Protecting device and method for angle-variable coating layers of turbine guide blades

A technology for turbine guide vanes and protection devices, applied in coating, metal material coating process, sputtering coating, etc., to achieve the effect of simple device structure, few accessories, and ensuring coating thickness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

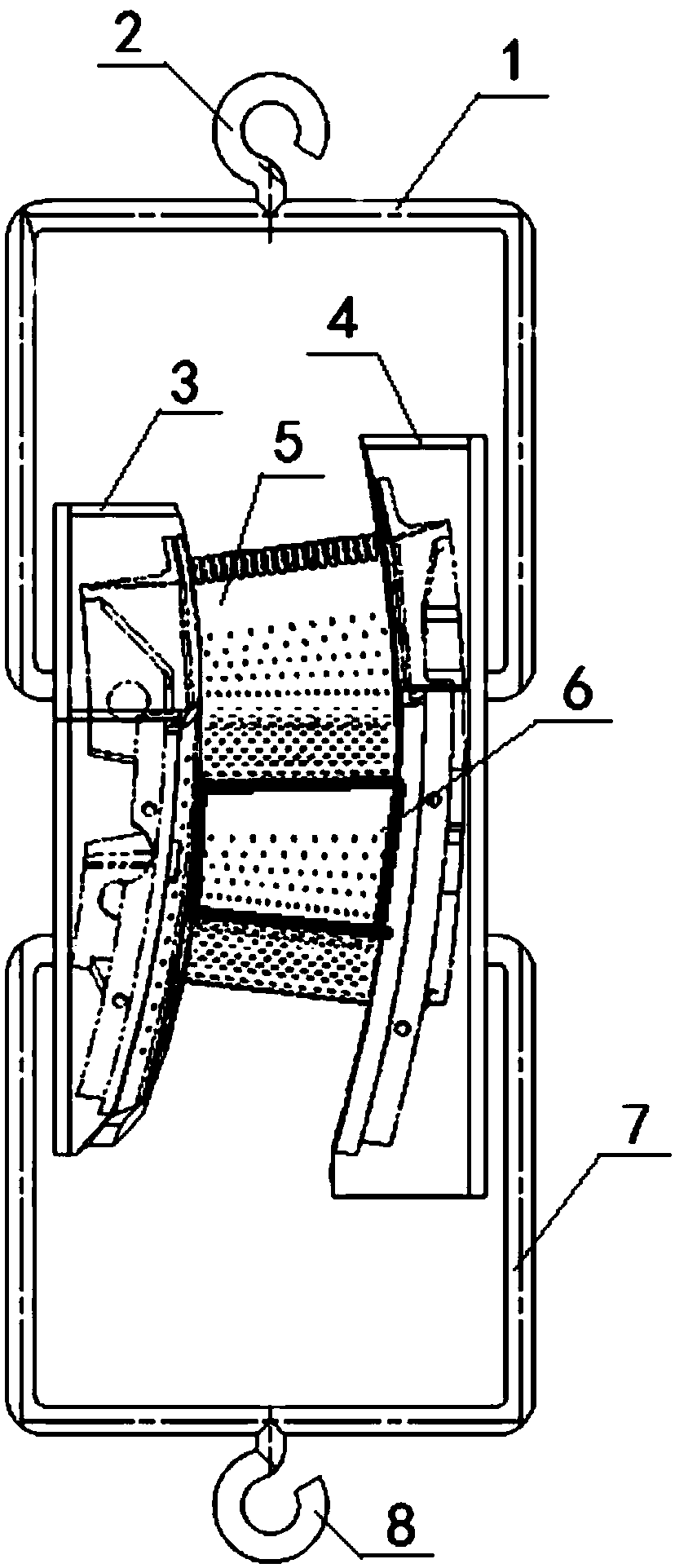

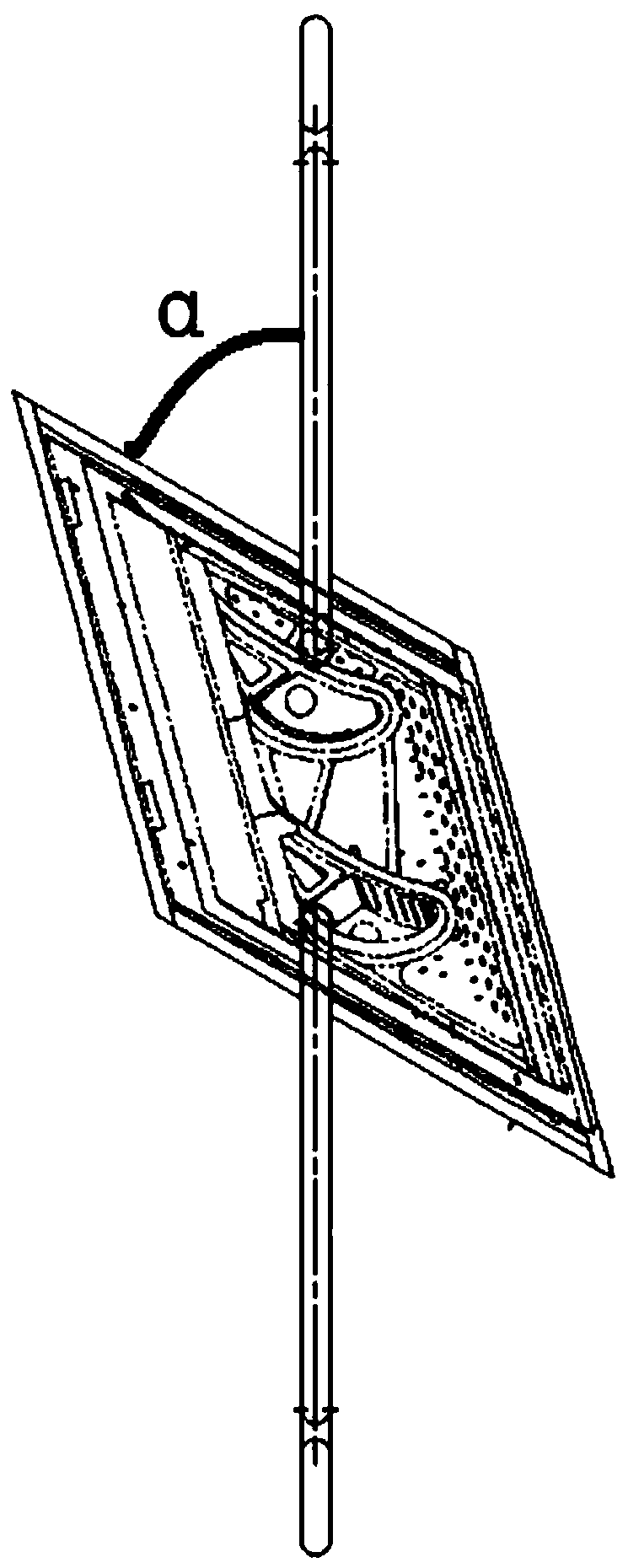

[0033] Referring to the accompanying drawings, a protective device for variable-angle coating of turbine guide blades, the device includes an inner edge plate protection box 3, an outer edge plate protection box 4, an upper hook 2, a lower hook 8, and an upper clip 1. The lower clip 7, etc., the inner edge plate protection box 3 and the outer edge plate protection box 4 are manufactured according to the shape of the product protection part, so as to realize the protection of the non-coated surface during coating, and the inner edge plate protection box 3 and the outer edge plate Two connecting holes of a certain size are drilled on the protective box 4, and the upper hook 2 and the lower hook 8 are respectively welded at the center of the upper clip 1 and the lower clip 7, and the upper clip 1 and the lower clip 7 are connected with the inner edge plate protection box ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com