Gas burner and method for controlling the same

a technology of burners and gas, applied in the direction of burners, combustion types, combustion regulation, etc., can solve the problems of reducing stability, overheating of glass, unstable flames, etc., and achieve the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

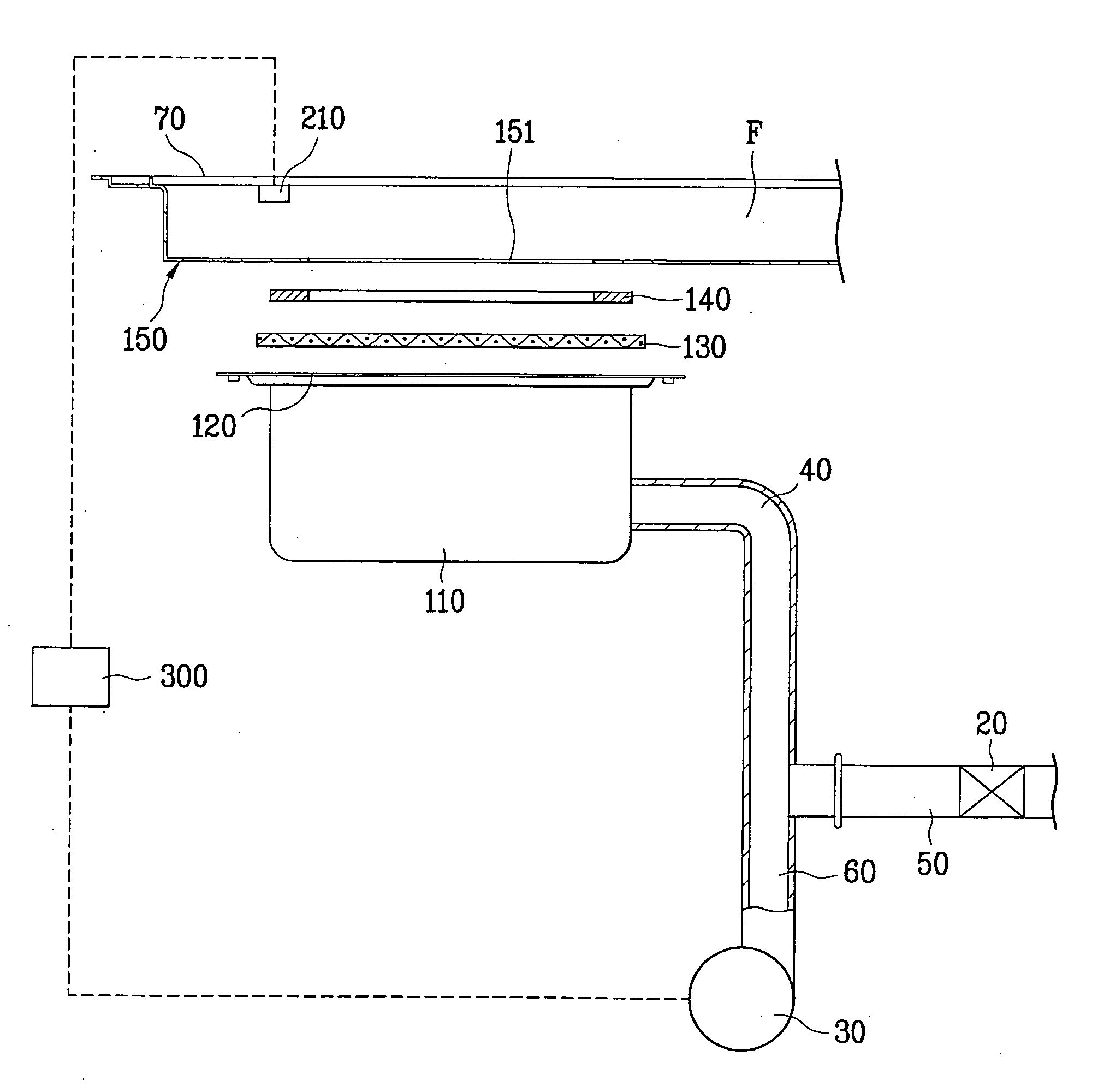

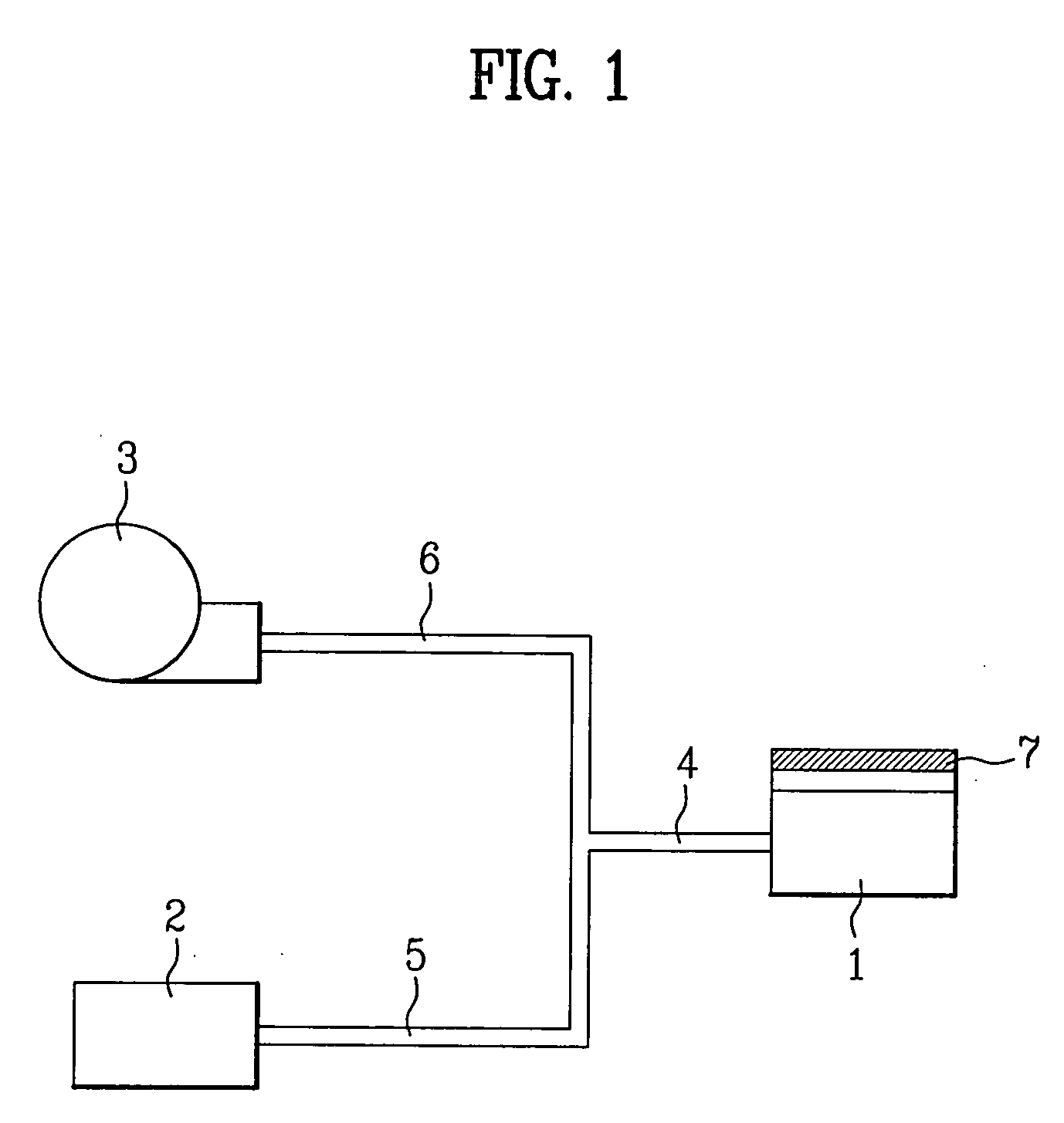

[0043] A gas burner according to the present invention will be described with reference to FIG. 3 and FIG. 4.

[0044] The gas burner according to the first embodiment of the present invention includes a burner body 100 burning a mixture gas of gas fuel and air, a temperature sensor 210 measuring a temperature of a glass 70 provided on the burner body 100, and a control part 300 controlling air flow supplied to the burner body 100 based on the measured value of the temperature sensor 210.

[0045] A mixing tube 40 is provided at one side of the burner body 100 and supplies the mixture gas to the burner body 100. The mixing tube 40 is connected with a gas supplying tube 50 and an air supplying tube 60. The gas supplying tube 50 supplies gas fuel and the air supplying tube 60 supplies air.

[0046] The gas supplying tube 50 and the air supplying tube 60 are respectively connected with a gas supplying valve 20 and an air supplying fan 30.

