Corrugated roller hot spraying production and restoring method

A repair method and technology of corrugated rollers, which are applied in coating, melt spraying, and metal material coating processes, etc., can solve the problems of wasting manpower and material resources, affecting production efficiency, labor, etc., and achieve prolonging service life and high production efficiency , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

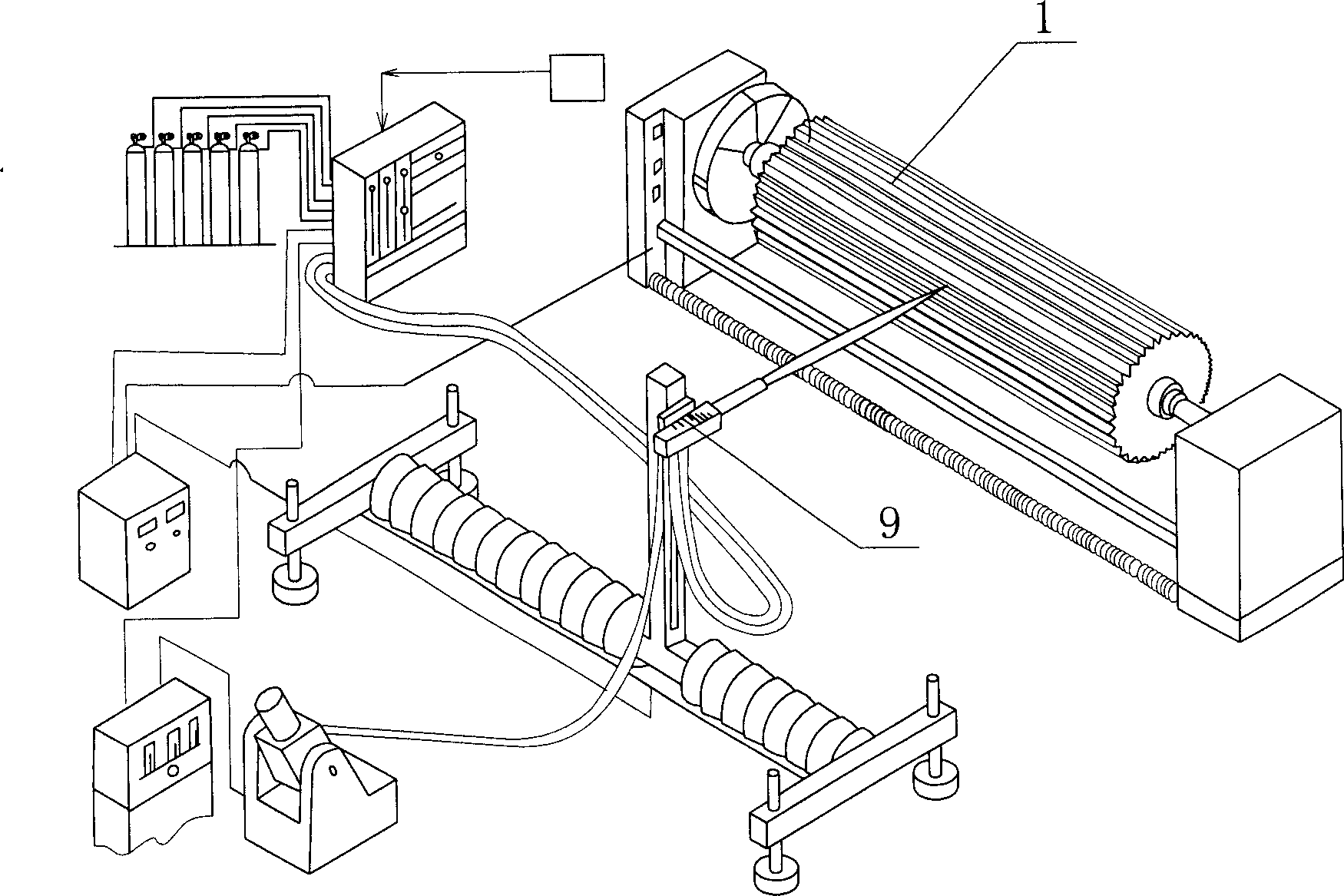

[0019] Such as Figure 3 to Figure 5 As shown, a method for manufacturing and repairing a corrugated roller by thermal spraying according to the present invention includes the following method steps: first, the corrugated roller is subjected to tooth profile processing; then, the teeth of the corrugated roller are subjected to nitriding treatment or carbon - Nitriding treatment; secondly, local heat quenching and tempering treatment is carried out on the teeth of the corrugating roller; and then the tooth surface of the corrugating roller is strengthened with a wear-resistant coating;

