HMX coated with GO (graphene oxide) through electrostatic self-assembly and preparation method of HMX

An electrostatic self-assembly, octogen technology, applied in the directions of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, attack equipment, explosive processing equipment, etc., can solve the problem of reducing the detonation performance of explosives and the quality of the coating Advanced problems, to achieve the effect of simple experimental equipment requirements, uniform coating thickness, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 5g of HMX and soak and clean Octogen with ethanol, then suction filter and dry to obtain Octogen after cleaning.

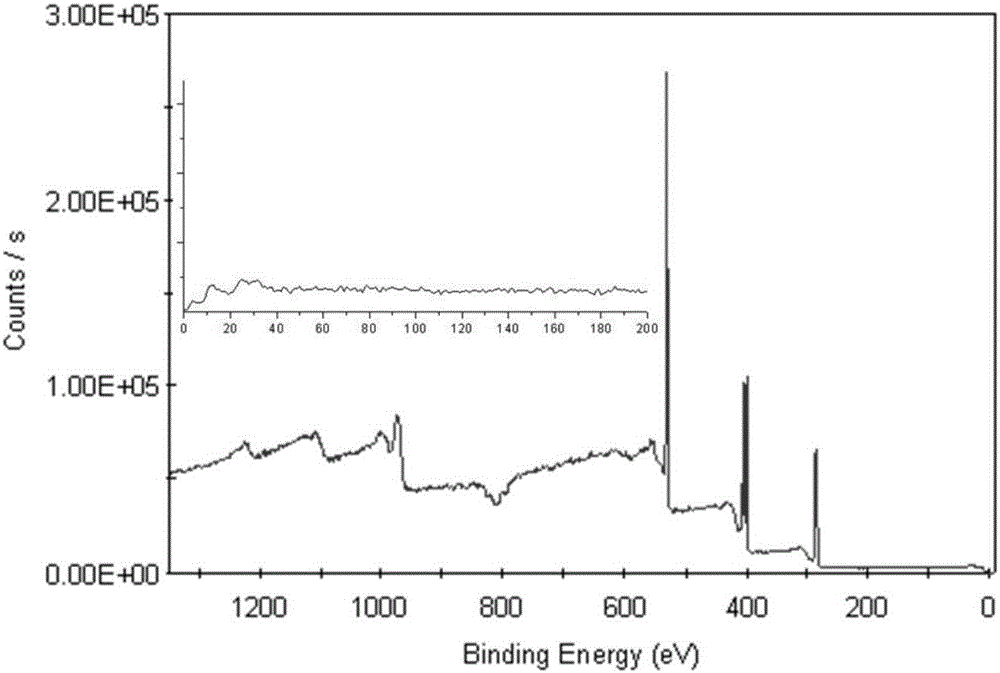

[0044]Put the cleaned Octogen in a beaker; measure 100mL of n-hexane and pour it into the beaker; add 0.2mL APS dropwise into the beaker, then stir and reflux for 8h under heating at 80°C, and then use a large amount of ethanol to dissolve the solid Rinse; followed by drying at 75° C. for 8 hours to obtain amino surface-modified HMX.

