Flexible film photovoltaic reel-to-reel CSD spraying coating device

A flexible thin film and coating device technology, applied in photovoltaic power generation, liquid chemical plating, climate sustainability, etc., can solve the problems of loss, uneven overall coating, inconsistent liquid level of coating lateral solution, etc., to ensure coating quality, Ensure the effect of coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

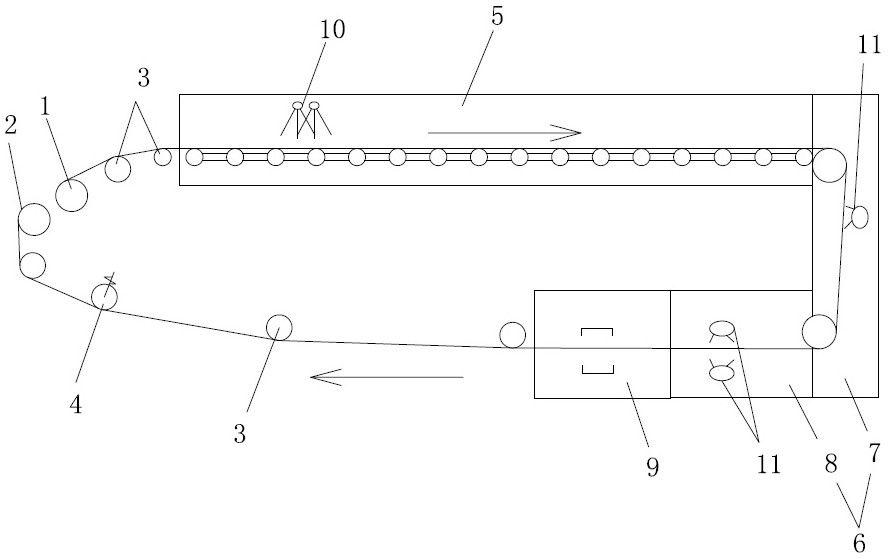

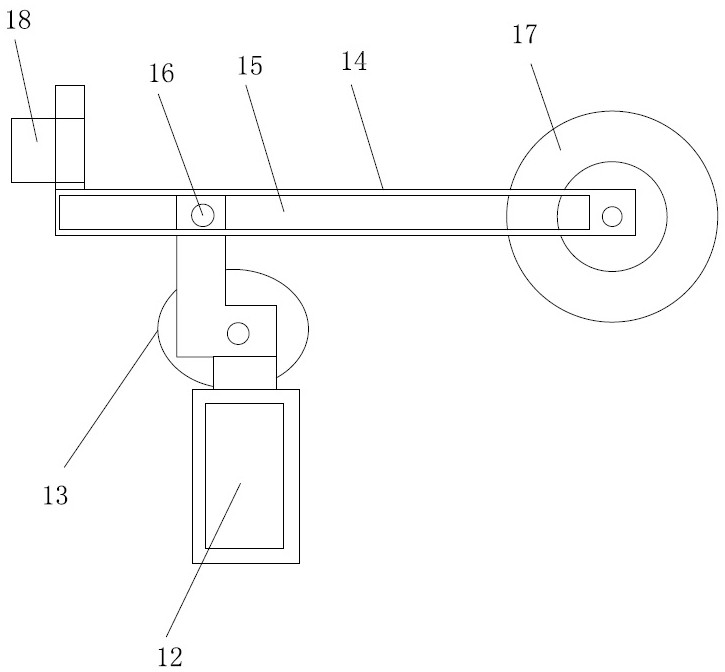

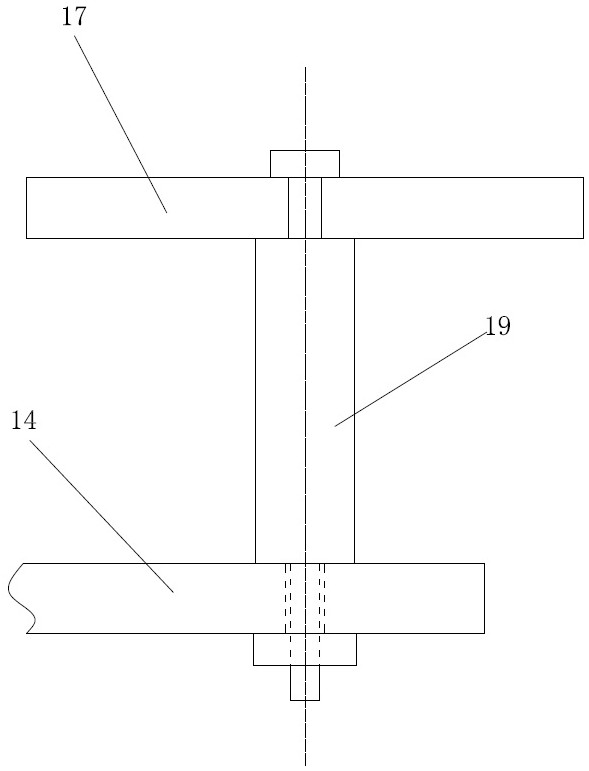

[0022] Embodiment: a kind of flexible film photovoltaic roll-to-roll CSD spray coating device, such as figure 1 shown. The device includes an unwinding shaft 1, a winding shaft 2 and a number of conveying rollers 3. The unwinding shaft outputs coated coils through the conveying rollers and then winds up to the winding shaft. One of the conveying rollers close to the winding shaft is the tension roller 4. The coating surface of the coated coil 21 is the front, and the coating section 5, the washing section 6, and the drying section 9 are successively arranged between the unwinding reel 1 and the rewinding reel 2, and the coating section 5 is forwardly transported with the coated coil facing upward, The coating section 5 is arranged horizontally, and a coating solution spray nozzle 10 is arranged above the front end of the coating section 5 . The front end 7 of the washing section is vertically and downwardly conveyed the coated coil, and the rear end 8 of the washing section i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com