Lithium-ion battery and preparation method thereof

A technology of lithium-ion batteries and manufacturing methods, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve problems such as inability to block electronic pathways, limitations, and limited battery safety improvements, and achieve improved cycle performance and high temperature. Preservation performance, guarantee of coating uniformity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

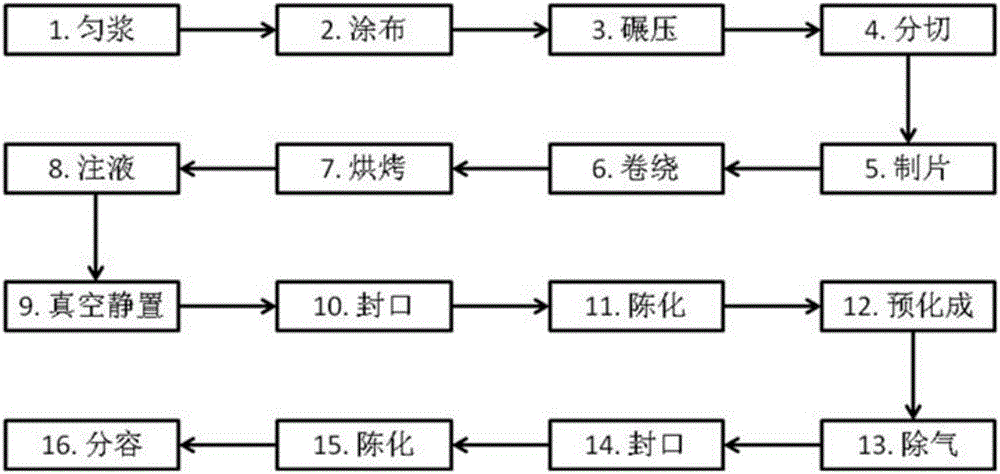

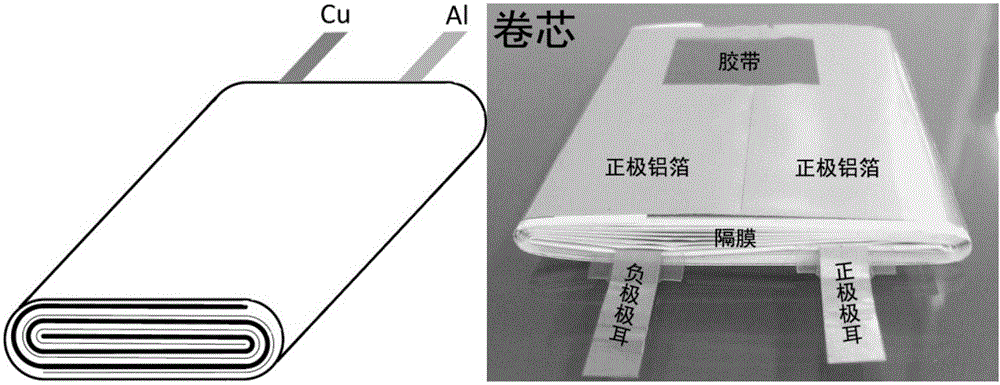

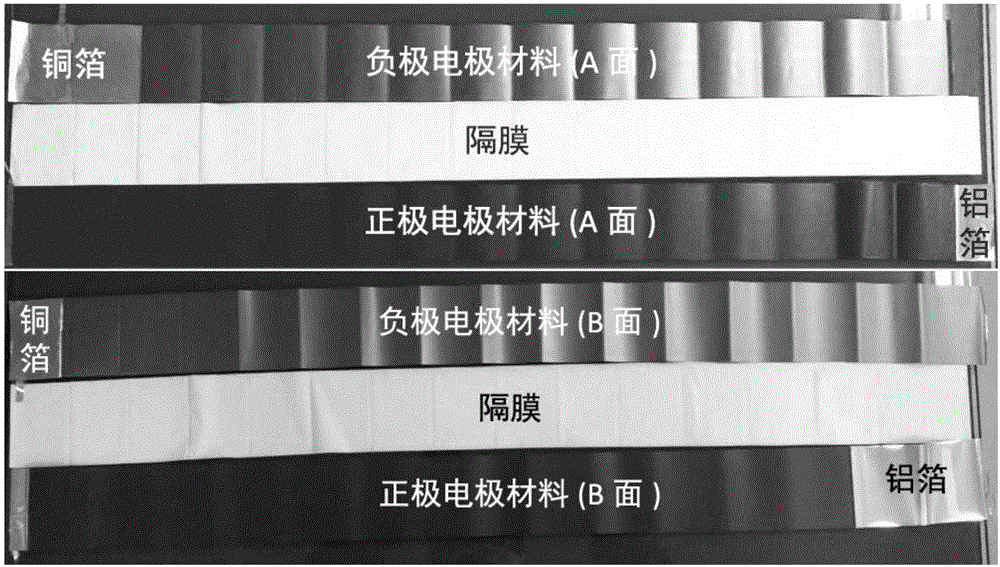

[0064] Cell preparation:

[0065] (1) homogenate:

[0066] The positive electrode active material lithium cobaltate (LiCoO 2) mixed with conductive agent superconducting carbon black (Super P) and thickener / binder polyvinylidene fluoride (PVDF) in a mass ratio of 97:1.5:1.5, adding an appropriate amount of solvent N-methylpyrrolidone (NMP) , through the high-speed shearing action of the planetary agitator and the high-speed dispersing disc, a stable and uniform fluid with a certain viscosity is formed, which is the positive electrode slurry;

[0067] The negative electrode active material natural graphite (NG, Natural Graphite) and the conductive agent superconducting carbon black (Super P), the thickener carboxymethyl cellulose (CMC) and the binder styrene-butadiene rubber (SBR) at a ratio of 96:1: 1.5:1.5 mass ratio mixing, add appropriate amount of deionized water (H 2 O), the high-speed shear action of the planetary agitator and the high-speed dispersing disc forms a st...

Embodiment 2

[0096] The thickness of the diaphragm was changed to 9 μm, and the others were consistent with Example 1.

[0097] It was tested that the volumetric energy density of the full battery reached 716Wh / L at a charge-discharge rate of 0.5C, and the capacity retention rate of 500 cycles was 86.5%. The discharge capacity of the full battery was measured after it was placed at a high temperature of 85°C for 4 hours. 93.2% of one discharge capacity. The battery was subjected to the acupuncture test, and the result was passed.

[0098] Compared with Example 1, the thickness of the separator in the battery of Example 2 is reduced to 9 μm, so that the thickness of the battery is greatly reduced and the energy density is significantly improved. At the same time, the capacity retention rate, high temperature performance and safety performance are not significantly reduced. The surface of the negative electrode sheet and the area where the current collector is not covered by the electrode m...

Embodiment 3

[0100] Sputter coating (Al 2 o 3 ) is wiped off with a solvent, and the others are consistent with Example 1.

[0101] It was tested that the volumetric energy density of the full battery reached 685Wh / L at a charge-discharge rate of 0.5C, and the capacity retention rate of 500 cycles was 86.2%. 94.4% of one discharge capacity. The battery was subjected to an acupuncture test, and the result was a failure.

[0102] Compared with Example 1, there is a nano-protective layer on the surface of the positive electrode and the negative electrode sheet of Example 3, and the energy density, cycle performance, and high-temperature storage performance of the battery are not greatly affected; and the area where the current collector is not covered by the electrode material There is no nano-protective layer, and the battery fails when it is needled, indicating that the presence of a nano-protective layer in the area of the current collector not covered by the electrode material is als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com