Large-diameter screw tightening supporting equipment

A large-caliber, equipment-based technology, applied in mechanical equipment, metal processing equipment, metal processing, etc., can solve problems such as poor color of screws and nuts, high friction between screws and nuts, damage to screws and nuts, etc., to achieve Sufficient tightening, easy tightening, and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

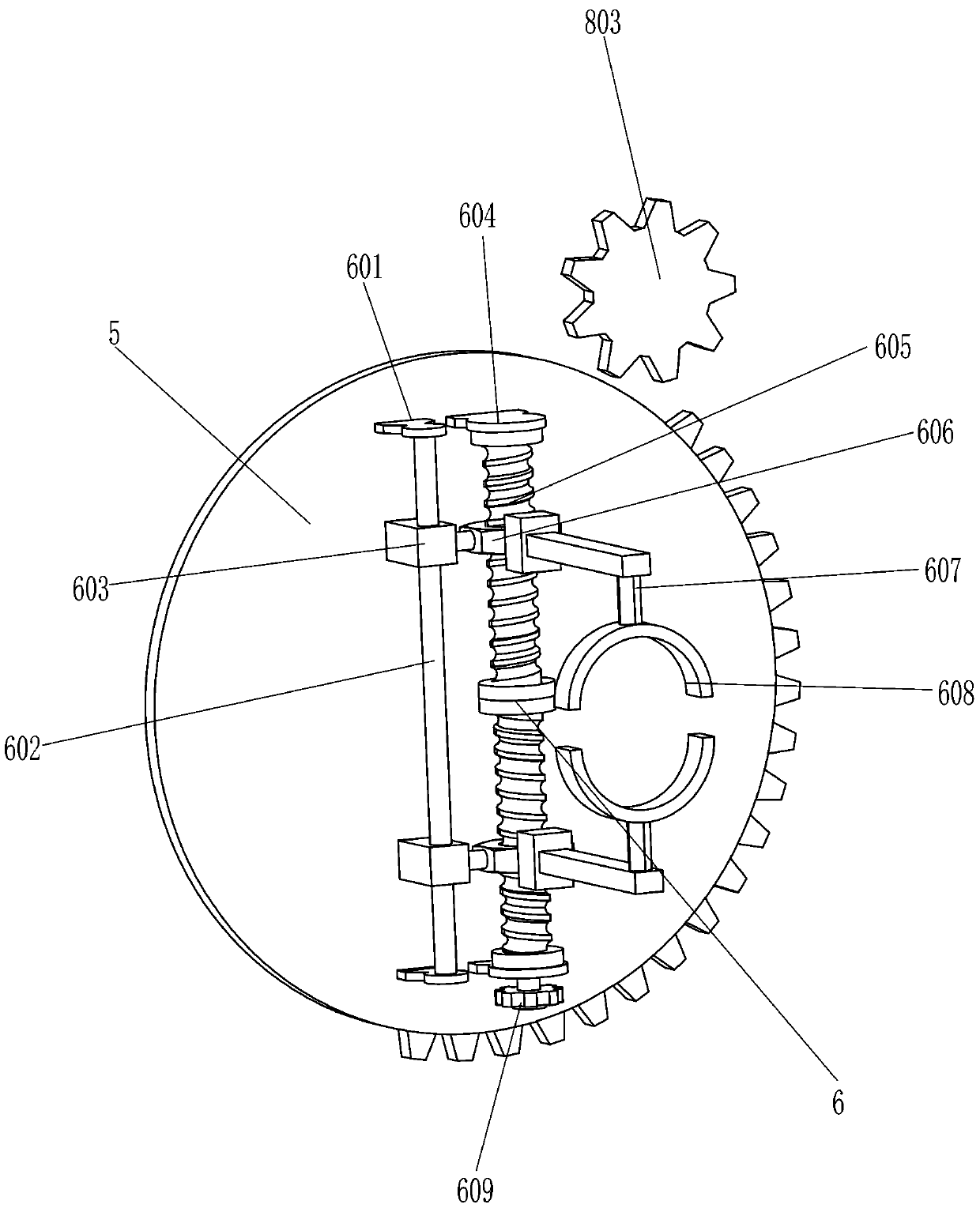

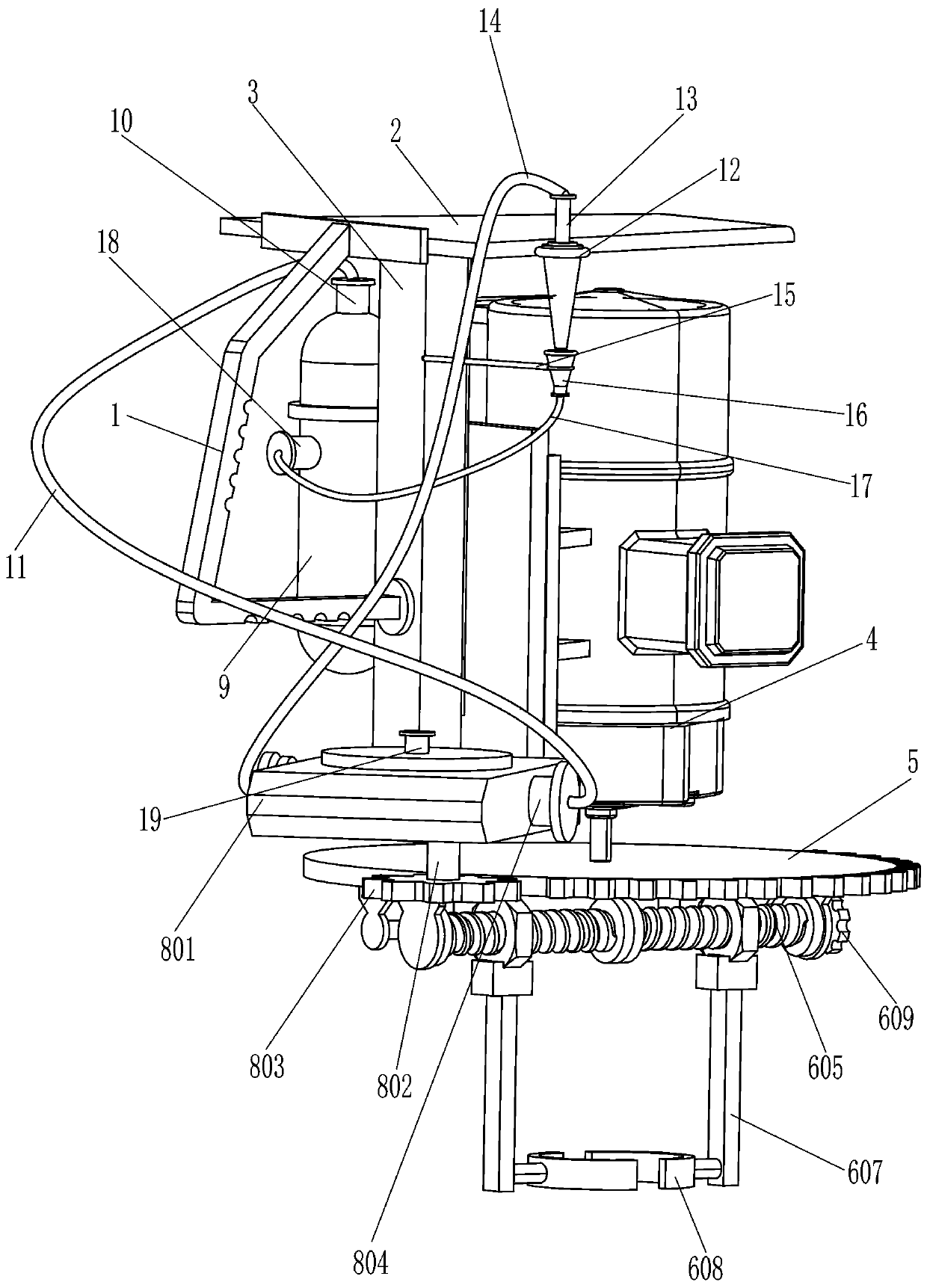

[0021] An auxiliary tightening device for large-diameter screws, such as Figure 1-3 As shown, it includes a handle 1, a mounting plate 2, a mounting column 3, a driving motor 4, a gear plate 5, a tightening device 6, a connecting block 7, a pumping device 8, a liquid storage tank 9, a liquid inlet assembly 10, a first Hose 11, placement ring 12, nozzle 13 and second hose 14, the top right end of the handle 1 is provided with a mounting plate 2, the left side of the bottom of the mounting plate 2 is provided with a mounting column 3, the lower left side of the mounting column 3 is connected to the handle 1 The right end of the lower part is connected, and the right side of the mounting column 3 is provided with a driving motor 4, and the bottom end of the output shaft of the driving motor 4 is connected with a gear plate 5, and the half side of the gear plate 5 is provided with gear teeth, and the bottom of the gear plate 5 is provided with a tightening device 6, The left fron...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 As shown, it also includes a placement frame 15, a liquid collection bucket 16, a return pipe 17 and a reinjection assembly 18. The front side of the upper part of the mounting column 3 is provided with a placement frame 15, and the placement frame 15 is provided with a liquid collection bucket 16, and the liquid collection bucket 16 is in contact with the nozzle 13, the bottom end of the liquid receiving bucket 16 is connected with a return pipe 17, the left side of the liquid storage tank 9 is provided with a refill assembly 18, and the left end of the refill assembly 18 is connected to the back end of the return pipe 17.

