Cold rolling treatment device for high-quality steel preparation

A processing device and steel technology, which is applied to the surface coating liquid device, workpiece surface treatment equipment, manufacturing tools, etc., can solve the problems of prolapse, anti-oxidation liquid smearing effect, poor wall cleaning effect of steel, and inconvenience of cold-rolled steel strip, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0043] The present invention provides the following preferred embodiments

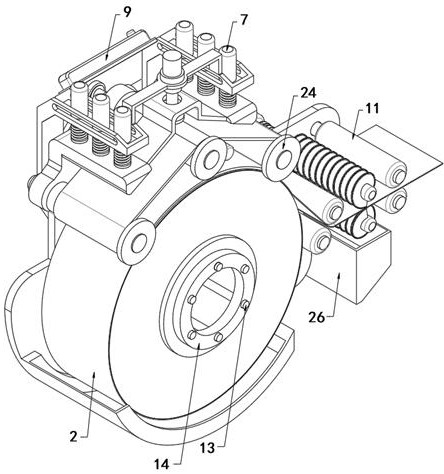

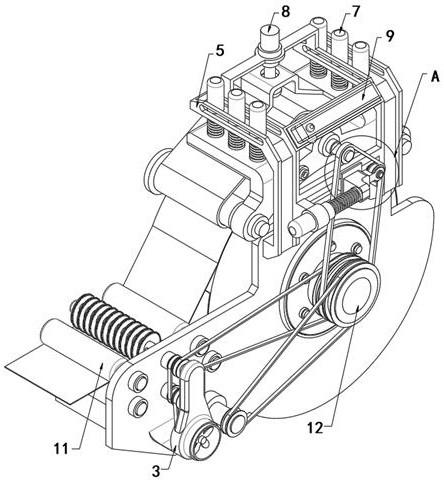

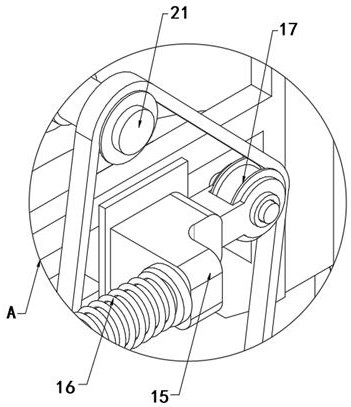

[0044] like Figure 1-7 As shown in the figure, a cold-rolling treatment device for the preparation of high-quality steel products includes a stand 1, and a coiling mechanism is rotatably connected between the inner surfaces of the stand 1, and a cold-rolled steel strip 2 is wound on the surface of the coiling mechanism. The surface of the seat 1 is fixedly installed with a dust cover 3, a servo motor 4 and a top frame 5, the inner wall of the dust cover 3 is rotatably connected with a rotating shaft 6, and a set of exhaust fans is fixedly installed on the peripheral side of the rotating shaft 6, and the output shaft of the servo motor 4 The end is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com