Large shaft liner upper plate welding assembly of right-front lower sway arm

An assembly and side plate technology is applied in the field of welding assembly of the upper plate of the large shaft sleeve of the right front lower swing arm, which can solve the problems of inconvenient installation and disassembly, unreliable installation, and difficult to find, etc., and achieves stable installation, avoids welding failure, and is convenient. looking for effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

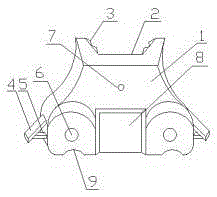

[0011] The invention provides a welding assembly for the upper plate of the large shaft sleeve of the right front lower swing arm. Slot 9, when installing, firstly open the card slot 2 on the body 1, set the card teeth 3 on the inner wall of the card slot 2, set the positioning hole 7 and the installation hole 6 on the body 1, and set the fluorescent sticker between the two installation holes 6 8. The two sides of the body 1 are provided with side plates 4 respectively, and the side plates 4 are connected with the support plate 5 , and an escape groove 9 is provided on the body 1 .

Embodiment 2

[0013] After positioning the main body 1 through the positioning hole 7, install the positioning bolts in the positioning hole 7 to complete the positioning work. During this process, the side plate 4 and the support plate 5 assist the main body 1 without artificial support, reducing the intensity of manual operation. The triangular structure The positioning method makes the installation more stable and reliable, and effectively avoids the failure of welding work caused by unreliable fixation. The main body 1 is provided with an escape groove 9 to avoid hindering the movement of other parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com