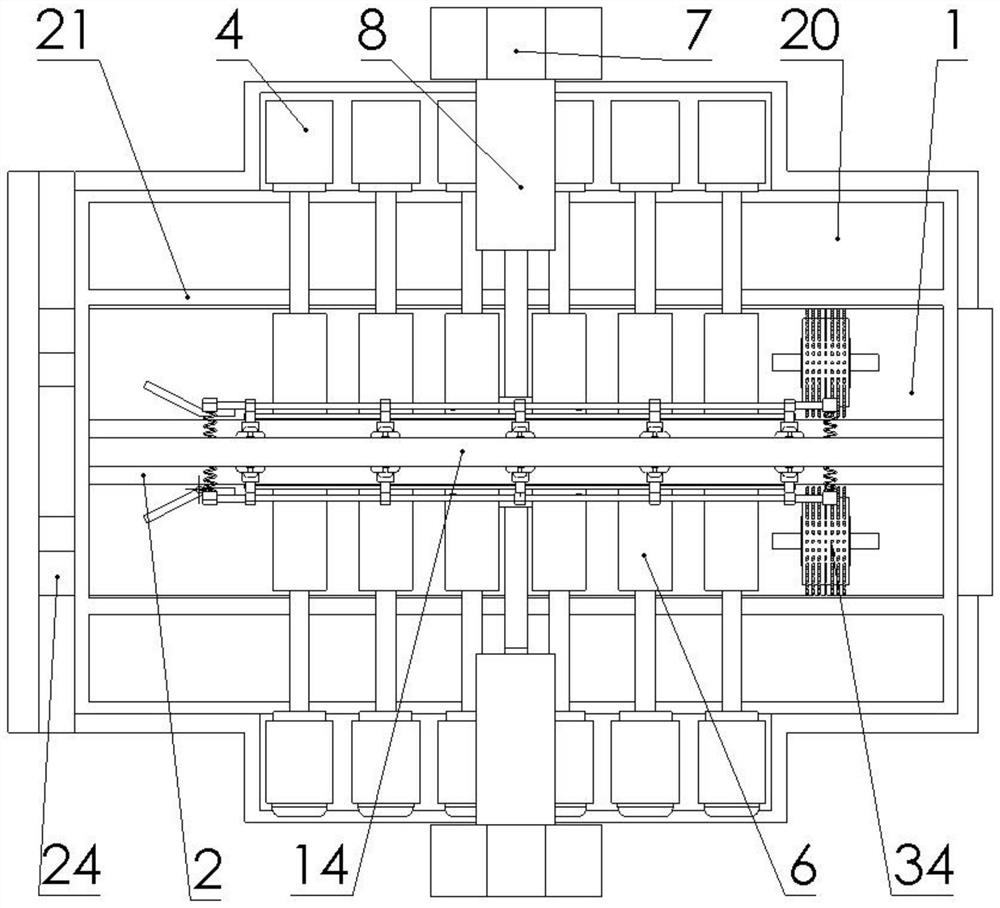

A kind of wood processing equipment

ActiveCN109483670BFast fusionFit tightlyAdhesive application devicesRubber materialElectric machinery

The invention discloses a kind of wood processing equipment, which includes a wooden board to be processed, a rubber material collection pool and a rubber material static pool arranged on both sides of the rubber material collection pool are arranged under the wooden board; There is a motor base, and the motor base is equipped with motors at even intervals in the longitudinal direction; a glue discharge device is installed above the wooden board; a scraping device is provided on both sides of the wooden board, and a brushing device is provided at the discharge end; There is a preheating frame in front of the feeding end; the present invention can quickly perform preheating, gluing, scraping and gluing operations on wooden boards, and is suitable for boards of different widths and sizes, and the coating is comprehensive and uniform, and the glue can be Recycling, single and double-sided rubber coating are optional; the whole process is automatically controllable, reliable and efficient.

