A kind of plasma surfacing iron-based cr with micron ti added 3 c 2 Hypereutectic wear-resistant coating and preparation method thereof

A technology of wear-resistant coating and plasma pile, which is applied in the field of surface wear-resistant coating, can solve the problems of poor process characteristics, reduce production costs, prolong the service life of surface modified workpieces, etc., prevent powder agglomeration, and solve the problem of poor coating Neatness, effect of improving cladding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

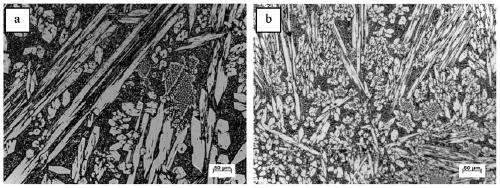

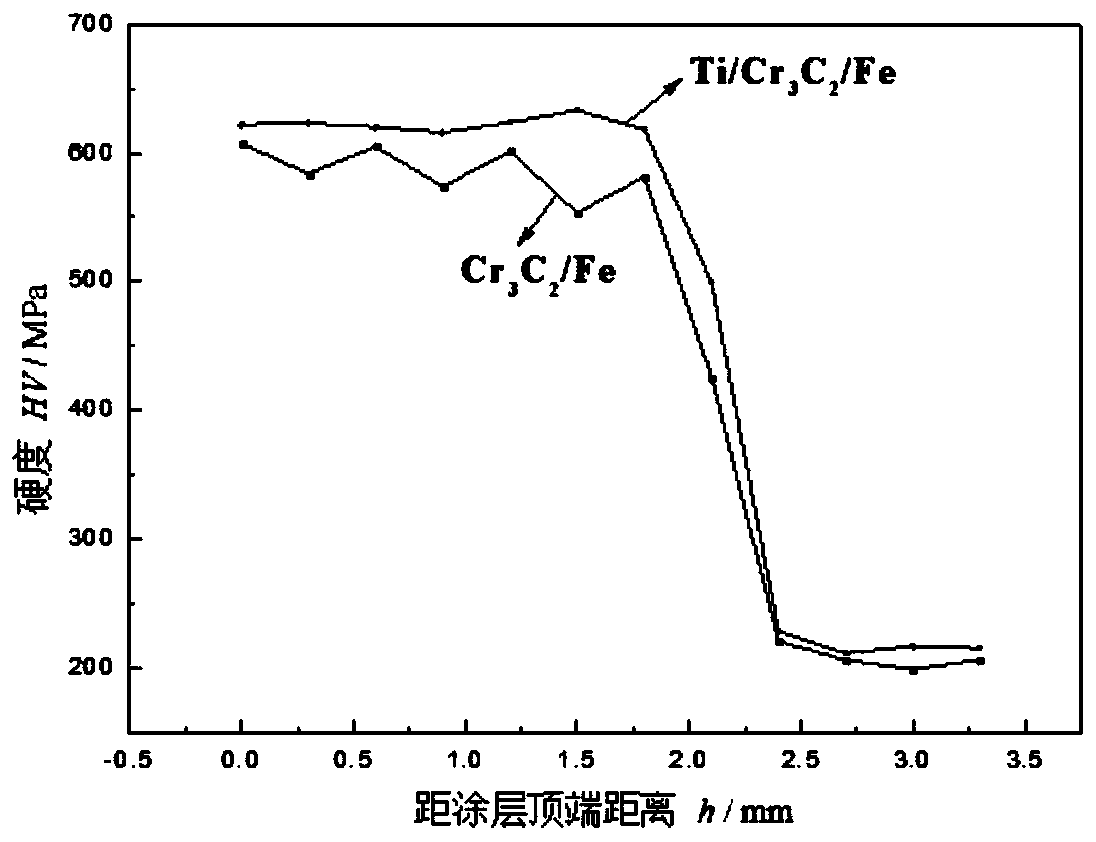

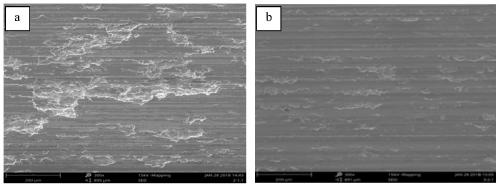

[0050] combine Figure 4 , Figure 5 and Figure 6 , a plasma surfacing iron-based Cr with micron Ti added in this embodiment 3 C 2 A hypereutectic wear-resistant coating, the hypereutectic wear-resistant coating includes a composite coating 2, one end of the composite coating 2 is provided with a first iron-based coating 3, and the surface of the composite coating 2 is provided with a second iron-based coating Coating 4; Composite coating 2 comprises the following components in mass percentage: 59% of iron-based self-fluxing alloy powder, micron Cr 3 C 2 Powder 40%, micron Ti powder 1%; the first iron-based coating 3 and the second iron-based coating 4 both include iron-based self-fluxing alloy powder; wherein, the above-mentioned iron-based self-fluxing alloy powder includes the following mass percentage Components: C0.12%, Cr15%, Ni3.5%, Mo1.2%, Fe is the balance; the particle size of iron-based self-fluxing alloy powder is 45-180μm, micron Cr 3 C 2 Powder adopts NiC...

Embodiment 2

[0081] A kind of plasma surfacing iron-based Cr with micron Ti added in this embodiment 3 C 2 Hypereutectic wear-resistant coating, the hypereutectic coating includes the following components in mass percentage: 69.5% iron-based self-fluxing alloy powder, micron Cr 3 C 2 Powder 30%, micron Ti powder 0.5%, wherein, the above-mentioned iron-based self-fluxing alloy powder is composed of the following components by mass percentage: C0.14%, Cr16%, Ni4%, Mo1.4%, Fe is the balance; The particle size of the iron-based self-fluxing alloy powder is 45-180 μm, and the micron Cr 3 C 2 The powder is NiCr-Cr 3 C 2 The powder has a particle size of 15-45 μm, and the particle size of the micron Ti powder is 50-90 μm; specifically, the hypereutectic coating is made by plasma surfacing, and the preparation method is as follows:

[0082] Step a: Substrate 1 pretreatment:

[0083] In this embodiment, low-carbon steel is selected as the surfacing base material 1, and the surface to be surf...

Embodiment 3

[0094] A kind of plasma surfacing iron-based Cr with micron Ti added in this embodiment 3 C 2 Hypereutectic wear-resistant coating, the hypereutectic coating includes the following components in mass percentage: 49.2% iron-based self-fluxing alloy powder, micron Cr 3 C 2 Powder 50%, micron Ti powder 0.8%, wherein, the above-mentioned iron-based self-fluxing alloy powder is composed of the following components by mass percentage: C0.16%, Cr18%, Ni4.5%, Mo1.6%, Fe is more than Amount; iron-based self-fluxing alloy powder particle size is 45 ~ 180μm, micron Cr 3 C 2 Powder adopts NiCr-Cr 3 C 2 The powder has a particle size of 15-45 μm, and the particle size of the micron Ti powder is 50-90 μm; specifically, the hypereutectic coating is made by plasma surfacing, and the preparation method is as follows:

[0095] Step a: Substrate 1 pretreatment:

[0096] In this embodiment, low-carbon steel is selected as the surfacing base material 1, and the surface to be surfacing is po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com