Manufacturing method of shielding frame and ultrathin substrate film solar cell

A solar cell and manufacturing method technology, which is applied in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of device reliability relying on packaging process, affecting coating effect, and expensive laser equipment, etc. The effect of eliminating the removal process, ensuring the uniformity of the coating and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

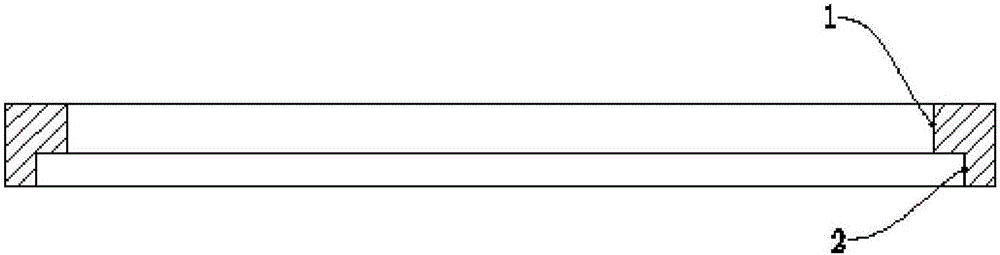

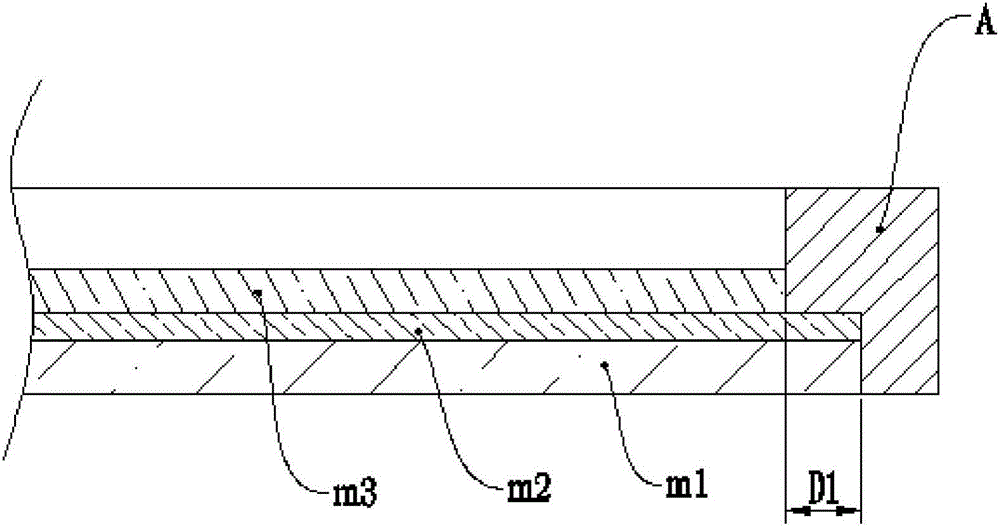

[0028] like figure 1 , figure 2 As shown, the shielding frame is composed of a rectangular upper frame 1 and a lower frame 2 set up and down in the thickness direction, and the rectangular inner hole size of the upper frame is smaller than the rectangular inner hole size of the lower frame, thereby forming a stepped surface on the inner wall; The size of the rectangular inner hole of the frame matches the edge size of the substrate m1 of the thin-film solar cell to be processed; the size of the rectangular inner hole of the upper frame matches the edge size of the coating layer of the thin-film solar cell to be processed.

[0029]The first embodiment of the manufacturing method of the ultra-thin substrate thin film solar cell of the present invention comprises the following steps:

[0030] 1. Provide an ultra-thin glass substrate m1, the thickness of the glass is between 0.70mm and 0.05mm, and clean the thin glass;

[0031] 2. Deposit the buffer layer m2 on the ultra-thin g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com