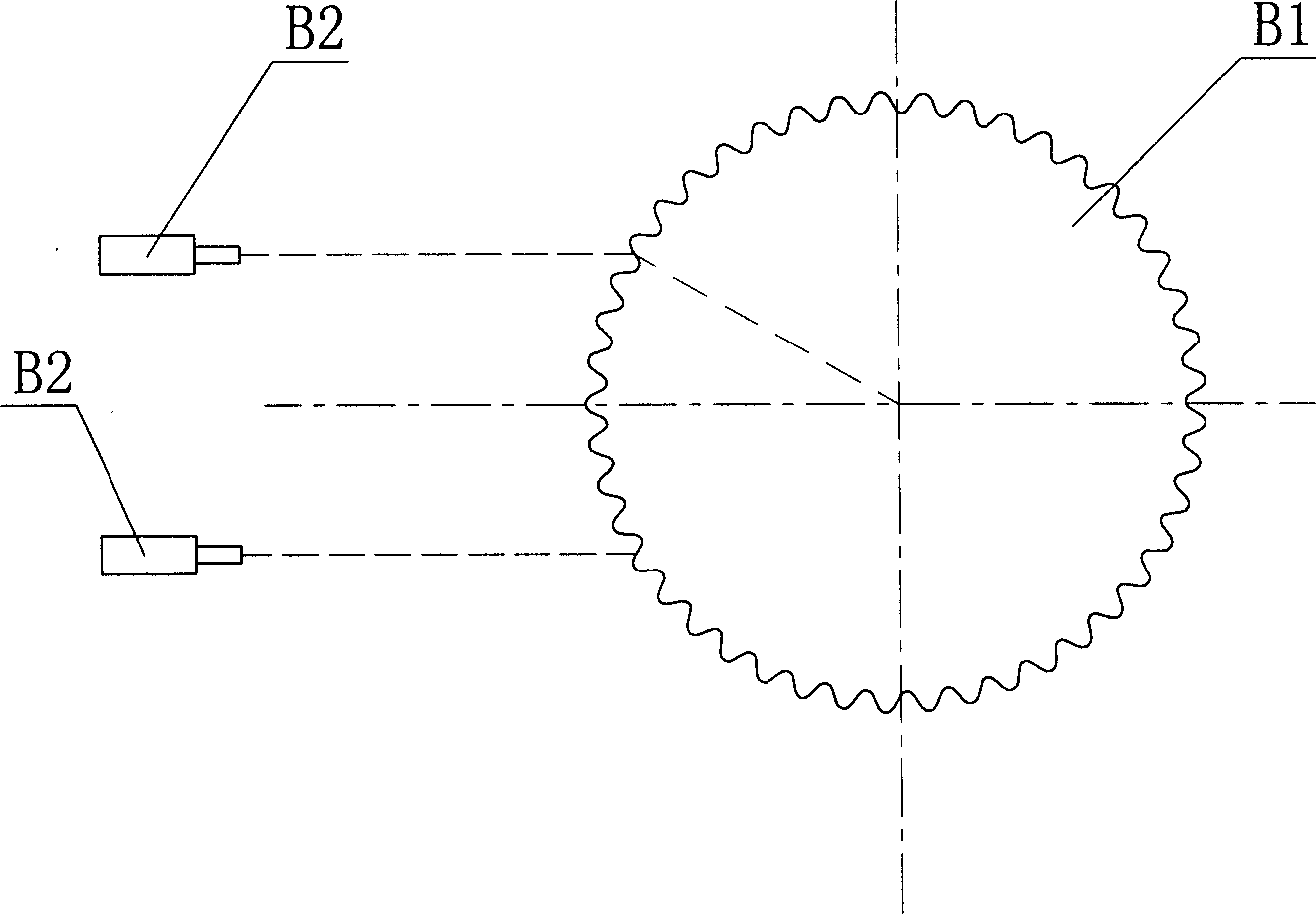

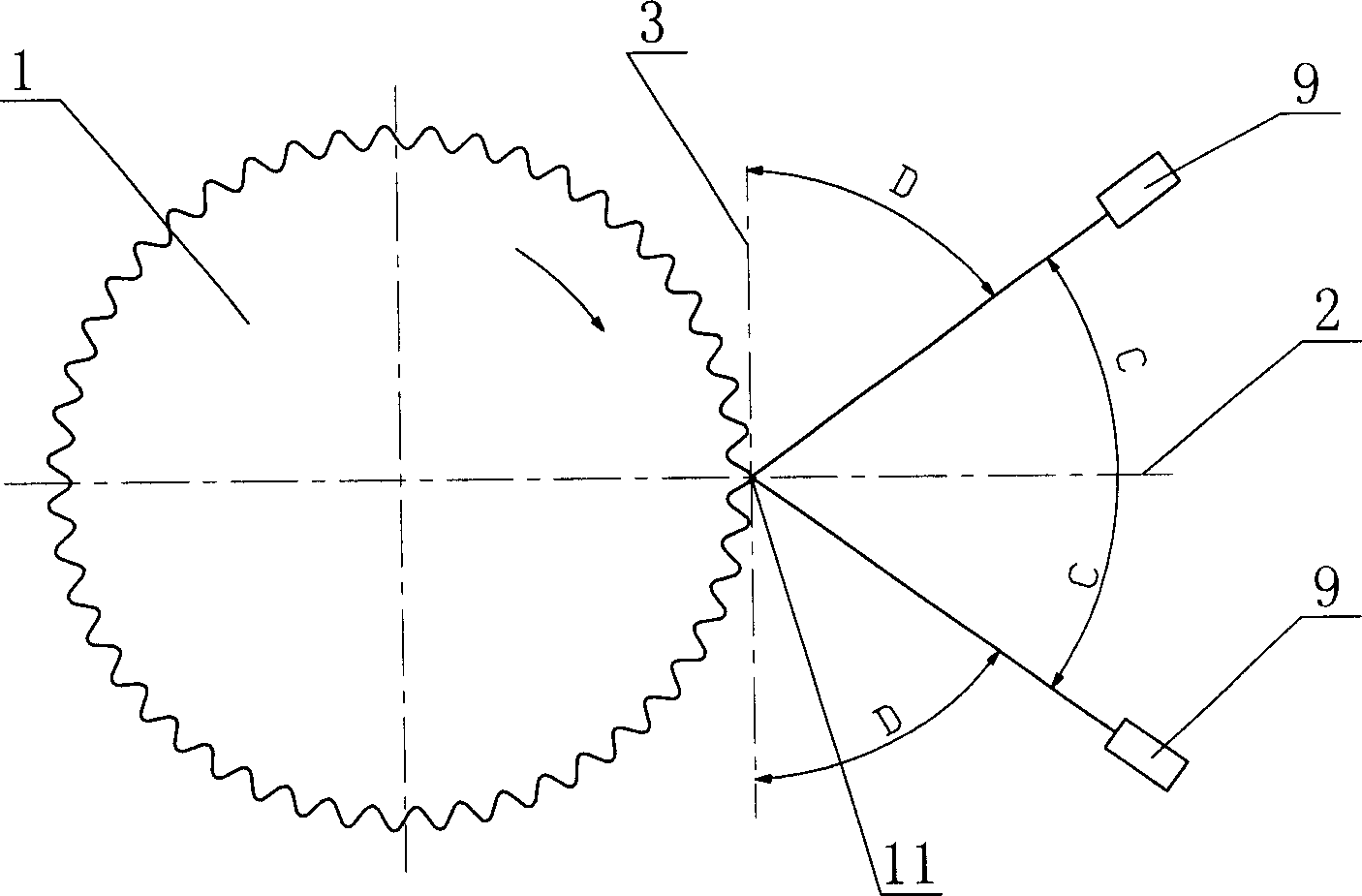

[0020] Among them, the supersonic spraying system is used to strengthen the wear-resistant coating on the tooth surface of the corrugated roller. The steps of the method for quickly determining the spraying angle of the spray gun are as follows:

[0021] (1) According to the tooth shape parameters of the corrugating roller, the cross-sectional tooth shape of the corrugating roller is drawn prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com