Owner:湖南省杨林木业有限公司

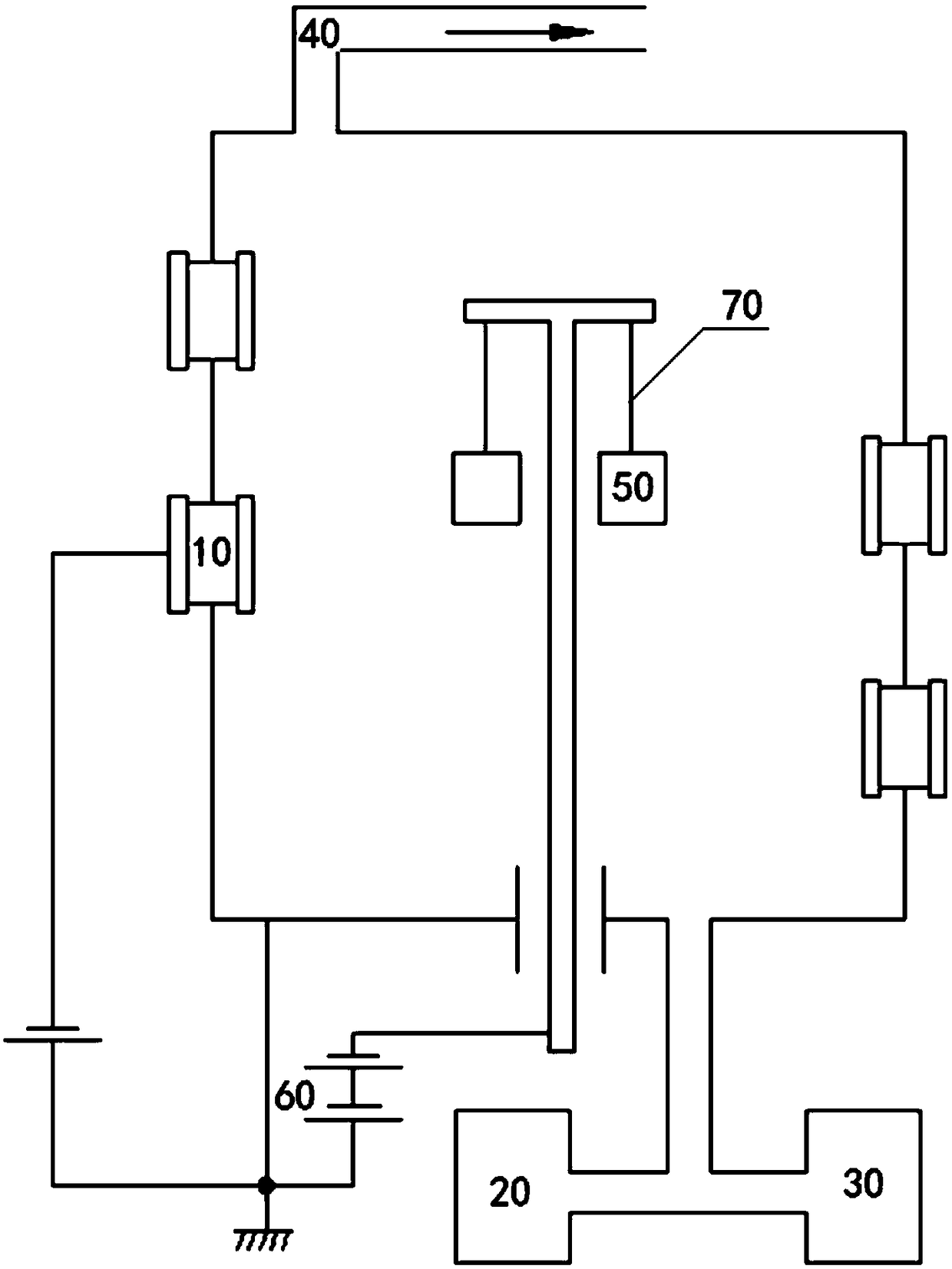

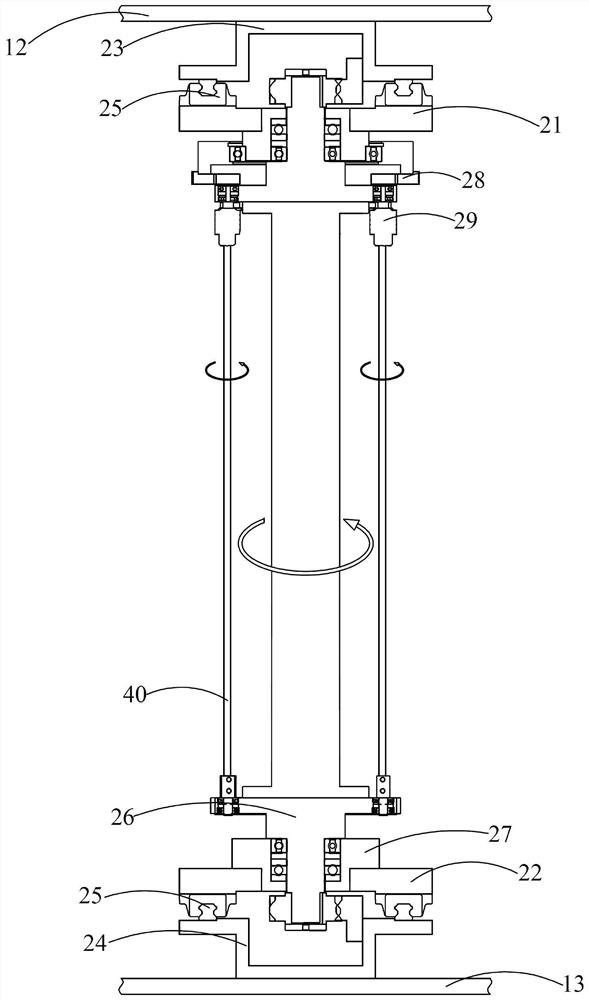

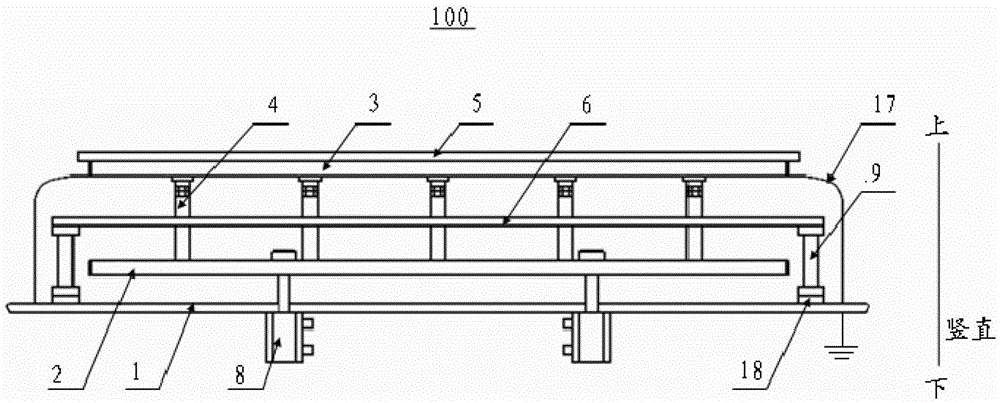

Plasma processing equipment and its lower electrode mechanism

ActiveCN103866296BSolve the problem of poor groundingImprove flatnessChemical vapor deposition coatingEngineeringRepeatability

The invention discloses a lower electrode mechanism of plasma processing equipment. The lower electrode mechanism comprises a lower electrode base plate, an ground pole supporting member, a ground pole, a support plate supporting member, a support plate, and a heater, and the lower electrode base plate is grounded. The ground pole supporting member is arranged above the lower electrode base plate, and is capable of being vertically lifted up and down. The upper end of the ground pole is connected to the support plate supporting member, and the lower end of the ground pole is connected to the ground pole supporting member. The support plate supporting member is arranged above the ground pole supporting member, is grounded, and is electrically insulated from the ground pole. The support plate is supported by the support plate supporting member, and is directly grounded through the support plate supporting plate. The heater is arranged between the support plate supporting member and the ground pole supporting member. The lower electrode mechanism has the advantages of simple ground current route and high repeatability, and solves the problem of imperfect earth of lower electrode. The invention also discloses plasma processing equipment comprising the lower electrode mechanism.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A multi-scale particle-reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and its preparation method

The invention discloses a multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and a preparation method thereof, and belongs to the technical field of surface wear-resistant coatings. The plasma surfacing iron-based hypereutectic wear-resistant coating is prepared from the following components in a plasma surfacing mode, and wherein the components comprise, by mass, 48-69% of iron-based self-fluxing alloy powder, 