Self-adjustment type spraying equipment carrier platform

A technology of spraying equipment and carrier platform, applied in the direction of spraying device, etc., can solve the problems of uneven coating on spraying surface, tear-like, failing to meet construction requirements, etc., and achieve the goal of improving spraying quality, ensuring uniformity and ensuring coating uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

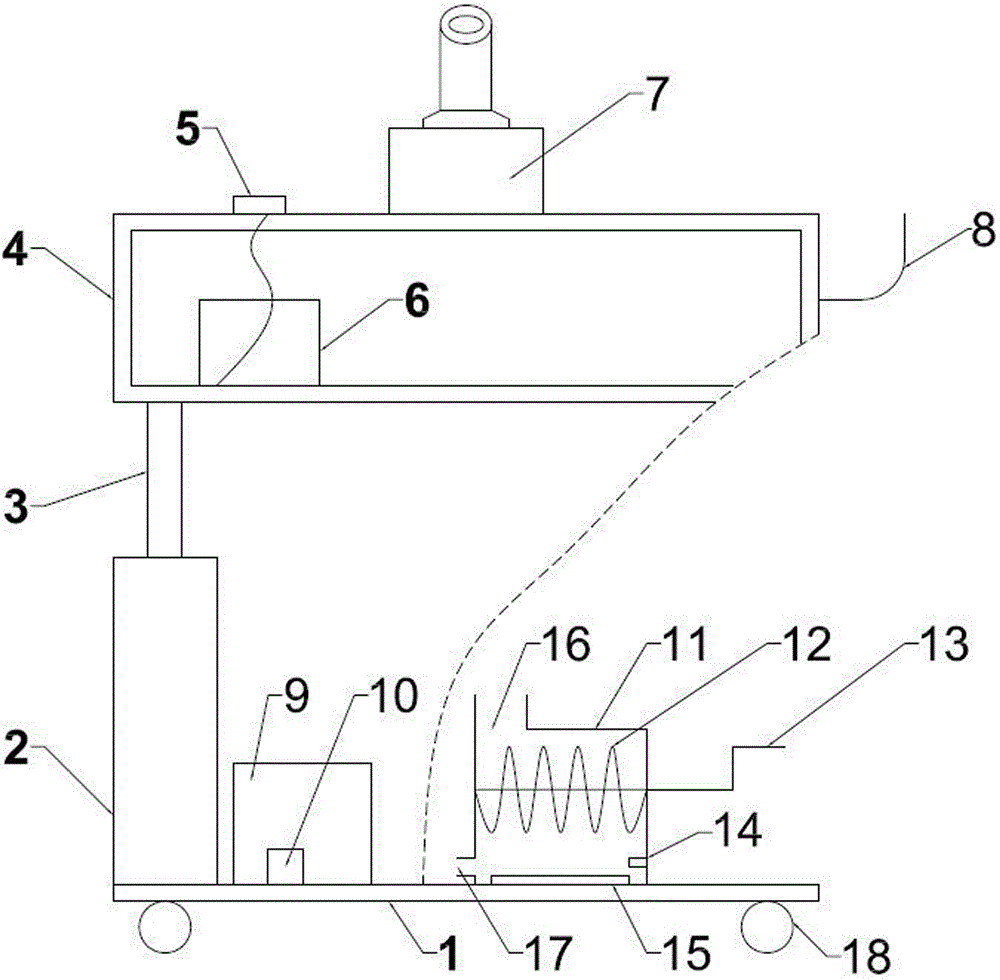

[0021] Such as Figure 1-3 Shown, a kind of self-regulating type spraying equipment carrier platform, it comprises that a rectangular base plate 1 is set, a universal wheel 18 is installed at the four corners of the lower surface of the base plate 1, and a universal wheel 18 is installed on each universal wheel 18. brake pads.

[0022] A vertical hydraulic cylinder 2 is provided at four corners of the upper surface of the bottom plate 1, and the output direction of the hydraulic cylinder 2 is vertically upward. A rectangular support body 4 is arranged above the base plate 1 , and the four corners of the lower surface of the support body 4 are respectively connected with the tops of the output shafts 3 of the corresponding hydraulic cylinders 2 below. This allows the group of hydraulic cylinders 2 to push and adjust the support body 4 to move up and down in the vertical direction.

