Fuel-engine-driven compression-absorption combined type heat pump system

An engine-driven, heat pump system technology, used in fuel, heat pump and heating, thermal energy, power fields, can solve application limitations, performance impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

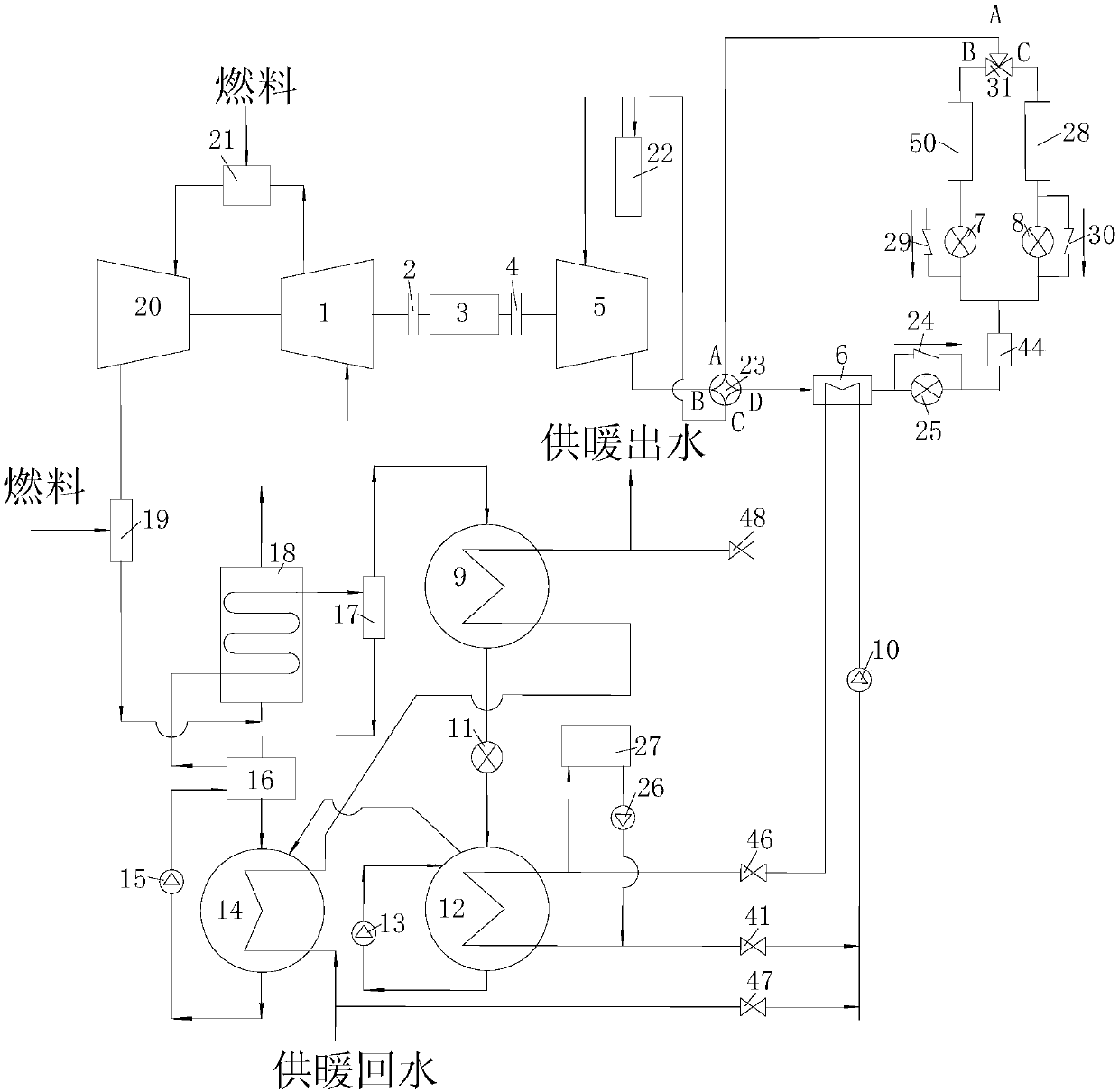

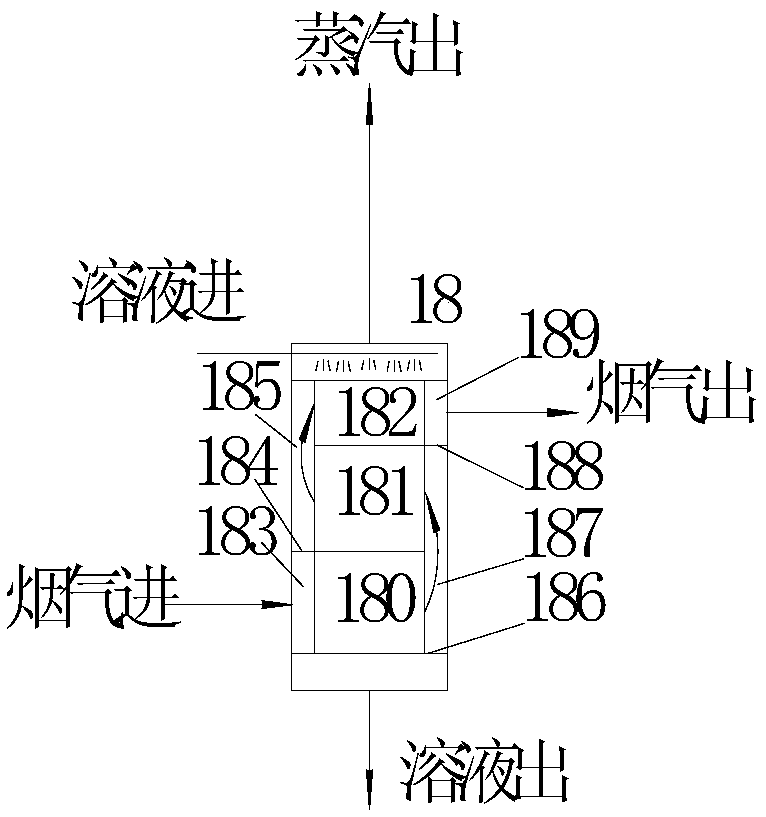

[0063] Embodiment 1. The compression-absorption composite heat pump system driven by the fuel engine of the present invention adopts the scheme 1 of a gas turbine, such as figure 1As shown, it includes compressor 1, clutch 2, clutch 4, coupling 3, compressor 5, condenser 6, condenser 9, evaporator 12, absorber 14, solution heat exchanger 16, gas-liquid separator 17 , generator 18, afterburning combustion chamber 19, turbine 20, combustion chamber 21, gas-liquid separator 22, four-way valve 23 and three-way valve 31.

[0064] The outlet of compressor 1 is connected to the inlet of combustion chamber 21, the outlet of combustion chamber 21 is connected to the inlet of turbine 20, the outlet of turbine 20 is connected to the inlet of supplementary combustion chamber 19, and the turbine 20 is connected to compressor 1 and compressor 5. The outlet of the supplementary combustion chamber 19 is connected to the shell-side inlet of the generator 18, the tube bundle outlet of the gener...