30-50% of micron Cr3C2 powder, 0.5-1% of micron Ti powder, and 0.5-1% of nano Y2O3 powder. The preparation method of the plasma surfacing iron-based hypereutectic wear-resistant coating comprises the following steps of substrate pretreatment, preparation and drying of composite powder, preparation of the coating and post-heat treatment.By using the technical scheme, on the basis that hardness and wear resistance of the multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating can be further improved, the process performance of the coating can be improved obviously, and cracks of the coating are effectively prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

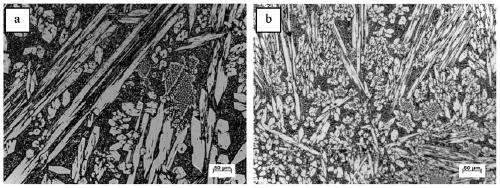

A kind of plasma surfacing iron-based cr with micron ti added 3 c 2 Hypereutectic wear-resistant coating and preparation method thereof

ActiveCN109234727BSpeed up meltingImprove cladding qualityMetallic material coating processesCrazingAlloy

The invention discloses a plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistant coating layer added with micrometer Ti and a preparation method thereof and belongs to the technical field of wear-resistant coating layers on the surfaces. The plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistant coating layer is prepared from the following components in percent by mass after plasmasurfacing: 49%-69.5% of iron-based self-fluxed alloy powder, 30%-50% of micrometer Cr3C2 powder and 0.5%-1% of micrometer Ti powder. The plasma-surfacing iron-based Cr3C2 hypereutectic wear-resistantcoating layer is prepared by the following steps: pretreatment of base materials, preparation and drying of composite powder, preparation of the coating layer and post heat treatment. By use of the technical scheme disclosed by the invention, on the basis of improving the hardness and wear resistance of the plasma-surfacing iron-based hypereutectic wear-resistant coating layer enhanced by multiscale particles, the process characteristics of the coating layer can be obviously improved, and the generation of cracks of the coating layer can be effectively prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Semiconductor process equipment