[0047] The burner body 100 includes a burner chamber 1...

second embodiment

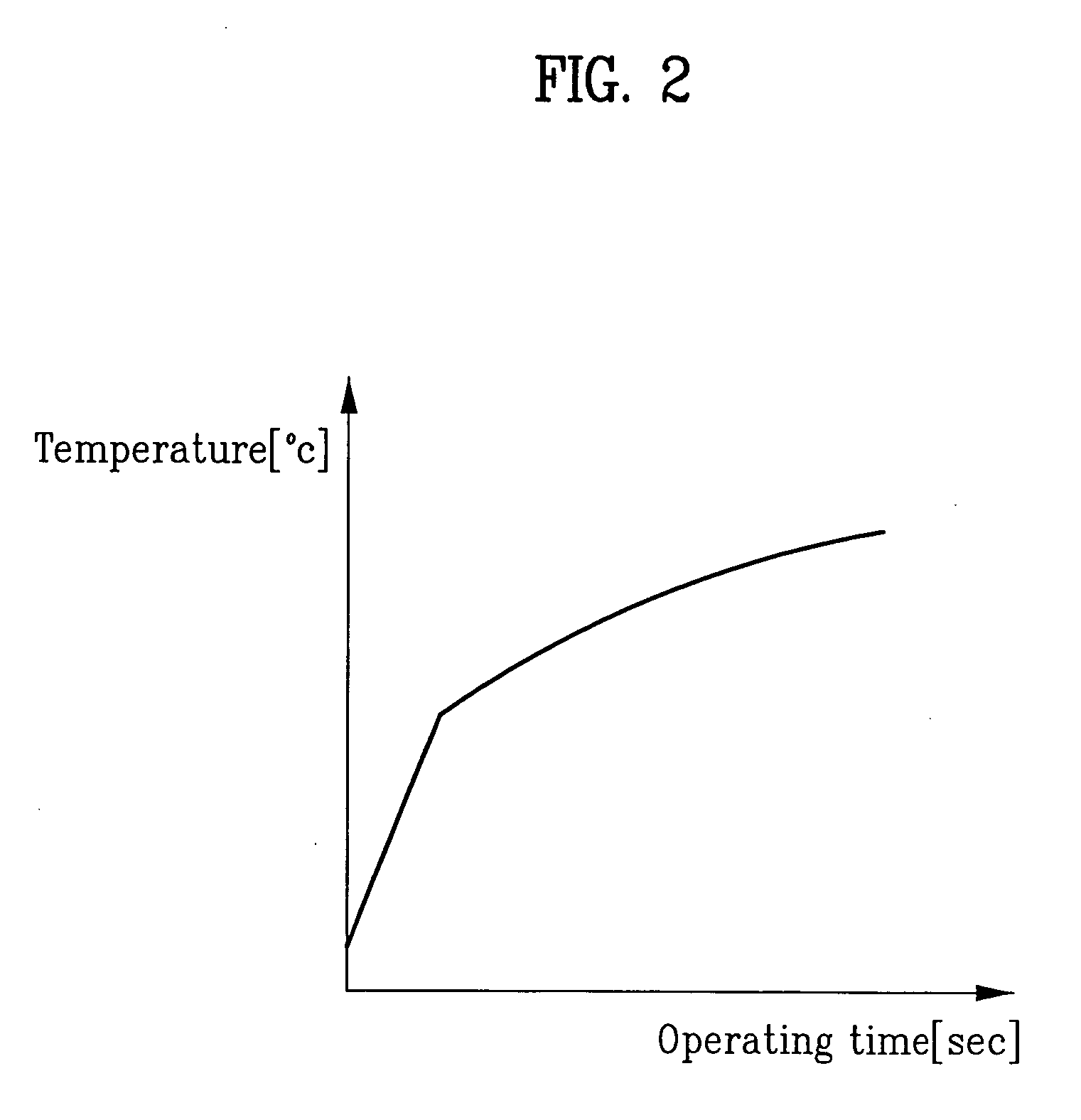

[0065] A method for controlling a gas burner according to the present invention will be described with reference to FIG. 6 and FIG. 7.

[0066] In the second embodiment unlike the first embodiment, a pressure sensor 220 is provided to measure inner pressure of the gas burner. In more detail, the pressure sensor 220 is provided inside the air supplying tube 60 and is connected with the control part 300 provided at one side of the gas burner.

[0067] The control part 300 controls the RPM of the air supplying fan 30 based on the pressure measured by the pressure sensor to control the air flow.

[0068] The position of the pressure sensor may be selected optionally inside the gas burner. The present invention is not limited to the aforementioned first embodiment. Both the pressure sensor and the temperature sensor may be provided. A sensor that measures a separate characteristic value may be provided. Examples of the characteristic value include speed of exhaust gas, quantity of exhaust gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com