Temperature measurement and sampling control method

A sampling control and controller technology, applied in the field of steelmaking, can solve problems such as gun body burning and hindering the operation of molten steel trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

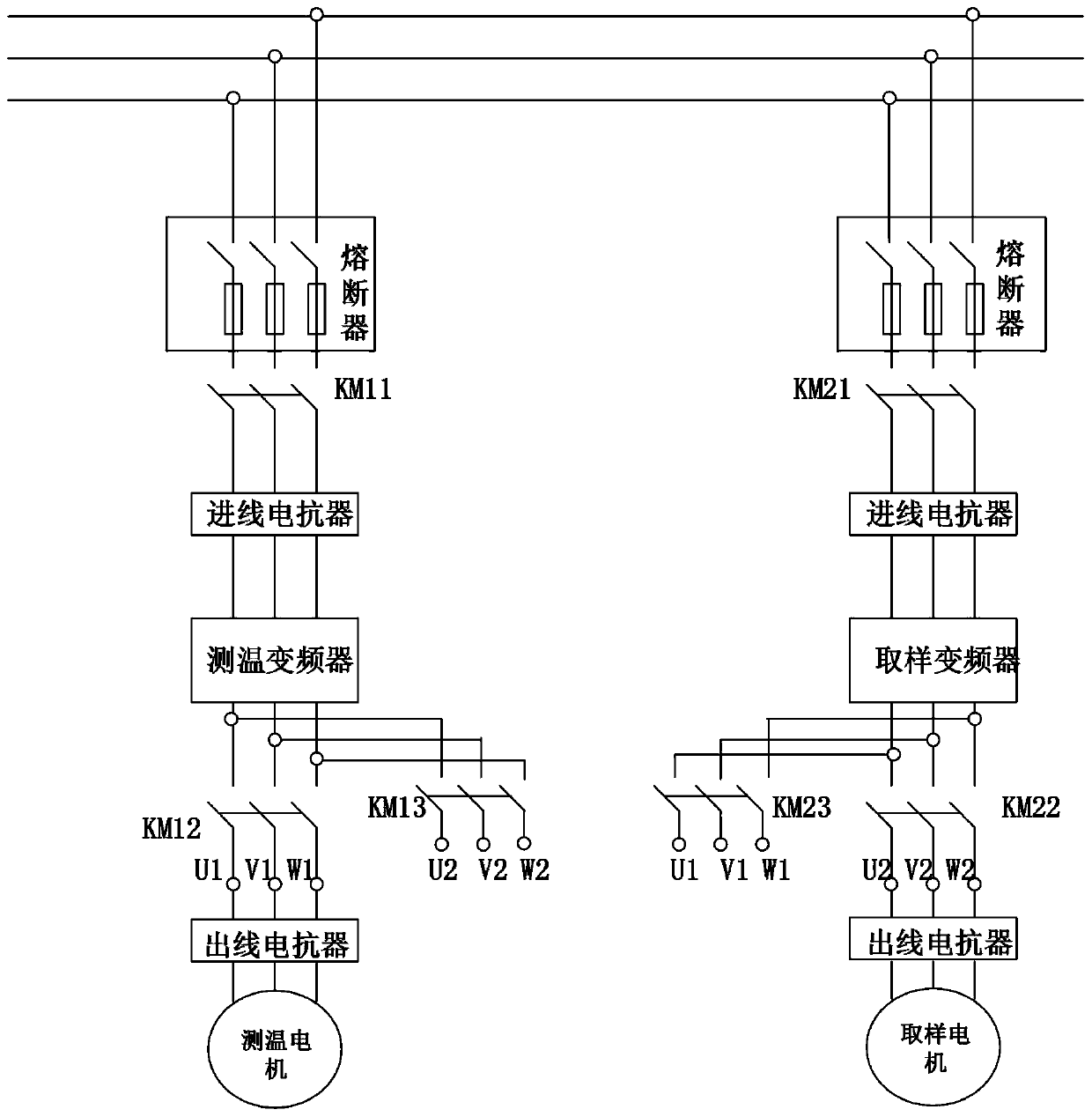

Method used

Image

Examples

Embodiment approach

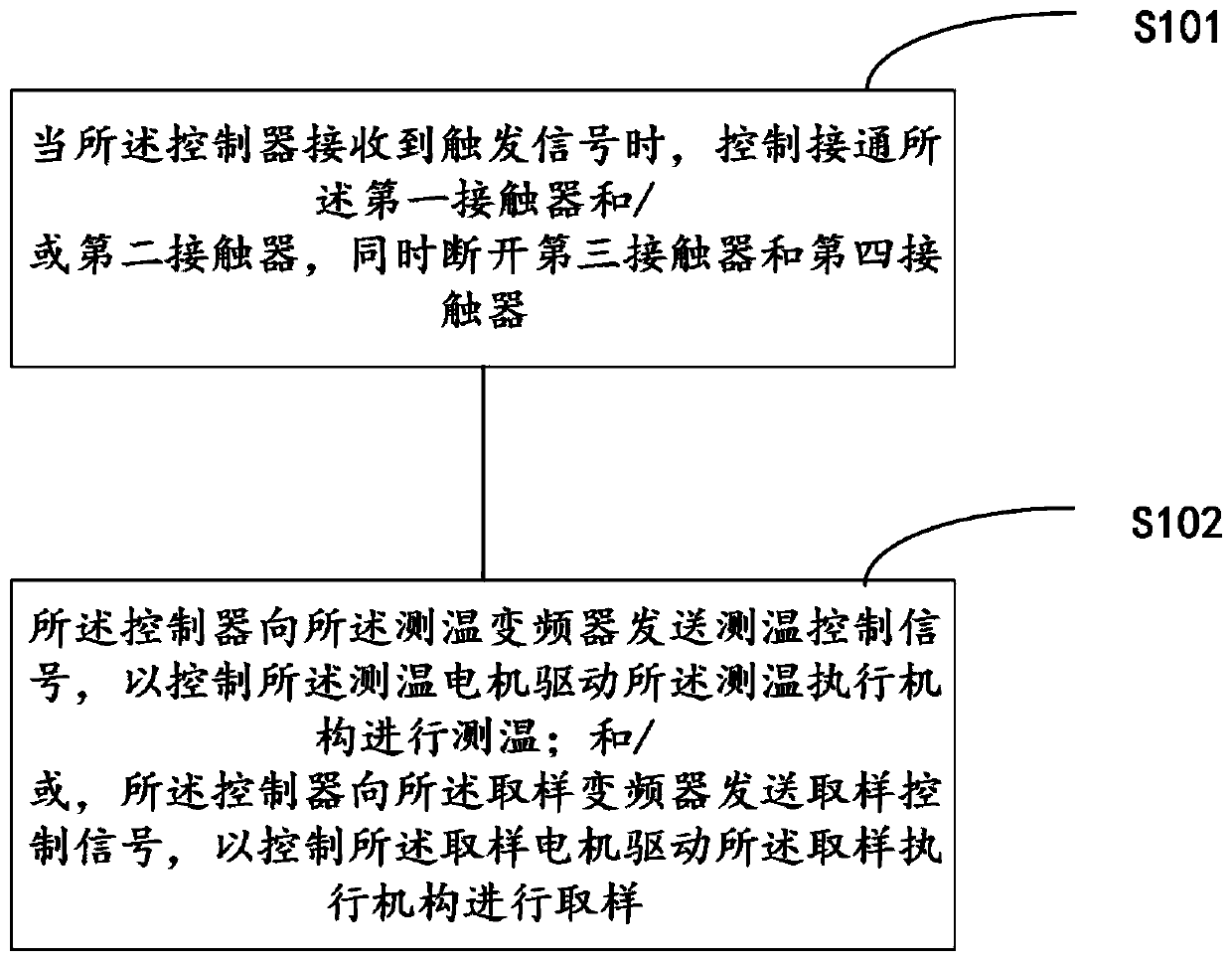

[0059] As an optional implementation, the method also includes:

[0060] When the controller receives the fault signal of the temperature measuring frequency converter, it judges whether the sampling frequency converter is in a standby state and judges whether the position of the sampling actuator is higher than a first preset height;

[0061] If the sampling frequency converter is in the running state, after the sampling actuator completes one sampling and the position of the sampling actuator is higher than the first preset height, the fourth contactor is controlled to be turned on, and the fourth contactor is turned off. Open the first contactor to make the sampling frequency converter control the temperature measurement actuator to complete the temperature measurement.

[0062] When the temperature measurement frequency converter fails, it can ensure the smooth progress of sampling, and can complete the temperature measurement as quickly as possible by means of the samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com