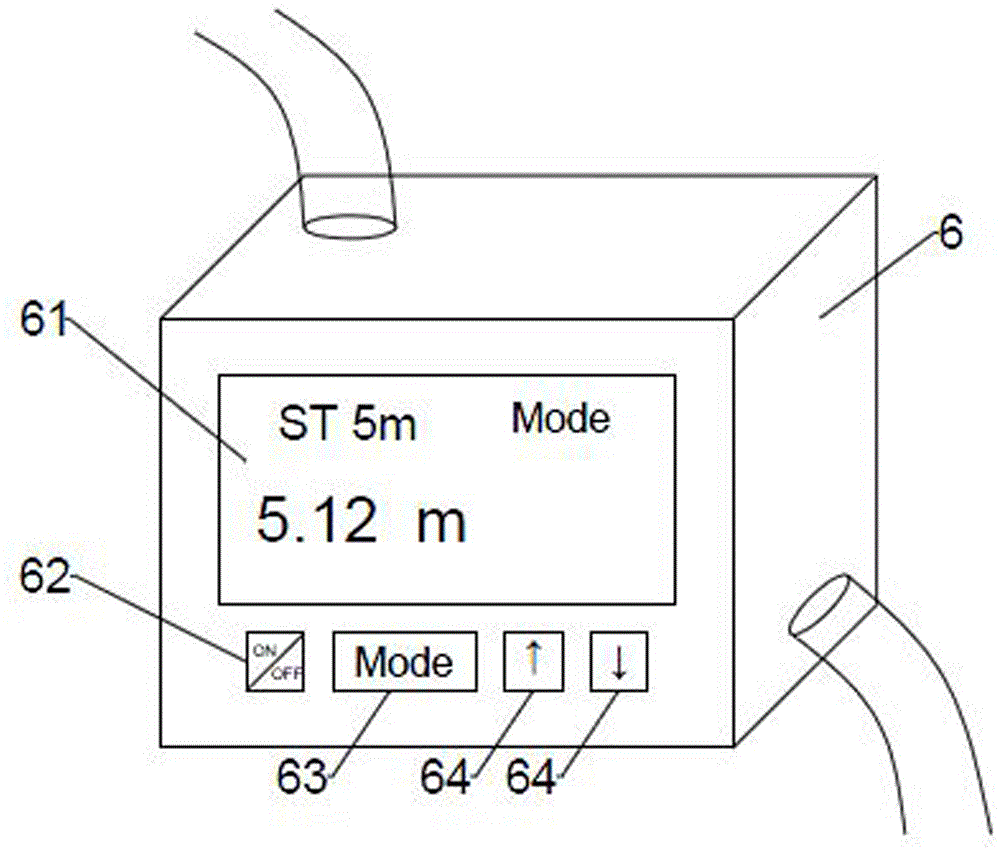

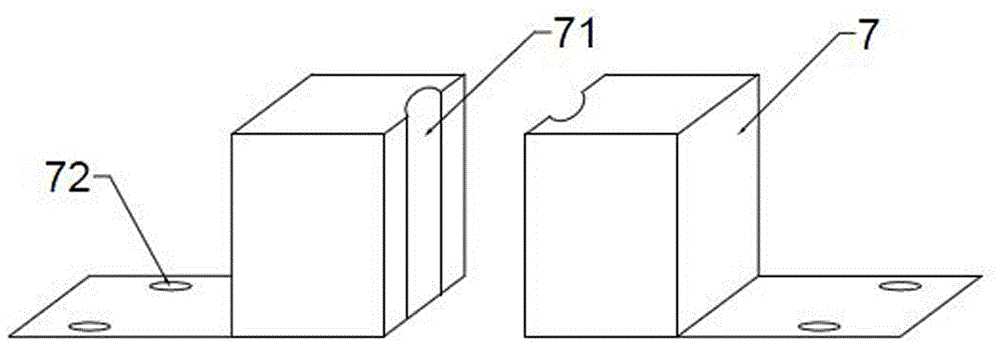

[0023] A cavity is provided on the support body 4, and one side wall of the cavity is a clamsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com