A multi-scale particle-reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and its preparation method

A plasma stack and particle-enhanced technology, applied in the field of surface wear-resistant coating, can solve problems such as poor process characteristics and reduce production costs, and achieve the effects of preventing agglomeration, avoiding uneven tissue, and preventing growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

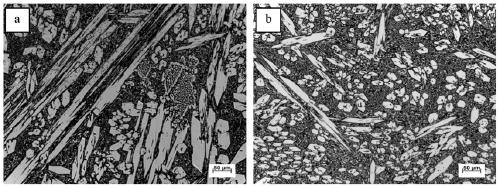

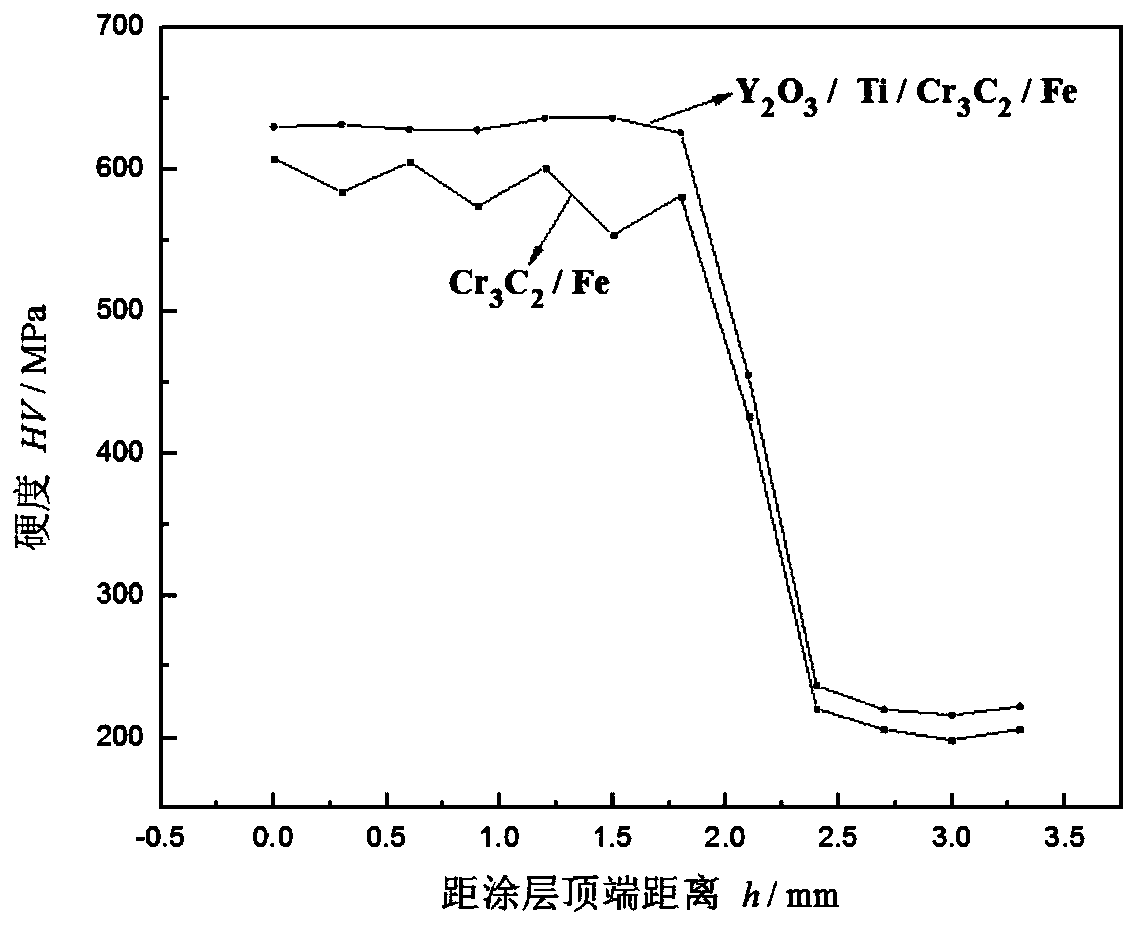

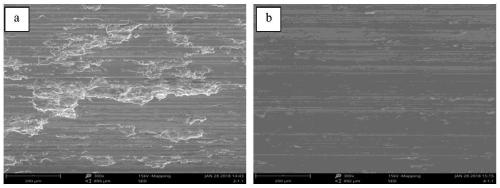

[0050] Combine Figure 4 , Figure 5 with Image 6 In this embodiment, a multi-scale particle-reinforced plasma surfacing iron-based hypereutectic wear-resistant coating includes the following mass percentage components: iron-based self-fluxing alloy powder 58%, micron Cr 3 C 2 40% powder, 1% micron Ti powder, nano Y 2 O 3 1% powder, wherein the iron-based self-fluxing alloy powder is composed of the following components by mass percentage: C0.12%, Cr15%, Ni3.5%, Mo1.2%, Fe as the balance; iron-based self-fusing The particle size of the alloy powder is 45~180μm, micron Cr 3 C 2 The powder adopts NiCr-Cr 3 C 2 The particle size of the powder is 15~45μm, the particle size of micron Ti powder is 50~90μm, nano Y 2 O 3 The particle size of the powder is 40-70 nm; specifically, the hypereutectic coating is made by plasma surfacing, and the preparation method is:

[0051] Step a: Substrate 1 pretreatment:

[0052] In this embodiment, low-carbon steel is selected as the surfacing substrate...

Embodiment 2

[0080] A multi-scale particle-enhanced plasma surfacing iron-based hypereutectic wear-resistant coating of this embodiment includes the following mass percentage components: iron-based self-fluxing alloy powder 69%, micron Cr 3 C 2 30% powder, 0.5% micron Ti powder, nano Y 2 O 3 0.5% of the powder, wherein the iron-based self-fluxing alloy powder is composed of the following components by mass percentage: C0.14%, Cr16%, Ni4%, Mo1.4%, Fe as the balance; iron-based self-fluxing alloy The particle size of the powder is 45~180μm, micron Cr 3 C 2 The powder adopts NiCr-Cr 3 C 2 The particle size of the powder is 15~45μm, the particle size of micron Ti powder is 50~90μm, nano Y 2 O 3 The particle size of the powder is 40-70 nm; specifically, the hypereutectic coating is made by plasma surfacing, and the preparation method is:

[0081] Step a: Substrate 1 pretreatment:

[0082] In this embodiment, low-carbon steel is selected as the surfacing substrate 1, and the surface to be surfacing is...

Embodiment 3

[0093] A multi-scale particle-enhanced plasma surfacing iron-based hypereutectic wear-resistant coating of this embodiment includes the following mass percentage components: iron-based self-fluxing alloy powder 48.4%, micron Cr 3 C 2 Powder 50%, micron Ti powder 0.8%, nano Y 2 O 3 Powder 0.8%, wherein the iron-based self-fluxing alloy powder is composed of the following components by mass percentage: C0.16%, Cr18%, Ni4.5%, Mo1.6%, Fe as the balance; iron-based self-fusing The particle size of the alloy powder is 45~180μm, micron Cr 3 C 2 The powder adopts NiCr-Cr 3 C 2 The particle size of the powder is 15~45μm, the particle size of micron Ti powder is 50~90μm, nano Y 2 O 3 The particle size of the powder is 40-70 nm; specifically, the hypereutectic coating is made by plasma surfacing, and the preparation method is:

[0094] Step a: Substrate 1 pretreatment:

[0095] In this embodiment, low-carbon steel is selected as the surfacing substrate 1, and the surface to be surfacing is pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com