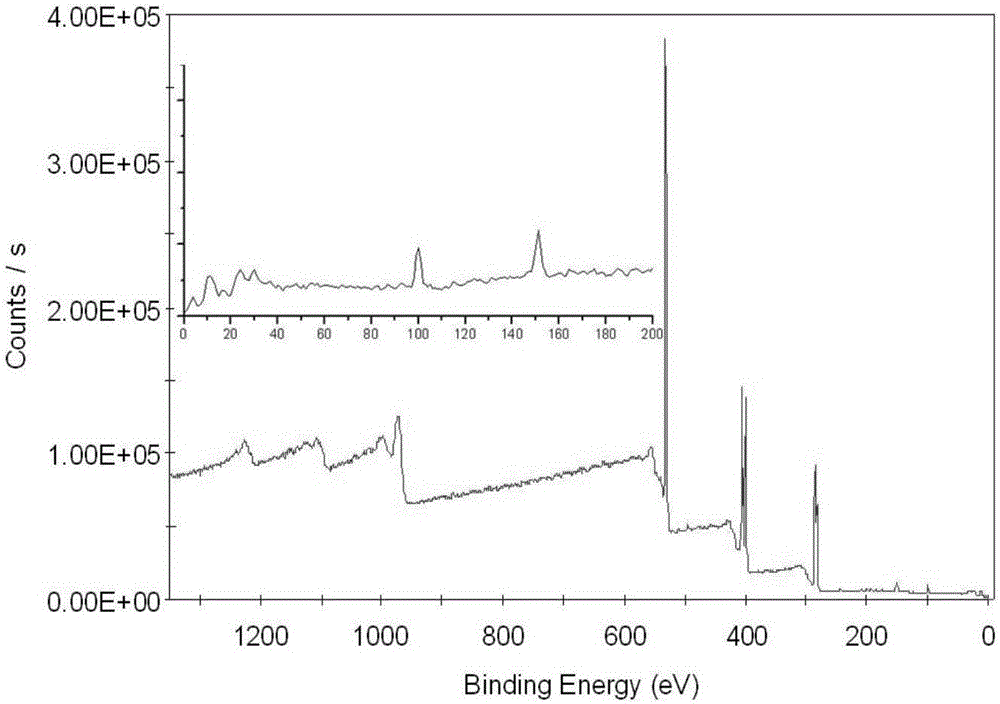

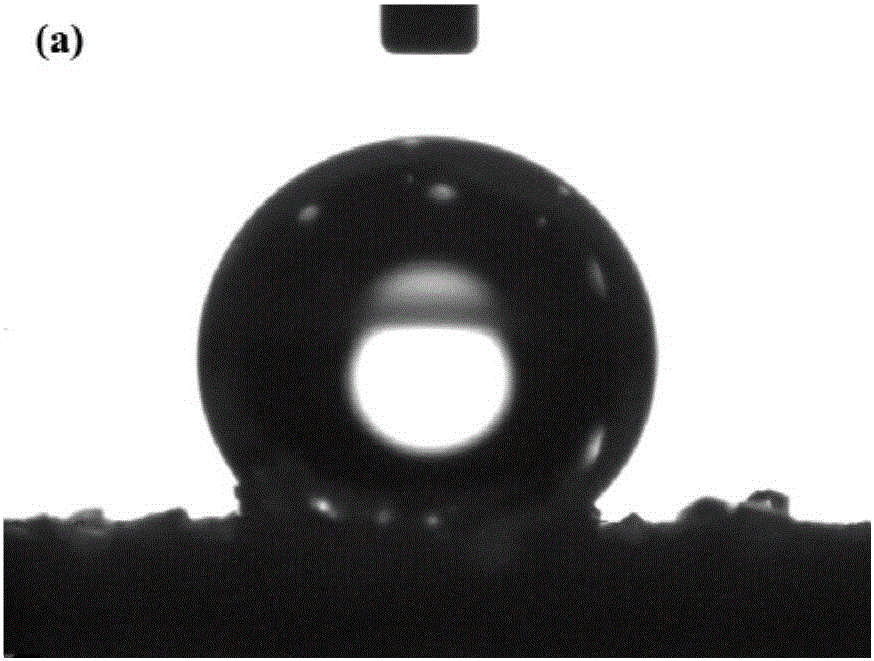

[0045] Weigh 0.2 g of amino surface-modified HMX, add it into a beaker filled with 25 mL of deionized water, and then slowly drop dilute hydrochloric acid into the beaker to adjust the pH to 4.5 to obtain a HMX solution. Weigh 0.02g of GO, add it to 25mL deionized water, and disperse it by ultrasonic until the solution is transparent, then slowly add dilute ammonia water to the solution, and adjust the pH to 8.5 to obtain a graphene oxide solution; then mix the HMX solution with the graphene oxide solution Mix and keep...

Embodiment 2

[0053] Weigh 10g of HMX and soak and clean Octogen with ethanol, then suction filter and dry to obtain Octogen after cleaning.

[0054] Put the cleaned Octogen in a beaker; measure 100mL of toluene and pour it into the beaker; add 0.3mL KH-550 dropwise into the beaker, then stir and reflux at 120°C for 12h, and then use a large amount of ethanol to The solid was rinsed; followed by drying at 80° C. for 6 h to obtain amino surface-modified HMX.

[0055] Weigh 0.5 g of amino surface-modified HMX and add it into a beaker filled with 30 mL of deionized water, then slowly add dilute hydrochloric acid dropwise into the beaker to adjust the pH to 5.5 to obtain a HMX solution. Weigh 0.05g of GO, add it to 30mL deionized water, ultrasonically disperse until the solution is transparent, then slowly add dilute ammonia water to the solution, adjust the pH to 8 to obtain a graphene oxide solution; then mix the HMX solution with the graphene oxide solution Mix and keep stirring until the g...

Embodiment 3

[0057] Weigh 10g of HMX and soak and clean Octogen with ethanol, then suction filter and dry to obtain Octogen after cleaning.

[0058] Put the cleaned Octogen in a beaker; measure 100mL of toluene and pour it into the beaker; add 0.3mL of A1120 dropwise into the beaker, then stir and reflux at 120°C for 12h, and then treat the solid with a large amount of ethanol Rinse; then dry at 75°C for 8 hours to obtain amino surface-modified HMX.

[0059] Weigh 0.5 g of amino surface-modified HMX, add it into a beaker filled with 30 mL of deionized water, and then slowly drop dilute hydrochloric acid into the beaker to adjust the pH to 4.5 to obtain a HMX solution. Weigh 0.05g of GO, add it to 30mL deionized water, ultrasonically disperse until the solution is transparent, then slowly add dilute ammonia water to the solution, adjust the pH to 8.5 to obtain a graphene oxide solution; then mix the HMX solution with the graphene oxide solution Mix and keep stirring until the graphene (GO)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com