Interference fit composite cylinder sleeve disassembling furnace

A technology of interference fit and compound cylinder, which is applied in the direction of furnace heating elements, electric heating devices, electrical components, etc., can solve the problems of large damage to the workpiece jacket and the inner tank of the workpiece, high requirements for equipment sealing, and liquid nitrogen personnel injury, etc., to achieve Reduce remanufacturing cost, reasonable structural design, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

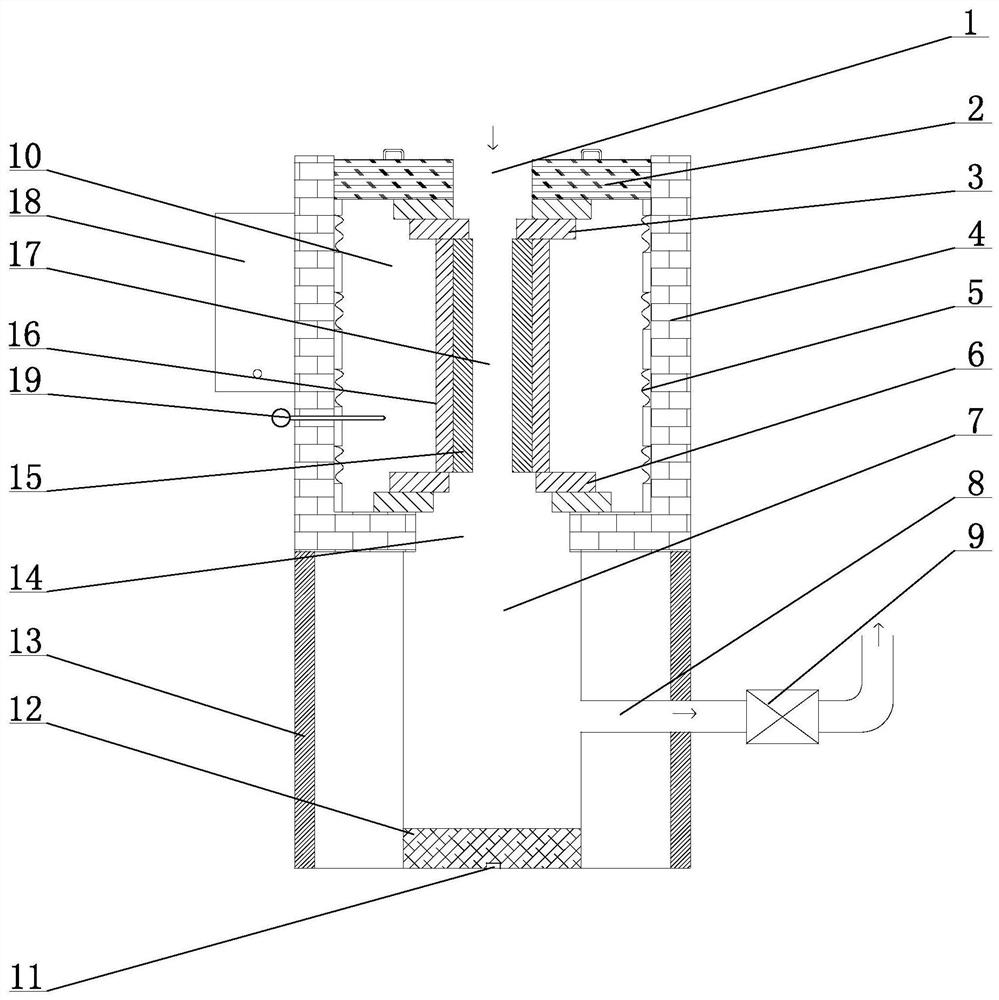

[0018] like figure 1 , the interference fit composite cylinder liner dismantling furnace of the present invention is used to dismantle the workpiece jacket 16 and the workpiece liner 15, including the furnace lining 4, the top of the furnace lining 4 is provided with a furnace cover 2, and the furnace cover 2 and the furnace lining 4 form a The furnace 10, the workpiece jacket 16 and the workpiece liner 15 are arranged in the furnace 10; the furnace 10 is also provided with an upper variable diameter brick 3 and a lower variable diameter brick 6, and the upper variable diameter brick 3 is arranged between the workpiece jacket 16 and the furnace cover 2 The lower variable-diameter brick 6 is arranged between the workpiece jacket 16 and the lower wall of the furnace lining 4, and the inner diameter of the lower variable-diameter brick 6 is greater than the outer diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com