Novel paint roller

A new type of paint, applied in the field of paint rollers, can solve the problems of increased coating times, discontinuous coating work, and different coating thicknesses, so as to reduce paint dip steps, ensure coating uniformity, and avoid paint dripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

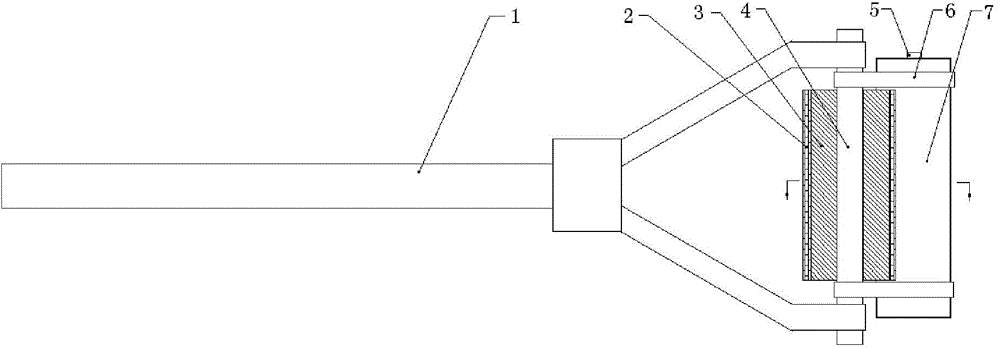

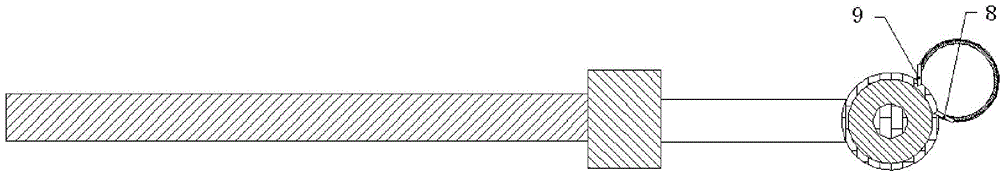

[0012] Such as Figure 1-Figure 2 As shown, a new type of paint roller created by the present invention includes a rotating shaft 4, a roller 3, an elastic bristle cover 2, a material tank and a brush handle 1, and the rotating shaft 4 is inserted in the roller 3 and is slidably connected with it , the elastic bristle cover 2 is set on the cylinder 3, the rotating shaft 4 is fixed on the brush handle 1; the material tank includes a tank body 7, a discharge chute, a tank cover 5, Scraper and fixed bracket 6, the cross-section of the tank body 7 is a circular hollow body, the tank cover 5 is screwed to the tank body 7, and the fixed bracket 6 is used for fixedly connecting the The tank body 7 and the rotating shaft 4, the discharge groove is located on the tank body 7; the elastic bristle cover 2 blocks the discharge groove; the scraper blade includes the first A scraper 8 and a second scraper 9, the first scraper 8 and the second scraper 9 are respectively fixed on the two sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com