ActiveCN112391597AUniform atmosphereEnsure coating uniformityVacuum evaporation coatingSputtering coatingPhysicsDeposition process

The embodiment of the invention provides semiconductor process equipment. The semiconductor process equipment is used for carrying out a rare earth deposition process on a substrate, and comprises anelectrode assembly and an air inlet mechanism which are arranged on the top wall of a process chamber and extend in a first direction; the air inlet mechanism is arranged around the electrode assembly; a moving mechanism is arranged at the bottom in the process chamber, extends in a second direction and is used for bearing and driving the substrate to move in the second direction, and the second direction is intersected with the first direction; and an air extracting mechanism is arranged on the top wall of the process chamber and communicates with the process chamber, the air extracting mechanism is located on one side of the electrode assembly, the air extracting mechanism is provided with an air extracting opening in the process chamber, and the air extracting opening extends in the first direction and is close to the air inlet mechanism and used for enabling process gas in the process chamber to evenly pass through the surface of the substrate. According to the semiconductor process equipment, the sputtering rate of the target material can be greatly improved while the coating uniformity is ensured, so that the production cost is greatly reduced.

Owner:北京七星华创集成电路装备有限公司

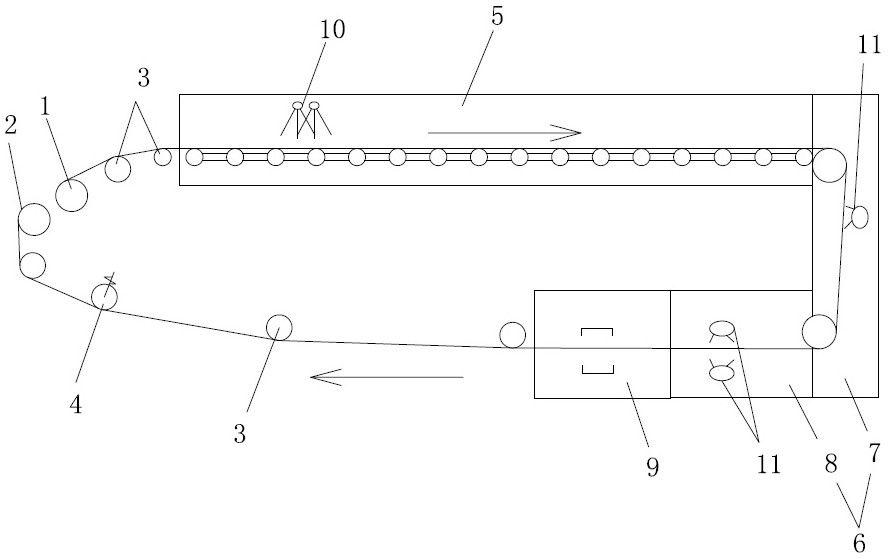

Flexible film photovoltaic reel-to-reel CSD spraying coating device

ActiveCN113437169AEnsure coating uniformityGuarantee coating qualityFinal product manufactureLiquid/solution decomposition chemical coatingSpray nozzleThin membrane

The invention relates to a flexible thin film photovoltaic reel-to-reel CSD spraying and coating device, and solves the problem that a coating solution is easy to run off from two sides on the surface of a stainless steel substrate coiled material which is flatly conveyed, and the coating is not uniform. The device comprises an unwinding shaft, a winding shaft and a plurality of conveying rollers. A film coating coiled material output by the unwinding shaft sequentially passes through the conveying rollers and then is wound on the winding shaft, a film coating section is arranged behind the unwinding shaft, a film coating solution spraying nozzle is arranged above the front end of the film coating section, and a plurality of side supports for lifting the side edges of the film coating coiled material upwards are arranged on the two sides of the film coating section. A plurality of pressing wheels are arranged on the inner sides of the side supports. According to the film coating coiled material, a lifting maintaining structure with the low middle and the two high sides is formed in the coating section, it is ensured that when a film coating solution is maintained to be deposited on the surface of the film coating coiled material, the liquid level height of the solution is consistent, meanwhile, reverse backflow cannot be formed on the two sides of a coating film, the uniformity of transverse coating of the film coating coiled material is ensured, and the continuity of longitudinal film coating is achieved; and the industrial production requirement of roll-to-roll CSD spray film coating can be met.

Owner:浙江尚越新能源开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com