Embodiment 2

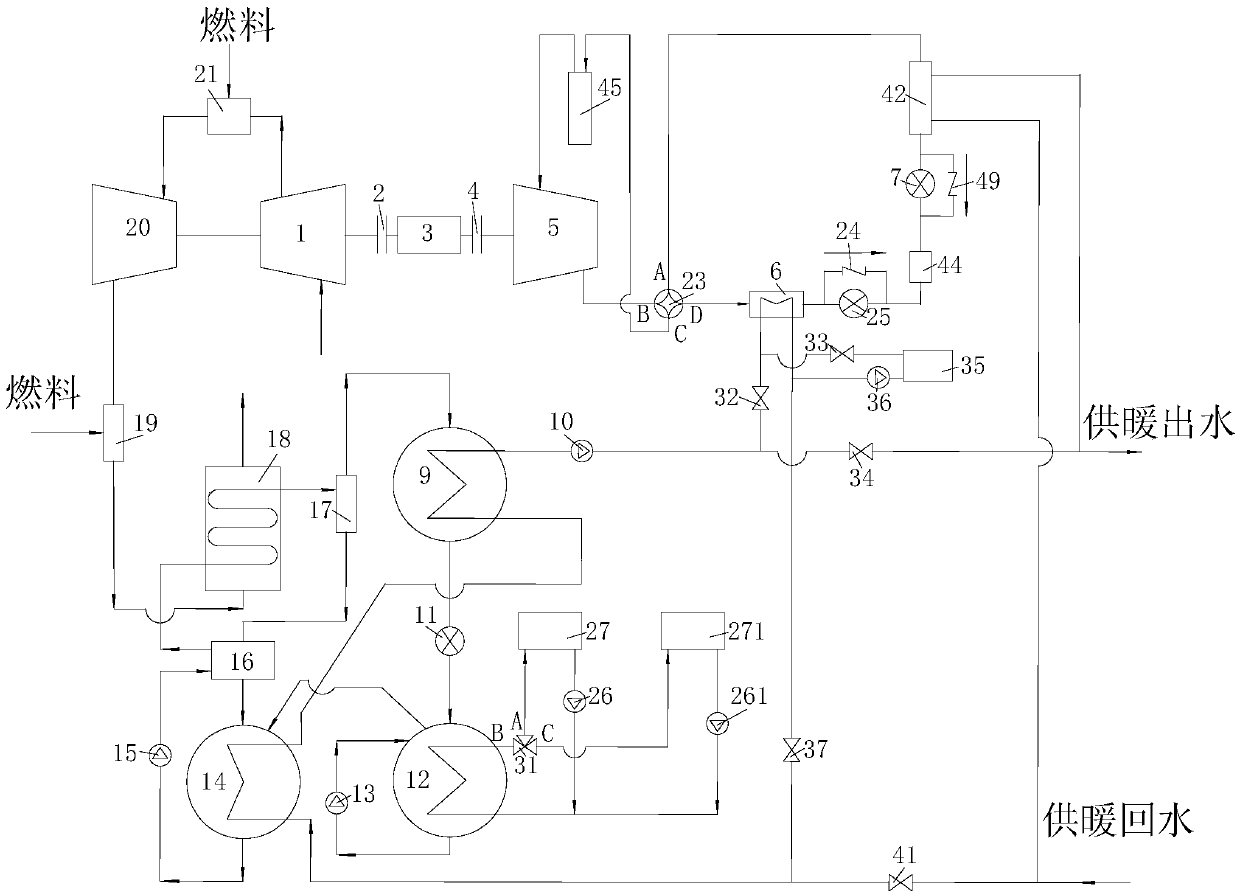

[0080] Embodiment 2. The compression-absorption composite heat pump system driven by the fuel engine of the present invention adopts the scheme 2 of a gas turbine, such as figure 2 Shown; including compressor 1, clutch 2, clutch 4, coupling 3, compressor 5, condenser 6, condenser 9, evaporator 12, absorber 14, solution heat exchanger 16, gas-liquid separator 17 , generator 18, afterburning combustion chamber 19, turbine 20, combustion chamber 21, gas-liquid separator 22, four-way valve 23 and three-way valve 31.

[0081] The outlet of compressor 1 is connected to the inlet of combustion chamber 21, the outlet of combustion chamber 21 is connected to the inlet of turbine 20, the outlet of turbine 20 is connected to the inlet of supplementary combustion chamber 19, and the turbine 20 is connected to compressor 1 and compressor 5. The outlet of the supplementary combustion chamber 19 is connected to the shell-side inlet of the generator 18, the tube bundle outlet of the generato...

Embodiment 3

[0105] Embodiment 3. The compression-steam injection compound heat pump system driven by the fuel engine of the present invention adopts the scheme 3 of the gas turbine, such as Figure 4 As shown, it includes compressor 1, clutch 2, clutch 4, coupling 3, compressor 5, condenser 6, condenser 52, evaporator 28, evaporator 50, evaporator 54, generator 18, supplementary combustion Chamber 19, turbine 20, combustion chamber 21, gas-liquid separator 22, four-way valve 23 and three-way valve 31, nozzle 58, suction chamber 57, mixing chamber 56, diffuser pipe 51.

[0106] The outlet of compressor 1 is connected to the inlet of combustion chamber 21, the outlet of combustion chamber 21 is connected to the inlet of turbine 20, the outlet of turbine 20 is connected to the inlet of supplementary combustion chamber 19, and the turbine 20 is connected to compressor 1 and compressor 5. The outlet of the supplementary combustion combustion chamber 19 is connected to the inlet of the shell si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com