Nanometer iron powder light igniting device

A technology of nano-iron powder and ignition device, which is applied in the field of optical ignition, can solve the problems of bulky ignition device and difficult ignition, and achieve the effect of simple structure, easy recovery and large heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

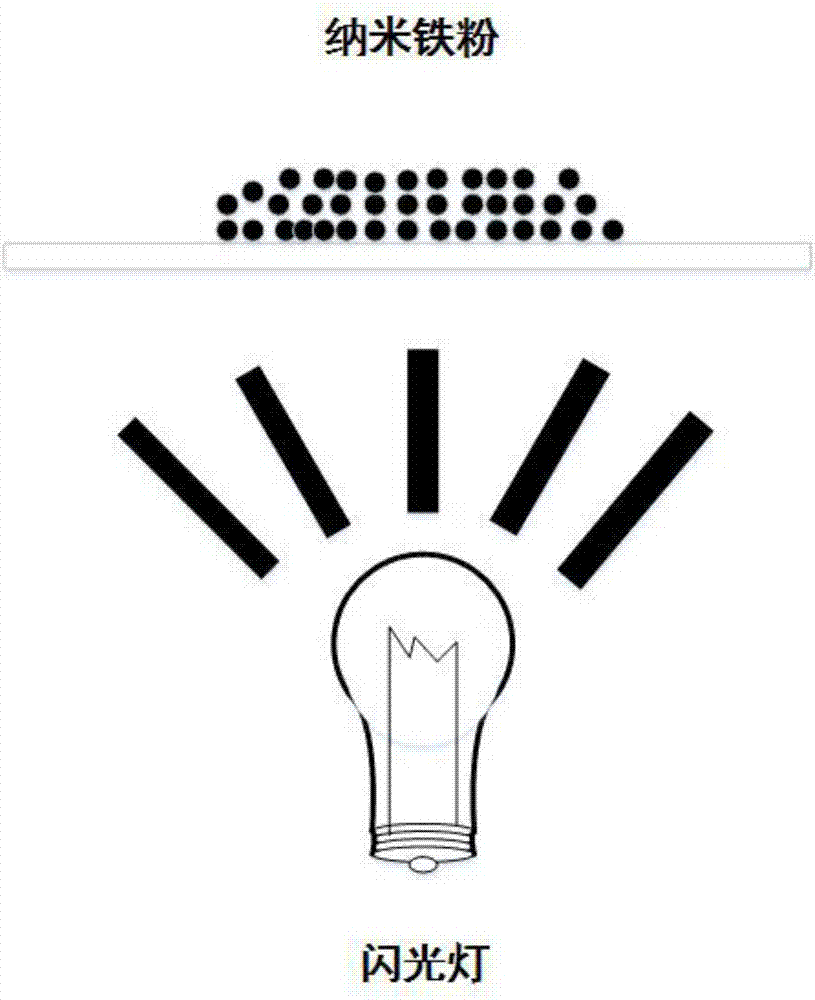

[0011] combine figure 1 , a nano-iron powder optical ignition device, which uses a flash lamp 1 to release light pulse energy in a very short time, and the nano-iron powder 3 absorbs the light energy. At this time, the oxide layer on the surface of the nano-iron powder 3 is destroyed, so that the inner nano-iron particles It reacts with the surrounding air and releases heat to achieve the purpose of ignition.

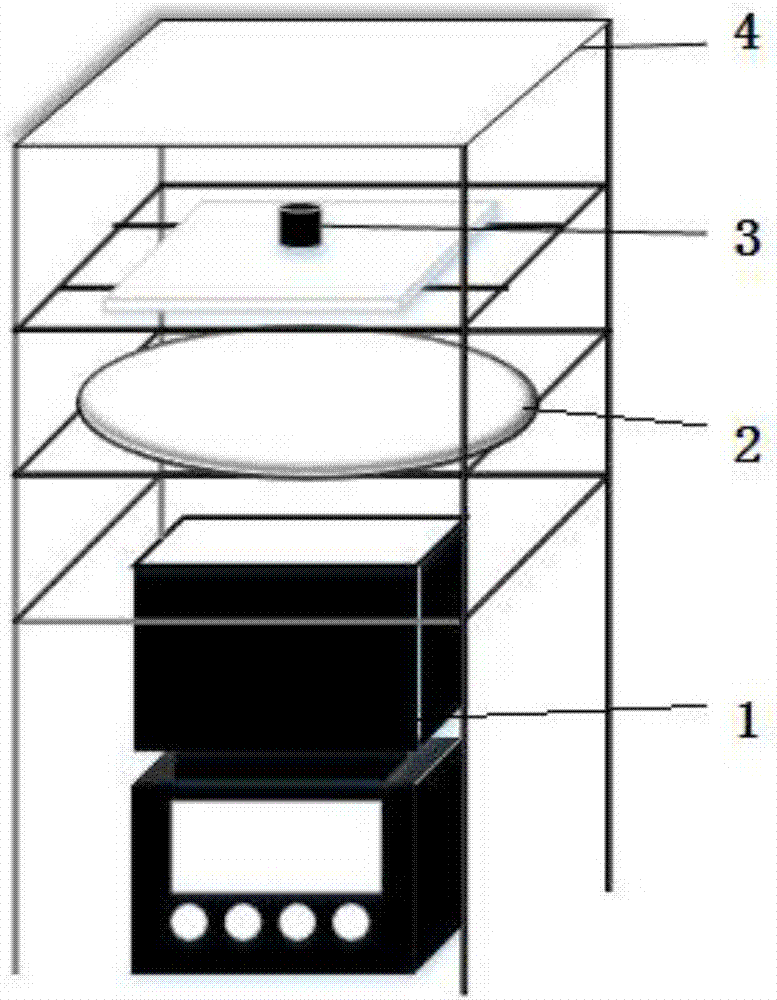

[0012] combine figure 2 , a nano-iron powder light ignition device is divided into two parts: a light source and a light intensifier. The hardware of the system mainly includes two parts: a flashlight 1 located under the material, a reflector 4 and a condenser 2 for light intensification. The nanostructure material is exposed to the light source of ordinary flashlight, and the divergent natural light gathers energy through the condenser 2, and at the same time, part of the light scattered to the surrounding is absorbed by the nanomaterial through the reflection of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com