Bearing ball detection device

A detection device, a technology of bearing balls, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve problems such as disadvantages, improve detection effect, detection difficulty, etc. The effect of improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

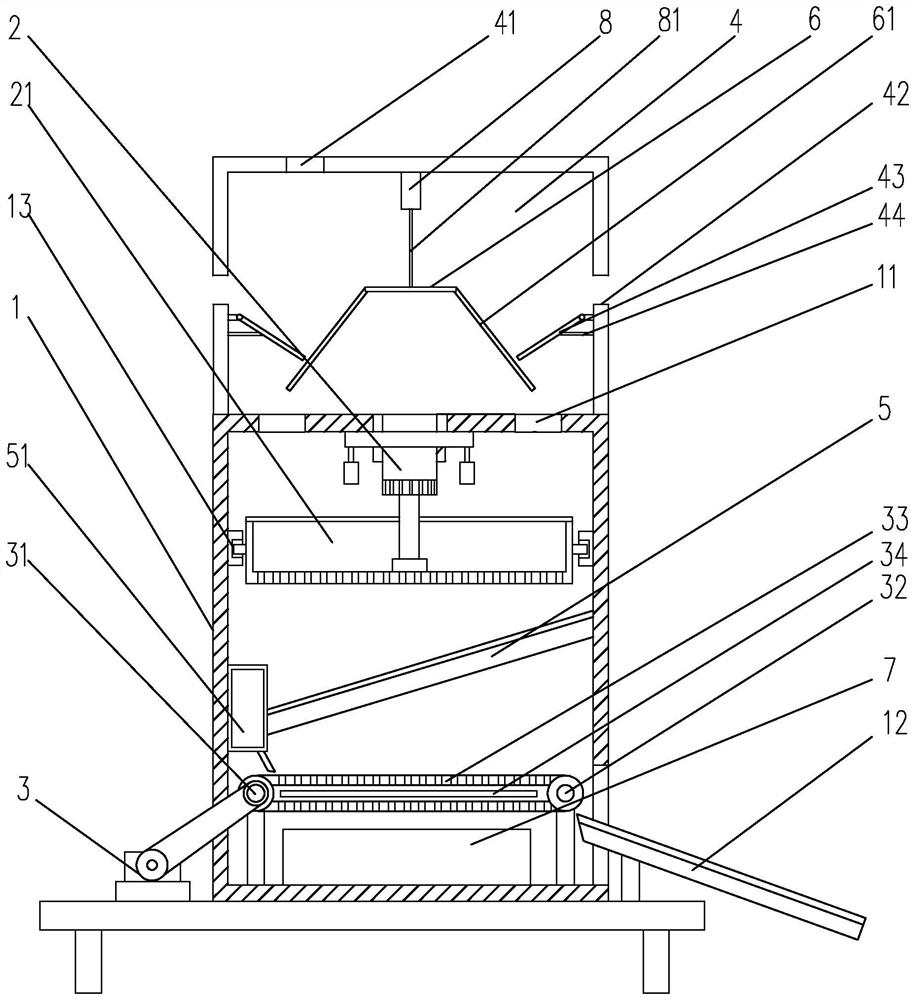

[0021]The present embodiment discloses a bearing ball detection apparatus, comprising a housing 1, the housing 1 is provided with an inlet 11, the inlet port 11 is connected to the initial screening mechanism, the housing 1 is provided with a rotating frame 21 and a first drive for driving the rotation of the rotating frame 21 rotation, the rotating frame 21 is provided with a first sieve hole, the housing 1 is provided under the rotating frame 21 is provided with a conveyor mechanism, the conveying mechanism comprises a driving wheel 31, a driven wheel 32 and a second drive member 31 to drive the driving wheel 31, The drive wheel 31 and the driven wheel 32 is connected by a conveyor belt 33 transmission, the conveyor belt 33 is provided with a second sieve hole, the seat 1 is provided with a collection box 7 under the conveyor belt 33, the seat 1 corresponding to the driven wheel 32 position is provided with an outlet. The beneficial effect of such a setting is that, using the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com