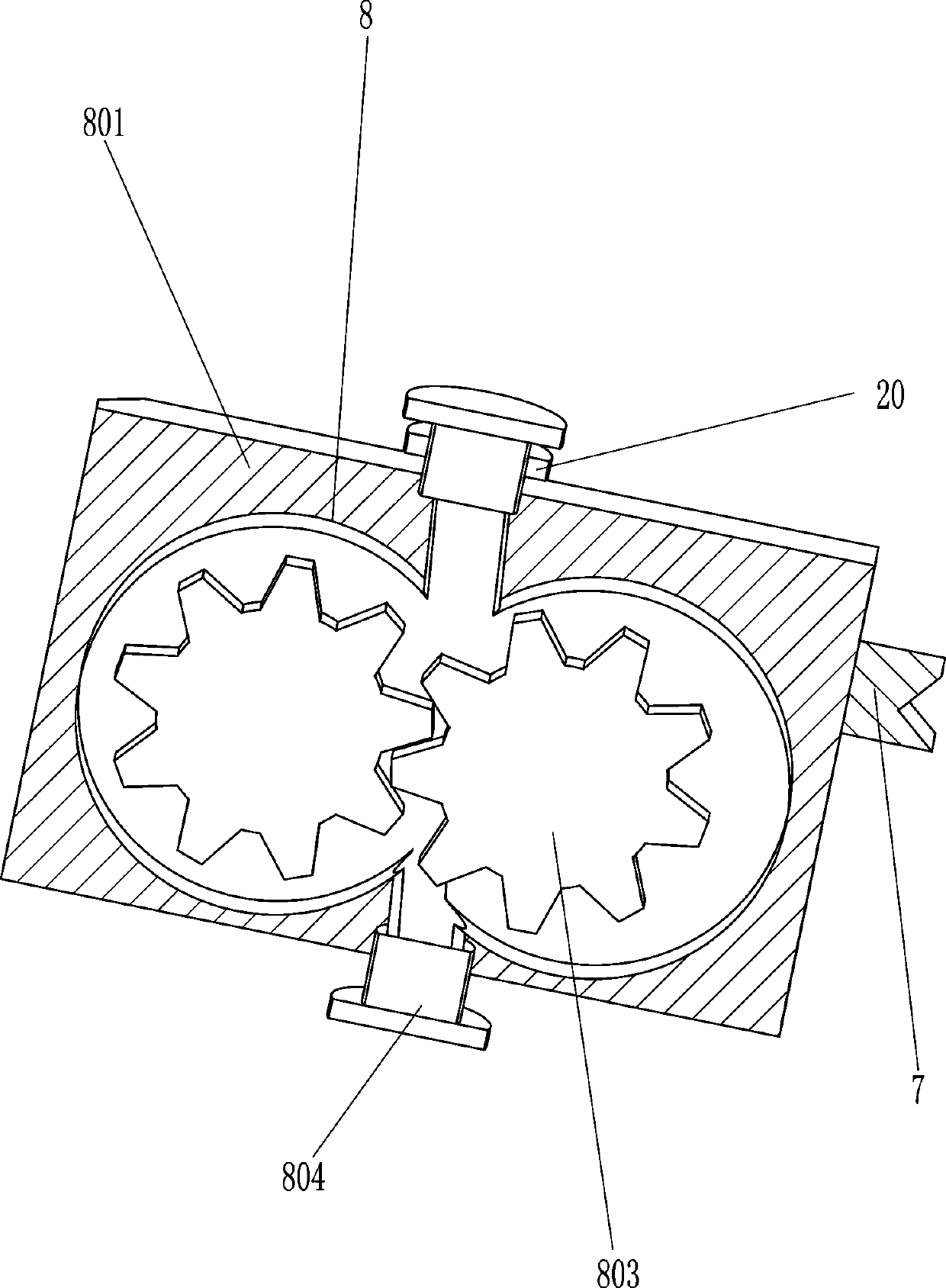

[0029] It also includes a breather valve 19 and a lock valve 20 , the pump body 801 is provided with a breather valve 19 in the middle of the top, and the connection sleeve 804 on the front side is provided with a lock valve 20 .

[0030] When the worker puts the nozzle 13 back into the placement ring 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com